Insert injection molding is a manufacturing process that integrates typically metal or plastic inserts into molded parts, producing strong components with enhanced mechanical properties and functionality.

Widely used in automotive, consumer electronics, and medical devices, it offers precision, durability, and efficiency.

This article explores the insert molding process, materials like engineering plastics and metals, benefits such as reduced assembly and labor costs, applications including medical equipment and digital control panels.

What Is Insert Injection Molding?

Insert injection molding is a sophisticated manufacturing process that combines pre-placed inserts with molten plastic within a mold cavity.

This technique is designed to integrate metal inserts, plastic inserts, or other materials into molded parts, enhancing their functionality and structural integrity.

Unlike traditional injection molding, where only plastic is injected into the mold, injection molding inserts introduce additional materials to create a composite part.

The types of inserts used in this process are varied and can include metal inserts like screws, pins, and threaded inserts, as well as plastic inserts and other materials.

These inserts are carefully positioned within the mold cavity before the molten plastic is injected.

This ensures that the inserts are securely embedded within the final product, providing enhanced strength and durability through metal insert molding.

In comparison to traditional injection molding, insert injection molding offers numerous advantages.

While conventional injection molding is limited to creating parts from a single material, insert injection molding allows for greater design flexibility and the integration of multiple materials.

Steps Of Insert Molding Process

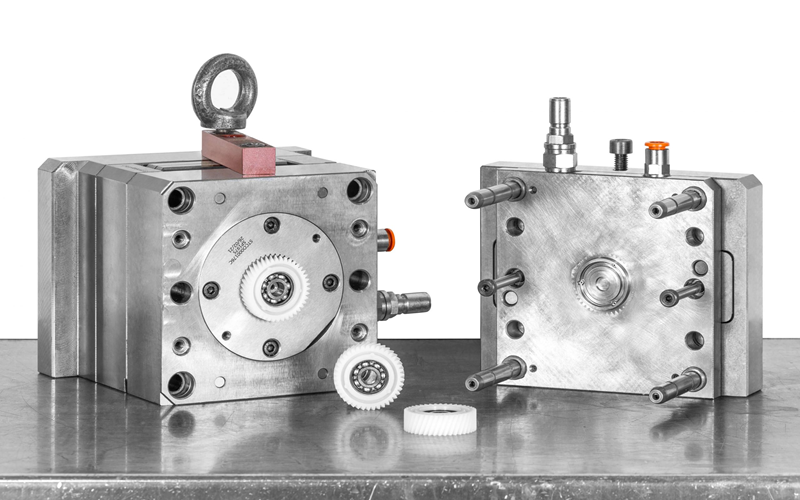

Insert injection molding is a precise manufacturing technique that integrates pre-placed inserts into plastic components to create robust, multifunctional parts.

The process begins with the critical step of insert placement, where metal or plastic inserts—such as screws, connectors, or threaded inserts—are accurately positioned in a custom-designed mold.

This placement often utilizes automated insertion systems like robotic arms to ensure consistent insert location and orientation, which is vital for part quality and repeatability.

Once the inserts are securely positioned, the mold closes to encapsulate them properly.

Next comes the injection phase, where molten material—commonly engineering plastics such as ABS, polycarbonate, or nylon—is delivered via an injection unit into the mold cavity under high pressure.

This molten plastic flows around the inserts, filling the mold’s intricate features and vents present to allow air to escape, ensuring complete coverage and bonding.

The cooling phase follows, during which the plastic solidifies and bonds firmly with the inserts, forming a single, cohesive plastic part with embedded components.

Maintaining optimal temperature and pressure during this phase is crucial to prevent defects such as deformation or internal stress. After solidification, the mold opens, and the molded part is ejected carefully to avoid damage or excess material on the part.

Post-molding operations may include removing excess material, surface finish treatments, or heat treatment processes to enhance part durability and performance.

Throughout the process, careful control of parameters like deformation temperature and moisture absorption is essential to ensure the final product meets stringent mechanical properties and service temperature requirements.

