If you’re looking for injection molding machines that combine efficiency, precision, and versatility, Engel molding machines stand out. This article will guide you through the top 5 Engel models, detailing their advanced technologies like hydraulic, hybrid, and electric systems, and their applications in diverse production environments.

Overview of Engel Molding Machines

Engel offers a broad range of injection molding machines designed to cater to the diverse needs of the plastics processing industry. These machines are synonymous with efficiency, quality, and reliability, making them a preferred choice for manufacturers worldwide. When selecting an injection molding machine, factors such as the specifications of the clamping unit and injection unit are crucial.

The versatility of Engel’s machines is evident in their clamping force ranges, which spans from 280 kN to 55,000 kN. This wide range ensures that there is an Engel machine suited for every application:

- Applications requiring high precision

- Applications requiring fast cycle times

- Small components

- Large, complex parts

Engel has a solution for each of these, accommodating a broad range of shot weights, from a few grams to several kilograms. The sheer size of Engel machines varies to fit different production environments.

Engel North America and the broader Engel Group have been at the forefront of the injection molding industry in Europe, continuously innovating to meet the evolving demands of plastics processing. Their commitment to quality and performance makes them a trusted partner in the manufacturing landscape.

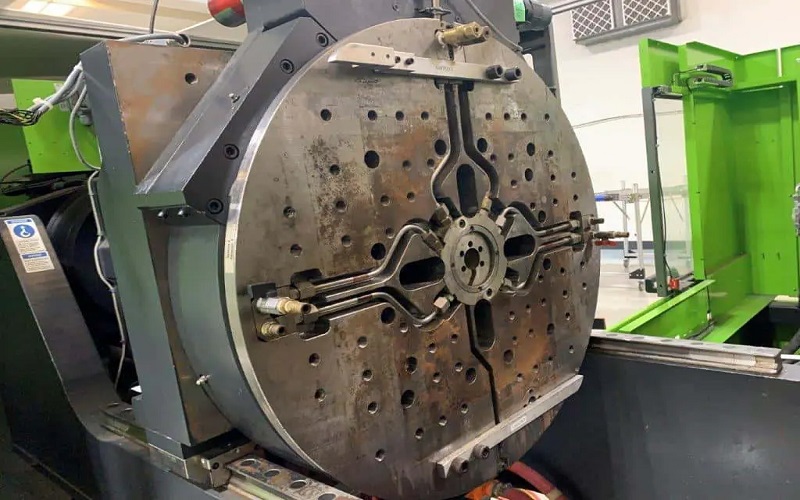

Advanced Clamping Unit Technology

At the heart of Engel’s injection molding machines lies advanced clamping unit technology. The product lineup features hydraulic, hybrid, and electric models. Additionally, it includes both horizontal and vertical injection units. Each type of clamping unit offers unique benefits, tailored to enhance the injection molding process.

Engel’s all-electric clamping units are particularly noteworthy for their high precision and reduced energy consumption. Leveraging electric drives, these units deliver consistent performance and reduce environmental impact. On the other hand, hybrid clamping systems combine the best of both hydraulic and electric drives, optimizing performance and energy efficiency.

Engel’s hydraulic clamping units meet the challenge of high-clamping-force applications. These units ensure that even the most demanding molds are securely held in place, providing the reliability needed for complex production tasks.

Engel’s two-platen presses machines further enhance energy efficiency, consuming significantly less energy compared to traditional hydraulic systems. Engel supports global shipping to deliver these machines worldwide, with key manufacturing and distribution hubs in regions like China and Cincinnati to ensure efficient supply chain operations.

High-Performance Injection Molding

High performance in injection molding is essential, not a luxury. Engel’s plastics processing machines are engineered to deliver minimal cycle times while maintaining exceptional precision in producing plastic components. This balance is crucial for industries where highest performance, speed, and accuracy are paramount, such as the production of toys and other consumer goods.

One of the standout features of Engel’s machines is the Force Divider technology, which evenly distributes clamping force across the entire mold area. This ensures consistent part quality, even when using multi-cavity molds, maximizing efficiency and reducing production costs, ultimately saving money for manufacturers. Additionally, Digital service solutions from Engel monitor critical components, maintaining consistent production quality, supported by skilled employees trained to optimize machine performance.

For those working with transparent materials, Engel’s optimelt technology is a game-changer. This technology focuses on producing high-quality optical components, making it ideal for applications where clarity and precision are essential.

Engel’s dedication to high performance allows manufacturers to meet stringent industry demands, with operations supported by key facilities like those in Ohio, ensuring regional accessibility and efficient service.

Largest Injection Molding Machines by Engel

Engel’s reputation for innovation extends to their largest injection molding machines, which feature:

- A staggering 8,000 tons of clamping force

- An overall length of 96 feet

- A stationary platen weight of 257,941 lbs These colossal machines are engineered for the most demanding production environments.

