Injection molding shrinkage happens when plastic parts contract as they cool, leading to potential issues with final dimensions.

In this article, we dive into the causes of shrinkage and offer effective strategies to control it. You’ll learn how to calculate shrinkage accurately and make informed decisions to produce high-quality parts consistently.

Understanding Injection Molding Shrinkage

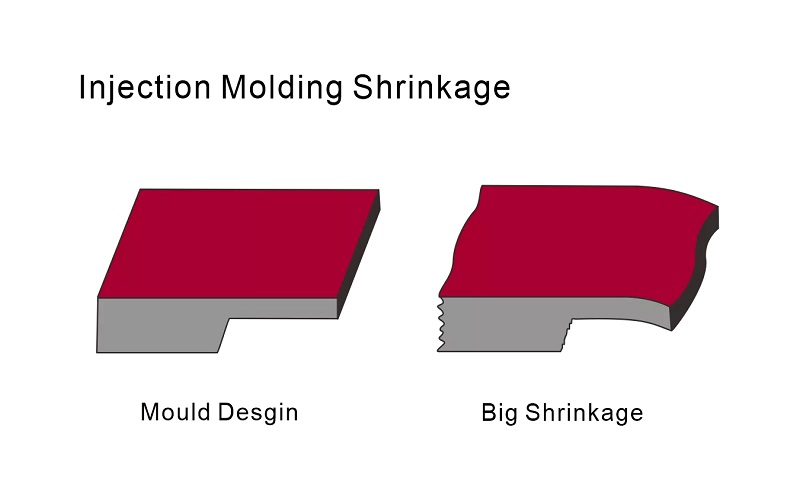

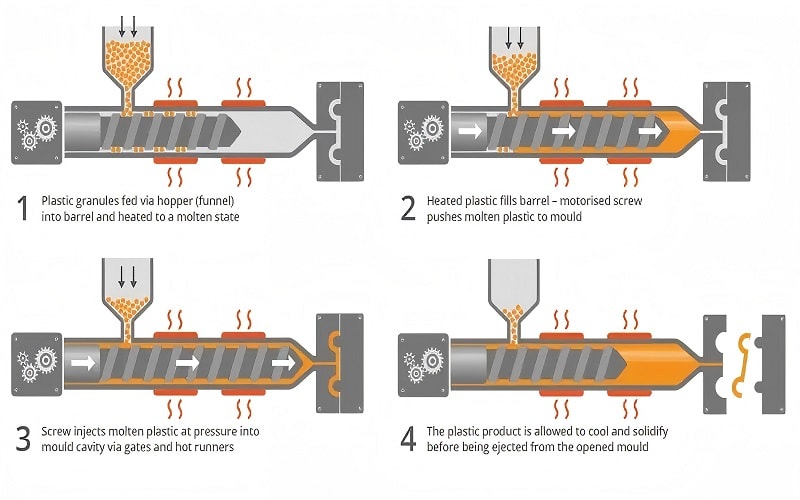

Injection molding shrinkage refers to the contraction of polymers during the cooling phase, indicating a volume decrease of plastics and plastic shrinkage. This phenomenon is an inherent aspect of the injection molding process, primarily occurring while the part is cooling in the mold.

However, the molded part may continue to shrink slightly even after ejection as it stabilizes in its final form. Understanding this behavior is essential for manufacturers to predict and manage the dimensional changes that occur during production.

While it is impossible to eliminate shrinkage entirely, recognizing its inevitability allows for better planning and control. Injection molders must account for this factor to ensure the final product meets the specified dimensions and quality standards.

Understanding the expected shrinkage behavior enables manufacturers to make better decisions about mold design and material selection, which ultimately reduces the impact of shrinkage on the final product.

