With the widespread use of plastics, there are growing concerns about their safety, especially their impact on human health and the environment.

In 3D printing, for example, the choice of material not only affects the quality of the print, but is also directly related to health and environmental safety.

Next, we’ll take a closer look at the properties of ASA and its potential impacts to help you understand whether this material is reliable for productive life.

What Is ASA? Composition and Properties

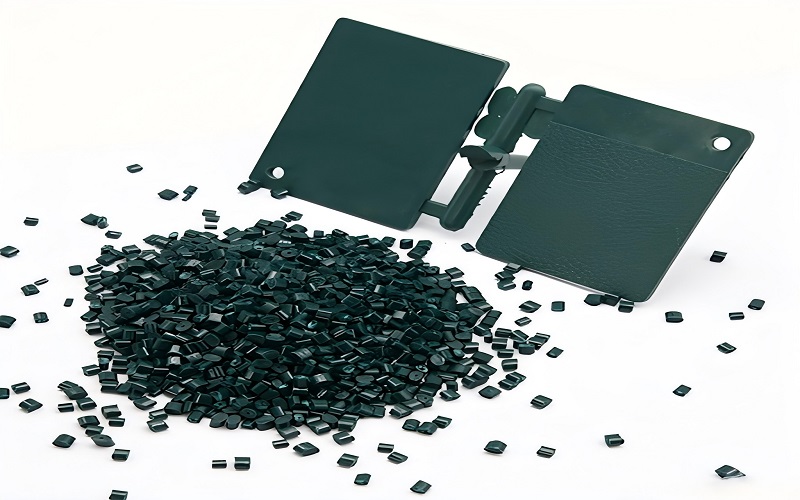

ASA is actually not that complicated. It is a thermoplastic composed of three components: acrylonitrile, styrene and acrylic rubber.

This combination gives ASA many unique advantages: UV resistance, good weather resistance and strong chemical resistance, so it is particularly suitable for outdoor use.

For example, ASA is often used in automotive parts, gardening tools and outdoor signs.

Unlike ABS, which is easy to age and turn yellow in the sun, ASA can better withstand the sun and various bad weather.

Key Properties of ASA

Main properties of ASA plastics:

| Property | Specific Value |

| Tensile Strength | 40-55 MPa |

| Flexural Strength | 60-80 MPa |

| Impact Strength (Notched Izod) | 10-20 kJ/m² |

| Vicat Softening Temperature | 95-105°C |

| Melting Temperature | 210-240°C |

| Heat Deflection Temperature (1.8 MPa) | 85-100°C |

| Water Absorption | 0.3-0.5% |

| Density | 1.05-1.10g/cm³ |

Applications of ASA in Industry

ASA (Acrylonitrile-Styrene-Acrylate) is widely used in the following fields due to its durability and UV resistance:

- Automotive industry: used to manufacture automotive exterior parts such as bumpers and trims.

- Construction: used to make roofing materials, window frames and exterior wall decorations.

- Gardening: used to produce durable gardening tools and flower pots.

- Electronic devices: used in housings to provide protection.

- Consumer goods: used in household appliance housings and toys.

- 3D printing: used as a printing material that is resistant to high temperatures and weathering.

Health Risks: Is ASA Plastic 3D Printing Safe?

So, is ASA 3D printing safe? It actually depends on the environment in which it is used, especially the ventilation conditions. When printing, ASA will release some volatile organic compounds (VOCs) and ultrafine particles (UFPs). If ventilation is not good, it may bring some health risks.

1.Volatile organic compounds (VOCs): When printing ASA, some VOCs are produced, mainly styrene and acrylonitrile. Styrene has a strong odor, and long-term exposure may cause headaches, respiratory irritation, and even affect the nervous system. Acrylonitrile is more important because it is a possible carcinogen that irritates the skin and respiratory system, and long-term exposure may cause damage to the liver and lungs.

2.Ultrafine particles (UFPs): UFPs are very small particles that can penetrate deep into the lungs and even enter the bloodstream. Although research on UFPs is still ongoing, there is evidence that these particles may aggravate respiratory problems and pose long-term health risks.

Long-term exposure to VOCs and UFPs, especially in unventilated environments, will gradually increase health risks over time.

Safety Precautions: How to Print ASA Safely?

If you want to safely use ASA printing, just take a few simple precautions.

Maintain ventilation: Make sure your workspace is well ventilated by opening windows and using fans.

Use a closed printer: A closed 3D printer can better control and manage harmful gases that may be emitted.

Wear personal protective equipment (PPE): If you are printing in a less than ideal environment, wear a mask and gloves when handling ASA prints to give yourself an extra layer of protection.

Monitor air quality: Consider using an air quality monitor to keep an eye on harmful substances in the air. This is especially important if you print frequently or are in public spaces.

By paying attention to these simple things, you can feel more at ease when using ASA printing.

Is ASA Safe in Food Contact Applications?

Using ASA to 3D print kitchenware may sound good, but it is not suitable for direct contact with food. The main reasons are:

ASA contains some chemical components that may migrate into food, especially when heated or encounter acidic foods.

In addition, the printed surface may have tiny scratches or dents, which are easy to harbor dirt and bacteria, and become unhygienic over time.

If you want to print items that come into contact with food, it is best to choose 3D printing materials marked as food safe. For example, some PETG materials have passed food contact certification, which is a better choice.

In general, if it is used occasionally to hold food and for short-term contact, it may be okay, but if it is used for long-term use, it is recommended to choose materials that have passed food safety certification to ensure that it is safe to use.

Fire Safety: Is ASA Flammable?

ASA is a thermoplastic that is generally safe for everyday use, but it does have some flammability.

While ASA itself will not spontaneously combust, it may burn in high temperatures, especially near an open flame, and release toxic fumes, such as styrene and acrylonitrile, which can be harmful to the respiratory system.

Overall, while ASA is not particularly flammable, be sure to maintain good ventilation when using ASA, especially in enclosed spaces, and try to avoid placing ASA near heat sources.

Environmental Impact: Is ASA Eco-Friendly?

ASA’s environmental impact is less than ideal. First, ASA is not biodegradable, which means it can stay in landfills for a long time, which will add to the problem of plastic pollution. Although its durability allows products to last longer and reduce the trouble of frequent replacement, once these products reach the end of their life, they have to be thrown away and become garbage.

In addition, recycling ASA is more troublesome. Not every recycling station has the ability to handle this material, which makes our waste disposal more complicated.

In contrast, some biodegradable materials, such as PLA, are much better. Although it is not as durable as ASA, it can decompose in the natural environment and is more environmentally friendly.

ASA vs. Alternatives: Finding the Right Material for Your Project

Here is a summary of the pros and cons of ASA alternatives:

- ABS: cheap and easy to print, but poor weather resistance and easy to fade.

- PETG: strong and impact-resistant, releases less harmful fumes, but prints at a higher temperature.

- PLA: environmentally friendly and easy to print, but does not perform well in hot or humid environments.

- TPU: flexible and wear-resistant, but requires specific settings for printing.

- ASA+: better performance and stability, but may be more expensive.

Based on these characteristics, you can choose the most suitable material.

Final Thoughts: Is ASA Safe to Use?

So, is ASA safe? The answer is yes!

For most ordinary users, ASA is widely used in daily life, especially in outdoor furniture, car parts, gardening tools and toys. These products can still maintain good performance under the erosion of sunlight and rain, so ASA can be regarded as a relatively safe material.

However, if you often print or work in a closed space, you still need to be more careful and ensure good ventilation.

If you are interested in ASA plastics, please contact us and we will provide you with more services!