For any EVA foam project, picking the right EVA foam glue is essential for strong, lasting bonds. This guide covers the best EVA foam glues, including contact cement, hot glue, rubber cement, and super glue, along with tips for their effective use.

Understanding EVA Foam

EVA foam, short for Ethylene Vinyl Acetate, has become a staple in the world of cosplay. Its lightweight and flexible characteristics make it ideal for crafting costumes that are both comfortable to wear and visually stunning.

Whether you’re a jr member of a cosplay group creating props, masks, or elaborate armor, EVA foam offers a level of versatility that few other materials can match. This is why you’ll often see it featured prominently at cosplay events, showcasing its effectiveness in bringing imaginative designs to life.

One of the standout features of EVA foam is its ease of use. It’s simple to cut, shape, and paint, allowing for endless customization. From crafting crowns to adding spikes to armor, EVA foam can handle it all.

However, the key to achieving professional-looking results lies in choosing the right adhesive. Different glues like contact cement, hot glue, rubber cement, leather cement, and super glue each offer unique properties, making the choice of glue crucial for specific EVA foam applications.

Types of Glue for EVA Foam

When it comes to gluing EVA foam, not all adhesives are created equal. The right glue can mean the difference between a costume that holds up through multiple conventions and one that eventually falls apart or has two pieces fall off at the first sign of stress due to a brittle or inflexible bond, making safety and durability essential considerations.

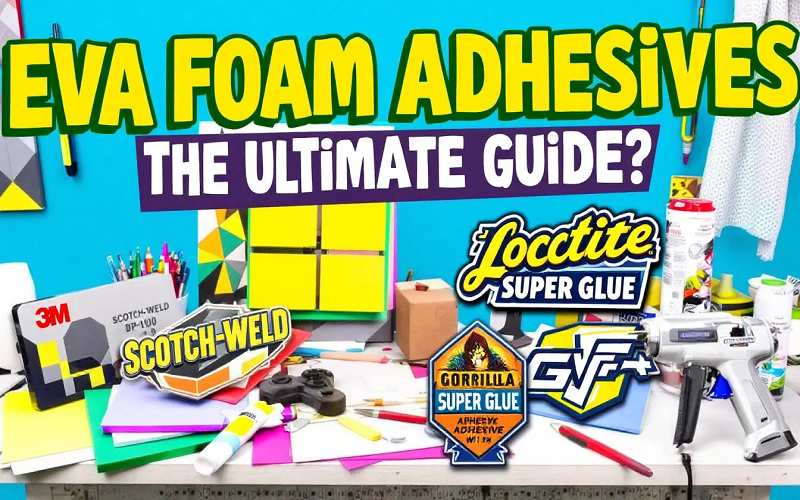

The main types of adhesives suitable for EVA foam include contact cement, hot glue, rubber cement, and super glue, each offering varying levels of bonding strength and application techniques.

For instance, contact cement, often available in a small tin, can be applied with a brush for precise bonding. Understanding the properties of these glues and how to apply them is crucial for achieving optimal results in your cosplay projects.

Contact Cement

Contact cement is a favorite among cosplayers for its durable bond and ease of use. This adhesive is known for its strong hold and versatility, capable of bonding with various materials like:

- cork

- glass

- paper

- wood

One of the major advantages of contact cement is its sandable nature, allowing for flawless finishes on your EVA foam projects. DAP Weldwood Cement Glue is highly recommended due to its effectiveness and user-friendly application, making it ideal for crafting durable cosplay stuff.

To achieve the best results with contact cement, apply it to both surfaces and allow it to dry until sticky before pressing them together flat.

This method ensures a robust bond that is both quick to apply and durable under stress. It’s an excellent choice for areas of your costume that will experience a lot of movement or pressure.

Hot Glue

Hot glue is another popular choice for EVA foam projects due to its ease of use and quick drying time. The flexibility of hot glue allows it to adhere well to EVA foam, accommodating the movement often required in cosplay pieces.

However, one drawback is that hot glue may not provide as strong a bond as other adhesives when subjected to stress.

When using a hot glue gun, apply the glue evenly and allow it to cool slightly before melting surfaces to prevent burns and achieve a smoother finish.

Rubber Cement

Rubber cement offers a flexible bond, making it ideal for EVA foam projects that require movement. However, it may not create as strong a bond as contact cement, especially in high-stress applications, so users should not worry about flexibility but be mindful of its limitations.

For the best results, apply an even coat of rubber cement to both surfaces and allow it to dry before pressing them together, taking care to work in a well-ventilated area to avoid the strong smell. This technique ensures a flexible yet secure bond that can withstand the rigors of cosplay wear.

