Expanded polystyrene (EPS) is a foam material made from polystyrene beads. It is used in construction, packaging, and art due to its versatility. This article explores what EPS is, its applications, and why it’s widely used.

Understanding Expanded Polystyrene (EPS)

Expanded Polystyrene (EPS) is a rigid foam made from polystyrene beads that expand when heated, creating a lightweight yet durable material. The customization in manufacturing allows EPS products to vary in density, shape, and size, making them suitable for a wide range of styrofoam applications, including insulation materials.

EPS’s unique properties have made it a staple in industries such as construction, packaging, and even art, particularly for its effectiveness in insulation materials for walls, roofs, and floors.

Composition and Properties

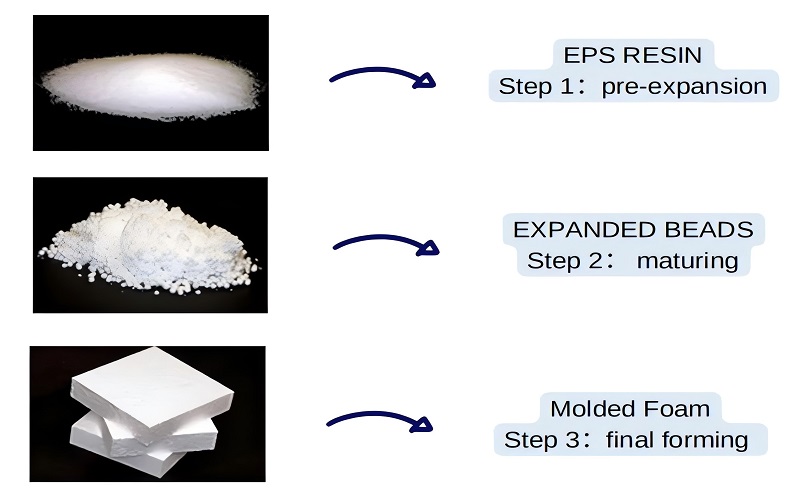

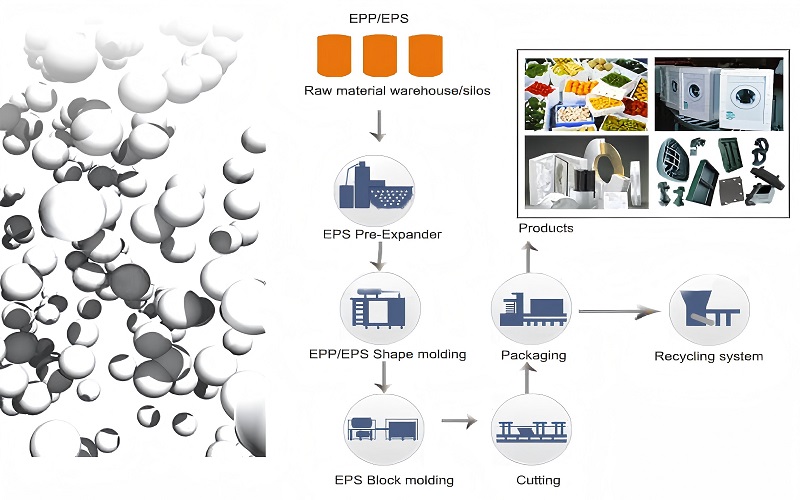

EPS is composed of a polymer compound derived from polymerizing styrene, which forms polystyrene as its foundational component. The manufacturing process begins with polystyrene beads that are expanded using steam, leading to the formation of foam.

This foam, characterized by its lightweight and air-filled design, provides long-term stable thermal conductivity. Additionally, a foaming agent is added to the raw material, enhancing EPS’s thermal insulation properties when heated. These foam products, often covered with protective layers for added durability, are essential for various applications, with customizable thickness to meet specific insulation or structural requirements.

Historical Development

Polystyrene was first industrialized in the 1930s in Germany, marking its significant entry into the materials market. The momentum continued post-World War II, with full-scale production of polystyrene beginning in the U.S. in 1957 to meet the growing demand for versatile materials.

EPS, known for its lightweight nature and high heat insulation properties, has since become indispensable in modern applications.

Applications of EPS Foam products

EPS foam is a versatile material utilized in various industries, ranging from residential construction to packaging and civil engineering. Its effectiveness in serving specific needs within different sectors is well-documented through numerous case studies, showcasing its adaptability and unique properties.

Whether used for insulation, protective packaging, or custom applications, EPS products demonstrate remarkable versatility. In Canada, EPS is widely adopted for its excellent thermal insulation in harsh climates, while its smooth surface enhances its suitability for protective packaging and structural applications.