This insert injection molding process is widely used across industries such as automotive, medical devices—including medical knobs and dental instruments—and consumer electronics. It provides cost-effective manufacturing of complex parts with superior structural integrity and aesthetic appeal.

Materials Used In Insert Injection Molding

Insert injection molding involves embedding pre-formed components, typically metal or plastic inserts, into a molded plastic part. The choice of materials is critical to ensure compatibility, durability, and performance.

Thermoplastics

Common choices like ABS, polycarbonate, and nylon are widely used in insert injection molding for their versatility, excellent mechanical properties, and strong bonding capabilities with inserts.

These engineering plastics provide the primary molded structure, ensuring durability and resistance to wear, moisture absorption, and varying service temperatures.

Their compatibility with metal inserts and other non plastic parts makes them ideal for producing cost sensitive parts and complex components with high structural integrity.

Thermosets

Materials such as epoxy or phenolic resins are selected for their exceptional high heat resistance, dimensional stability, and chemical durability, making them ideal for demanding applications where performance under stress and elevated temperatures is critical.

These thermoset materials provide excellent rigidity and resistance to deformation, complementing the engineering plastics used in insert injection molding to enhance the overall mechanical properties and longevity of the final product.

Metal Inserts

Brass, stainless steel, and aluminum inserts are commonly used in insert injection molding due to their excellent strength, electrical conductivity, and corrosion resistance.

These metal inserts are typically employed for threaded or structural components, providing enhanced mechanical properties and durability to the final molded part.

Selecting the right metal insert material is crucial to withstand the high temperatures and pressures of the injection molding process while ensuring a strong bond with the plastic.

Benefits Of Insert Injection Molding

Insert injection molding is a manufacturing process that integrates pre-formed components, such as metal or plastic inserts, into a molded plastic part, offering numerous advantages for producing complex, high-quality components.

Enhanced Component Strength

By embedding metal or high-strength inserts, the insert injection molding process significantly improves the structural integrity and load-bearing capacity of plastic parts.

This enhancement makes the components suitable for demanding applications where durability and mechanical performance are critical.

The metal inserts strengthen the overall part, providing resistance to wear, impact, and environmental factors, which extends the product’s service life and reliability.

Improved Design Flexibility

Insert injection molding allows for the seamless combination of different materials, enabling the creation of complex geometries and multifunctional parts without requiring additional assembly steps.

This process not only enhances design freedom but also supports the integration of various insert components such as threaded inserts, metal parts, or plastic elements, resulting in highly customized and durable products.

By using the right mold and carefully selecting compatible materials, manufacturers can optimize structural integrity and reduce excess material waste, making insert molded parts both efficient and cost-effective.

Reduced Assembly Costs

Integrating inserts during the molding process eliminates the need for post-molding assembly, significantly reducing labor costs, time, and potential errors associated with secondary operations.

This streamlined approach not only accelerates production but also minimizes manual handling, leading to higher efficiency and lower overall manufacturing expenses.

In particular, labor costs reduces substantially due to the automation and simplification of the manufacturing workflow.

Additionally, the cost element related to tooling and insert materials is carefully managed to ensure overall cost-effectiveness in production.

Enhanced Durability And Reliability

The strong bond formed between the insert and the molded plastic ensures exceptional durability and reliable performance throughout the product’s lifecycle.

This secure integration minimizes the risk of loosening, wear, or failure even under repeated mechanical stress, extreme environmental exposure, or varying service temperatures.

As a result, insert molded parts exhibit superior structural integrity, making them ideal for demanding applications where long-term reliability is critical.

Improved Product Consistency

The automated nature of the insert injection molding process ensures precise and repeatable placement of inserts within the mold cavity.

This high level of accuracy leads to consistent part quality, minimized variability in production, and reduced risk of defects.

As a result, manufacturers benefit from improved yield rates and reliable performance across large production volumes, making the process ideal for cost sensitive parts and high-demand applications.