Key Causes of Mold Shrinkage

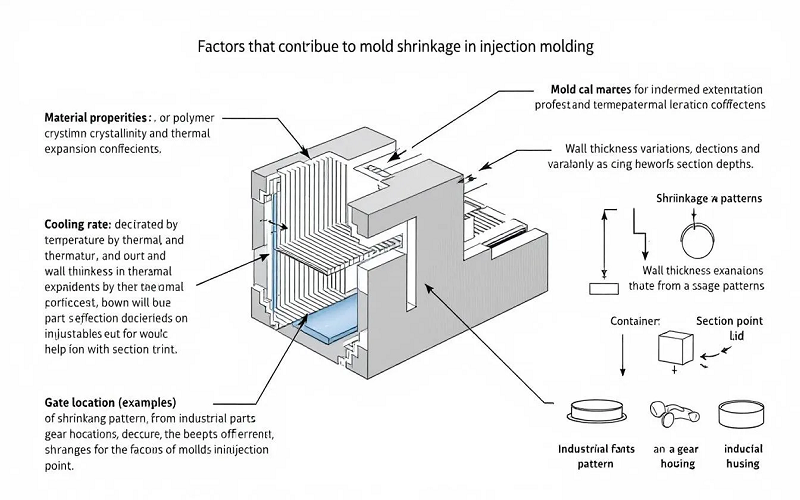

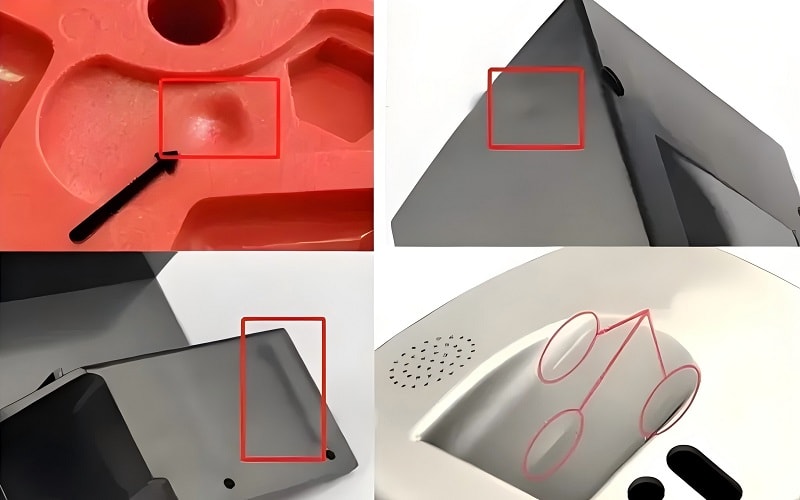

Several factors contribute to mold shrinkage, heavily affecting the quality and dimensions of molded parts. Key causes include the loss of fluids like plasticizers and the presence of internal stresses within the material. These elements can lead to excessive shrinkage, negatively impacting the part’s geometry, appearance, and performance, which in turn may cause production disruptions.

Mold design also plays a significant role in this process, influencing the cooling and solidification of the part, thereby affecting the degree of shrinkage experienced. Accurate calculation of mold shrinkage is essential for ensuring that molded parts meet specified dimensions. Shrinkage is typically expressed as a percentage, accounting for the dimensional change that occurs as molded parts cool.

Estimating the shrink rate before starting the injection molding process helps minimize errors and ensures the final product meets the required specifications. Despite these efforts, variability can still occur, and mold engineers often need to adjust process settings post mold shrinkage to control shrinkage effectively.

Calculating Mold Shrinkage

Accurately calculating mold shrinkage is crucial in the injection molding process. This involves analyzing thermoplastics and thermosets during molding to predict dimensional changes in the final product. Evaluating shrinkage percentages helps manufacturers understand material contraction from molding to cooling, allowing for necessary design adjustments.

These calculations ensure high-quality production standards and precise dimensions in molded parts.

Steps to Calculate Mold Shrinkage

Developing a prototype tool is a fundamental step in accurately measuring shrinkage and providing an opportunity to make tooling adjustments before full-scale production. Precision measurement tools are essential for determining the exact dimensions of injection molded parts, ensuring that the calculated shrinkage values are reliable.

