Determining the injection molding price is essential for budgeting your project effectively.

This article explains the key factors that influence the cost of injection mold tooling in injection molding, outlines typical price ranges, and offers money-saving tips to help you manage your injection molding expenses efficiently.

Injection Molding Price Overview

Grasping injection molding costs is essential for assessing manufacturing expenses before implementation. The injection molding process involves creating parts by injecting molten material into a mold, and various factors determine the overall cost.

Factors such as production volume, part complexity, and material selection significantly influence the final price and should be considered during the planning stages.

Part complexity heavily impacts molding costs:

- Intricate designs might need complex molds and longer production times, raising overall expenses.

- When produced in large volumes with tight tolerances, injection molding becomes highly cost-effective, significantly lowering the per-unit price.

- Typically, the costs for injection molding projects can range from $3,000 to $100,000 or more, depending on the complexity and volume.

Additional expenses like mold setup, maintenance, and raw materials should also be considered beyond the mold price, including setup costs.

Understanding these factors allows manufacturers to make informed decisions about their injection molding projects.

This knowledge helps in budgeting accurately and ensuring that the projects remain within financial constraints while achieving desired quality and production efficiency.

Key Factors Affecting Injection Mold Cost

The main cost factor in injection molding is often the metal molds, which can account for a significant portion of the cost of the mold and total expenses.

In complex projects, making molds with intricate designs and a robust mold base can drive costs to exceed $80,000, representing a significant investment.

A simple single-cavity plastic injection mold, with a basic mold base, usually costs between $1,000 and $5,000, whereas an average mold for simple parts, including the cost of making molds, may cost around $12,000.

Understanding the plastic injection molding cost is essential for budgeting effectively.

Various factors determine the cost of injection molds, including:

- Part size

- Complexity

- Material

- Anticipated quantities

Larger molds are generally more expensive due to increased material and machining requirements. The choice of raw material can significantly affect overall tooling costs due to varying properties.

Factors like mold complexity, size, material, and tooling collectively determine injection mold costs. The following sections explore equipment costs, tooling costs, and material costs in detail.