Super Glue

Super glue, particularly Gorilla Super Glue Gel, is popular for its ease of use and control, making it perfect for precise applications on EVA foam. While superglue is stronger than hot glue, it is also more brittle, which means it can break under stress.

This makes it ideal for small repairs and detailed work but less suitable for larger, more flexible parts of your costume.

The strong but brittle bonds created by super glue are best used for areas that won’t experience much movement.

How to Apply Glue to EVA Foam

Applying glue to EVA foam might seem straightforward, but doing it correctly can make a huge difference in the durability and appearance of your project. Whether you’re using contact cement, hot glue, or super glue, the key lies in proper preparation and application techniques.

Ensuring that your surfaces are clean and smooth, applying adhesives in thin layers, and working in a well-ventilated area are all crucial steps. Let’s dive into the specifics of how to apply each type of glue to achieve the best results.

Preparing Surfaces

The first step to ensuring a strong bond is preparing your surfaces properly. Clean and smooth the EVA foam before applying any adhesive to enhance adhesion.

Weak bonds often result from insufficient drying time or inadequate surface preparation. Make sure the surfaces are free of dust and moisture, and allow them to dry completely before applying glue.

Proper surface preparation can significantly reduce common issues like weak bonds and peeling edge.

Applying Contact Cement

Applying contact cement works requires a bit of patience and precision. Start by applying a thin layer of cement to both surfaces you intend to bond and allow them to dry until tacky. If the bond will be under significant pressure, consider applying a second layer for added strength.

Once both surfaces are ready, press them together carefully, as repositioning is not possible. Allow the bond to cure for 24 hours to achieve maximum strength.

Using Hot Glue

Using a hot glue gun for EVA foam can provide fast and effective bonding, but precision is key. Apply the hot glue in a thin, even layer along the edges of the foam, ensuring you work quickly to avoid the glue cooling before proper placement.

Cleaning up any excess adhesive immediately after application can prevent unsightly residue from forming. This technique helps create a strong bond without the mess.

Best Practices for Gluing EVA Foam

Mastering the art of gluing EVA foam involves more than just picking the right adhesive. It requires understanding best practices to ensure your projects not only look good but also last long. From working in a well-ventilated area to applying pressure for stronger bonds, these tips can make all the difference in your crafting process.

Let’s explore some of these best practices in detail, starting with the personally idea of effective communication.

Working in a Well-Ventilated Area

Working in a well-ventilated area is crucial when using adhesives, particularly those with strong odors like contact cement. Proper ventilation helps mitigate the inhalation of harmful fumes and reduces the risk of health issues.

It’s always recommended to use adhesives like contact cement in well-ventilated spaces to minimize exposure and ensure a safer working environment.

Layering Techniques

Applying adhesives in thin, even layers is essential for achieving strong bonds and preventing excess glue from spilling over. Careful application of contact cement, for instance, should be done in a thin layer to prevent buildup that could compromise adhesion and affect the thickness of the bond.

Using too much glue can lead to peeling edges, so it’s best to apply a thin, even layer to maintain a clean and strong bond.

Applying Pressure

Consistent pressure on glued surfaces helps eliminate gaps and ensures a tighter bond. Applying pressure while the adhesive sets is crucial to prevent edges from peeling and to maintain the integrity of the bond.

This technique is especially important for EVA foam projects that will be subject to movement and stress.

Recommended Brands and Products

Choosing the right brand and product can make all the difference in your EVA foam projects. With so many options available, it can be overwhelming to decide which one to use.

Here, we’ll recommend some of the best brands and products for contact cement, hot glue guns, and super glues, ensuring you have the best tools for your cosplay creations.

Popular Contact Cements

Barge Super Stick Cement and DAP Weldwood Contact Cement are top choices for contact cements. Barge Super Stick Cement is known for its quick setting time and strong hold, making it ideal for foam and fabric applications. Additionally, barge cement is a reliable option for various bonding needs.

DAP Weldwood Contact Cement offers fast drying time and strong adhesion properties, ensuring your EVA foam projects are durable and long-lasting.

Best Hot Glue Guns

The Surebonder PRO2-60 and Gorilla Dual Temperature Hot Glue Gun are highly recommended for hot glue guns. The Surebonder PRO2-60 is praised for its temperature control and effectiveness with EVA foam.

The Gorilla Dual Temperature Hot Glue Gun offers versatility with its dual temperature settings, making it suitable for different foam applications. Surebonder’s Cosplay Glue Gun is also specially designed for bonding EVA foam and similar materials effectively.

