Foaming injection molding mixes a foaming agent with polymers to create parts that are light and strong. This innovative process offers cost savings and improved material usage.

This entry discusses the workings, advantages, and real-world applications of foaming injection molding.

Understanding Foaming Injection Molding

Foam injection molding is a specialized molding process that incorporates a foaming agent into polymers. This agent reacts to create a cellular structure within the material, resulting in a unique blend of properties that set foam injection molded products apart from their traditionally molded counterparts. Unlike standard injection molding, which focuses on high accuracy and precise tolerances, foam injection molding leverages the foaming agent to achieve different mechanical properties and structural advantages.

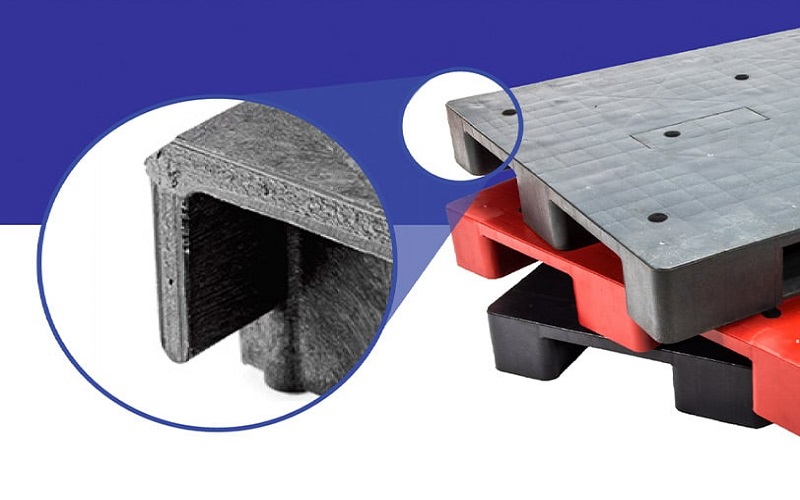

Structural foam molding, a subtype of foam injection molding, utilizes a low-pressure process often involving nitrogen gas or chemical blowing agents to create a lightweight yet strong product. This method stands out because it can produce parts with a cellular core and solid outer walls, combining the benefits of both foam and traditional injection molded foam.

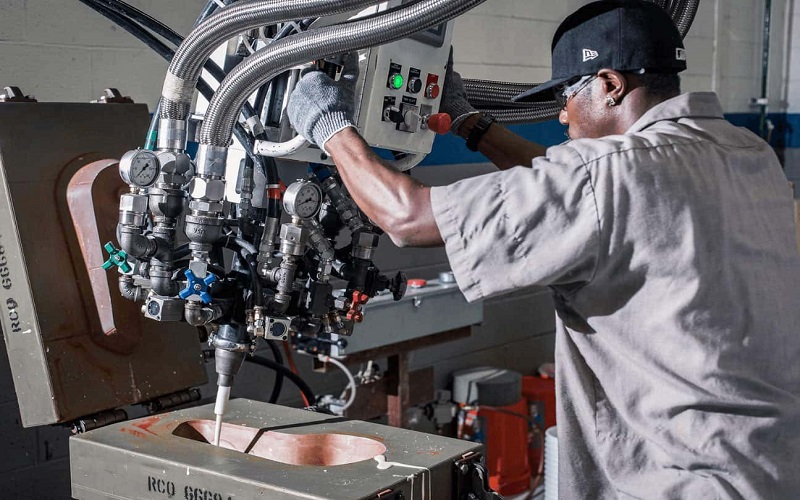

The use of an injection molding machine is crucial in this process, as they ensure the proper mixing and injection of materials to form the desired foam products. Understanding the basics of foam injection molding lays the groundwork for exploring the types of foaming agents and the numerous benefits this technique offers.