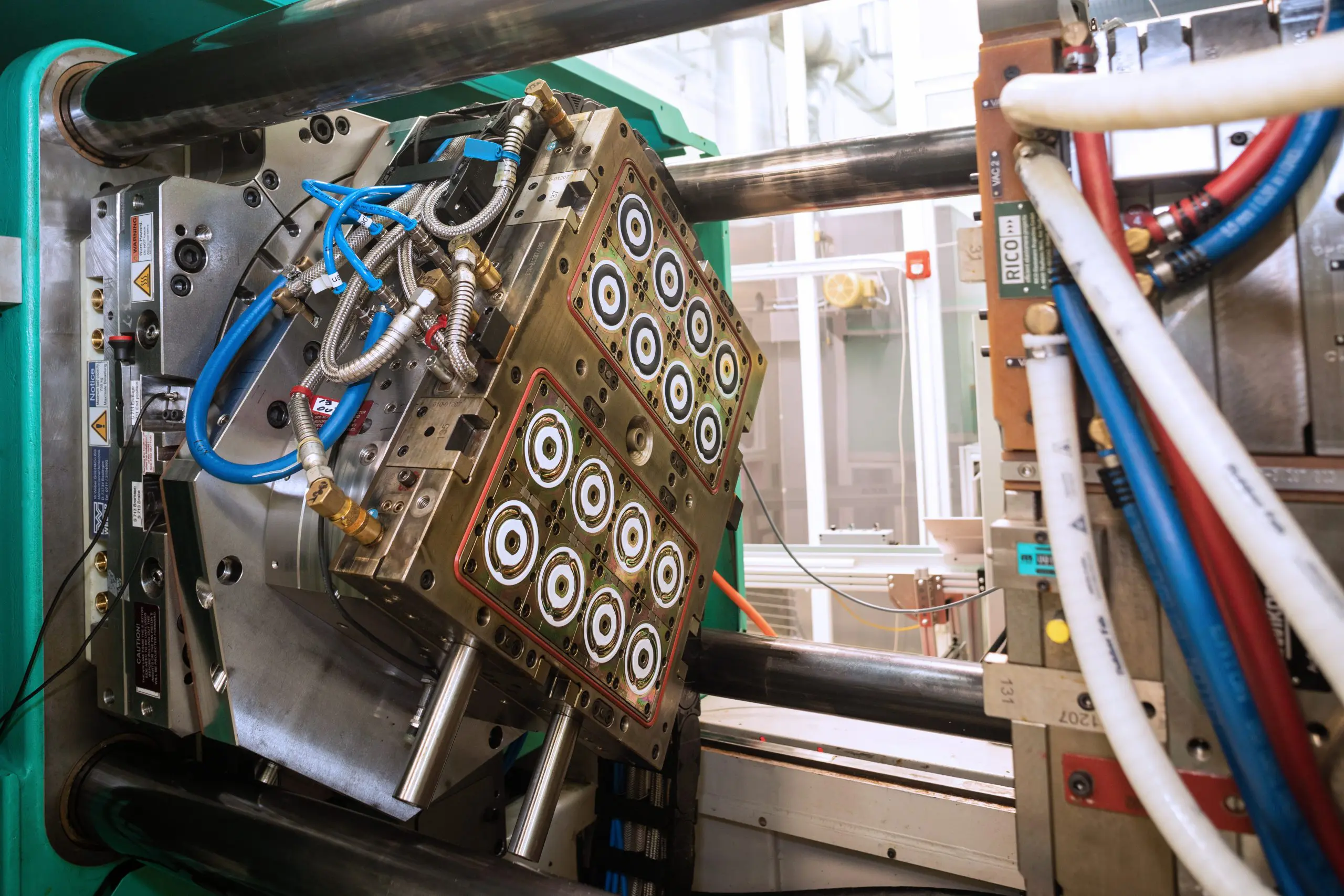

Equipment Costs

Large industrial injection molding machines generally cost between $50,000 and $100,000+. The size and level of sophistication of these machines greatly influence their price.

Hybrid injection molding machines, which combine electric and hydraulic systems, offer high precision and repeatability, making them cost-effective despite their higher upfront expenses. These machines maximize efficiency for versatile manufacturing needs, contributing to their overall cost-effectiveness.

For those looking to avoid high equipment costs, outsourcing to low cost injection molding service providers is a viable alternative.

This approach can be particularly beneficial for low production volumes, where investing in a small desktop injection molding machine and molding equipment might be the most cost-effective option.

Considering these equipment-related factors helps manufacturers make strategic decisions to save money and maintain cost-effectiveness.

Tooling Costs

Molds for plastic injection molding can be produced using various methods, including CNC machining, electrical discharge machining, and CNC machines 3D printing.

The costs of injection molds can vary dramatically, starting from around $100 for basic 3D printed molds to over $100,000 for advanced steel molds used in high-volume production.

CNC machining is preferred for its precision in producing durable aluminum molds, while electrical discharge machining is ideal for complex features. For a detailed estimate, consider requesting an injection molding quote.

Additionally, plastic injection molds and injection mold tooling play a crucial role in the manufacturing process.

Universal molds can serve as a budget-friendly alternative to custom molds, reducing overall tooling costs. These molds can be adapted for different parts, making them a cost-effective solution for manufacturers looking to save on upfront mold costs, all while being cast from the same mold.

Understanding various tooling methods and their associated tooling cost enables manufacturers to select the most appropriate and cost-effective options for their manufacturing process projects.

Material Costs

Plastic resin pellets used in injection molding generally cost between $1 and $5 per kilogram. This price range can vary based on different factors. Commonly used types of plastic resins in injection molding include:

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyurethane (PU)

- Polypropylene (PP)

- Polyethylene (PE)

These materials vary in cost and properties, influencing the overall mold material costs in injection molding.

Material costs in injection molding can be influenced by the type of resin, design specifications, and the quantity of material required.

Selecting the right material for a specific application is crucial for balancing cost and performance.

Considering these factors helps manufacturers optimize material choices to achieve cost-effective production while meeting specifications.

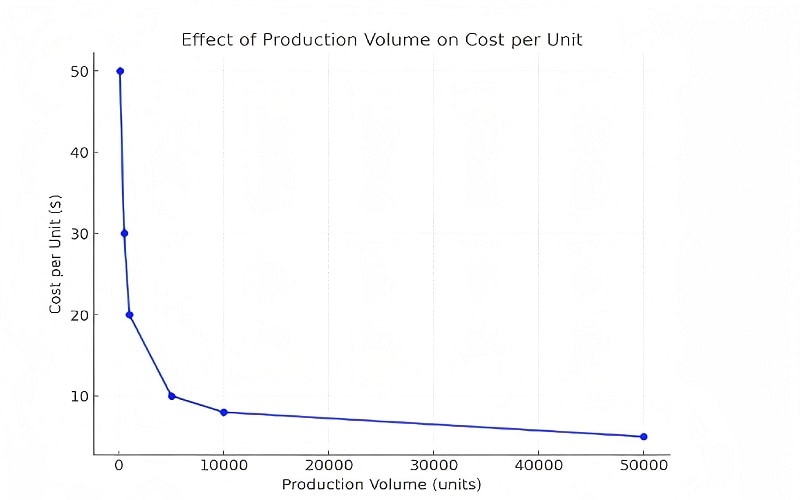

Production Volume and Its Impact

Higher production volumes lead to lower costs per unit, with costs decreasing significantly as the quantity increases.