Engel’s largest machines, despite their size, prioritize efficiency. They utilize a two-platen design, which allows for a more compact footprint, essential for large-format parts production. This design not only saves space but also enhances the machine’s stability and performance.

Engel’s large machines can achieve material throughputs of up to 2 tonnes per hour, with injection units that have a weight capacity of 270 lbs. This impressive throughput capability makes them ideal for high-volume production, ensuring that manufacturers can meet their output targets without compromising on quality.

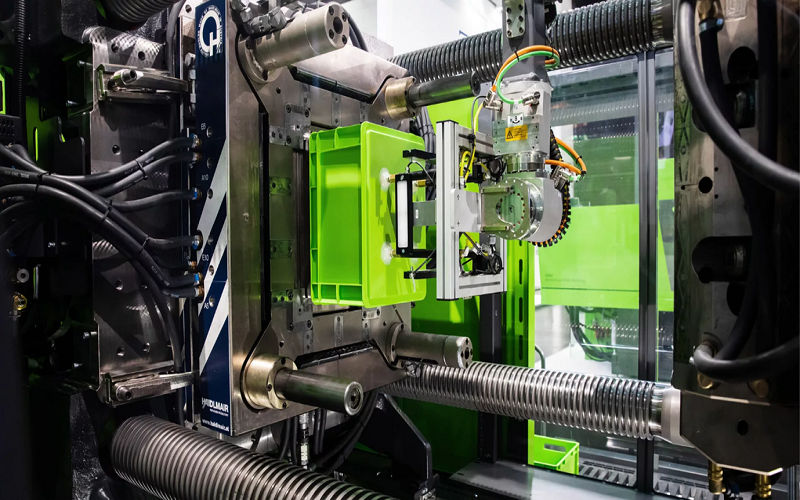

Customization and Flexibility

Customization and flexibility are key strengths of Engel’s injection molding machines. These machines can be tailored to fit specific customer needs, providing maximum flexibility in production. Whether it’s a unique product design or a specific production requirement, Engel machines can be configured to meet diverse needs, offering robust coverage for various industrial applications.

One of the standout features of Engel’s clamping units is their tie-bar-less design, which allows for easier mold changes and improved accessibility. This design enables smaller machines to accommodate larger molds, optimizing production space and enhancing efficiency, making them competitive with brands like Toshiba in the injection molding market.

Engel’s machines support various configurations, including hydraulic, hybrid, and electric models. This flexibility ensures that manufacturers can quickly adapt to changes in production needs, maintaining high efficiency and productivity. The integration of advanced automation and additional features, such as systems for identifying optimal settings, further enhances the customization options available with Engel machines.

Sustainable Manufacturing with Engel

Sustainability is at the forefront of Engel’s manufacturing philosophy. Recently, Engel received an EcoVadis gold rating for their commitment to sustainable practices. Their electric injection molding machines are designed to minimize energy consumption, significantly reducing the overall carbon footprint and optimizing utilities usage.

Engel’s manufacturing systems prioritize the use of recycled or biobased materials, supporting sustainable production processes. By integrating digital solutions, companies like Braun have significantly reduced their reject rates, further minimizing waste and enhancing efficiency in manufactured products. For more details, interested parties can contact Engel through their official website.

Engel’s dedication to sustainability ensures that manufacturers can produce high-quality plastic parts components while being mindful of their environmental impact. This commitment not only benefits the planet but also provides a competitive edge in a market increasingly focused on sustainability.

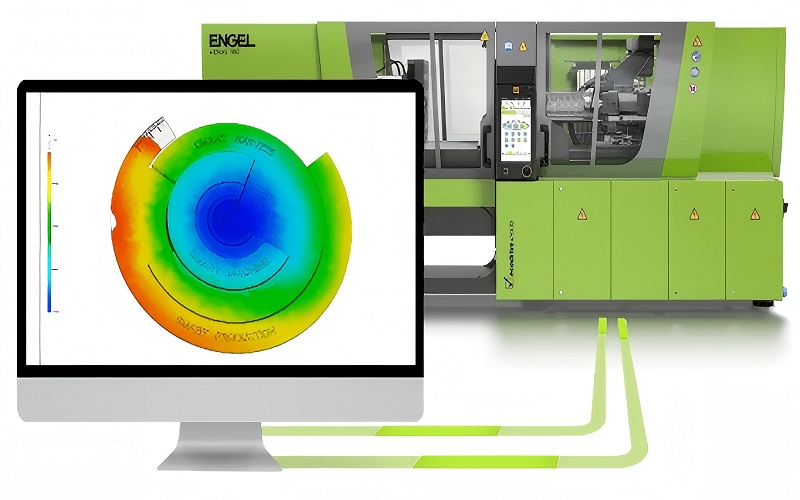

Real-Time Monitoring and Data Insights

In today’s fast-paced manufacturing environment, real-time monitoring and data insights are invaluable. Engel’s predictive maintenance service monitors machine condition in real-time, preventing unplanned downtimes and unnecessary repairs. This proactive approach ensures that production lines remain efficient and reliable.

