Polycarbonate is known for its superior impact resistance. This durability makes it an ideal material for various demanding applications.

From construction to safety gear, understanding why the impact resistance of polycarbonate stands out is crucial.

This guide dives into the factors that contribute to its robustness, compares it with other materials, and explores its real-world uses.

Understanding Polycarbonate’s Impact Resistance

Polycarbonate is a thermoplastic material primarily produced from bisphenol A (BPA). Known for its durability, transparency, high impact resistance, and excellent light diffusion, polycarbonate is a go-to material for various engineering applications.

Its molecular structure, featuring carbonate groups, significantly contributes to its robustness. Higher molecular weight in polycarbonate enhances its impact performance, up to a certain limit.

Lexan polycarbonate sheets, a popular brand, offer high impact strength, excellent clarity, and effective light diffusion, making them ideal for applications requiring both visibility and durability.

Current stock of Lexan sheets is widely available through suppliers in various sizes.

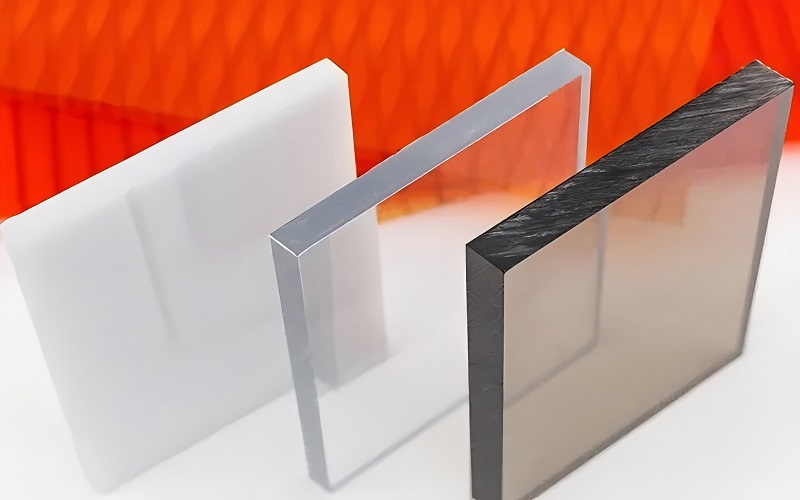

How Polycarbonate Differs from Other Plastics

Polycarbonate stands out from other plastics due to its unique physical properties.

Unlike acrylic, polycarbonate is less prone to shattering upon impact, which makes it a safer and more durable option.

Additionally, polycarbonate is significantly lighter than glass—about six times lighter, to be precise. This weight reduction not only eases installation and handling but also reduces overall material costs.

Another critical advantage is polycarbonate’s ability to combine high impact resistance with excellent clarity.

Applications Requiring High Impact Resistance

Polycarbonate’s superior impact resistance makes it a preferred material in various high-stress environments. In the construction industry, polycarbonate is extensively used for:

- Domelights

- Glazing

- Roofing sheets

- Sound walls

This is due to its enhanced resistance to breakage and intrusion, making it a strong ideal choice for projects that require long-lasting and durable materials designed for optimal performance.

Beyond construction, polycarbonate has been discovered to find applications in general-purpose protection, such as safety gear and bullet-resistant barriers. Its ability to access withstand extreme temperatures without breaking or distorting further expands its usability in diverse environments.

From the media sector to high-security installations, polycarbonate’s high impact strength and durability make it an indispensable material.

Factors Influencing Polycarbonate’s Impact Resistance

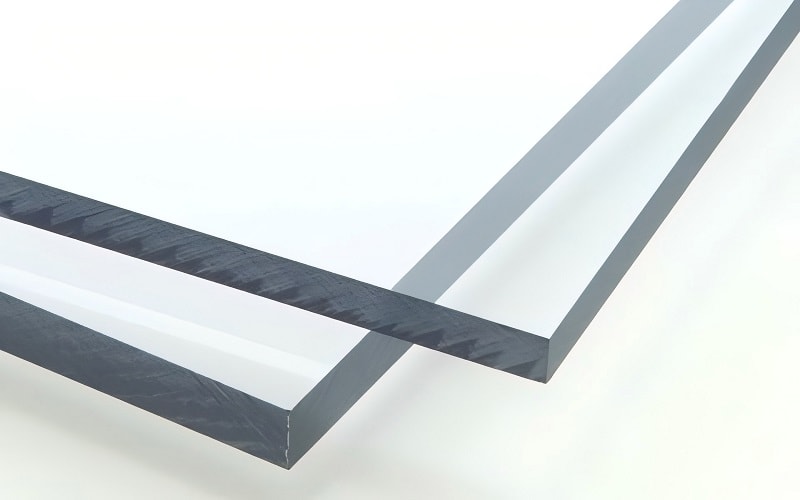

Several factors can influence the impact resistance of polycarbonate sheets. The thickness of the sheets plays a crucial role in determining their performance:

- Increasing thickness can enhance impact resistance.