Applications Of Insert Molded Parts

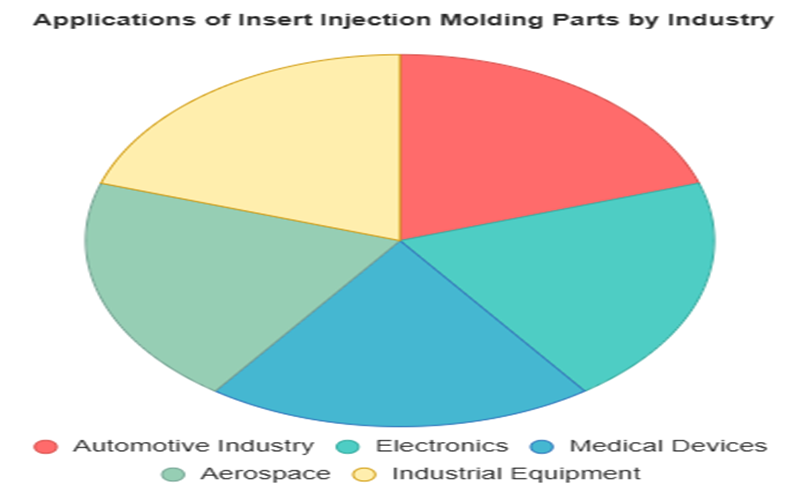

Insert injection molding part is widely used across various industries to produce high-precision, durable components by embedding metal or plastic inserts into molded plastic parts.

This process is ideal for creating complex, multifunctional parts with enhanced strength and reliability.

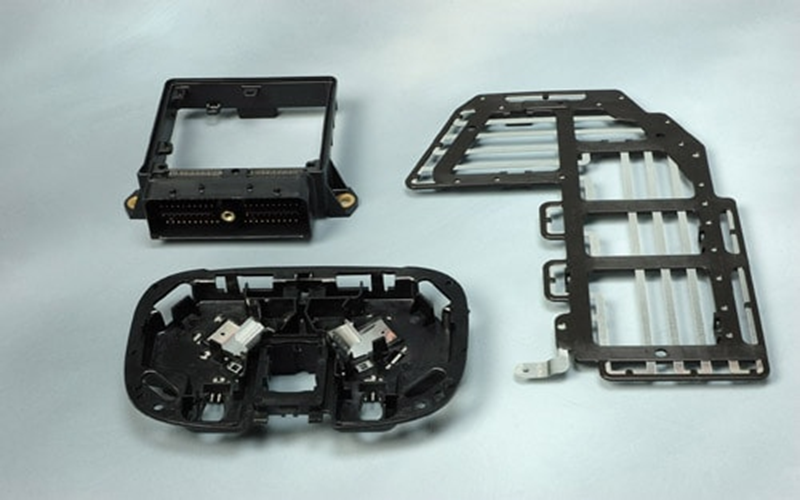

Automotive Industry

Insert injection molding is extensively used in the automotive industry for producing components such as threaded fasteners, sensor housings, and connectors.

Metal inserts provide the necessary strength and durability, while the plastic injection molding process ensures parts are lightweight, corrosion-resistant, and cost-effective.

This combination reduces labor costs and assembly time, making it ideal for high-volume production of complex automotive parts.

Electronics

Commonly applied in producing circuit board supports, connectors, and enclosures, where metal inserts ensure electrical conductivity and structural stability within plastic casings.

This application is especially prevalent in the consumer electronic industry, where insert molding enables the production of lightweight, durable, and compact components.

The process reduces assembly and labor costs, improves mechanical properties, and allows for precise placement of common inserts such as threaded inserts and metal pins, resulting in reliable and high-performance electronic parts.