Modifying injection speed can also optimize the filling of molds, ensuring efficient material flow and standard flow without introducing excessive stress. Following these steps allows manufacturers to achieve more accurate predictions of shrinkage and implement necessary design changes to accommodate expected dimensional shifts.

Using Shrinkage Values

Shrinkage values, expressed in percentages, quantify the degree of contraction that materials undergo during cooling. These values are crucial for designing molds that produce accurate and dimensionally stable parts in the injection molding process, taking into account the mold shrinkage rate. When shrinkage occurs, it is essential to consider how to affect shrinkage and these factors.

Mold designers must incorporate these calculated shrinkage values into the mold specifications to ensure the final parts meet the required mold dimensions. This approach allows them to anticipate and compensate for expected shrinkage, resulting in higher quality and more consistent production outcomes.

Factors Influencing Shrinkage Rates

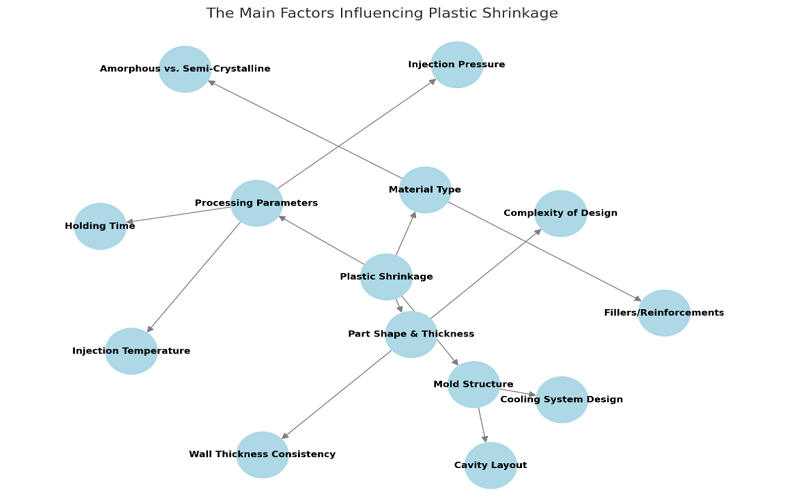

The dynamics of shrinkage are influenced by several key factors involved, including the polymer’s molecular structure and the thermal conditions during the cooling process.

These factors can significantly impact the shrinkage rates, making it essential for manufacturers to understand and control them to achieve the desired part quality.

Impact of Polymer Composition

Polymer composition plays a critical role in determining shrinkage behavior and the material properties that influence it. Key factors include:

- Higher molecular weight increases viscosity and pressure drop, leading to greater shrinkage.

- Polymers can experience up to 20% volume contraction during shrinkage.

- Crystallization behavior is crucial, with more crystalline materials shrinking more than semi-crystalline materials.

Semi-crystalline materials maintain their molecular orientation during cooling and recrystallize, resulting in higher shrinkage rates compared to amorphous polymers. Filled resins, however, typically show less shrinkage due to the presence of reinforcing fibers.

Additives like fillers, fibers, and pigments can affect polymer shrinkage in the following ways:

- Pigments act as nucleating agents that enhance cross-flow shrinkage in semi-crystalline polymers.

- Reinforcement fibers like glass reduce shrinkage in the orientation direction but may increase it in the transverse direction.

- Various materials, such as glass fiber and wood, can be used to fill resins to alter part properties.

Role of Processing Conditions

Processing conditions, particularly temperature, pressure, and cooling time, play a critical role in controlling shrinkage in injection molding. Optimizing these conditions is crucial for minimizing shrinkage during the production process. Maintaining consistent mold temperatures contributes to uniform cooling, which mitigates differential shrinkage in complex parts.

Adjusting processing conditions, such as temperatures, pressures, and cooling times, can effectively mitigate shrinkage. For instance, maintaining a warmer mold temperature can reduce shrinkage rates.