- Increasing thickness may lead to weight increase.

- Increasing thickness may reduce light transmission.

Additionally, environmental factors such as UV exposed and temperature variations can affect polycarbonate’s durability and structural integrity.

Thickness and Its Role in Performance

The thickness of polycarbonate sheets is a critical element affecting their impact resistance. Industrial polycarbonate plates can be manufactured up to four inches thick, while single-layer sheets are typically up to 0.5 inches thick.

However, increasing thickness also increases weight and decreases light transmission.

Manufacturers often work with customers to select the appropriate thickness, balancing protection with cost-effectiveness and weight considerations.

Environmental Effects on Polycarbonate Sheets

Environmental factors significantly impact the performance of polycarbonate sheets.

Although polycarbonate exhibits superior resistance to ultraviolet (UV) radiation compared to most plastics, prolonged exposure can lead to photo-aging, weakening its structure due to covalent bond breakage.

High temperatures can also lead to decomposition, resulting in pollutants like phenol derivatives and bisphenols, which can compromise the material’s integrity.

Innovative coatings like low-emissivity (low-E) and anti-scratch treatments can enhance polycarbonate’s thermal performance and longevity. These coatings improve the material’s durability under demanding conditions, making polycarbonate an even more reliable choice for various applications.

Testing Standards for Polycarbonate Impact Resistance

Testing standards are crucial for evaluating the impact resistance of polycarbonate sheets, including those developed by companies like General Electric. Key points include:

- Manufacturer data and third-party testing verification, subject to rigorous review, play a vital role in assessing polycarbonate’s performance in protective scenarios.

- Testing agencies and standards bodies classify polycarbonate for ballistic resistance, ensuring it meets safety and performance criteria for applications like security glazing and printing.

- One notable standard is ASTM F736-17, which measures the impact resistance of monolithic polycarbonate sheets using a free-falling weight with specialized tools.

Various factors are considered in these testing standards, including:

- Ballistic impact, where materials are subjected to high-velocity projectiles

- Explosive impact, testing resilience against sudden blasts

- Chemical exposure, evaluating durability under corrosive conditions

- High heat, assessing performance in extreme temperatures

- Flame resistance, ensuring safety in fire-prone environments

The primary focus of ballistic performance standards is on withstanding attacks from handguns or rifles, making polycarbonate a reliable choice for high-security applications developed for industries like defense.

Common Testing Methods

Standardized testing methods are vital for evaluating the impact resistance of polycarbonate sheets.

ASTM D3935 specifies tests for classifying polycarbonate materials based on their mechanical properties, such as flexural modulus and tensile strength.

These tests are crucial for ensuring that polycarbonate components can withstand expected impact forces in real-world applications.

By adhering to these standardized methods, manufacturers can guarantee that their polycarbonate products meet necessary safety and performance criteria.

Manufacturer-Specific Testing Protocols

Manufacturers often group testing protocols for polycarbonate according to categories like:

- Ballistic resistance

- Explosive resistance

- Forced entry

- Chemical or flame resistance

The Underwriters Laboratory (UL) has established a widely recognized standard for ballistic resistance in polycarbonate, which includes ten different levels.

Manufacturers may also follow standards set by the National Institute of Justice (NIJ) and ASTM F1233, ensuring comprehensive tested and certification of their products.

Comparing Polycarbonate with Other Materials

Polycarbonate’s high impact resistance sets it apart from materials like glass and acrylic.

While polycarbonate is generally more expensive than glass and acrylic, its durability and reduced replacement needs often make it a more economical choice in the long run.

The thickness of polycarbonate sheets influences their impact resistance, weight, and light transmission, making it essential to select the optimal thickness for each application.

Polycarbonate vs. Glass

Polycarbonate offers several advantages over glass:

- Better impact resistance, making it preferred for applications requiring high durability.

- Advancements in coating technologies have enabled its use in applications previously dominated by glass, such as energy-efficient windows.

- Significantly lighter than glass, providing benefits in handling and installation.

In the automotive industry, polycarbonate is increasingly used for headlamp lenses and windshields, where its high impact resistance and excellent clarity are essential. This shift highlights polycarbonate’s versatility and superior performance compared to traditional glass materials.

Polycarbonate vs. Acrylic

Polycarbonate offers several advantages over acrylic:

- It is 30 times stronger, providing superior impact resistance.

- It is more suitable for applications requiring enhanced durability and protection.

- It offers better flexibility, making it ideal for applications requiring bending or shaping.

In terms of clarity, polycarbonate offers comparable transparency to acrylic, making it suitable for applications where visibility is crucial.

While acrylic may have superior scratch resistance, polycarbonate’s impact resistance and flexibility often make it the preferred choice for high-stress environments.

