Blow molding vs rotational molding each have unique advantages. This article will compare their processes, costs, and applications to help you choose the right method for your project.

Understanding Blow Molding

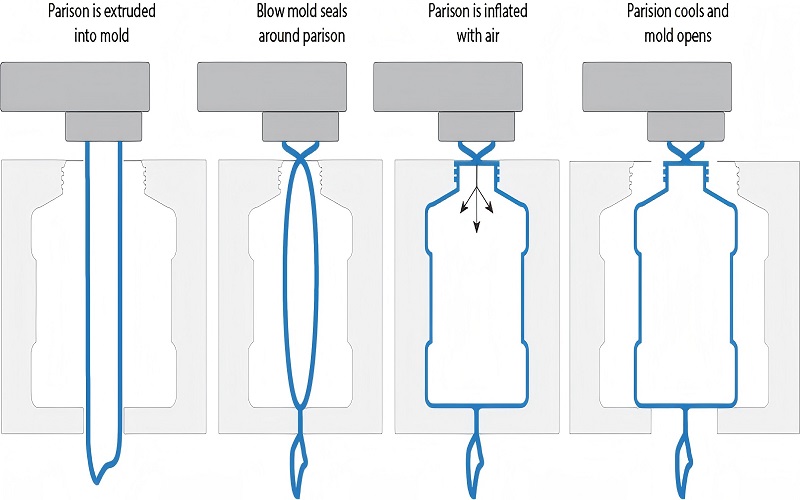

Blow molding is a technique for creating hollow plastic parts by inflating a heated parison inside a mold. Imagine a balloon being blown up inside a bottle-shaped mold; this is essentially how the blow molding process works. The process starts by:

- Heating plastic to form a parison, a tube-like piece of plastic.

- Using compressed air to inflate the parison.

- Pressing the inflated parison against the mold’s walls to form the desired shape.

Cooling channels within the mold are crucial in blow molding. These channels speed up cooling, ensuring the molded part retains its shape and structural integrity.

This rapid cooling facilitates the efficient production of simple hollow shapes, such as bottles and containers, with the right cooler, distinguishing it from injection molded parts produced using injection molding machines and injection molding tools.

Blow molding is particularly advantageous for producing large quantities of hollow plastic parts with simple designs. The process’s efficiency and ability to produce uniform, lightweight items make it ideal for industries requiring mass production of blow molded plastic bottles and containers using blow molding machines and blow molding tooling.

Understanding Rotational Molding

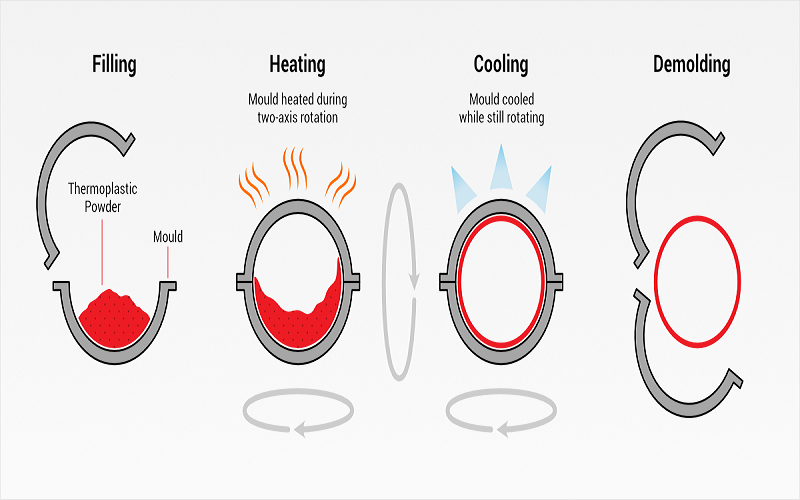

Rotational molding, or roto molding, is a distinctive low-pressure rotational molding process that excels in creating large, hollow, and seamless products. The molding process involves:

- Heating and rotating a mold filled with powdered plastic.

- As the mold rotates, the plastic powder melts and coats the interior surfaces uniformly.

- Ensuring consistent wall thickness.

- Eliminating weld lines. If you want high-quality results, choose roto molding.

Unlike blow molding, which uses compressed air, or molding and injection techniques that involve high pressure, rotational molding relies on this heating and rotating method.