Part Design Considerations

Optimizing part design and geometry is essential. It helps to minimize shrinkage and attain the desired dimensions and tolerances. Part geometry can make some designs more susceptible to shrinkage, especially those with uneven wall thickness, complex geometries, or sharp corners.

Uniform wall thickness is crucial to avoid differential shrinkage and subsequent warping. The placement and design of gates and vents can also directly affect the shrinkage behavior of the molded part, influencing cooling rates and shrinkage characteristics.

Strategies to Minimize Shrinkage

Several strategies can be employed to minimize shrinkage during the injection molding process. These strategies focus on:

- Optimizing cooling effects

- Adjusting wall thickness

- Managing plasticizing temperature These measures help prevent distortion and ensure the integrity of the molded parts.

Optimizing Cooling Channels

The design of cooling channels is critical for achieving even temperature distribution in molded parts. Properly designed cooling channels ensure that the cooling process is efficient, reducing the risk of uneven cooling and subsequent warping.

Optimizing cooling channels helps manufacturers achieve uniform cooling rates, minimizing shrinkage and improving the overall quality of molded parts.

Adjusting Wall Thickness

Optimizing wall thickness can enhance cooling efficiency, thus reducing the risk of shrinkage. Maintaining uniform wall thickness helps in achieving consistent cooling rates, which in turn minimizes differential shrinkage and increasing wall thickness.

Adjusting hold pressure and time can also minimize voids and improve the integrity of the molded parts. These adjustments ensure that the final product meets the desired specifications with minimal shrinkage.

Managing Plasticizing Temperature

Lowering the plasticizing temperature can help manage the viscosity of materials, facilitating better flow and reducing shrinkage. Managing the temperature and moisture content during the injection molding process is crucial for controlling the shrinkage behavior of plastic materials.

Optimizing the plasticizing temperature results in more consistent material flow, reducing shrinkage and ensuring high heat quality production outcomes.

Choosing Materials with Low Shrinkage

Choosing the right plastic materials for plastic injection molding can drastically reduce shrinkage and improve overall plastic parts quality. Materials with high or low shrinkage rates ensure better dimensional accuracy, reducing the need for rework and waste, including those with mold release grade properties.

This is particularly important in industries such as automotive and electronics, where strict tolerance requirements are essential to meet industry standards.

Amorphous vs. Semi-Crystalline Polymers

Different materials exhibit varying shrinkage characteristics, with semi-crystalline types like polyethylene shrinking more than amorphous materials. Semi-crystalline polymers generally experience greater shrinkage due to their structured molecular organization.

Amorphous polymers tend to have more consistent shrinkage characteristics, largely due to their random molecular structure. As temperature drops, intermolecular forces pull molecules closer together in amorphous polymers, leading to uniform shrinkage.

High and Low Shrinkage Polymers

Filled resins generally shrink less than unfilled resins, making them a preferred choice for applications requiring low shrinkage. Polyethylene (PE) has a wide range of shrinkage rates depending on its density and processing conditions, typically ranging from 0.5% to 4%.

Choosing the right polymer for injection molding is crucial to minimize shrinkage and ensure part quality. Understanding shrinkage rate differences among polymers aids in selecting materials for specific applications, enhancing product performance.

