Injection molding is a vital manufacturing process used to create precise plastic parts for industries ranging from automotive to consumer electronics.

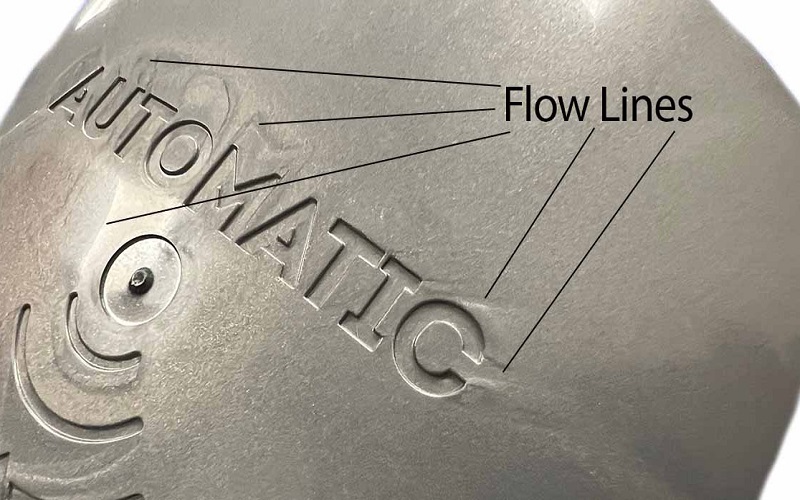

Despite its versatility, the injection molding process can produce defects like flow lines, also known as flow marks or wavy lines, which appear as visible streaks or patterns on the surface of molded parts. These injection molding defects can compromise both the aesthetic quality and, in some cases, the structural integrity of the finished product.

Understanding the causes of flow lines and implementing effective prevention strategies is essential for producing high-quality plastic parts.

This article delves into the nature of flow lines, their causes, and practical solutions to ensure a smooth injection process and flawless finished parts.

Understanding Flow Lines in Injection Molding

Flow lines occur when molten plastic flows unevenly within the mold cavity, creating visible marks in injection molding or wavy patterns on the surface of the molded part.

These defects are often caused by variations in material flow, uneven cooling, suboptimal process parameters like material temperature, or other inconsistencies.

While primarily a cosmetic issue, flow lines can sometimes indicate deeper problems in the injection molding process that may affect the part’s performance.

For example, flow marks in injection might suggest improper bonding of the material, which could weaken the part in high-stress applications.

The formation of flow lines is closely tied to how molten plastic behaves as it fills the mold.

When the material encounters resistance—such as poorly designed molds, improper gate locations, or inconsistent wall thickness—it can cool unevenly or flow in different directions, leading to visible defects.

Key Factors Causing Flow Lines

Several elements in the injection molding process can lead to flow lines, ranging from material properties to mold design and machine settings, which are among the most important factors.

One primary cause is poor material flow, where the molten plastic struggles to fill the mold cavity smoothly.

This can happen if the melt temperature, nozzle temperature, or barrel temperature is too low, causing the material to solidify before fully filling the mold. Similarly, a slow injection speed can result in early cooling, generally leaving wavy lines on the part’s surface.

Another critical factor is non-uniform cooling, often caused by inconsistent mold temperatures or inadequate mold coolant. When the molten plastic cools at different rates in thicker areas or thinner areas of the mold, it creates visible flow marks.

Uneven wall thickness in the part design exacerbates this issue, as thinner areas cool faster than thicker areas, disrupting the flow.

Additionally, poorly designed molds—such as those with suboptimal gate locations or insufficient mold gates—can cause the molten material to flow in different directions, leading to trapped air or wavy patterns. Consulting an applications engineer can help identify these important factors and optimize mold design.

Injection pressure also plays a role. If the pressure is too low, the mold may not fill completely, resulting in flow lines. Conversely, excessive pressure can cause other defects, so finding the right balance is crucial.

The Impact of Flow Lines on Molded Parts

Flow lines are more than just a visual imperfection.

In applications requiring high precision, such as medical devices or automotive components, flow marks can indicate areas of weakness where the material has not bonded properly.

This can compromise the structural integrity of the part, potentially leading to cracks or failures under stress. Even in less critical applications, flow lines can detract from the aesthetic appeal of the finished product, affecting its marketability.

The occurrence of flow lines is often linked to specific conditions in the mold.

