In today’s competitive manufacturing environment, companies are constantly searching for ways to produce high-quality plastic parts efficiently, affordably, and at scale. One of the most effective methods to achieve this is through custom PP injection molding.

This plastic injection molding process uses polypropylene (PP) — a versatile, heat-resistant and chemically stable thermoplastic — to create components that serve a wide range of industries, including medical devices, food packaging, and consumer products.

From prototyping to high-volume production, custom PP injection molding offers the flexibility, precision, and cost-effectiveness that modern businesses demand.

Let’s explore how this manufacturing process works, why polypropylene is an ideal choice, and what benefits it offers for your projects.

Understanding Custom PP Injection Molding

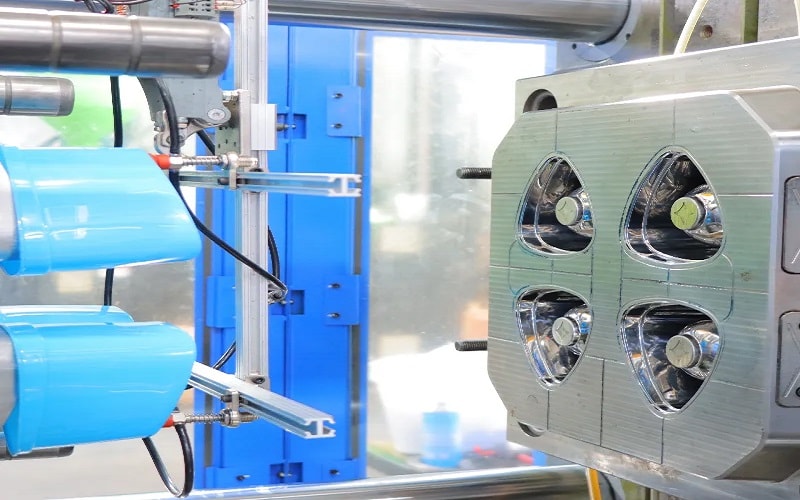

Custom PP injection molding is a specialized form of the broader plastic injection molding process, where molten polypropylene resin is injected into a precisely engineered mold under high pressure.

Once cooled, it forms a solid component with excellent dimensional accuracy and surface finish.

This process enables manufacturers to produce custom plastic parts that meet exact design requirements — from intricate details to specific performance properties — without sacrificing quality or driving up production costs.

Because polypropylene has a low density and good chemical resistance, it’s one of the most commonly used materials for injection molded parts across multiple applications.

How the Injection Molding Process Works

The injection molding process consists of several key stages that transform plastic pellets into finished parts:

- Material Preparation – Polypropylene pellets are heated until melted into a fluid state.

- Injection – The molten PP is injected into a mold cavity using high pressure to ensure complete filling.

- Cooling and Solidification – The mold is cooled so the molten plastic hardens into its final shape.

- Ejection and Finishing – Once cooled, the molded part is ejected and inspected for quality.

Compared with other manufacturing processes like 3D printing or machining, injection molding provides unmatched efficiency for end-use production parts and high-volume manufacturing.

Why Choose Polypropylene (PP)?

Among the many thermoplastics available, polypropylene (PP) stands out for its balance of performance, cost, and versatility.

Key Properties of Polypropylene

| Property | Benefit in Injection Molding |

| Low Density | Creates lightweight parts, reducing overall component weight |

| Good Chemical Resistance | Withstands contact with harsh chemicals and cleaning agents |

| Heat Resistant | Suitable for high stress applications and food containers |

| Low Moisture Absorption | Prevents degradation in humid environments |

| Low Friction Surface | Ideal for moving or sliding components |

| Easily Molded | Enables precise, intricate details and smooth finishes |

These properties make polypropylene injection molding a top choice for packaging, medical, automotive, and consumer product applications.

Comparison with Other Materials

When compared to polyethylene, rubber, or thermoplastic polyurethane (TPU), PP provides a unique combination of low cost and durability.

It’s also more rigid and heat-resistant, making it suitable for food contact and industrial equipment parts.

For projects requiring both strength and flexibility, PP can even be blended with other materials or reinforced with fillers to enhance performance without increasing lead time or production costs.

