Need a material that withstands high temperatures without losing shape?

Heat resistant acrylic does just that. It’s perfect for applications where standard acrylic would fail.

This article dives into the benefits, key properties, and industries that use heat resistant acrylic.

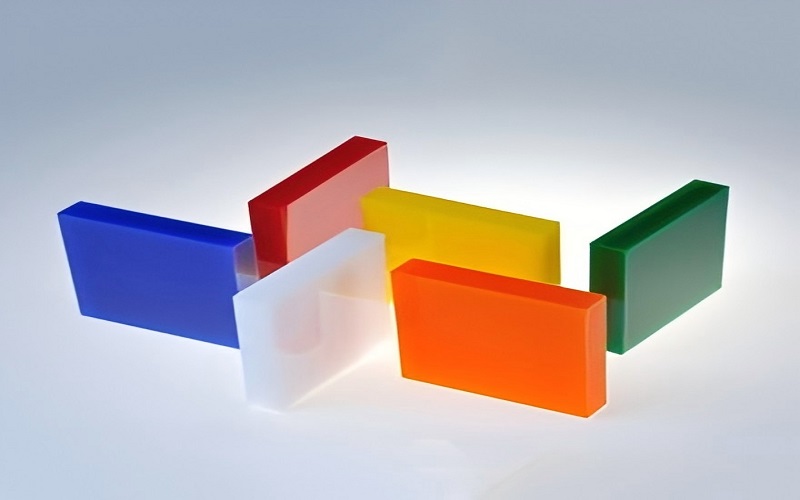

Overview of Heat Resistant Acrylic Sheet

One of the standout products in the field of heat-resistant acrylic is ACRYLITE® Heatstop. This heat-reflecting PMMA greatly improves thermal efficiency by reducing solar heat radiation and, being half the weight of glass fibers, provides a lighter alternative.

The Heatstop component is evenly distributed throughout the entire sheet, delivering consistent and reliable thermal performance across a variety of applications with unique qualities.

In addition to its thermal benefits, heat-resistant acrylic offers several impressive features. It is flame-inhibiting, UV-stable, and virtually unbreakable, making it an exceptionally durable and safe option for diverse uses.

Moreover, while acrylic sheets begin to soften between 160°F to 210°F (71°C to 99°C), they may start to deform around 320°F (160°C).

Notably, unlike some other plastics, acrylic burns cleanly without releasing harmful gases when exposed to flames, enhancing safety in high-temperature environments.

Key Properties of Heat Resistant Acrylic

| Property | Value/Description |

|---|---|

| Impact Resistance | Significantly higher (up to 17x standard glass) |

| Dimensional Stability | Maintains stability across wide temperature range |

| Heat Deflection Temperature | Up to 90°C |

| Versatility and Robustness | High (suitable for various industries) |

| Flame Resistance | High melting point, low flammability |

| Light Transmission | Up to 92% (clear grades) |

| Tensile Strength | Approximately 70-75 MPa |

| Hardness (Rockwell M) | Around 100 |

Impact Resistance and Dimensional Stability

Heat-resistant acrylic is renowned for its high impact resistance, making it significantly less likely to shatter compared to other materials.

This property is particularly valuable in applications where safety and durability are paramount.

Additionally, the material maintains dimensional stability across a wide range of temperatures, ensuring consistent performance even in fluctuating conditions.

Heat Deflection Temperature

The heat deflection temperature of heat-resistant acrylic can reach up to 90°C, allowing it to withstand high temperatures without losing its structural integrity.

This makes it an ideal choice for environments that experience extreme temperatures, as it can endure and perform reliably without compromising on quality.

Versatility and Robustness

Overall, the combination of high impact strength, dimensional stability, and the ability to withstand high temperatures makes heat-resistant acrylic a superior choice for projects requiring durable and reliable materials.

Its versatility and robustness ensure it can meet the demands of various industries and applications, showcasing its impact strength and heat resistance.

