Specializing in injection molding for custom plastic parts, we offer precision, efficiency, and tailor-made solutions from concept to completion.

Free DFM Analysis

Non-disclosure Agreement

low volume injection molding

T1 samples as fast as 2 weeks

16 years of experience, trusted by 900+ clients.

We offer comprehensive services in overmolding and insert molding for packaged components.

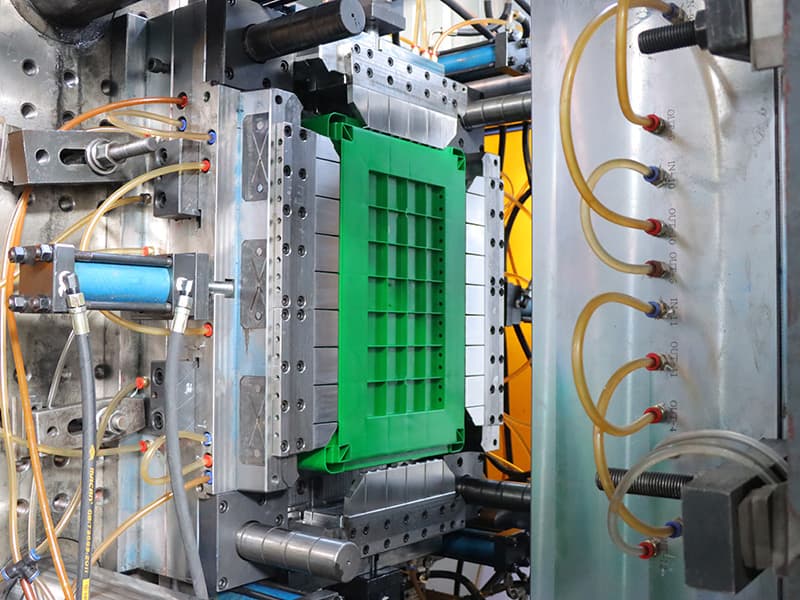

Plastic injection molding injects molten plastic into molds, creating precise, high-volume parts efficiently.

Insert molding combines pre-formed inserts with molten material in a mold, bonding them into an integrated part.

Overmolding produces multi-material parts in a single process, enhancing grip, durability, and aesthetics through layered molding.

Explore a wide range of injection molding materials, we can also source material for your project’s unique requirements.

ABS (Acrylonitrile Butadiene Styrene)

Main Applications: Automotive interior and exterior components, toys, home appliance casings, and electronic product housings.| Type | Grade | Data Sheet |

|---|---|---|

| ABS | MG47 | Data Sheet |

| ABS | PA-765 | Data Sheet |

| ABS | PA-707 | Data Sheet |

| ... |

PP (Polypropylene)

Main Applications: Packaging, automotive parts, textiles (e.g., ropes, thermal underwear, carpets), laboratory equipment.| Type | Reference | Data Sheet |

|---|---|---|

| PP | Q-571 | Data Sheet |

| PP | PH140-1 | Data Sheet |

| PP | HP400K | Data Sheet |

| ... |

HDPE (High-Density Polyethylene)

Main Applications: Bottles for milk and cleaning products, pipes and fittings, plastic bags, and playground equipment.| Type | Reference | Data Sheet |

|---|---|---|

| HDPE | HD 6070UA | Data Sheet |

| HDPE | HD 0200L | Data Sheet |

| HDPE | HD 300-3 | Data Sheet |

| ... |

LDPE (Low-Density Polyethylene)

Main Applications: Plastic bags, squeezable bottles, tubing, agricultural film, and packaging films.| Type | Reference | Data Sheet |

|---|---|---|

| LDPE | TX7003 | Data Sheet |

| LDPE | CA4676 | Data Sheet |

| ... |

PA6 (Polyamide 6)

Main Applications: Textile fibers, fishing lines, pipes, and engineering plastics for automotive and mechanical parts.| Type | Reference | Data Sheet |

|---|---|---|

| PA6 | 901510 | Data Sheet |

| PA6 | PA6NAT | Data Sheet |

| ... |

PA66 (Polyamide 66)

