Introduction

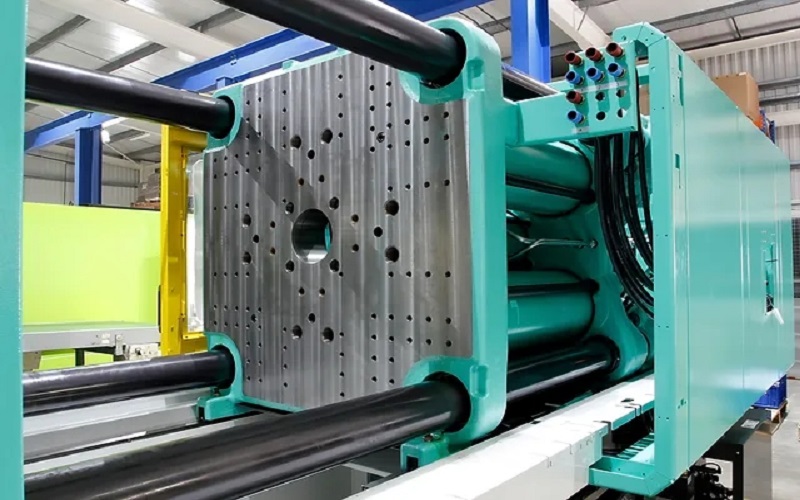

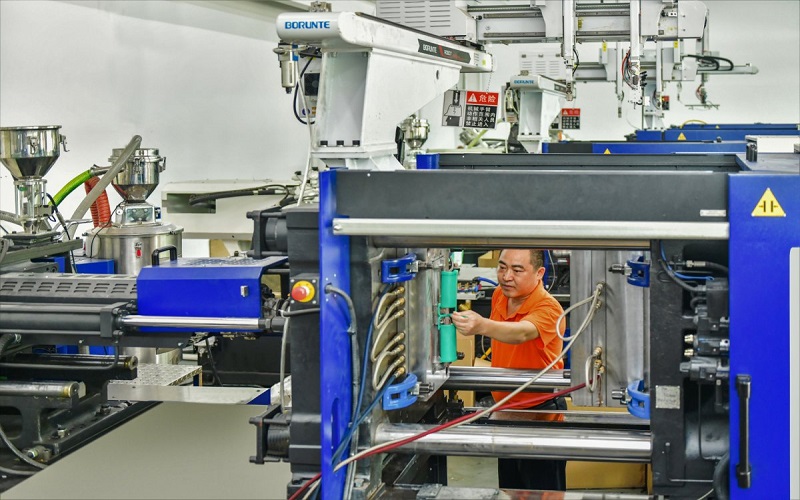

Injection molding is a widely used industrial process for manufacturing plastic products, applied across various industries. The development of injection molding technology continues to advance the manufacturing sector, and Australia’s mold manufacturing industry holds a significant position in the national manufacturing landscape.

In recent years, Australia’s mold manufacturing industry has seen remarkable growth, with continuous improvements in technological capabilities. The widespread application of advanced 3D printing and CNC machining technologies has made mold manufacturing more precise and efficient.

Moreover, many are investing in energy-saving equipment and environmentally friendly materials, aiming to boost productivity while reducing environmental impact. In this context, Australian mold manufacturing companies are leading the global market with their technological innovation and quality assurance.

This article will explore the unique strengths of these companies in terms of technology, production capacity, and sustainability, providing valuable insights for selecting the right injection molding partners in Australia.

Australia’s Plastic Injection Molding Companies

| No. | Company | Founded Year |

| 1. | A Plus Plastics Pty Ltd | 1973 |

| 2. | Aldom Motor Body Builders | 1975 |

| 3. | Plasticut | 1980 |

| 4. | Toolcraft Plastics (Australia) Pty Ltd | 1982 |

| 5. | Plastool International Pty Ltd | 1984 |

| 6. | Allmould Plastics Pty Ltd | 1985 |

| 7. | Melro | 1982 |

| 8. | Sneddon & Kingston Plastic | 1948 |

| 9. | Edplas Australia Pty Ltd | 1980 |

A Plus Plastics Pty Ltd

Website: https://aplusplastics.com.au/

Location: Sydney, New South Wales

Email: [email protected]

A Plus Plastics Pty Ltd is a long-established injection molding company based in Sydney. Since 1973, the company has specialized in the production of custom injection molds. They are known for their high-quality products and innovative solutions, providing professional services to various industries. A Plus Plastics utilizes advanced technology and has an experienced professional team to create exceptional plastic products, ensuring customer satisfaction.