The Foam Injection Molding Process

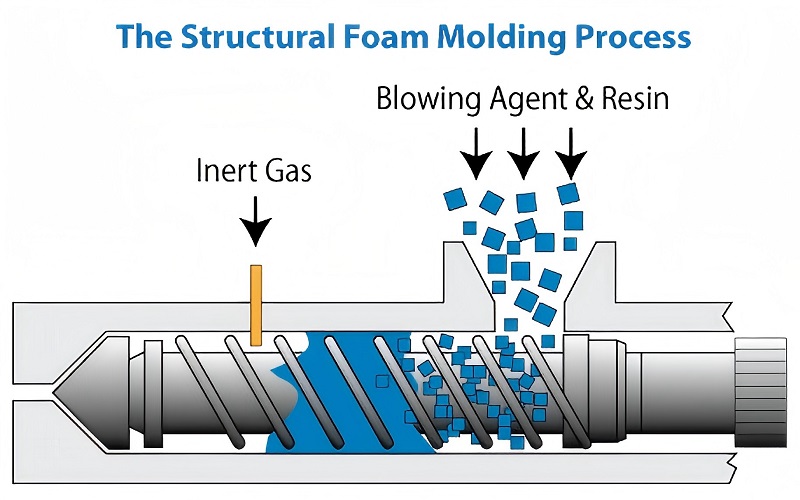

The foam injection molding process involves the following steps:

- Mixing polymers with blowing agents, which expand upon heating to fill mold cavities effectively.

- Injecting the mixed material under high pressure into a mold.

- Rapid expansion of the material inside the mold due to a drop in pressure.

- The abrupt pressure drop causes the gas to escape and foam.

- The foaming action pushes the molten resin to the extremities of the cavity using the eva injection molding process.

Once the mold cavity is filled, the cooling phase solidifies the foamed structure, ensuring the final product maintains its shape and properties, and achieves the desired density and mechanical characteristics.

Selecting suitable blowing agents and maintaining correct processing parameters are crucial for high-quality foam products, underscoring the importance of understanding each step in the production process to optimize production.

Types of Foaming Agents

Foaming agents play a pivotal role in foam injection molding, significantly impacting the final product’s characteristics. Common chemical foaming agents include azodicarbonamide and sodium bicarbonate, which decompose to release gases that form the cellular structure within the polymer. Reactive foaming agents like benzoyl peroxide are used in specific applications where precise control over the foaming reaction is required.

Physical foaming agents, typically gases such as nitrogen and carbon dioxide, are also widely used in foam injection molding. These gases expand within the polymer matrix, creating a uniform cellular structure that enhances the product’s mechanical properties. Choosing the right foaming agent influences the density, strength, and overall performance of the final foam products.

Key Benefits of Foam Injection Molding

A major benefit of foam injection molding is creating lightweight materials with enhanced mechanical properties compared to standard molded parts. Foam injection molded products are often more cost-effective due to reduced material usage and shorter production times. This makes the process particularly advantageous for large production runs where cost efficiency is paramount.

Besides cost savings, foam injection molding enhances structural strength due to the cellular core that reduces weight without compromising mechanical properties. This enhanced structural integrity makes foam injection molded parts suitable for applications where strength and durability are crucial.

The process also produces parts with minimal warpage and stress, ensuring high-quality products with excellent dimensional accuracy. These benefits make foam injection molding a preferred choice for manufacturers looking to balance performance, cost, and efficiency in their production processes.