For instance, improper gate locations can cause the molten plastic to enter the mold cavity unevenly, creating visible lines. Similarly, variations in wall thickness lead to uneven cooling, with thinner areas solidifying faster than thicker ones.

Trapped air within the mold can also disrupt material flow, contributing to flow marks. By addressing these issues through careful design and process optimization, manufacturers can minimize the risk of defects.

Strategies for Preventing Flow Lines

Preventing flow lines requires a holistic approach that combines optimized mold design, precise process control, and careful material selection.

| Parameter | Recommended Value | Purpose |

|---|---|---|

| Melt Temperature | 200–280°C | Enhances material flow |

| Mold Temperature | 50–100°C | Ensures uniform cooling |

| Injection Speed | 50–150 mm/s | Prevents early cooling |

| Injection Pressure | 80–150 MPa | Ensures complete mold filling |

| Wall Thickness | 2–4 mm | Maintains uniform cooling |

| Nozzle Diameter | 2–5 mm | Improves flow rate |

Enhancing Mold Design

The mold is the heart of the injection molding process, and its design significantly influences the formation of flow lines. A well-designed mold ensures smooth material flow and consistent cooling. One key aspect is gate location.

Mold gates serve as entry points for the molten plastic, and their placement determines how evenly the material fills the mold cavity. Strategically positioned gates can prevent the material from flowing in different directions, reducing the risk of flow marks.

Maintaining uniform wall thickness is equally important. Variations in wall thickness cause the molten plastic to cool at different rates, leading to flow lines.

By designing parts with consistent thickness, manufacturers can promote even cooling and minimize defects.

Advanced computer simulations are invaluable here, allowing engineers to model material flow and identify potential issues before production begins.

These simulations can optimize gate locations, mold geometry, and other design elements to ensure a fully filled mold with minimal defects.

Optimizing Process Parameters

Adjusting the settings on the injection molding machine is another effective way to prevent flow lines. Injection speed is a critical parameter.

A faster flow rate ensures the mold is filled before the molten plastic cools, reducing the likelihood of wavy lines.

However, the speed must be balanced to avoid other defects, such as flash or burn marks.

Temperature control is also essential. The melt temperature and nozzle temperature should be high enough to maintain smooth material flow but not so high as to degrade the plastic.

Similarly, the mold temperature must be carefully regulated using mold coolant to prevent non-uniform cooling.

Consistent temperatures across the mold core and cavity help ensure the molten plastic cools evenly, minimizing flow marks.

Injection pressure is another factor to consider. Adequate pressure ensures the mold is fully filled, overcoming resistance caused by complex geometries or narrow sections.

Selecting the Right Material

The choice of material can also influence the formation of flow lines. Some plastics are more prone to flow marks due to their viscosity or cooling properties.

For example, highly viscous materials may require higher melt temperatures or injection pressures to flow smoothly.

Consulting with material suppliers or conducting tests can help identify the best material for a specific application.

Additionally, additives can sometimes be used to improve flow characteristics, reducing the risk of defects.

Advanced Techniques for Reducing Flow Marks

For complex parts or high-volume production, advanced techniques can further reduce the risk of flow lines.

One approach is to increase the nozzle diameter, allowing for smoother material flow and reducing resistance at the entry point.

Another option is to use multi-gate systems, where multiple mold gates distribute the molten plastic more evenly across the mold cavity. This is particularly effective for large or intricate parts.

In some cases, modifying the mold surface can help. Polishing the mold cavity or applying specialized coatings can reduce friction and improve material flow, minimizing the formation of flow lines.

Additionally, venting the mold to release trapped air can prevent disruptions in the flow path, further reducing defects.

Conclusion

Flow lines in injection molding are a common challenge, but they are not insurmountable.

By understanding the causes—such as poor material flow, uneven cooling, or suboptimal mold design—manufacturers can implement targeted solutions to prevent these defects.

Optimizing mold design, fine-tuning process parameters, and selecting the right materials are all critical steps in ensuring smooth material flow and consistent cooling.

Advanced techniques, such as computer simulations and multi-gate systems, can further enhance results, particularly for complex parts.

With careful planning and ongoing monitoring, manufacturers can master the injection molding process, producing flawless plastic parts that meet both aesthetic and functional requirements.

By addressing flow lines proactively, the industry can continue to deliver high-quality finished products that meet the demands of modern applications.