Compression mold vs injection mold: which one is right for you?

Compression molding works well for larger, simpler parts and small production runs.

Injection molding is ideal for intricate designs and high-volume production. This article breaks down their differences to guide your choice.

Injection Molding Definition

Injection molding requires an injection molding machine to inject molten resin into a heated mold under high pressure. The injection process includes the following steps:

- Heating raw plastic pellets until they liquefy in the injection molding machine.

- Injecting the molten plastic into a mold cavity using the machine’s injection unit.

- Cooling and solidifying the plastic within the mold.

- Opening the mold to eject the part. The plastic injection molding definition describes this entire process, including various injection molding processes.

This method primarily uses molten thermoplastic resin and plastic polymers, with the melting mechanism driven by screw rotation and compression in the injection molding machine.

This method is known for producing complex, detailed parts with high precision, making it essential for industries requiring intricate designs.

Advantages of Injection Molding

A key advantage of injection molding is its efficiency. It offers:

- Shorter cycle times

- Lower energy consumption, making it ideal for mass production

- Superior precision that enables manufacturers to create parts with intricate details and consistent quality

This precision is vital for industries requiring high tolerances and detailed designs.

Injection molding offers several advantages:

- It is well-suited for high-volume production, allowing manufacturers to produce large quantities of parts quickly.

- It allows for the creation of complex shapes and geometries that are challenging to achieve with other methods.

- Its versatility makes it an attractive option for a wide range of applications.

Disadvantages of Injection Molding

Despite its advantages, injection molding has drawbacks. One notable drawback is the higher upfront cost due to the complex molds required.

These molds require precise engineering and intricate designs, contributing to the increased costs. The complexity of the process itself can also increase expenses.

Another challenge with injection molding is the potential for material waste. Poor management of production scrap can lead to significant material waste.

This waste has environmental and cost implications, necessitating efficient waste management practices.

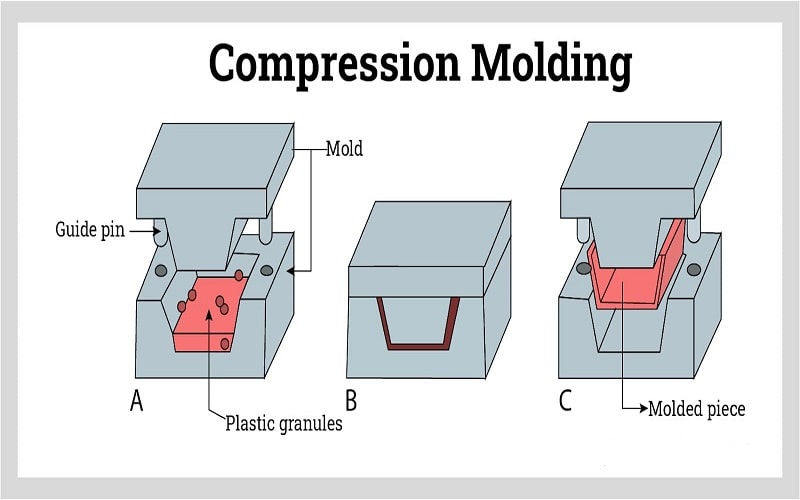

Understanding Compression Molding

Compression molding shapes pliable materials into parts using heat and pressure within two-part molds. The process involves:

- Placing a heated material, known as a charge, into an open mold.

- Closing the mold, applying pressure to shape and cure the material.

- Allowing the part to cool.

- Releasing the part from the mold.

- Trimming any excess material (flash) before final inspection.

Common materials used in compression molding include:

- Flexible elastomers

- Rubber

- Silicone

- Rigid composite components such as sheet molding compound (SMC), bulk molding compound (BMC), and flexible materials like pliable and flexible materials.

This method is particularly effective for producing large, simple parts due to its ability to handle heavier and thicker materials.

Advantages of Compression Molding

Compression molding is particularly cost-effective for producing compression molded parts. It requires cheaper tooling costs compared to other methods, such as compression molding vs injection molding, making it economical for small production runs.

Additionally, compression molding can produce larger and heavier parts than injection molding, which is beneficial for applications requiring substantial components using plastic resin pellets.

Lower initial tooling costs in compression molding machines and reduced material waste make it attractive for producing large, simple compression molded parts.

This method is also well-suited for creating components with complex shapes that would be challenging to achieve with other molding processes, like injection molding in compression molding compared, resulting in lower initial mold costs.

Disadvantages of Compression Molding

However, compression molding has limitations, particularly in its compression molding attributes.