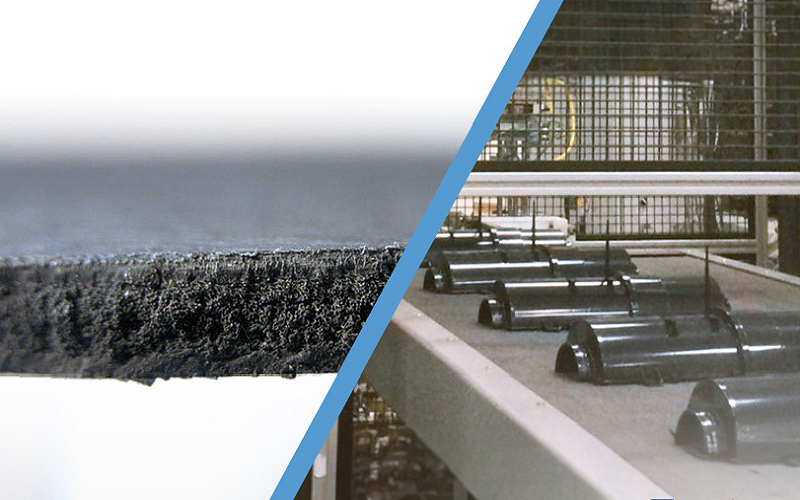

Characteristics of Foam Injected Products

Foam injected products feature a unique internal structure, typically a cellular core sandwiched between solid outer walls. This structure provides a high strength-to-weight ratio, making the products lighter than those produced through standard injection molding methods. The density of these products can range from 0.2 to 1.0 g/cm³, depending on the specific application and material used.

Foam injected products excel in durable performance, often showing improved impact resistance and suitability for demanding applications. Surface finishes can vary, with some products displaying patterns like wood grain or marble due to internal bubbles formed during the foaming process.

Additionally, eva foam is often used in various applications for its lightweight and resilient properties. Foams are also recognized for their versatility in different manufacturing processes.

Dimensional accuracy is another notable characteristic, as the process ensures homogeneous internal pressure, reducing distortion and warpage. This results in nearly stress-free parts with excellent dimensional stability, addressing internal shrinkage issues and meeting design specifications.

Applications in Various Industries

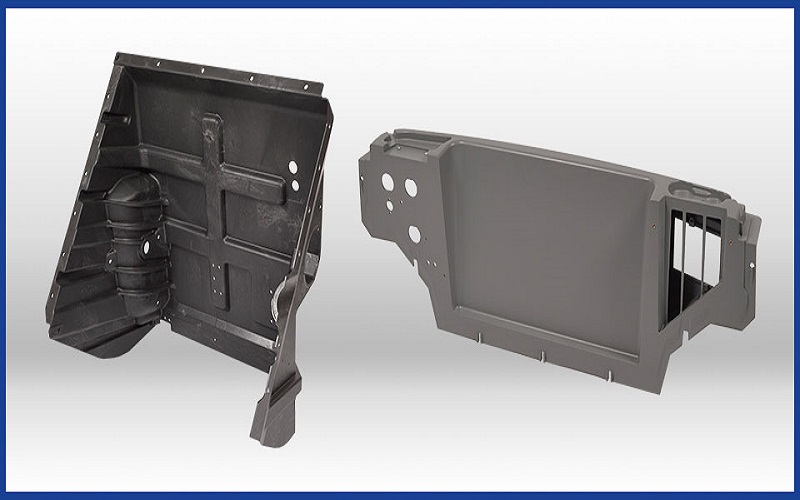

Foam injection molding finds applications across a wide range of industries, thanks to its versatility and cost benefits. In the automotive industry, it produces lightweight yet strong components, reducing vehicle weight and improving fuel efficiency.

The process is also popular in the production of helmets, shoes, and other sporting goods, where the combination of strength, durability, and lightweight properties is highly valued. Additionally, eva injection is utilized to enhance the performance of various foam products.

Consumer goods manufacturers also leverage foam injection molding to create eva products in various colors and designs, meeting aesthetic and functional requirements. The lightweight nature of foam manufactured injected products significantly reduces transportation costs, making it an economically attractive option for manufacturers.

Material Selection for Foam Injection Molding

Material selection directly impacts the final product’s quality and performance in foam injection molding. Common materials used include:

- Polystyrene: favored for its heat resistance and good foaming characteristics, making it ideal for packaging and insulation products.

- Polypropylene

- Polyethylene

- Polyurethane

- Polyamide

Each versatile material offers distinct properties suited for various applications.

Different plastics are valued for their specific properties and applications:

- Polypropylene: valued for its mechanical properties and chemical stability, making it popular for automotive components.

- Polyethylene: known for its impact resistance, suitable for pipes and sheets in various industries.

- Polyurethane: recognized for its elasticity and durability, used for cushions and gaskets.

- Polyamide: characterized by high wear resistance and mechanical strength, ideal for engineering plastic products.