Construction Industry

EPS insulation boards are available in multiple grades, making them suitable for various applications, including:

- Energy-efficient buildings

- Insulation

- Roofing systems

- Exterior Insulation and Finish Systems (EIFS)

These applications help improve energy efficiency and reduce energy costs.

Its lightweight nature commonly simplifies handling and installation, while its strength and durability make it a popular choice in commercial construction.

Packaging Solutions

EPS is widely used in packaging to protect fragile items during transit, owing to its lightweight and shock-absorbing properties. It cushions products, safeguarding electronics and food items from impacts during transportation on a ship. In the USA, EPS is a preferred material for its cost-effectiveness and reliability in packaging solutions.

In commercial settings, EPS is an essential component of packaging solutions, often formed into blocks for custom-fit protection, ensuring high-quality products are delivered to their destination intact. Its widespread access in the market makes it a go-to choice for businesses seeking efficient and protective packaging options.

Art and Events

EPS is a popular choice in the creative industries due to its malleability. Artists leverage EPS foam for creating large sculptures and installations, as it can be easily shaped and is cost-effective.

Its lightweight properties make it ideal for event decorations, allowing for easy transportation and setup.

Technical Advantages of EPS Products

EPS is primarily composed of 98% air, contributing to its exceptional thermal insulation properties. Its effectiveness spans various sectors, including thermal insulation, packaging, and civil engineering. The material’s high impact resistance, lightweight, and durability make it an ideal choice for a multitude of applications.

EPS products are known for their waterproof characteristics and resistance to fungi and bacteria, further enhancing their utility.

Impact Resistance

Expanded Polystyrene (EPS) exhibits enhanced impact resistance, especially in higher density foams that absorb shocks and mechanical stress effectively. Its composition and structure allow it to withstand significant forces without breaking or deforming, making it suitable for protective packaging.

Higher-density EPS provides better performance against impacts, ensuring that products remain undamaged during transport.

Thermal Insulation

EPS is utilized for insulation in walls, roofs, and floors, enhancing energy efficiency in buildings. The thermal conductivity of EPS foam is around 0.035 – 0.037 W/(m·K), making it an efficient insulator. Its closed-cell structure effectively prevents heat transfer, contributing significantly to indoor comfort and reducing energy costs.

EPS retains stable thermal conductivity over time, ensuring long-term energy efficiency.

Lightweight and Durable

EPS is widely recognized for its lightweight nature, making it easy to handle and install. This characteristic facilitates ease of installation in various applications, particularly in construction, where it also helps in reducing transportation costs.

Despite its lightweight nature, EPS maintains durability, making it a reliable choice for high-quality products.

Environmental and Sustainability Aspects

While EPS foam can take up to 500 years to decompose in landfills, contributing to long-term environmental issues, there are significant efforts towards sustainability. Epsilyte, for example, has committed to being 100% carbon neutral, showcasing a strong focus on environmental responsibility.

Using Epsilyte products can save almost half a ton of CO2 equivalents per year for a home insulated with their material, highlighting the environmental benefits of EPS.

Recycling Initiatives

Recycling EPS is crucial in minimizing landfill waste and promoting environmentally friendly practices. Kalamazoo offers quarterly EPS foam recycling events where residents can drop off foam for proper processing, demonstrating a collective effort towards sustainable waste management.

Community participation in these recycling events underscores the importance of America responsibility for the environment.

Sustainable Production

Advancements in EPS manufacturing processes aim to lower the environmental impact by minimizing waste and improving energy efficiency. Innovations in production methods focus on reducing waste and enhancing sustainability, ensuring that high-quality products are produced with a minimal carbon footprint.

Customization and Manufacturing Processes

EPS products can be customized to meet specific performance requirements by adjusting their density and shape during production. This flexibility allows manufacturers to cater to different functional needs, providing tailored solutions for various applications.

Assessing a manufacturer’s product range and the types of EPS machinery they offer is essential to meet specific production requirements and achieve desired outcomes.

Tailored Solutions

The density of EPS can be modified from as low as 10 kg/m³ for lightweight applications to over 40 kg/m³ for high-density requirements, allowing manufacturers to cater to different functional needs. Shapes and sizes of EPS can be modified through a molding process during its expansion phase, providing precise and tailored solutions for clients.

This customization enhances the versatility and applicability of EPS products across various industries.

Advanced Manufacturing Techniques

Modern EPS production techniques include controlled expansion processes that ensure uniformity in density and structural integrity of the final product. The production process involves a pre-expansion stage where polystyrene beads are expanded using steam before being molded.

Cutting of EPS is achieved using heated wire, allowing for precise shaping and customization to meet specific design requirements. This ensures that high-quality products are manufactured efficiently and sustainably.