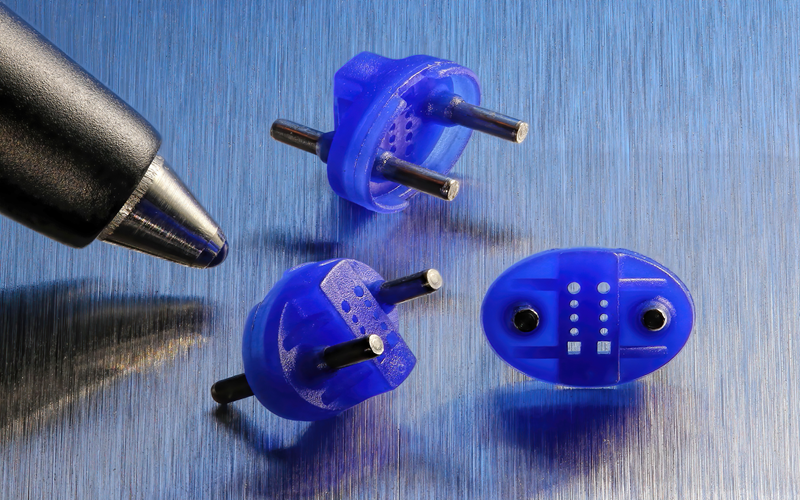

Medical Devices

Insert injection molding plays a crucial role in manufacturing medical devices by producing components such as surgical instruments, catheter parts, and medical enclosures.

The process integrates metal or plastic inserts to provide precision, strength, and durability, while biocompatible, rubber-like plastics ensure patient safety and comfort.

This method also supports humidity control and sterilization requirements, making it ideal for sensitive medical applications.

By reducing labor costs and eliminating post molding assembly, insert molding enhances production efficiency and consistency in the medical device industry.

Aerospace

Insert injection molding is widely applied in aerospace for manufacturing lightweight, high-strength components such as brackets, fittings, and structural supports.

These metal inserts enhance mechanical performance while maintaining low weight, which is critical in aerospace applications.

This process also reduces assembly and labor costs, improves part reliability, and ensures components meet stringent service temperature and mechanical property requirements typical of the aerospace industry.

Industrial Equipment

Insert injection molding is widely used in industrial equipment manufacturing for producing durable parts such as gears, bearings, and mounting brackets.

The incorporation of metal or plastic inserts provides enhanced wear resistance and structural support, making these components suitable for heavy-duty applications.

Typical examples include reinforced bushings and threaded inserts that ensure reliable performance under high stress and demanding service temperature conditions.

By producing parts with integrated inserts, manufacturers achieve cost-effective, high-strength solutions tailored for rigorous industrial environments.

Insert Molding vs Overmolding

Insert molding and overmolding are two distinct injection molding techniques that serve different purposes in manufacturing.

Insert molding involves placing a pre-formed insert, typically metal, into the mold cavity before injecting molten plastic, resulting in a single, integrated part with enhanced mechanical strength and durability.

This process is highly effective for applications requiring reinforced areas, such as threaded inserts in automotive and electronic components, and it reduces assembly and labor costs by eliminating secondary operations.

On the other hand, Overmolding is a two shot injection molding process where a second material, often a softer, rubber-like plastic, is molded over a pre-existing plastic substrate.

This technique is commonly used to add ergonomic features, improve aesthetics, or provide soft-touch surfaces on products like tool handles and consumer goods.

While overmolding offers greater design flexibility in terms of textures and materials, it generally involves additional manufacturing steps and higher costs compared to insert molding.

| Aspect | Insert Molding | Overmolding |

|---|---|---|

| Process | Precise insert placement before injection | Pre-molded substrate with second material |

| Material Compatibility | Dissimilar materials | Compatible materials |

| Applications | Threaded inserts in electronics, automotive | Grips on tools, soft-touch consumer goods |

| Cost and Efficiency | Reduces assembly costs in one step | Extra steps, enhances durability, aesthetics |

| Design Flexibility | Reinforces specific areas with inserts | Multi-material parts with varied textures |

Summary

In summary, insert injection molding is a powerful tool in the manufacturing industry, offering enhanced strength, cost efficiency, and design flexibility.

By understanding the process, materials, and benefits, you can harness its potential to create innovative and high-quality products.

Embrace the possibilities that insert injection molding offers and take your manufacturing capabilities to the next level.