Key Products and Services: Custom injection molding, tooling, and product development with a focus on high-quality standards.

Technological Capabilities: Advanced injection molding machinery, design for manufacturability, and extensive tooling capabilities.

Aldom Motor Body Builders

Website: https://aldom.com.au/

Location: Adelaide, South Australia

Email: [email protected]

Aldom Motor Body Builders is headquartered in Adelaide, South Australia, and has been operating since 1975. It is a renowned mold injection company in Australia, famous for custom vehicle bodies, including trailers, truck bodies, and specialized vehicle modifications. Utilizing CAD design and advanced manufacturing techniques, they deliver high-quality, durable products tailored to meet the specific needs of their clients. With a consistent commitment to innovation and customer satisfaction, Aldom Motor Body Builders has grown into a trusted brand in the industry.

Key Products and Services: Custom vehicle bodies, including trailers, truck bodies, and special-purpose vehicle modifications.

Technological Capabilities: Precision fabrication, CAD design, and advanced manufacturing techniques.

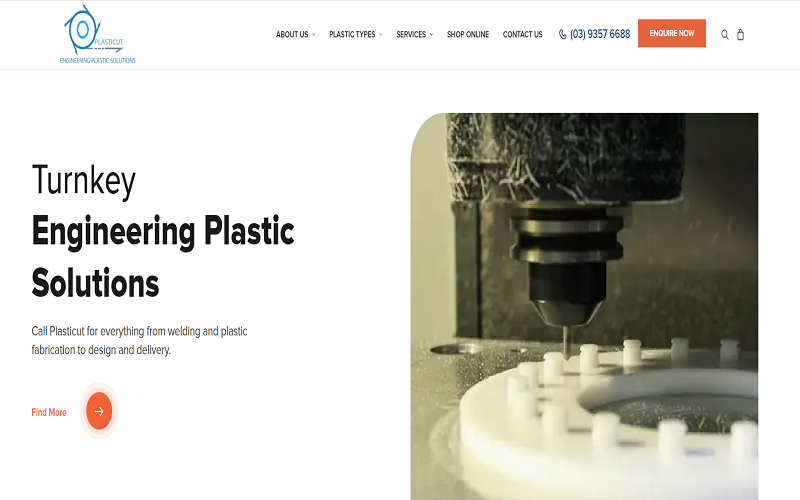

Plasticut

Website: https://www.plasticut.com.au/

Location: Melbourne, Victoria

Email: [email protected]

Plasticut is a mold injection company established in 1980 and headquartered in Melbourne, Victoria. With extensive industry experience and expertise, Plasticut specializes in custom plastic fabrication, CNC (Computer Numerical Control) machining, and laser cutting services. Their operations span multiple industries, including automotive, electronics, medical devices, construction, and consumer goods. The company works closely with clients to ensure every project meets or exceeds expectations.

Key Products and Services: Custom plastic fabrication, CNC machining, and laser cutting services.

Technological Capabilities: High-precision CNC machining, laser cutting, and extensive fabrication capabilities.

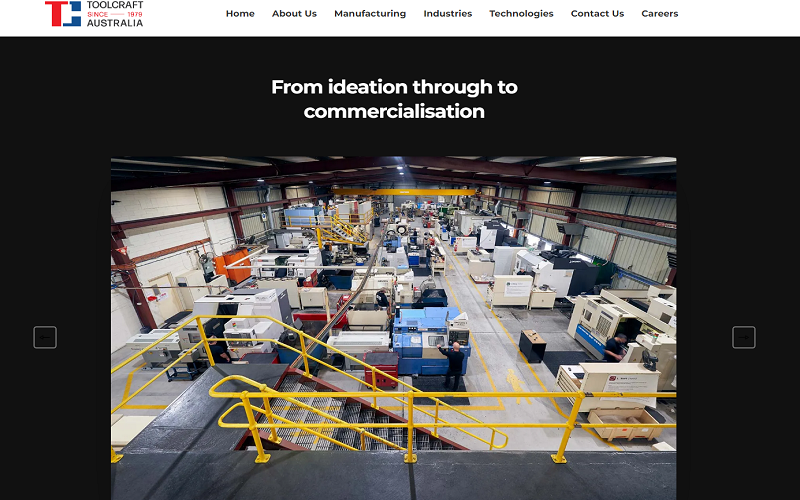

Toolcraft Plastics (Australia) Pty Ltd

Website:https://toolcraft.com.au/

Location: Sydney, New South Wales

Email: [email protected]

Toolcraft Plastics (Australia) Pty Ltd is a leading plastic injection molding company in Australia, offering comprehensive plastic manufacturing services from design to mass production. The company is dedicated to quality and innovation, with primary services including advanced CAD design and engineering, rapid prototyping, high-precision mold manufacturing, and injection molding of various plastic materials. Toolcraft Plastics is ISO 9001 certified, ensuring the highest standards of quality. For more information, please visit the company’s website.