Versatile Super Glues

When it comes to super glues, Loctite Super Glue and Gorilla Glue are excellent choices. Loctite Super Glue is known for its quick bonding strength and is ideal for detailed projects involving EVA foam. Gorilla Super Glue is also favored for its quick bonding capabilities and strong adhesion.

These super glues are perfect for small repairs and detailed work, ensuring that your EVA foam creations are both durable and precise.

Troubleshooting Common Issues

Even with the best techniques and adhesives, issues can still arise when working with EVA foam. Common problems such as weak bonds, peeling edges, and messy applications can detract from the quality of your projects. Understanding how to troubleshoot these issues is key to achieving professional results.

When EVA foam is curved or heat-formed, it can exert a pull on the adhesive, which may cause the bond to weaken or come apart if the wrong glue is used. It’s important to select adhesives that can withstand this pull, especially for shaped or bent pieces.

Let’s look at some common issues and their solutions.

Weak Bonds

Weak bonds are often a result of improper application or insufficient curing time. Super glue, while excellent for quick fixes, is not ideal for larger EVA foam projects due to its brittle nature. To prevent weak bonds, ensure you apply the adhesive properly and allow adequate curing time.

If a bond is weak, reapplication of the glue or extending the cured time can help strengthen it.

Peeling Edges

Peel edges can occur when the adhesive is not applied evenly or when surfaces are not properly prepared. To prevent this, ensure that surfaces are clean and smooth before gluing, and apply the glue evenly to maintain a strong bond.

If peeling edges are already present, reapply adhesive to the affected areas and use pressure to ensure the bond is restored. Avoid excessive glue application, which can lead to a messy finish and further peeling.

Messy Applications

Messy applications are often the result of applying too much glue or not cleaning up excess adhesive immediately. Applying glue in thin layers helps ensure a cleaner application and prevents glue from oozing out. When using a hot glue gun, apply the glue in a steady, consistent line to prevent globs and uneven surfaces.

If excess glue does occur, quickly wiping with a wet cloth can help clean it up before it dries.

Advanced Techniques

For those looking to take their EVA foam projects to the next level, advanced techniques such as heat forming and creating flexible forms can provide enhanced aesthetics and functionality. These methods require a bit more skill and patience but can significantly improve the quality and durability of your cosplay creations.

Let’s delve into these advanced techniques.

Heat Forming

Heat forming allows you to manipulate EVA foam into custom shapes by using heat to soften the material. Using a heat gun, hold it about four inches away from the foam to prevent overheating and craft bends and curves. It’s important to heat both sides of the area being shaped to ensure even flexibility and avoid damage.

The benefits of using heat on EVA foam include creating customized shapes that enhance the look and functionality of your cosplay props.

Flexible Joints

Flexible joints are essential for cosplay costumes as they allow for movement while ensuring the parts remain securely attached. Adhesives like rubber cement and contact cement are ideal for creating flexible joints, as they bond well while allowing for movement. Hot glue is also suitable due to its quick setting time and flexibility when cooled.

To achieve strong bonds in flexible joint, apply the adhesive in thin layers, allowing each layer to cure before adding additional ones.

Summary

In summary, achieving the best results with EVA foam in your cosplay projects involves selecting the right adhesive and applying it correctly. From understanding the properties of different glues to mastering advanced techniques like heat forming and creating flexible joints, every step is crucial.

By following these guidelines, you can ensure your EVA foam creations are both durable and visually stunning. So, pick up your tools, choose your glue wisely, and start crafting your next masterpiece!

Frequently Asked Questions

What is the best glue for EVA foam?

For EVA foam, contact cement such as DAP Weldwood is the best choice due to its strong bond and versatility. For quick fixes or detailed projects, hot glue and super glue are also effective options.

How do I prevent peeling edges on my EVA foam projects?

To prevent peeling edges on your EVA foam projects, make sure surfaces are clean and apply adhesive evenly. If peeling occurs, reapply glue to the affected areas and use pressure to restore the bond effectively.

Can I use super glue for large EVA foam projects?

Using super glue for large EVA foam projects is not advisable because it tends to be brittle. Instead, opt for contact cement or hot glue for better flexibility and adhesion on larger areas.

How do I achieve clean glue applications?

For clean glue applications, apply in thin layers and maintain a steady, consistent line to avoid globs. Promptly clean any excess glue with a damp cloth for best results.

What are the benefits of heat forming EVA foam?

Heat forming EVA foam offers the ability to create custom shapes, enhancing both the aesthetics and functionality of projects such as cosplay props. This technique allows for intricate bends and curves, leading to more detailed and professional-looking results.