Is acrylic food safe? Yes, acrylic can be food safe when it meets specific FDA guidelines. This article covers everything you need to know about using acrylic for food storage and handling.

Introduce

- Acrylic, or PMMA, is recognized as food safe when it complies with FDA guidelines and does not leach harmful chemicals into food.

- Heat resistance is limited in acrylic, making it unsuitable for microwaves and dishwashers, and prolonged sunlight exposure can degrade its quality.

- When selecting food-grade plastics, factors such as safety standards, material properties, and intended applications must be considered; HDPE and polypropylene are often preferred due to their durability and chemical resistance.

What is Acrylic?

Acrylic, also known as polymethyl methacrylate (PMMA), is a type of plastic that is celebrated for its outstanding clarity and strength. Often used as a lightweight and shatter-resistant alternative to glass, acrylic offers a range of benefits that make it suitable for various applications, from household items to industrial uses.

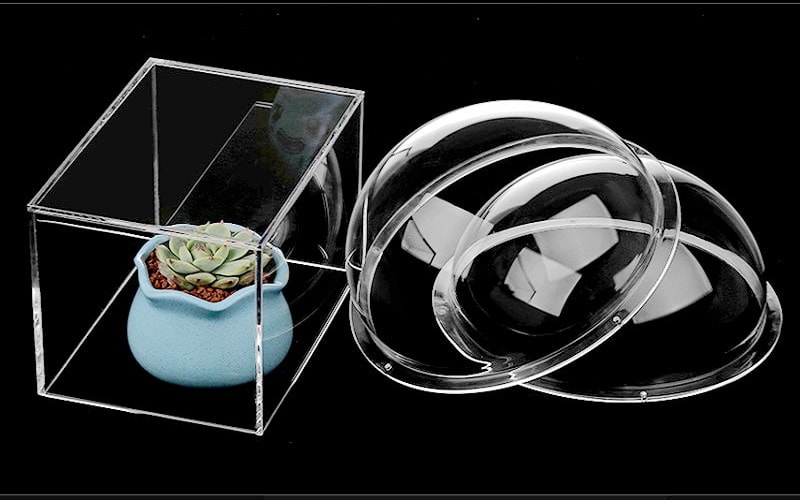

Its versatility is underscored by its common usage in products like display cases, aquariums, and kitchenware. Its transparency and durability make acrylic a preferred choice where visibility and strength are needed.

Common Uses of Acrylic

Acrylic’s adaptability is evident in its widespread use across different sectors. For instance, it is frequently employed to create display cases that not only protect items but also allow customers to view them clearly. This makes acrylic an ideal material for retail environments where product visibility is crucial.

Another popular application is in aquariums. Acrylic provides a clear view of aquatic life while being less prone to breakage compared to glass.

In the kitchen, acrylic is used for various utensils and storage containers, offering the dual benefits of being lightweight and transparent.

Is Acrylic Food Safe?

The safety of acrylic in food contact applications is a common concern. Acrylic, particularly PMMA, is recognized as safe for food contact when it adheres to FDA guidelines. This means that, under normal usage conditions, acrylic does not leach harmful chemicals into food, making it a viable option for food storage and presentation.

However, there are specific conditions and standards that acrylic must meet to be considered safe for food contact. These include limitations on heat exposure and the types of foods stored in acrylic containers. Understanding these standards is crucial for ensuring food safety.

FDA Compliance of Acrylic

FDA compliance requires acrylic to be made with FDA compliant approved processes and materials that don’t leach harmful substances into food. At least 50% of the polymer units in acrylic must come from approved monomers to meet this requirement.

Acrylic materials for food contact must be free of harmful additives and meet specific FDA conditions. Such compliance allows acrylic to be safely used in food contact applications and food contact application like storage containers and food displays.

Heat Resistance and Acrylic

Heat resistance is a crucial factor in evaluating acrylic’s suitability for heat resistant food contact applications. Unlike some other plastics, acrylic has limited heat resistance and can warp or melt when exposed to high temperatures. Therefore, it should not be used in microwaves or dishwashers.

Prolonged sunlight exposure can cause acrylic to degrade, possibly resulting in chemical leaching. Therefore, it is essential to use acrylic containers in ways that avoid high heat and direct sunlight to maintain their safety and structural integrity.

Potential Risks of Using Acrylic

While acrylic is popular for food contact applications, it is not without risks. One of the primary concerns is the potential for chemical leaching, especially when storing acidic foods. Using food safe plastic containers labeled as food-safe can help mitigate this risk.

Another risk is the use of polycarbonate plastics, often confused with acrylic, which may contain BPA—a chemical associated with health concerns. Adhering to safety standards and best practices for cleaning and maintaining acrylic items minimizes these risks.

Comparing Acrylic with Other Food Grade Plastics

Comparing the properties of different food-grade plastics is essential. Acrylic is often chosen for its transparency, durability, and visual appeal. However, other plastics like polypropylene and HDPE offer different benefits that can be more suitable for certain applications.