Main Applications: Automotive components, electrical and electronic parts, consumer goods, and fibers for textiles and carpets.| Type | Reference | Data Sheet |

|---|---|---|

| PA66 | 70G33L | Data Sheet |

| PA66 | HR-HG7 | Data Sheet |

| PA66 | 2440GM7 | Data Sheet |

| ... |

PC (Polycarbonate)

Main Applications: Eyewear lenses, water bottles, bulletproof glass, greenhouses, digital disks (CDs, DVDs), and exterior lighting fixtures.| Type | Reference | Data Sheet |

|---|---|---|

| PC | PC-175 | Data Sheet |

| PC | PC-115 | Data Sheet |

| ... |

PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene blend)

Main Applications: Automotive interior and exterior parts, electronic housings, medical devices, and luggage.| Type | Reference | Data Sheet |

|---|---|---|

| PC/ABS | PC-540 M30 | Data Sheet |

| PC/ABS | PC-540A | Data Sheet |

| ... |

PMMA (Polymethyl Methacrylate) or Acrylic

Main Applications: Signage, light fixtures, aquariums, barriers, optical lenses, and acrylic nails.| Type | Reference | Data Sheet |

|---|---|---|

| PMMA | ECL | Data Sheet |

| PMMA | AFP | Data Sheet |

| ... |

POM (Polyoxymethylene) or Acetal

Main Applications: Precision parts, gears, bearings, kitchen appliances, ski bindings, and zippers.| Type | Reference | Data Sheet |

|---|---|---|

| POM | GP-FG | Data Sheet |

| POM | ACE091L | Data Sheet |

| ... |

PS (Polystyrene)

Main Applications: Disposable cutlery, CD and DVD cases, plastic models, food packaging, and insulation.| Type | Reference | Data Sheet |

|---|---|---|

| HIPS | PH-55Y | Data Sheet |

| HIPS | AVPS 100-3 | Data Sheet |

| ... |

PLA (Polylactic Acid)

Main Applications: Biodegradable packaging, disposable tableware, and 3D printing filament.| Type | Reference | Data Sheet |

|---|---|---|

| PLA | BG4400 | Data Sheet |

| ... |

TPO (Thermoplastic Polyolefin)

Main Applications: Automotive bumpers and dashboard skins, roofing membranes, and medical devices.| Type | Reference | Data Sheet |

|---|---|---|

| TPO | ADX-5007 | Data Sheet |

| TPO | ADX-5017 | Data Sheet |

PEEK (Polyether Ether Ketone)

Main Applications: Aerospace components, automotive parts, medical implants, and cookware.| Type | Reference | Data Sheet |

|---|---|---|

| PEEK | 4447 | Data Sheet |

| PEEK | 7759 | Data Sheet |

| ... |

PC-PBT (Polycarbonate-Polybutylene Terephthalate blend)

Main Applications: Automotive body parts, electrical connectors, and housings that require heat resistance and toughness.| Type | Reference | Data Sheet |

|---|---|---|

| PC-PBT | 9KF20400 | Data Sheet |

| ... |

PC-PET (Polycarbonate-Polyethylene Terephthalate blend)

Main Applications: Electronics, automotive components, and containers that require a good barrier to gas and moisture.| Type | Reference | Data Sheet |

|---|---|---|

| PC-PET | HI-9005 | Data Sheet |

| ... |

PE-PS (Polyethylene-Polystyrene)

This appears to be a less common blend or might be inaccurately listed. Typically, PE and PS are used separately due to their distinct properties.| Type | Reference | Data Sheet |

|---|---|---|

| PE+PS | 2010GF | Data Sheet |

| ... |

PPA (Polyphthalamide)

Main Applications: High-temperature automotive parts, electronics, cookware handles, and mechanical parts requiring high strength and stiffness.| Type | Reference | Data Sheet |

|---|---|---|

| PPA | DA-310ST | Data Sheet |

| ... |

PPS (Polyphenylene Sulfide)

Main Applications: Automotive and aerospace parts, electrical and electronic components, and chemical-resistant coatings.| Type | Reference | Data Sheet |

|---|---|---|

| PPS | Arolux PPS | Data Sheet |

| ... |

PCT (Polycyclohexylenedimethylene Terephthalate)