Key Products and Services: Precision injection molding, tooling, and assembly services for various industries.

Technological Capabilities: Advanced injection molding machines, precision tooling, and quality control systems.

Plastool International Pty Ltd

Website: https://plastool.com.au/

Location: Sydney, New South Wales

Email: [email protected]

Plastool International Pty Ltd is a leading plastic injection molding and mold manufacturing company based in Australia. The company is equipped with advanced 3D printing and CNC machining equipment, ensuring seamless integration at every design stage. Additionally, Plastool International offers customized mold solutions to meet the specific needs of various industries and products. They hold a prominent position in the plastic manufacturing industry and are a trusted partner for their clients.

Key Products and Services: Precision injection molding, toolmaking, and production services.

Technological Capabilities: Cutting-edge molding technology, CAD/CAM systems, and comprehensive quality assurance.

Allmould Plastics Pty Ltd

Website: https://allmouldplastics.com.au/

Location:Sydney, New South Wales

Email: [email protected]

Allmould Plastics Pty Ltd is a mold manufacturer based in Sydney, New South Wales. Since its establishment in 1985, Allmould Plastics has specialized in custom injection molding and tooling services. The company is dedicated to delivering high-quality, precise plastic products across various industries. Utilizing modern injection molding machines and advanced design optimization software, Allmould Plastics ensures efficient production and exceptional product quality. Their commitment to innovation and customer satisfaction has solidified their position as a trusted leader in the mold manufacturing industry.

Key Products and Services: Custom injection molding, tooling, and product development.

Technological Capabilities: Utilizes modern injection molding machines, precision tooling, and design optimization software.

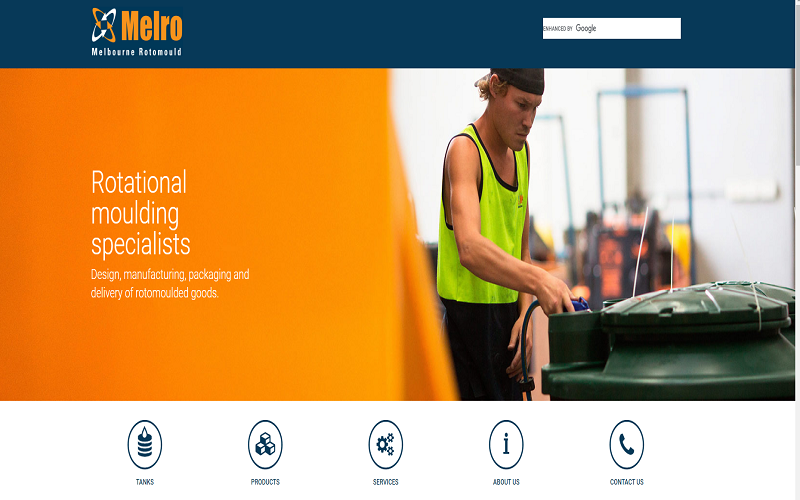

Melro

Website: https://www.melro.com.au/

Location:20 Campbell Street, Pakenham VIC 3810, Australia

Email: [email protected]

Melro is a company based in Victoria, founded in the 1970s, renowned for its high-quality plastic products. They specialize in rotational molding technology, producing mainly water tanks, chemical storage tanks, and custom plastic products. They provide solutions for agricultural, commercial, and industrial clients, with products designed to be durable and suitable for harsh environments. Melro emphasizes environmental protection and sustainable development by upgrading eco-friendly equipment, recycling waste, and reducing environmental impact.

Key Products and Services: Specializing in water storage tanks, water treatment products, and custom plastic products, and providing installation and maintenance services.

Technological Capabilities: Specializes in the design, manufacturing, and delivery of rotomoulded plastic products, including water tanks and custom mouldings.

Sneddon & Kingston Plastic

Website: https://www.skpackaging.com.au/

Location: Preston, VIC

Email: info@Sneddon & Kingston Plastic.com.au

For the past 60 years, Sneddon & Kingston Plastics has been producing high-quality injection molded products, establishing itself as a benchmark in the global plastic products and mold manufacturing industry. Based in Preston, Melbourne, the company specializes in plastic injection molding and mold making. Their skilled team uses 3D CAD software, providing a practical understanding of creative plastic design. Sneddon & Kingston Plastics’ services include plastic product design, prototyping, injection molding, mold design, and manufacturing, with their products primarily serving the automotive, packaging, medical, and construction sectors.