Choosing the Right EPS Manufacturer

Selecting the right EPS manufacturer involves assessing their commitment to quality, proven track record, and customer-centric approach. It is crucial to evaluate a manufacturer’s reputation and customer reviews to ensure reliability.

Companies like Epsilyte have pledged to achieve complete carbon neutrality in their operations, highlighting their commitment to sustainability.

Quality Standards

Commitment to quality starts with skilled employees and ensures a seamless project experience for the company. Manufacturers should provide certifications and customers testimonials to verify their adherence to high quality, knowledge, excellence, and reliability standards.

Ensuring that a manufacturer meets the highest standards of quality criteria is essential for obtaining high-quality products that produce specific needs.

Customer Support and Services

Excellent customer service is essential for building trust and ensuring satisfaction among EPS suppliers’ clients. Experienced engineers should be available for every order to provide technical support and ensure proper product selection and application. A proactive customer service team can significantly enhance the overall experience by addressing client concerns promptly and effectively.

Case Studies and Real-World Examples

Real-world examples illustrate the diverse applications of EPS in residential and commercial settings. From energy-efficient homes to industrial insulation, these case studies highlight the practical benefits and versatility of EPS products, providing valuable insights for potential users.

Kalamazoo College’s program to collect and recycle EPS foam into insulation panels and roof materials is a testament to the material’s sustainability and adaptability, showcasing Michigan foam products as a viable solution.

Residential Projects

EPS has been utilized in homes to improve energy efficiency and comfort, often integrated into foundations and wall systems. In a Michigan home built with 52 windows, EPS SIPs achieved an airtight standard with a blower test indicating only 0.2 air changes per hour.

Products like Mono Slab® combine forming and insulation into a single step to build effective energy-efficient foundation solutions for homes.

Commercial and Industrial Applications

EPS is widely used in several commercial applications, such as insulation, packaging, and construction, due to its lightweight nature and durability. In industrial settings, EPS products are employed for thermal insulation, significantly contributing to energy efficiency. The cost-effectiveness of EPS products stems from their lightweight nature, which reduces shipping costs and labor during installation.

Additionally, EPS is utilized for noise reduction, enhancing work environments in industrial applications. In governmental applications, EPS is leveraged for infrastructure projects, such as road construction and public building insulation, showcasing its adaptability.

Overall, EPS demonstrates its significant role in modern industry and governmental applications through its versatility and efficiency.

Summary

Throughout this exploration of Expanded Polystyrene (EPS), we’ve seen its remarkable versatility and efficiency across various applications. From its robust use in the construction industry to its critical role in packaging and art, EPS stands out as a high-quality material that meets diverse needs.

Its technical advantages, including impact resistance, thermal insulation, and lightweight nature, make it an invaluable asset. Moreover, the ongoing efforts towards environmental sustainability and advanced manufacturing techniques highlight the responsible and innovative use of EPS.

As you consider integrating EPS products into your projects, remember the importance of selecting a reliable manufacturer committed to quality and customer support. Embrace the benefits of EPS and experience the transformative impact it can have on your projects.

Frequently Asked Questions

What is Expanded Polystyrene (EPS)?

Expanded Polystyrene (EPS) is a lightweight and rigid foam created from expanded polystyrene beads, valued for its durability and insulating qualities. Its versatility allows for widespread use in construction, packaging, and artistic endeavors.

How is EPS used in the construction industry?

EPS is utilized in the construction industry primarily for its insulation properties in walls, roofs, and floors, enhancing energy efficiency and lowering energy costs. Its role in roofing systems and Exterior Insulation and Finish Systems (EIFS) further underscores its importance in modern building practices.

What are the environmental impacts of using EPS?

The environmental impacts of using EPS include its prolonged decomposition period of up to 500 years in landfills, although sustainability efforts like recycling initiatives can help reduce its negative effects. Transitioning to more sustainable practices is crucial for minimizing EPS’s ecological footprint.

Can EPS be customized for specific applications?

Yes, EPS can be customized for specific applications by modifying its density, shape, and size during production, thus offering tailored solutions for various industries.

What should I consider when choosing an EPS manufacturer?

When choosing an EPS manufacturer, prioritize their commitment to quality and established reputation, as well as their customer-centric approach and adherence to high standards. These factors are essential to ensure you receive reliable products and services.

What should I consider when choosing michigan foam products as my EPS manufacturer?

When selecting michigan foam products as your EPS manufacturer, consider their commitment to quality, established reputation, and customer-centric approach. Ensure they adhere to high standards, offering reliable, customizable Expanded Polystyrene (EPS) solutions tailored to your specific needs in construction, packaging, or other applications.