Main Applications: Electrical connectors, under-the-hood automotive parts, and appliances requiring high heat resistance.| Type | Reference | Data Sheet |

|---|---|---|

| PCT | CG923 | Data Sheet |

| ... |

EPDM (Ethylene Propylene Diene Monomer rubber)

Main Applications: Roofing membranes, vehicle seals, tubing, and electrical insulation.| Type | Reference | Data Sheet |

|---|---|---|

| ... |

MPR (Modified Polyphenylene Ether)

Main Applications: Often used in blends for automotive parts, electronics, and appliances requiring high heat resistance and dimensional stability.| Type | Reference | Data Sheet |

|---|---|---|

| ... |

POE (Polyolefin Elastomer)

Main Applications: Automotive interior parts, footwear, adhesives, and impact modifiers for plastics.| Type | Reference | Data Sheet |

|---|---|---|

| ... |

PVC (Polyvinyl Chloride)

Main Applications: Pipes, window frames, vinyl siding, and medical devices. "Shore A" refers to a scale of hardness.| Type | Reference | Data Sheet |

|---|---|---|

| ... |

PVC (Polyvinyl Chloride)

Main Applications: Pipes, window frames, vinyl siding, and medical devices.| Type | Reference | Data Sheet |

|---|---|---|

| PVC | 2212-7-118 | Data Sheet |

| ... |

TPE (Thermoplastic Elastomer)

Main Applications: Flexible parts that require rubber-like properties, such as seals, gaskets, and grips.| Type | Reference | Data Sheet |

|---|---|---|

| ... |

TPU (Thermoplastic Polyurethane)

Main Applications: Phone cases, medical devices, footwear.| Type | Reference | Data Sheet |

|---|---|---|

| ... |

TPV (Thermoplastic Vulcanizates)

Main Applications: Automotive Industry, building and Construction, medical devices, electrical and electronics| Type | Reference | Data Sheet |

|---|---|---|

| ... |

SPI (Society of the Plastics Industry) standard is more common in the United States, offering a classification system based on the polish and texture of molds, affecting the final product’s surface.

VDI (Verein Deutscher Ingenieure) standard, prevalent in Europe, provides detailed texturing guidelines using a scale measured in micrometers to achieve specific surface roughness.

| Class | Surface Roughness | Applicable Materials |

|---|---|---|

| A-1 | Ra 0.012- 0.025 µm | Acrylic |

| A-2 | Ra 0.025-0.05 µm | Acrylic, PC |

| A-3 | Ra 0.05-0.10 µm | ABS, Acrylic. PS, Nylon, PC |

| B-1 | Ra 0.05-0.10 µm | ABS, Acrylic, PP. PS, Nylon, PC |

| B-2 | Ra 0.10- 0.15 µm | ABS, Acrylic, PP. PS, Nylon, PC |

| B-3 | Ra 0.28-0.32 µm | ABS, Acrylic, PP. PS, Nylonylic, PC |

| ... |

| Class | Surface Roughness | Applications |

|---|---|---|

| 12 | Ra 0.40 µm | Low Gloss |

| 15 | Ra 0.56 µm | Low Gloss |

| 18 | Ra 0.80 µm | Satin finish |

| 21 | Ra 1.12 µm | Dull finish |

| 24 | Ra 1.60 µm | Dull finish |

| 27 | Ra 2.24 µm | Dull finish |

| ... |

We also offer a wide range of textures that can be applied to mold surfaces to impart various aesthetic and functional finishes to the final plastic products like Mold-Tech

Our post-processing involves surface finishing, quality checks and packing to ensure product specifications.

Indirect gravure process using silicone pad to transfer ink onto irregular surfaces.

Screen printing: ink pushed through a mesh screen onto a substrate for vibrant prints.

High-precision technique employing a focused laser beam to mark materials with accuracy.

Nuts installed by melting plastic around them for secure attachment in materials.

Involves joining individual parts together to create a functional product or subassembly.

Submit your design files easily online for initial review and assessment.

Receive a detailed quote along with DFM analysis for optimized manufacturing.

Custom tool creation for injection molding of your design.

First round of sample production to ensure design and quality alignment.

Send samples for review and approve samples to green-light full-scale production.

Efficient mass production begins with agreed quality standards.