Key Products and Services: IML Containers, Injection Moulding, Injection Moulding Tooling, Food Packaging,

Technological Capabilities: Design Support, Focus on plastic packing

Edplas Australia Pty Ltd

Website: https://edplasaustralia.com.au/

Location: Sydney, NSW

Email: info@Edplas Australia.com.au

Since 1980, Edplas Australia has been serving its customers with extensive experience in the field of injection molding. Headquartered in Peakhurst, New South Wales, the company stands out for its ability to mass-produce unique and impressive plastic products, regardless of size. Their production facility is equipped with an array of heavy-duty machinery specifically designed for injection molding. Edplas Australia caters to a wide range of industries, including agriculture, engineering, healthcare, warehousing, logistics, automotive, mining, railway, and construction.

Key Products and Services: Plastic Injection Molding, Tooling Making, CNC Machining

Technological Capabilities: Design Support

Environmental and Sustainability Initiatives for Injection Mold Companies in Australia

Mold injection molding companies in Australia have invested significant resources in their commitment to reducing environmental impact and improving energy efficiency. Below are some of their specific sustainability initiatives and environmental measures:

1. Use of environmentally friendly materials:

Use of recyclable plastics

Use of biodegradable plastics

2. On energy-saving equipment:

Introduction of advanced energy-saving injection molding equipment

Adoption of Internet of Things (IoT) and automation technologies

3. Waste Management:

Implementing a strict waste management system

Adoption of recycled water system

These green manufacturing and environmental protection measures not only improve productivity, but also enhance the company’s competitiveness in the marketplace.

Conclusion

The aforementioned companies – A Plus Plastics Pty Ltd, Aldom Motor Body Builders, B&C Plastics, Plasticut, Toolcraft Plastics (Australia) Pty Ltd, Plastool International Pty Ltd , Allmould Plastics Pty Ltd,Sneddon & Kingston Plastic and Edplas Australia Pty Ltd Each company has something different to offer, whether it’s a custom injection molding solution to high-precision mold making, or a full range of design and production services.

Each of these companies represents the very best in mold injection molding in Australia.

Whether you need customized solutions, high precision components or mass production, these companies will meet your needs.

FQA

How do Australian injection mold manufacturers ensure quality control?

Australian injection mold manufacturers ensure quality through three key measures. Firstly, they are often ISO 9001 certified, ensuring their processes meet global standards.

Secondly, they use advanced inspection equipment like CMMs, optical measurement systems, and laser scanners for precise quality checks.

Lastly, they establish detailed production processes and Standard Operating Procedures (SOP) to ensure strict adherence at every step.

What are the latest trends in Australia’s injection molding industry?

Internet technologies, particularly smart manufacturing and automation, alongside environmental sustainability, are the latest trends in the Australian injection molding industry. Internet technologies encompass the integration of smart manufacturing, rapid prototyping, and digital management. On the sustainability front, many companies are beginning to use recyclable and biodegradable materials to reduce the environmental impact of plastic waste.

How do Australian injection mold companies handle custom mold design?

Injection molding companies in Australia efficiently handle custom mold designs by following these steps to ensure that customer needs are met and high quality products are delivered:

Requirements Analysis: Thoroughly understand the customer’s specific needs and product requirements.

Conceptual Design: Create a preliminary design model to ensure it aligns with the customer’s expectations.

Prototyping: Develop prototypes using 3D printing or other advanced technologies, then test and verify to ensure the design is accurate.

Mold Manufacturing:Execute the actual manufacturing of the mold using high-precision machining techniques.

Quality Control: Conduct comprehensive inspection and testing of the mold to ensure it meets all standards.

Delivery and Support: After passing all tests, deliver the molds to customers and provide installation, commissioning, operation training, and ongoing technical support.

What certifications do top Australian injection mold manufacturers hold?

Certification refers to the process where a formal, independent organization evaluates a company to determine if it meets specific standards or regulations, and then issues a corresponding certificate.

By obtaining these certifications, companies can enhance their market reputation and competitiveness, while also ensuring sustainable and compliant operations.

For example, ISO 9001 is a quality management system certification, ISO 14001 is an environmental management system certification, and AS/NZS 4801 is an occupational health and safety management system certification.

What is the average cost of an injection mold?

The average cost of injection molds in Australia varies due to several factors, including the complexity of the mold, its size, material selection, production quantity, and design requirements.

Complex designs and extended development periods can significantly increase the total cost of the mold. The actual cost for specific projects needs to be evaluated based on detailed requirements.