As production volume increases, fixed costs are spread over more units, resulting in a significant reduction in per-unit costs.

This principle makes high-volume production particularly cost-effective for large production volumes in large-scale manufacturing projects.

Clearly communicating expected production volumes to molders helps in understanding and managing costs effectively. Different production volumes—low, medium, and high—each have unique cost implications.

Understanding these differences allows manufacturers to plan their production runs strategically to optimize costs.

Low-Volume Production

Low-volume production in injection molding typically refers to:

- Manufacturing of parts ranging from 100 to a couple thousand.

- A typical production cycle time of about 3 days.

- One part produced per cycle for a single cavity mold.

While the cost of a single cavity mold size is less, its production rate is slower compared to other mold types.

Family injection molds are utilized to create different shapes of parts simultaneously, which can optimize low-volume production. These molds offer several benefits:

- Allow manufacturers to produce multiple parts in one cycle

- Increase efficiency

- Reduce overall costs Leveraging family molds helps businesses achieve cost-effective low-volume production.

Medium-Volume Production

For medium-volume production, outsourced molds are typically required to meet the demand effectively. Medium-volume production typically refers to the manufacturing of batches consisting of 5,000 to tens of thousands of parts.

This production scale offers a balance between cost and efficiency, making it suitable for many industrial applications, including considerations of mold production and mold size.

Outsourcing molds for medium-volume mass production allows manufacturers to meet demand without significant upfront equipment investment. This approach helps manage costs while maintaining production efficiency and quality.

High-Volume Production

In high-volume injection molding production, the cost per part is typically around $1.75. High-volume production significantly decreases the cost per part due to shared upfront expenses.

This production scale is defined as producing hundreds of thousands of molded parts.

Steel molds are often required to achieve the durability necessary for high-volume production. Multi-cavity molds become cost-effective when producing large quantities of parts, significantly reducing the cost per unit.

Using high-volume production techniques helps manufacturers achieve substantial cost savings and production efficiency in mold making.

Design Considerations to Reduce Injection Molding Costs

Complex designs that require intricate molds lead to higher tooling costs and extended production times. Increased design complexity results in higher costs due to the need for extra research and technical expertise.

Selecting the appropriate mold classification can lead to significant savings by avoiding over-engineering.

Common strategies to control injection mold costs include:

- Eliminating unnecessary cosmetic features

- Optimizing part designs

- Providing detailed engineering drawings or 3D CAD models to allow moldmakers to assess designs accurately and identify potential issues early in the mold design process

With this approach, manufacturers can implement cost-reducing design features effectively.

Simplifying Design Features

Eliminating unnecessary features and cosmetic finishes, including high mold polish, can significantly lower injection molding costs.

Unnecessary features, textured surfaces, and cosmetic add-ons can increase injection molding costs. Eliminating these elements helps manufacturers achieve significant cost savings and improve efficiency.

Removing undercuts can facilitate easier part ejection, reducing tooling complications and potential costs. Simplifying mold designs and removing unnecessary elements streamline the production process and create a more cost-effective solution.

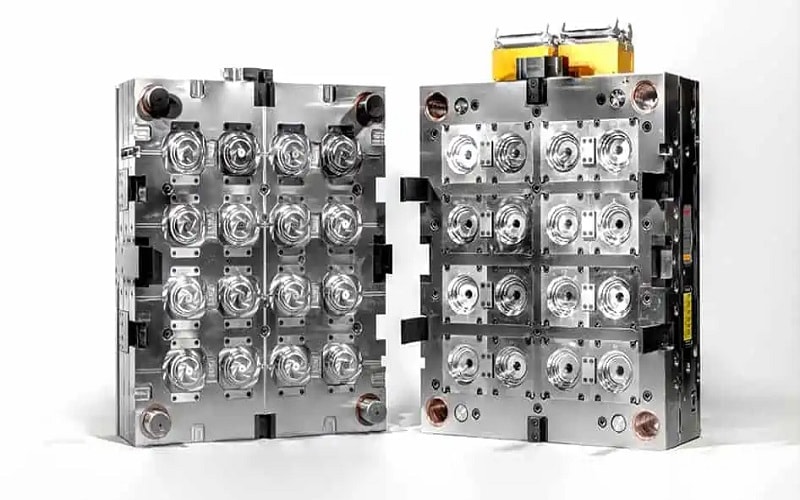

Using Multi-Cavity Molds

Multi-cavity molds and family injection molds have the following characteristics:

- Multi-cavity molds can produce multiple parts at once, significantly reducing part costs.