The quality of the final foamed product is also influenced by the drying process of the materials used. Proper material drying ensures effective foaming agent performance, resulting in a high-quality product. Therefore, selecting the appropriate material involves assessing properties such as:

- Load-bearing capability

- Shock absorption

- Resistance to chemicals

- Resistance to temperature

These properties help meet the required quality standards.

Design Considerations for Foam Injection Molding

Designing for foam injection molding involves considering several factors to ensure optimal results. A key consideration is the wall thickness of structural foam products, which should exceed 0.25 inches to enable the chemical reaction for creating a honeycomb structure. Thicker walls may be required for achieving tighter tolerances in certain applications.

Effective material flow within the mold is crucial for high-quality foam products, as inconsistent flow can lead to defects and compromise functionality. Proper ventilation in molds prevents defects like sink marks and warping, ensuring the product meets design specifications.

CAE simulation tools significantly enhance product design and optimization by:

- Predicting material behavior

- Optimizing mold design These improvements lead to better-performing and cost-effective end products. Additionally, rotating molds can:

- Improve the distribution of foam material

- Result in more uniform properties in the final product.

Comparing Foam Injection Molding with Standard Injection Molding

Foam injection molding operates differently from standard injection molding in various ways. A primary difference is the pressure used; foam injection molding operates under atmospheric pressure, unlike the higher pressure in standard injection molding. This pressure difference can significantly lower material and production costs for foam injection molding.

Another key difference is melt viscosity; foam injection molding’s lower melt viscosity provides lower cavity pressure and better efficiency. This process can produce precise products with dimensional accuracy within tight tolerances, making it suitable for high-precision applications.

Foam injection molding is particularly effective for producing parts with thicker walls and large parts, which are challenging with standard methods. These differences highlight foam injection molding’s unique advantages in specific applications and its growing popularity among manufacturers. Additionally, eva injection molding offers similar benefits in certain scenarios.

How to Optimize Your Foam Injection Molding Process

Optimizing the foam injection molding process involves several strategies, including enhancing energy efficiency during production. Foam injection processes can be more energy-efficient than traditional methods, reducing overall production costs.

Foam injection molding typically results in longer cycle times due to the expansion and filling phase of the foam core. Manufacturers can optimize cycle times by fine-tuning processing parameters and utilizing advanced technologies to speed up cooling and improve overall production efficiency in injection moulding.

Implementing these strategies helps manufacturers achieve better product quality and reduce production costs, making foam injection molding more attractive for various applications.

Summary

In summary, foam injection molding offers numerous benefits, including lightweight materials, cost-effectiveness, and enhanced structural strength. The process involves unique steps and requires careful selection of materials and foaming agents to achieve optimal results.

With its growing applications across various industries, foam injection molding is poised to become a key technique in modern manufacturing.

By understanding its process, benefits, and optimization strategies, manufacturers can leverage this technique to produce high-quality, cost-effective products.

Frequently Asked Questions

What is foam injection molding?

Foam injection molding combines a foaming agent with polymers to produce lightweight and durable cellular structures. This process enhances product efficiency and performance.

What are the benefits of foam injection molding?

Foam injection molding provides significant advantages, including cost-effectiveness, lightweight materials, enhanced structural strength, and improved dimensional accuracy. These benefits make it an efficient choice for various applications.

What types of foaming agents are used in foam injection molding?

Foam injection molding commonly utilizes chemical foaming agents such as azodicarbonamide and sodium bicarbonate, along with physical agents like nitrogen and carbon dioxide. Each type plays a crucial role in creating the desired foamed structure.

How does foam injection molding differ from standard injection molding?

Foam injection molding differs from standard injection molding in that it operates under atmospheric pressure and utilizes lower melt viscosity, allowing for more efficient production of thicker walls and larger parts. This method enhances the quality and performance of larger components.

What materials are commonly used in foam injection molding?

Foam injection molding commonly uses materials such as Polystyrene, Polypropylene, Polyethylene, Polyurethane, and Polyamide, each selected for their specific qualities tailored to different applications.