Knowing the strengths and weaknesses of each material helps consumers choose the right plastic for their needs.

Acrylic vs. Polypropylene

Polypropylene is favored for its heat resistance and chemical safety, making it ideal for food storage. Polypropylene can withstand higher temperatures than acrylic, making it dishwasher safe and microwave safe.

However, acrylic offers superior visual clarity and is often used in applications where appearance is important, such as display cases and food containers for serving. Choosing between acrylic and polypropylene depends on the intended use and specific needs.

Acrylic vs. HDPE

High-Density Polyethylene (HDPE) is notable for its chemical resistance and durability, making it excellent for food storage.

HDPE is less prone to scratching and breaking compared to acrylic, which can be a significant advantage in heavy-duty applications.

Although both are food-safe, HDPE’s higher chemical resistance makes it better for storing a wider variety of foods. Acrylic, on the other hand, is often chosen for its clarity and impact resistance in more delicate applications.

Acrylic vs. Polycarbonate

Polycarbonate provides superior clarity and strength compared to acrylic, making it ideal for applications needing visibility and durability.

It is known for its exceptional toughness and shatter resistance, which reduces the likelihood of cracking under stress.

However, BPA leaching concerns make acrylic a safer alternative for food contact applications. The decision between using acrylic or polycarbonate will depend on the balance between the need for strength and the importance of avoiding BPA-related health risks.

Best Practices for Using Acrylic in Food Contact Applications

Following best practices for cleaning and maintenance ensures the safe use of acrylic in food contact applications. Proper handling and storage extend the lifespan of acrylic items and keep them safe for food use.

This section will provide practical tips on how to clean and store acrylic containers to maintain their quality and safety.

Cleaning and Maintenance

Using mild soap and water to clean acrylic items helps avoid scratches and maintain clarity. Avoid harsh chemicals or abrasive materials to prevent surface damage. Ammonia-based cleaners can cause cloudiness and should be avoided on acrylic.

Store acrylic containers in a cool, dry place to prolong their lifespan and maintain quality.

Storing Foods in Acrylic Containers

Avoid storing high-fat or strongly pigmented foods in acrylic containers to prevent staining or deterioration.

Acrylic containers are valued for their durability and ease of cleaning, making them a practical choice for food storage, unlike plastic containers.

Adhering to best storage practices, such as avoiding extreme heat and proper cleaning, ensures the quality and safety of foods in acrylic containers.

Choosing the Right Food Grade Plastic for Your Needs

Choosing the right food-grade plastic depends on factors such as material properties, safety standards, and intended use. Evaluating these factors helps make informed choices about food safe plastics for food contact applications.

Knowing the strengths and weaknesses of different materials ensures the chosen plastic meets application needs.

Factors to Consider

Consider physical and thermal properties, safety standards, and cleaning durability when choosing plastics for food contact applications. HDPE is preferred for its ease of customization into food-safe grades and chemical resistance.

Consumer perception and the intended use of the plastic are also important considerations. Meeting all necessary safety standards is crucial for maintaining food safety and quality.

Popular Choices for Specific Applications

HDPE and polypropylene are popular for food storage due to their durability and safety profiles. HDPE’s lightweight, strength, and chemical resistance make it ideal for food packaging and storage. It is commonly used for milk containers and other heavy-duty hdpe food safe storage applications.

Polypropylene is often chosen for food storage due to its heat and chemical resistant properties. Its durability and safety make it suitable for various applications, such as food containers and cooking utensils.

Summary

Summarizing the key points, acrylic is a versatile and visually appealing material that is safe for food contact when used correctly.

However, its limitations in heat resistance and potential chemical leaching must be considered. Comparing acrylic with other food-grade plastics like polypropylene, HDPE, and polycarbonate helps consumers make informed decisions based on their specific needs.

Choosing the right material involves understanding the properties, safety standards, and best practices for each type of plastic. This guide provides a comprehensive overview to help you make the best choice for your food contact applications.

Frequently Asked Questions

Is acrylic safe for food contact?

Acrylic is safe for food contact if it complies with FDA guidelines. Therefore, it is important to ensure that the specific acrylic product you are using adheres to these standards.

Can acrylic be used in the microwave?

Acrylic should not be used in the microwave as it has low heat resistance and can warp or release harmful chemicals. For safe microwave use, opt for microwave-safe glass or ceramic alternatives.

How do I clean acrylic food containers?

To effectively clean acrylic food containers, use a mixture of mild soap and water while steering clear of abrasive materials and ammonia-based cleaners. This approach will help maintain the clarity and integrity of the containers.

What are the alternatives to acrylic for food storage?

Food-grade plastics such as HDPE (High-Density Polyethylene) and polypropylene serve as excellent alternatives to acrylic for food storage due to their durability and chemical resistance. Consider using these materials to ensure safe and effective food preservation.

Are there any risks associated with using acrylic for food storage?

Yes, there are risks associated with using acrylic for food storage, primarily due to potential chemical leaching if not used properly. It is essential to adhere to safety guidelines to mitigate these risks.