Applications in Various Industries

Heat-resistant acrylic’s exceptional properties make it suitable for use in many industries, including automotive, aerospace, and construction.

Its durability, temperature resistance, and energy efficiency are just a few reasons why this material is increasingly favored for diverse projects.

Automotive Uses

In the automotive industry, heat-resistant acrylic is prized for its lightweight properties, making it an excellent choice for various car components.

Safety glazing is another critical application, where the virtually unbreakable nature of heat-resistant acrylic provides enhanced protection for passengers.

As the automotive industry continues to advance, the unique properties of heat-resistant acrylic are becoming more important. Its ability to withstand high temperatures and resist fire makes it an indispensable material for modern automotive designs.

Whether for sports equipment or electrical components, heat-resistant acrylic offers unparalleled benefits.

Aerospace Applications

The aerospace sector also leverages the advantages of heat-resistant acrylic, particularly for aircraft windows and canopies.

The material provides exceptional clarity and impact resistance, ensuring pilots have clear visibility while maintaining safety and transparency standards.

In aviation, where extreme conditions are the norm, heat-resistant acrylic is essential. It serves as cabin windows and canopies, offering excellent visibility and impact resistance, which are crucial for ensuring passenger safety and comfort.

Construction Benefits

In construction, heat-resistant acrylic is commonly used for roofing and glazing, enhancing energy efficiency and thermal insulation properties.

Its ability to maintain stable temperatures helps reduce cooling costs, making it a cost-effective choice for building projects.

Acrylic sheets provide superior insulation compared to traditional glazing materials, contributing to energy efficiency in buildings.

This not only benefits the environment but also reduces operational costs, making heat-resistant acrylic a preferred material in modern construction projects.

Advantages Over Traditional Materials

When compared to traditional materials like glass and polycarbonate, heat-resistant acrylic stands out for several reasons. It boasts 17 times greater impact resistance than standard glass, offering superior durability and safety.

Additionally, acrylic is approximately 35% less expensive than polycarbonate, making it a cost-effective alternative.

Heat-resistant acrylic’s flame-resistant properties are another significant advantage. These sheets can prevent fire spread and reduce damage, thanks to their high melting point and low flammability. This makes them ideal for safety applications where minimizing the risk of ignition is crucial.

Unlike polycarbonate sheets, acrylic sheet can be polished to remove scratches, maintaining their aesthetic appeal over time. T

hicker sheets also provide greater rigidity and strength, making them suitable for load-bearing applications. These benefits make heat-resistant acrylic a versatile and practical choice for various projects.

Features Enhancing Performance

Heat-resistant acrylic offers several features that enhance its performance. One of the most notable is its ease of shaping and molding without losing quality. This allows for versatile applications across different projects, meeting specific requirements with ease.

High-performance acrylic coatings are designed to resist heat and moisture, preventing issues like warping or cracking in high-temperature environments.

These coatings also feature UV stability, protecting against discoloration and degradation from sunlight exposure, showcasing their qualities. You won’t have to worry about their performance.

The easy application of these coatings ensures effective use even in warm conditions, making them a reliable choice for various uses.

