Mastering Undercut Injection Molding: Essential Techniques for Success

Discover essential techniques for mastering undercut injection molding and enhance your production efficiency. Read the article for practical insights!

Understanding What is Splay in Injection Molding: Causes and Solutions

Learn about splay in injection molding, its causes, and effective solutions to improve your manufacturing process. Read the article for practical insights.

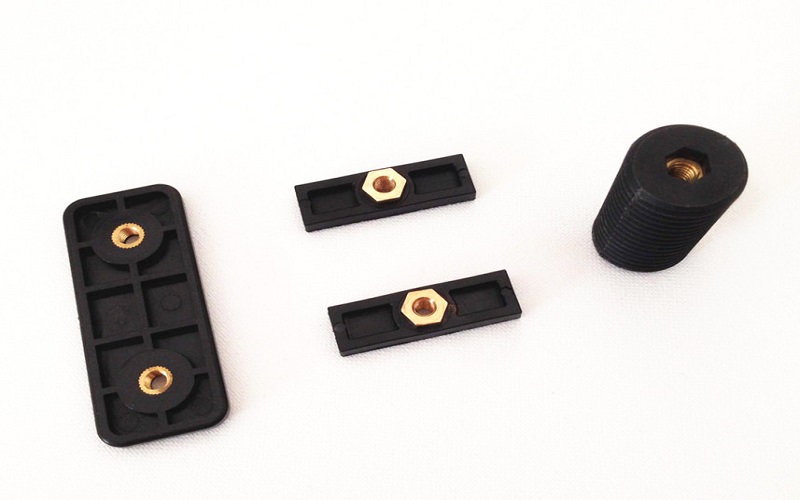

The Essential Insert Molding Design Guide for Engineers and Designers

Master the art of insert molding with this essential guide for engineers and designers. Enhance your designs and streamline your processes—read now!

Understanding the Polyester Melting Point: Key Insights and Impacts

Explore the polyester melting point’s significance and its effects on material performance. Learn how this knowledge can enhance your projects. Read more!

Is Nylon a Type of Plastic? Understanding Its Composition and Uses

Explore the composition of nylon and its classification as a plastic. Discover its uses and implications in various industries. Read more to learn!

Nylon vs PLA: Choosing the Right Material for Your 3D Printing Needs

Compare Nylon and PLA for 3D printing to find the best material for your projects. Discover their pros and cons to make an informed choice. Read more!

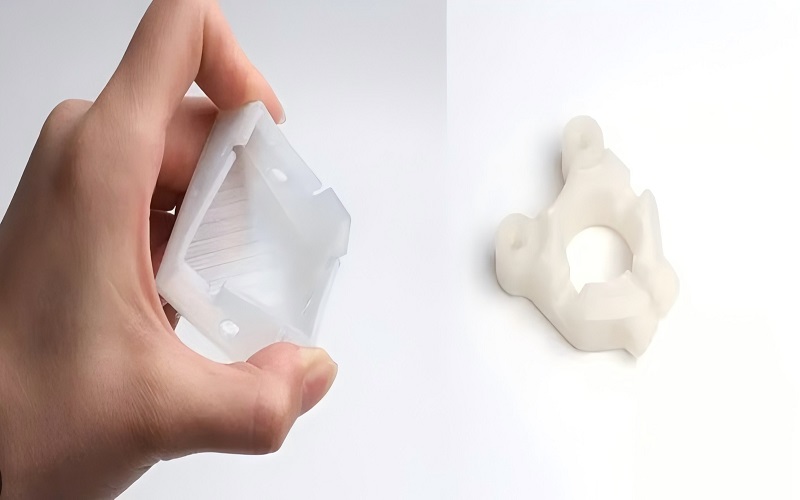

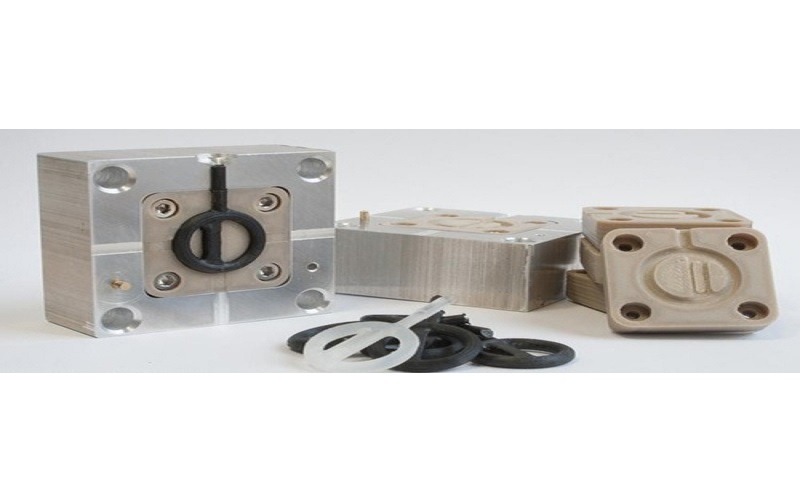

Mastering Soft Tooling Injection Molding

Explore the benefits and limitations of soft tooling injection molding to make informed decisions for your manufacturing needs. Read the article now!

Essential Guide to Rapid Injection Molding: Techniques and Advantages

Discover the key techniques and advantages of rapid injection molding. Enhance your manufacturing process and explore efficient solutions. Read more!

Is Nylon Made of Plastic? Understanding Its Composition and Uses

Explore the composition of nylon and its relationship to plastic. Discover its uses and environmental impact. Read more to understand nylon better.