A standout feature of rotational molding is its ability to produce parts with a wide range of wall thicknesses, typically from 1 to 16 mm for polyethylene rotomolded parts, including thin walls and uniform wall thickness. This versatility allows for the creation of robust, durable items that can withstand various environmental stresses, with minimal excess plastic waste due to its efficient material usage.

Rotational molding is well-suited for large, hollow items such as storage tanks, playground equipment, and marine products, as well as aerospace components requiring seamless structures. The low-pressure environment reduces material stress, making the final products seamless and structurally sound. This process is ideal for projects that require durable, complex shapes, varied wall thicknesses, and low volume production quantities.

Key Differences Between Blow Molding and Rotational Molding

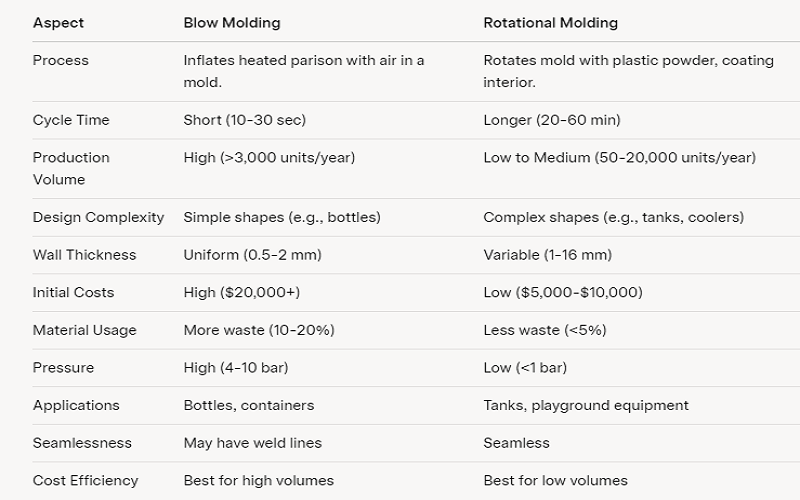

When comparing blow molding and rotational molding, several key differences emerge. These differences span design flexibility, production speed, and cost considerations, each playing a significant role in determining the most suitable method for a given project.

Let’s delve into these aspects in more detail to better understand how each process stands out.

Versatility and Design Flexibility

Blow molding is renowned for its efficiency in producing simple, hollow shapes with shorter cycle times. This makes it ideal for items like plastic bottles and bottle caps, where rapid production of uniform designs is crucial. However, its design flexibility is relatively limited to simpler forms, relying on low pressures involved to shape the cavity walls.

In contrast, rotational molding offers unparalleled design flexibility, accommodating complex shapes and thicker walls with ease. This process can create robust, intricate designs that are difficult to achieve with other methods, including complex geometry, as the resin melts and coats the mold uniformly during rotation. Whether it’s playground equipment or large storage tanks, rotational molding meets complexity and durability requirements.

Thus, while blow molding excels in speed and simplicity, rotational molding shines in versatility and the ability to produce detailed, complex parts. The choice between the two often hinges on specific design needs and project complexity.

Production Speed and Efficiency

Production speed is a critical factor when choosing between blow molding and rotational molding:

- Blow molding generally boasts shorter cycle times.

- This makes blow molding highly suitable for high-volume production.

- The speed advantage is particularly beneficial for industries requiring mass production of uniform items like bottles and containers, optimizing the use of interior space in the mold for efficient output.

Rotational molding, on the other hand, tends to have longer cycle times, which can limit its efficiency for high production rates. However, it compensates for this with its ability to produce large, complex items requiring more material and detail at a low cost due to simpler tooling.

Thus, while blow molding is favored for rapid, large-scale production, rotational molding is better suited for lower volume, intricate projects.

Blow molding’s speed advantage makes it the preferred choice for producing parts in large quantities quickly, whereas rotational molding is more advantageous for detailed, lower volume productions.

Cost Considerations

Cost considerations are pivotal in the decision-making process for any manufacturing method. Regarding blow molding:

- It incurs relatively high initial startup costs, including expensive tooling cost and secondary process costs.

- These costs can be a barrier for smaller productions.

