Gas assisted injection molding is an advanced manufacturing process that improves upon traditional injection molding to create plastic parts with complex designs and hollow sections.

By using pressurized gas, typically nitrogen, this method enhances part quality, reduces material use, and lowers production costs.

This guide provides a clear overview of gas assisted injection molding, its techniques, benefits, and applications, making it accessible for design engineers, manufacturers, or anyone new to the process.

From the injection molding process to cost considerations, we’ll cover the essentials for producing high-quality molded parts.

Understanding Gas Assisted Injection Molding

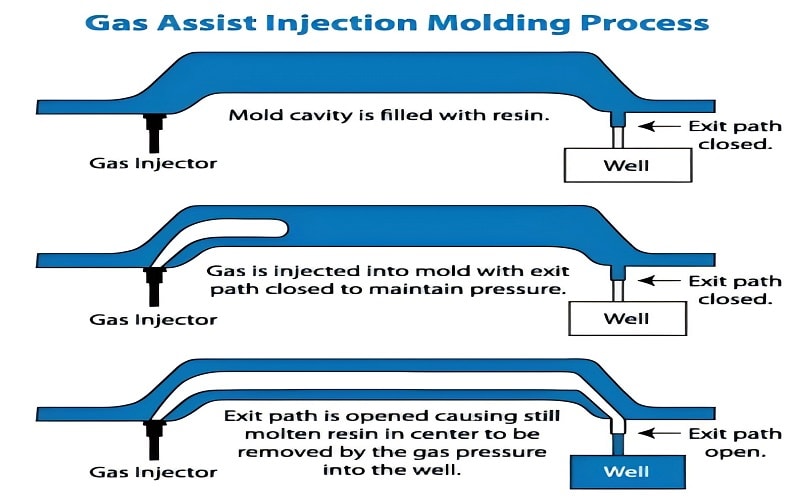

Gas assisted injection molding, also known as gas assist molding, starts with injecting a partial amount of molten plastic, such as acrylonitrile butadiene styrene (ABS), into a mold cavity.

This “short shot” leaves the mold partially filled, allowing pressurized nitrogen gas to be injected through gas injection points.

The gas flows through strategically designed gas channels, pushing the molten resin against the mold walls to form hollow parts.

This ensures uniform pressure, reducing defects like sink marks and surface blemishes for a smooth surface finish.

Unlike conventional injection molding, which uses more plastic to fill the mold entirely, gas assisted injection molding uses less plastic material, resulting in lighter parts with improved dimensional stability.

The gas penetration follows the path of least resistance, shaping the plastic into complex designs with hollow sections, such as handles or panels. This reduces internal stresses and less shrinkage, making it ideal for parts requiring precision and a high-quality cosmetic appearance.

The setup includes a molding machine with a gas control unit to manage pressurized gas, typically nitrogen, which is inert and safe.

Materials like ABS or transparent plastic materials are chosen for their flow properties and aesthetic appeal.

The mold features gas channels to guide gas to the mold extremities, ensuring even distribution. The table below summarizes the key components:

Key Components of Gas Assisted Injection Molding

| Component | Description |

| Molding Machine | Includes a gas control unit to regulate pressurized nitrogen gas. |

| Mold Cavity | Designed with gas channels and injection points for precise gas flow. |

| Plastic Material | Thermoplastics like ABS, selected for flow and aesthetic properties. |

| Pressurized Gas | Usually nitrogen, used to form hollow sections and ensure uniform pressure. |

Techniques for Gas Assisted Injection Molding

The injection molding process begins with preparing the molding machine and mold, which is designed with gas injection points and channels.

A short shot of molten resin, such as ABS, is injected into the mold cavity, filling it partially to leave space for the gas.

The melt temperature of the thermoplastic material must be precisely controlled to ensure smooth flow without degradation.

Pressurized inert gas, typically nitrogen, is then injected, pushing the molten plastic against the mold walls to create hollow areas and a smooth outside surface.