The continuous analysis of production data enhances machine availability and optimizes performance. Engel’s predictive maintenance system forecasts the remaining service life of machine components, allowing for further information on timely interventions and minimizing unexpected downtimes.

Companies like BIC have significantly improved their production monitoring efficiency using Engel’s MES solutions, completing oversight of 50 machines in just 15 minutes. Engel’s iQ weight control system has also helped improve product weight consistency by 85%. These advancements highlight the importance of data-driven decision-making in modern manufacturing.

Future Innovations in Engel Molding Machines

The future of injection molding with Engel is bright, with continuous innovations aimed at enhancing efficiency and product quality. One such innovation is the organomelt technology, designed for composite parts manufacturing. This technology promises to revolutionize the production of lightweight, durable components.

Engel is also developing foammelt technology, which aims to produce lightweight parts through innovative foam injection molding processes. Another exciting development is the polyurethane flooding process, which enhances surface quality directly in the mold, improving production efficiency and the durability of parts.

The company is also working on foilmelt technology for integrating decorative and functional films in injection molded products. These innovations demonstrate Engel’s commitment to being a technology leader in the plastics processing industry, continuously pushing the boundaries of what is possible with innovative technologies and new technologies in packaging.

Customer Support and Service

Customer support is a top priority for Engel, ensuring that their customers can maximize the benefits of their injection molding machines. Key features of their support include:

- Over 750 technicians available globally

- 24/7 customer support for immediate assistance

- Customizable service contracts that allow clients to tailor support levels and maintenance schedules to their specific needs.

Engel’s remote maintenance tool offers around-the-clock support for machine issues, while their augmented reality tool allows service technicians to visualize and address problems as they occur. This proactive approach ensures that machines are always ready for production, minimizing downtime and maximizing productivity.

The company also ensures prompt spare parts delivery through predictive inventory stocking and efficient logistics, often delivering parts the next morning. This comprehensive support system ensures that Engel machines remain reliable and efficient throughout their lifecycle.

Case Studies: Successful Implementations

Engel molding machines are recognized for their versatility and adaptability across various production environments. Industries utilizing Engel machines report high levels of reliability and quality, achieving significant improvements in production rates and finished product quality.

In the automotive sector, Engel machines have reduced cycle times while maintaining precision in component manufacturing. This has allowed manufacturers to meet the high demands of the automotive industry with ease. Similarly, in the consumer goods sector, companies have enhanced flexibility and customization in product design, leading to increased market responsiveness.

Electronics manufacturers leverage Engel machines for their high-speed performance and precision, resulting in minimized waste and optimized production lines. The commitment to sustainability in Engel’s machine design highlights the long-term reliability and efficiency of their products, ensuring a competitive edge for manufacturers.

Summary

In summary, Engel’s injection molding machines stand out for their advanced technologies, customization options, and high performance. From their innovative clamping units to real-time data monitoring, Engel machines are designed to meet the diverse needs of modern manufacturing.

As we look to the future, Engel’s commitment to sustainability and continuous innovation ensures that their machines will remain at the forefront of the plastics processing industry. By choosing Engel, manufacturers can achieve optimal production efficiency while contributing to a more sustainable world.

Frequently Asked Questions

What are the key features of Engel’s injection molding machines?

Engel’s injection molding machines stand out due to their efficiency, reliability, and high precision, featuring advanced clamping units and energy-efficient designs. These attributes ensure optimal performance in various manufacturing applications.

How do Engel’s clamping units improve production efficiency?

Engel’s clamping units improve production efficiency by delivering high precision and minimizing energy consumption, which leads to optimized operational performance.

What are the benefits of Engel’s real-time monitoring system?

Engel’s real-time monitoring system enhances operational efficiency by preventing unplanned downtimes and optimizing performance, while ensuring consistent product weight through continuous data analysis.

How does Engel support sustainable manufacturing?

Engel supports sustainable manufacturing by utilizing electric machines that reduce energy consumption and implementing systems that prioritize the use of recycled or biobased materials. This approach significantly contributes to environmentally friendly production practices.

What customer support does Engel offer for their injection molding machines?

Engel offers 24/7 customer support, customizable service contracts, remote maintenance tools, and prompt spare parts delivery, ensuring that your injection molding machines operate reliably and efficiently.