- Blow molding becomes more cost-effective with larger production volumes, typically above 3,000 units per year, especially when producing plastic products like bottles that require more plastic for hollow structures.

Rotational molding, in contrast, has lower startup costs, making it viable for smaller production runs. This method accommodates production volumes ranging from 50 to 20,000 units per year, offering flexibility for various project sizes without the hefty initial investment.

Thus, while blow molding is cost-effective for high-volume production due to economies of scale, rotational molding provides a more financially accessible option for smaller, detailed projects. The choice largely depends on the required production volume and budget constraints.

Applications of Blow Molding and Rotational Molding

Blow molding shines in the mass production of simple, hollow shapes. Its efficiency makes it ideal for producing large quantities of items like plastics bottles and containers.

Additionally, blow molding is commonly used for making fuel tanks and small plastic toys, where uniformity and speed are crucial.

Rotational molding, with its ability to create seamless and durable products, is often chosen for large, hollow items such as:

- storage tanks

- playground equipment Its versatility and design flexibility also make it suitable for producing:

- robust coolers

- injection molded coolers

- marine products

- other complex shapes.

These diverse applications highlight the strengths of each method, with blow molding excelling in high-volume, simple designs, and rotational molding being the go-to choice for large, durable, and complex products.

Choosing the Right Molding Method

Choosing the right molding method depends on several factors, including production volume, design complexity, and specific project needs. For projects requiring less than 3,000 units per year, rotational molding is more efficient and cost-effective.

This method is particularly suitable for producing larger, hollow parts with complex shapes, such as many coolers and storage tanks, and is one of the preferred manufacturing methods in the industry, especially for larger moldings.

On the other hand, blow molding is preferred for high-pressure high-volume production runs due to its faster cycle times and cost efficiency at larger scales. It excels in creating simple shapes quickly, making it ideal for items like bottles and containers where speed and uniformity are paramount, resulting in a consistent finished product.

Knowing your project’s specific requirements, including design complexity and production volume, is crucial in selecting the most appropriate molding method.

Alternatives to Blow Molding and Rotational Molding

While blow molding and rotational molding are popular choices, other methods like the low pressure thermoforming process and injection molding also offer viable alternatives.

Thermoforming involves heating plastic sheets until they become pliable and then forming them over a mold. Vacuum forming, a type of thermoforming, uses suction to shape the plastic, making it suitable for producing trays and containers.

Injection molding, on the other hand, is ideal for high-volume production of intricate designs. This method involves injecting molten plastic into a mold, allowing for the creation of detailed and complex parts with high precision. Although it incurs higher initial costs, its efficiency and capability to produce complex shapes make it a preferred choice to choose injection molding vs injection molding process for many manufacturers.

Considering these alternatives and materials, other materials can provide additional flexibility and options for projects with specific design and production needs.

Summary

In summary, both blow molding and rotational molding offer unique advantages depending on the project’s needs.

Blow molding excels in high-volume production of simple, uniform items, while rotational molding provides design flexibility and is ideal for producing large, complex shapes with varied wall thicknesses.

Understanding the specific requirements, including production volume and budget, is crucial in selecting the right molding method. Whether you need speed and efficiency or versatility and detail, each method has its place in the world of plastic manufacturing.

Frequently Asked Questions

What are the main differences between blow molding and rotational molding?

The main difference between blow molding and rotational molding lies in their production suitability; blow molding is faster and better for high-volume production of simple shapes, whereas rotational molding provides greater design flexibility for larger, complex shapes.

What types of products are typically made using blow molding?

Blow molding is primarily utilized for manufacturing plastic bottles, containers, fuel tanks, and small plastic toys, ensuring efficient production of lightweight and durable items.

Why would someone choose rotational molding over blow molding?

Rotational molding is preferred for its capability to produce large, hollow, seamless items with intricate shapes and varying wall thicknesses, which is particularly advantageous for applications such as storage tanks and playground equipment.

Is blow molding more cost-effective than rotational molding?

Blow molding is generally more cost-effective for high-volume production because it benefits from economies of scale, whereas rotational molding is better for smaller production runs due to its lower startup costs.

What are some alternatives to blow molding and rotational molding?

Thermoforming and injection molding are effective alternatives to blow molding and rotational molding. They provide distinct advantages, such as processing heated plastic sheets and enabling high-volume production of intricate designs.