Polycarbonate vs. Lexan Sheets

Polycarbonate and Lexan sheets share key traits but differ slightly:

- Both offer excellent impact resistance, ideal for durable applications like safety shields.

- Lexan, a polycarbonate brand, benefits from advanced coating technologies for better scratch resistance, suitable for protective glazing.

- Lighter than glass, both ease handling in construction and automotive uses.

In aerospace and automotive, Lexan sheets are used for canopies and panels, matching polycarbonate’s clarity and durability for versatile, high-performance applications.

Enhancing Polycarbonate’s Impact Resistance

Recent advancements have introduced various methods to enhance the impact resistance of polycarbonate sheets. Advanced coatings, chemical modifications, and surface treatments significantly improve the material’s durability and performance.

Incorporating silicone-based additives into polycarbonate formulations can also enhance scratch resistance, abrasion, and wear durability.

Coatings and Treatments

UV-curable hard coatings with nanoparticles can enhance the scratch resistance of polycarbonate, achieving hardness levels that protect against abrasions.

Nanofillers such as nanosilica can be added to polycarbonate to increase surface hardness and improve wear resistance without compromising transparency.

Advanced surface modification techniques like plasma treatment can create thin, hard coatings on polycarbonate, enhancing its scratch resistance.

Leading manufacturers often implement unique testing protocols that may exceed standard requirements to enhance polycarbonate’s resistance and quality. These coatings and treatments ensure that polycarbonate remains a reliable and durable material for various applications.

Innovations in Polycarbonate Manufacturing

New manufacturing techniques allow for creating lightweight polycarbonate products that retain high impact resistance while improving design flexibility.

Recent advancements in injection molding and extrusion technologies have led to the production of complex polycarbonate components with enhanced performance characteristics.

These innovations ensure that polycarbonate continues to meet the evolving needs of various industries.

Real-World Examples of Polycarbonate’s Impact Resistance

Polycarbonate’s exceptional impact resistance makes it a preferred material in varied applications, significantly enhancing safety and durability.

In the automotive industry, polycarbonate is used for headlamp lenses and windshields due to its ability to withstand high impact and provide clarity.

This showcases polycarbonate’s versatility and superior performance in demanding environments.

Automotive Industry Use Cases

The primary application of polycarbonate in the automotive industry is for automotive headlamp lenses, which require clarity and durability.

Polycarbonate is also used in other components due to its lightweight and durable nature, making it an essential material in the automotive sector.

Safety and Security Applications

Polycarbonate is widely used for making bullet-resistant windows and protective barriers, thanks to its ability to absorb impact energy.

The material is often preferred in safety applications because it can withstand high-pressure impacts without shattering.

Polycarbonate’s lightweight properties enhance its use in riot shields and safety glazing, making it easier to transport and handle.

Polycarbonate is commonly used in eyewear lenses due to its scratch resistance and impact strength, contributing to personal safety. While acrylic may be more transparent, polycarbonate’s impact resistance makes it suitable for high-stress environments like security applications.

Summary

Polycarbonate’s unique combination of high impact resistance, durability, and versatility makes it an indispensable material across various industries.

From construction to automotive and safety applications, polycarbonate sheets provide enhanced protection and performance.

Advancements in coatings and manufacturing techniques continue to improve polycarbonate’s properties, ensuring its relevance in future applications.

By understanding the factors influencing its performance and the rigorous testing standards it undergoes, we can appreciate why polycarbonate remains the material of choice for high-impact applications.

Frequently Asked Questions

Why Polycarbonate has enhanced resistance compared to other plastics?

Polycarbonate’s enhanced resistance comes from its amorphous structure, strong intermolecular bonds, and ductility, allowing it to absorb and dissipate impact energy better than other plastics.

How does the thickness of polycarbonate sheets affect their performance?

The thickness of polycarbonate sheets significantly impacts their performance; thicker sheets provide greater impact resistance but may reduce light transmission and increase weight. Choosing the appropriate thickness is essential for balancing these factors based on your specific application needs.

What are some common applications of polycarbonate in the automotive industry?

Polycarbonate is commonly utilized in the automotive industry for headlamp lenses and windshields because of its exceptional impact resistance and clarity. This makes it a preferred material for enhancing vehicle safety and visibility.

How do coatings and treatments enhance polycarbonate’s impact resistance?

Coatings and treatments enhance polycarbonate’s impact resistance by providing UV protection and incorporating advanced materials like nanoparticles, which bolster scratch resistance and overall durability. This not only prolongs the lifespan of polycarbonate but also maintains its clarity and performance in demanding environments.

What testing standards are used to evaluate polycarbonate’s impact resistance?

Polycarbonate’s impact resistance is evaluated using standards such as ASTM F736-17 and ASTM D3935, which assess its mechanical properties to ensure safety and performance criteria are met.