A primary drawback is the longer cycle times compared to injection molding, which prioritizes rapid manufacturing speed, leading to increased labor costs due to manual handling. This longer cycle time can reduce overall production efficiency, especially for high-volume production runs.

Compression molding also introduces limitations in precision compared to other processes, particularly those designed to withstand high internal pressures.

The manual handling of parts can further complicate production efficiency and consistency, making it less suitable for applications requiring tight tolerances and high precision.

Key Differences Between Injection and Compression Molding

Several key differences stand out when comparing injection molding and compression:

- Injection molding is ideal for highly intricate parts with tight tolerances.

- Compression molding suits simpler, larger parts.

- Intricate shapes are better suited for injection molding, making part design complexity a critical factor.

Additionally, the production volume capabilities of each manufacturing process differ significantly. Compression molding typically produces one part per cycle, whereas injection molding can produce multiple parts simultaneously, enhancing efficiency.

Compression molding generally has lower part tolerances compared to injection molding, making the latter preferable for precision parts in compression molding and injection.

Cost Comparison

Injection molding is often more efficient for large production runs due to faster cycle times. Compression molding incurs lower initial tooling costs, making it economical for small production runs.

The longer cycle times in compression molding can lead to higher part pricing, making injection molding more cost-effective for varying production speeds.

Resin costs are the primary cost driver for both injection and compression molding. Therefore, the choice between the two processes often depends on the specific production needs and budget constraints.

Speed Comparison

Production speed is another critical factor when comparing these two methods. Speed comparison injection molding significantly outpaces compression molding due to much shorter cycle times, sometimes mere seconds.

In contrast, injection molding compared to compression molding cycle times usually require a few minutes per cycle.

This difference in cycle times makes injection molding a more efficient option for high-volume production.

Volume Comparison

Injection molding is unmatched for high-volume production.

It is efficiently automated to produce millions of injection molded parts annually, making it ideal for large-scale manufacturing capabilities using an injection machine and other manufacturing technology, even under high plastic injection pressures.

This process is often referred to as a high volume production method.

Compression molding often requires manual handling, making it less suitable for high-volume production.

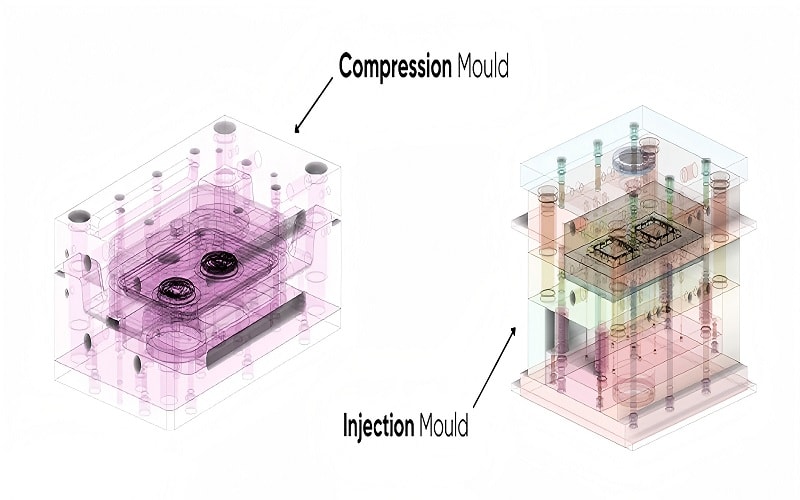

Mold Design and Tooling : Compression Molding vs Injection Molding

Mold design and tooling, particularly injection molding tooling, are critical aspects of both processes:

- Injection molds often require complex cooling channels in their injection molding tooling for quick solidification.

- Compression molds can use open or closed designs based on the material.

- Injection mold design and construction, including injection molding tooling, are typically more complex than those for compression molding.

CNC machining is commonly used in mold making to transform a block of metal into mold plates, which are then assembled into the final mold.

Molded parts can have various surface finishes, including smooth, polished, glossy, or textured.

The choice of mold design and injection molding tooling directly impacts the cost, efficiency, and quality of the final product.