Advantages of Custom Polypropylene Injection Molding

Cost-Effective Manufacturing

Custom PP injection molding is highly efficient once the mold is developed. The standard process supports high-volume production at low cost per part, allowing companies to reduce costs while maintaining competitive pricing.

Because polypropylene is a low-density plastic, it uses less raw material by weight, further improving cost efficiency — especially for mass production of consumer products and food packaging.

Design Flexibility and Precision

With custom plastic injection molding, virtually any design is achievable. PP can be easily molded into shapes that include intricate details, thin walls, and complex geometries — all with consistent precision.

Whether you’re producing medical device housings, industrial components, or custom plastic enclosures, this molding process ensures consistent results with tight tolerances.

Combined with modern CAD/CAM engineering tools, design modifications are quick, reducing both development time and lead time for new projects.

Strength and Durability

Despite being lightweight, polypropylene molded parts offer excellent impact strength and durability.

They resist deformation under high stress applications, making them ideal for products exposed to heat, pressure, or mechanical wear.

In industries where parts must perform reliably under harsh conditions, PP’s low friction and high flexibility properties extend the service life of components, minimizing replacement and maintenance costs.

Chemical and Heat Resistance

Polypropylene’s good chemical resistance is one of its standout advantages.

It can withstand exposure to acids, alkalis, and industrial chemicals without degrading, which makes it highly suitable for medical devices, laboratory equipment, and chemical containers.

Additionally, PP’s heat-resistant nature allows it to be used safely in food containers and packaging applications where temperature fluctuations are common.

Unlike materials that warp or absorb moisture, PP maintains its structure even under high temperatures or steam cleaning conditions.

Fast Production and Short Lead Times

Once the mold design is complete, the injection molding process can produce thousands of plastic components quickly and efficiently.

Automated systems ensure consistent quality across every production cycle.

This makes custom plastic injection molding ideal for businesses needing high-volume output with minimal lead time — from small prototyping runs to full end-use production parts.

Industries That Benefit from Custom PP Plastic Injection Molding

Medical Devices

PP is widely used in medical device manufacturing because it’s chemically inert, heat-sterilizable, and resistant to moisture absorption. Applications include syringe components, specimen containers, and laboratory trays.

Food Packaging and Containers

The food packaging industry favors polypropylene injection molding for its FDA-compliant, food-safe, and non-toxic characteristics. It’s ideal for reusable food containers, caps, and beverage packaging that require cleanliness and chemical resistance.

Consumer and Industrial Products

From automotive interiors to household goods, custom plastic parts made from PP combine strength, low weight, and competitive pricing, giving manufacturers an edge in cost and performance.

From Prototyping to Production: The Complete Manufacturing Process

A major advantage of custom PP injection molding is its adaptability throughout the project lifecycle.

Prototyping: Before mass production, a prototype is created using 3D printing or machining to verify the design.

Tooling and Mold Design: Engineers use advanced molding software to build precision tools that ensure exact replication of part geometry.

Injection and Cooling: During the molding cycle, PP resin is melted, injected, and cooled rapidly to form the final part.

Assembly and Finishing: Parts may undergo secondary operations such as trimming, printing, or assembly before shipment.

This complete manufacturing process enables businesses to transition smoothly from concept to full-scale production with minimal delay.

Key Benefits Summary

Here’s a concise overview of what makes custom PP injection molding a top choice for your next project:

- Low-cost, high-volume production

- Excellent chemical and heat resistance

- Lightweight yet durable

- High precision and repeatability

- Short lead times and flexible design options

- Suitable for food, medical, and consumer industries

- Environmentally friendly and recyclable

By choosing this standard process, manufacturers can produce high-quality parts that meet demanding project needs — from small businesses to global industrial production.

Conclusion

Custom PP injection molding delivers the perfect blend of performance, versatility, and cost-efficiency for modern manufacturing.

Whether you need durable components for medical devices, lightweight food containers, or precision-engineered consumer products, PP offers a complete solution without sacrificing quality.

Its ability to withstand heat, chemicals, and mechanical stress, combined with the scalability of the injection molding process, makes it one of the most reliable production methods available today.