Precise gas control is essential to maintain uniform pressure and prevent defects like sink marks caused by uneven cooling.

The gas assisted plastic injection molding is timed to occur as the mold walls begin to cool but before the plastic fully hardens, ensuring tighter tolerances and a consistent part appearance.

Design engineers optimize gas channels to guide gas penetration effectively, supporting features like ribs or hollow sections.

Testing small batches helps fine-tune the melt temperature, gas pressure, and injection timing to produce a high-quality final product with minimal residual stress.

Benefits of Gas Assisted Injection Molding

Gas assisted injection molding offers significant advantages over traditional methods, making it a preferred choice for many applications.

The use of pressurized gas improves part quality by pressing the molten plastic firmly against the mold walls, reducing sink marks and surface blemishes.

This results in a smooth surface finish and an enhanced cosmetic appearance, ideal for visible parts like consumer products.

The hollow sections improve dimensional stability, making parts less prone to warping and stronger overall, especially for complex designs with support features like ribs.

Material savings are a key benefit.

The short shot technique uses less plastic material, reducing part weight and material costs.

Hollow parts lower shipping expenses, and the high-quality finish minimizes secondary operations like trimming.

Faster cycle times, driven by the gas cooling the plastic quickly, boost production efficiency.

These factors contribute to cost savings, making gas assisted injection molding a cost-effective solution for producing multiple parts.

Applications of Gas Assisted Injection Molding

Gas assisted injection molding is used across various industries to create lightweight, durable parts with complex geometries. This section explores its key applications and why it’s effective.

Gas assisted injection molding excels in producing parts that balance strength, weight, and aesthetics.

Its ability to create hollow parts with precise shapes makes it a go-to method for industries requiring high-quality components.

From automotive to medical applications, the process delivers parts with reduced material use and enhanced functional performance, addressing both cost considerations and design constraints.

Automotive and Consumer Products

In the automotive industry, gas assist molding is used for parts like door handles, dashboards, air ducts, and armrests.

The hollow sections reduce part weight, improving fuel efficiency, while maintaining strength and a polished cosmetic appearance.

For consumer products, such as appliance casings, furniture components, or electronic housings like remote control casings, the process ensures smooth surfaces and complex designs with less plastic material.

Materials like ABS are often used for their durability and aesthetic appeal.

Medical and Industrial Components

In medical and industrial fields, gas assisted injection molding produces precise, lightweight parts like equipment housings and diagnostic tool casings.

The process supports tighter tolerances and high-quality finishes, critical for medical devices where precision is essential.

Industrial applications include structural components that require reduced weight and strength, such as machinery covers.

The ability to mold complex shapes with hollow areas makes this method versatile for demanding applications.

Cost Considerations and Best Practices

Cost considerations include the initial investment in a molding machine with gas control capabilities and custom molds with gas channels.

While setup costs can be significant, the process offers savings through reduced material use, lighter parts, and faster cycle times.

Using less plastic material lowers production and shipping costs, and minimizing secondary operations reduces labor expenses.

Design engineers should account for nitrogen gas and maintenance costs to ensure cost-effective production.

Best practices include:

- Designing molds with optimized gas channels for uniform gas flow and pressure.

- Controlling melt temperature and gas injection timing to avoid defects like sink marks.

- Testing small batches to adjust settings for dimensional stability and part quality.

- Using materials like ABS for flow and aesthetic properties.

- Monitoring cycle time to maximize efficiency without compromising quality.

Conclusion

Gas assisted injection molding enhances traditional injection molding by using pressurized nitrogen gas to create lightweight, high-quality parts with complex designs.

By reducing material use, improving part appearance, and lowering costs, it’s a valuable method for industries like automotive, consumer products, and medical manufacturing.

Mastering techniques like precise gas control and mold design, while considering cost factors, ensures the production of durable, precise molded parts.

This guide offers a clear foundation for understanding and applying gas assisted injection molding effectively.