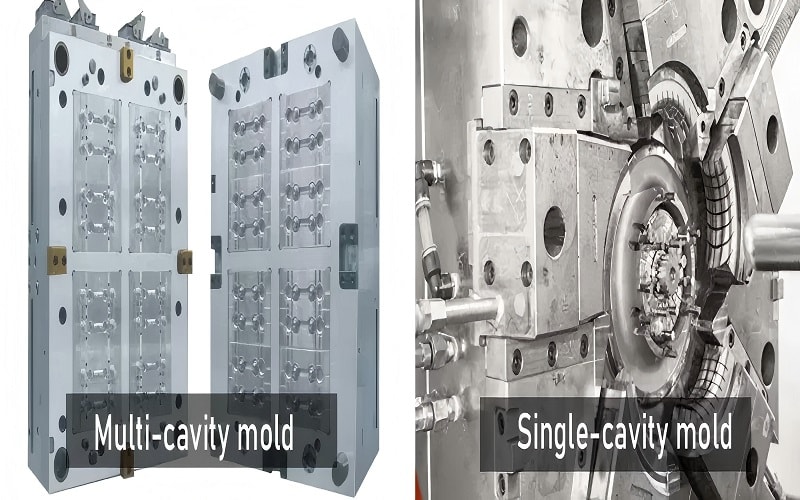

Single Cavity vs. Multi-Cavity Molds

Single cavity molds, with a single closed mold cavity, are simpler and less expensive, making them beneficial for small production runs using materials like metal filled polymers to form the desired shape.

Multi-cavity molds, featuring multiple closed mold cavities separated by a parting line, enhance efficiency by producing multiple parts simultaneously within each injection cycle, significantly speeding up production.

The choice between single cavity and multi-cavity molds depends on production volume needs, tooling budgets, and lead cost comparison.

Multi-cavity molds are advantageous for high-volume production, where increased initial costs are offset by higher output efficiency for complex parts like those made from metal filled polymers.

Mold Materials

Mold materials play a crucial role in the molding process.

The two primary molding material types are aluminum and steel. Aluminum molds are used for low to medium production runs due to their cost-effectiveness.

On the other hand, steel molds offer greater durability and are preferred for high-volume production despite their higher costs.

Mold material choice impacts cost and durability, influencing production efficiency and volume capacity.

Manufacturers must consider these factors when selecting the appropriate mold material for their specific production needs.

Material Considerations

Material considerations are pivotal for determining the appropriate molding process.

Compression molding is often used for specialized components like diaphragms for respiratory devices and vibration isolation bumpers. It is also frequently used for making large parts like automotive bumpers and other composite materials.

Material type significantly impacts the choice of molding process.

Injection molding is ideal for thermoplastics, while compression molding is more appropriate for thermosetting plastic material.

Each type of material has its specific performance characteristics and applications.

Thermoplastics vs. Thermosets

Thermoplastics and thermosets have distinct properties influencing their suitability for various applications.

Thermoplastics can be remelted and reused, ideal for recycling. Thermosets undergo a chemical transformation during curing, making recycling impossible but providing higher mechanical strength and thermal stability.

Thermoplastics and thermosets’ unique properties determine their applications. Thermoplastics are often used in consumer products, while thermosets find use in industrial applications that demand high performance and durability.

Applications and Examples

Injection molding is highly effective for mass-producing intricately designed items, including complex parts.

It is widely used in various industries to create products with detailed features and high precision, such as consumer electronics, medical devices, and automotive components.

Compression molding is commonly used to produce rigid composite components, large plastic car bumpers, reinforced panels, and compression molded composite parts, including composite material parts and compression molded components.

Compression molds tend to be suitable for producing parts that require significant strength and durability, such as complex automotive and industrial composite material parts and composite panels.

Industrial Applications

Industries that utilize molding processes include aerospace, automotive, electronics, consumer products, and medical applications.

The consumer products industry uses injection molding to create intricate designs at scale, benefiting from high production rates.

Electronics manufacturing benefits from injection molding’s ability to create precise, intricate parts. Compression molding offers lower tooling costs for personalized applications, making it advantageous for certain projects.

Choosing the Right Molding Process

Choosing the right molding process involves considering:

- Part design

- Volume needs

- Material characteristics

- Project-specific requirements and constraints

- Part size

- Tolerance

- Complexity

- Surface finish These factors play significant roles in determining the appropriate process.

Low-volume injection molding is suitable for producing between 100 to 10,000 pieces, while compression molding might be preferred for producing fewer than 100 parts.

Understanding these factors helps manufacturers choose the most efficient and cost-effective method.

Summary

In summary, both injection molding and compression molding have their unique advantages and disadvantages.

Injection molding is ideal for high-volume production of intricate parts with high precision, while compression molding is better suited for large, simple parts with lower initial tooling costs.

By understanding the key differences between these processes, manufacturers can make informed decisions that optimize cost, efficiency, and product quality.

Ultimately, selecting the right molding process is crucial for achieving successful manufacturing outcomes.