Advanced Techniques to Control Shrinkage

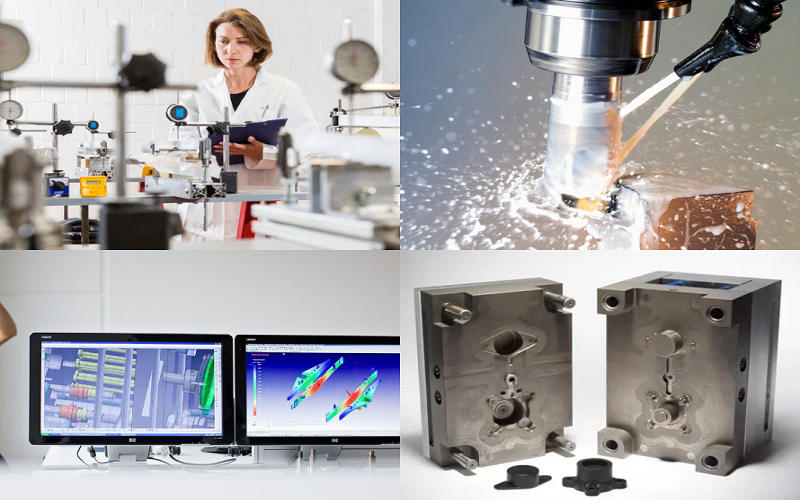

Advanced techniques such as simulation software and fine-tuning process parameters allow manufacturers to predict and control shrinkage more effectively.

These methods offer greater precision in managing the injection molding process, leading to higher quality outcomes.

Simulation Software

Simulation software plays a crucial role in addressing potential shrinkage issues early during the design phase by:

- Visualizing expected shrinkage, providing insights into how different design elements will behave during injection molding.

- Allowing for testing design changes.

- Helping to identify effective strategies for managing and minimizing shrinkage.

Fine-Tuning Process Parameters

Optimizing back pressure is important to achieve desired results for specific material and mold design. Increasing back pressure can improve the filling and uniformity of molded parts. However, excessive high pressure can cause issues such as sink marks or voids in the final product.

Fine-tuning processing parameters optimizes the injection molding process for minimal shrinkage and high-quality outcomes.

Real-World Applications and Case Studies

Utilizing test shots before production allows for precise calibration of shrinkage rates based on real molding conditions. A prototype tool enables precise shrinkage measurements and allows for tooling adjustments before full-scale production begins. Simulation tools can significantly decrease production timelines by minimizing the number of physical trials needed.

For example, a smartphone housing project utilized acrylonitrile butadiene styrene for its surface quality and employed in-mold decoration to streamline production and enhance aesthetics. Another case involved a medical device manufacturer that successfully produced a complex component using medical-grade polycarbonate (PC) and advanced mold design, ensuring precision and compliance with regulatory standards.

In developing sustainable packaging, a company chose polylactic acid (PLA) for its eco-friendly properties and optimized the injection molding process to ensure cost efficiency and mechanical strength. These real-world applications demonstrate how effective shrinkage management can lead to successful project outcomes.

Summary

In short, managing injection molding shrinkage is a multifaceted challenge, and by accurately calculating shrinkage, optimizing cooling channels, adjusting wall thicknesses, managing plasticizing temperatures, and selecting low-shrinkage materials, manufacturers can dramatically improve the quality and dimensional accuracy of their injection molded parts.

Armed with this knowledge, you’ll be better able to address shrinkage in your injection molding process, ensuring consistent and high-quality production.

Frequently Asked Questions

Why is shrinkage an inevitable part of the injection molding process?

Shrinkage is an inevitable part of the injection molding process due to the natural contraction of polymers as they cool, which results in a decrease in volume. This contraction occurs while the part is still in the mold and continues slightly after ejection until the part stabilizes.

How can I calculate mold shrinkage accurately?

To calculate mold shrinkage accurately, develop a prototype tool and employ precision measurement tools while adjusting the injection speed to optimize material flow. This approach enables precise predictions of dimensional changes and enhances production quality.

What role do processing conditions play in controlling shrinkage?

Processing conditions, including temperature, pressure, and cooling time, play a crucial role in controlling shrinkage by ensuring uniform cooling and minimizing differential shrinkage in complex parts. Therefore, careful optimization of these parameters is essential for achieving desirable outcomes.

How do different polymer compositions affect shrinkage?

Different polymer compositions significantly affect shrinkage rates, with semi-crystalline polymers exhibiting greater shrinkage than amorphous ones due to their structured molecular organization. Additionally, the inclusion of additives such as fillers and fibers can further alter shrinkage behavior.

What advanced techniques can be used to control shrinkage in injection molding?

Utilizing simulation software is essential for predicting and managing shrinkage effectively during the design phase. Furthermore, optimizing process parameters, such as back pressure, enhances the uniformity and quality of molded parts.