- Family injection molds result in a higher initial cost but allow for faster and more efficient production.

- The complexity of multi-cavity molds leads to higher initial costs due to design and manufacturing demands.

However, multi-cavity molds increase production rates and reduce cycle times, leading to enhanced overall efficiency. Family molds allow for the simultaneous production of multiple parts, optimizing mold usage and further reducing costs.

The number of multiple cavities in a mold impacts part costs and output, making them a cost-effective choice for high-volume production and mold cavities.

Self-Mating Parts

Self-mating parts are designed to connect with themselves, creating a simplistic and efficient mold design. By utilizing self-mating parts, manufacturers can:

- Streamline the mold process, as a single half mold can be employed for the entire same part.

- Significantly cut down mold costs.

- Provide a substantial reduction in overall manufacturing expenses.

Incorporating self-mating parts into designs simplifies production while driving down costs, leading to improved manufacturing efficiency.

Utilizing this design consideration allows manufacturers to achieve cost savings and enhance production effectiveness.

Choosing Cost-Effective Materials

Using less expensive plastic resins can lead to notable savings in plastic injection molding costs and expenses, directly impacting the final cost of the product.

Commonly used cost-effective plastics in injection molding include ABS and polypropylene due to their affordability and versatility.

These materials offer different mechanical properties suited for various applications, making them a practical choice for many manufacturers.

Raw material costs make up a significant portion of the overall unit price for injection molding, emphasizing the need for cost-effective material choices.

Choosing the right materials significantly influences the final cost of injection molding, balancing performance and affordability to ensure the final product meets quality standards without breaking the budget.

Insert Molding and Overmolding Techniques

Insert molding is a process that positions metal inserts in the mold before the plastic injection molding process. An example of insert molding is including metal fasteners inside plastic components.

This technique produces plastic parts that have metal inserts fused directly into them.

As a result, the parts exhibit greater strength. Insert molding allows for the integration of metal inserts into plastic parts, providing enhanced strength and durability.

Overmolding involves creating an injection molded part using injection molding and then placing that part in another mold for a second injection process with a different material.

An example of overmolding is the application of soft rubber grips in products like toothbrushes, which can include injection molded parts.

Overmolding and insert molding offer several benefits:

- Combine different materials into a single part, effectively eliminating the assembly process and contributing to cost savings.

- Reduce the need for additional fasteners.

- Simplify assembly.

These factors lead to overall lower cost reductions.

Leveraging DFM Analysis

Implementing Design for Manufacturability (DFM) early in the design process minimizes the risk of costly design errors and production delays.

DFM assists in aligning project goals with manufacturing capabilities, ensuring efficient production.

Addressing potential operational constraints early through DFM improves tooling performance and optimizes part designs to reduce manufacturing costs.

Moldfill analysis, a part of DFM, predicts plastic flow and cooling to avoid issues in injection molding. The DFM approach emphasizes assessing design tolerances and functionality based on specific project details.

Utilizing DFM ensures that material selection considers both cost and performance characteristics, leading to overall production efficiency. This strategic approach helps manufacturers achieve cost-effective and high-quality injection molding.

Getting Accurate Injection Molding Quotes

The location of mold manufacturing significantly influences costs, including repair costs, due to labor rates and quality variances.

Outsourcing injection molding can be more cost-effective than purchasing expensive equipment, especially for small to medium production volumes.

Informing your mold builder about your target price for the parts can help achieve more accurate pricing.

Various additional costs, including typical labor costs, may be included in injection molding pricing, such as:

- Finishing

- Post-processing services

- Inspection

- Packaging

Using online cost calculators, like the ICOMold injection mold cost calculator, can provide quick answers to how much does injection molding cost d accurate quotes for mold costs.

Providing detailed information and using these tools allows manufacturers to obtain precise injection molding quotes and budget more effectively.

Summary

Understanding injection molding costs is essential for managing manufacturing budgets and ensuring project success.

Key factors influencing costs include equipment, tooling, and material expenses, as well as production volumes.

By simplifying design features, using multi-cavity molds, and incorporating self-mating parts, manufacturers can significantly reduce costs.

Choosing cost-effective materials, leveraging insert molding and overmolding techniques, and utilizing DFM analysis can sometimes make injection molding expensive, but they further drive cost efficiency.

Accurate injection molding quotes help in precise budgeting and planning. By adopting these strategies, businesses can achieve cost-effective injection molding and maintain high-quality production standards.