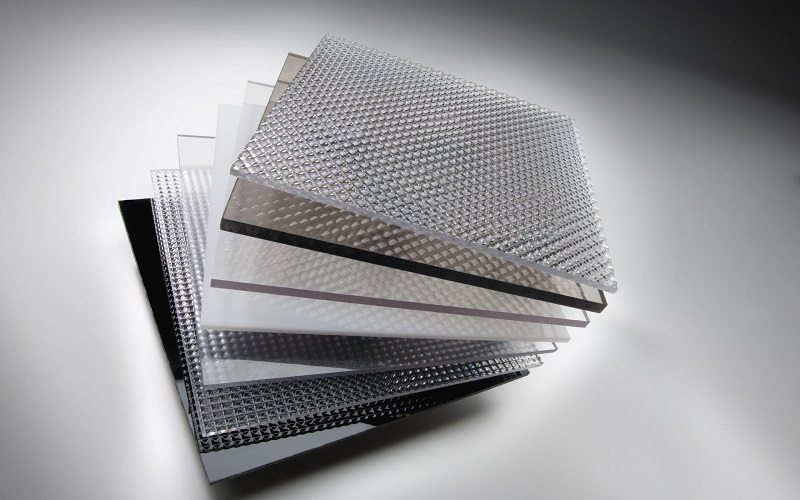

How to Choose the Right Thickness

Selecting the right thickness for acrylic sheets is crucial for the success of any project. Acrylic sheets are available in various thicknesses, typically ranging from:

- 1/16 inch (1.5 mm)

- up to 4 inches (100 mm) The thickness impacts:

- durability

- flexibility

- overall outcome of the project.

While cost can increase with thickness, choosing the appropriate thickness and depth can prevent issues like sagging and ensure structural stability.

Thinner sheets are more flexible, ideal for projects requiring bending or cutting, while thicker sheets offer greater rigidity, stiffness, and strength for heavy-duty applications.

Maintenance and Durability

Maintaining the clarity and durability of acrylic sheets is relatively straightforward.

Avoid using abrasive materials that can scratch the surface. Instead, clean the sheets with warm, soapy water and a soft cloth to preserve their clarity.

To maintain acrylic sheets:

- Polish with plastic polish or car wax to help restore their shine over time.

- Prevent warping in hot weather by keeping the sheets out of direct sunlight.

- Use protective films to guard against scratches and abrasions during storage.

Environmental Impact

Heat-resistant acrylic is a green, environmentally friendly choice for several reasons. Producing this material requires less energy compared to glass or metal, contributing to lower overall energy consumption.

Its lightweight nature also reduces transportation emissions, further lessening its environmental footprint.

Moreover, heat-resistant acrylic sheets can be recycled without losing their original quality, making them a sustainable option.

Their durability means they last longer, decreasing the frequency of replacement and associated waste.

Using heat-resistant acrylic significantly improves environmental sustainability.

Summary

Heat-resistant acrylic offers a myriad of benefits, from exceptional impact resistance and thermal efficiency to environmental sustainability.

Its versatile applications across various industries, including automotive, aerospace, and construction, make it an invaluable material for modern projects.

As we look to the future, the potential of heat-resistant acrylic is limitless. Its unique properties and advantages over traditional materials position it as a cornerstone for innovation and efficiency in countless applications.

Embracing this material can lead to more sustainable, cost-effective, and durable solutions.

Frequently Asked Questions

What makes heat-resistant acrylic different from regular acrylic?

Heat-resistant acrylic differs from regular acrylic due to its unique Heatstop component, which minimizes heat radiation and improves thermal efficiency. This makes it a superior choice for environments with high temperatures.

Can heat-resistant acrylic be used in high-temperature environments?

Heat-resistant acrylic can indeed be used in high-temperature environments, as it can withstand temperatures up to 90°C.

What are the key differences between polycarbonate sheets and heat-resistant acrylic?

Polycarbonate sheets offer 17x greater impact resistance and a 130°C heat deflection temperature, while heat-resistant acrylic (e.g., ACRYLITE® Heatstop) excels at heat reduction with a 90°C limit.

How does heat-resistant acrylic contribute to environmental sustainability?

Heat-resistant acrylic contributes to environmental sustainability by requiring less energy for production, reducing transportation emissions due to its lightweight properties, and being recyclable without quality loss. This makes it an eco-friendly option in various applications.

What maintenance is needed for heat-resistant acrylic sheets?

To ensure the longevity of heat-resistant acrylic sheets, it is essential to clean them with warm, soapy water and a soft cloth while avoiding abrasive materials.

Additionally, polishing them with plastic polish or car wax and applying protective films can help prevent scratches.