When choosing a material, the most important thing is safety.

Delrin, also known as polyoxymethylene (POM-H), is often used in many industrial projects because of its durability.

But many people ask: Is Delrin safe? Especially when it is used in food contact, medical equipment or precision parts, it is more important to know whether it is safe.

In this article, we will briefly introduce the characteristics of Delrin, its safety in food, whether there are health risks, and compare it with other materials. I hope that through this article, you can clearly judge whether Delrin is suitable for your project.

Why Is Delrin So Popular?

Delrin is a very strong plastic, scientifically known as polyoxymethylene (POM), which comes in two types: homopolymer (POM-H) and copolymer (POM-C).

Its biggest advantages are high strength, wear resistance, stability under heavy loads, and resistance to deformation.

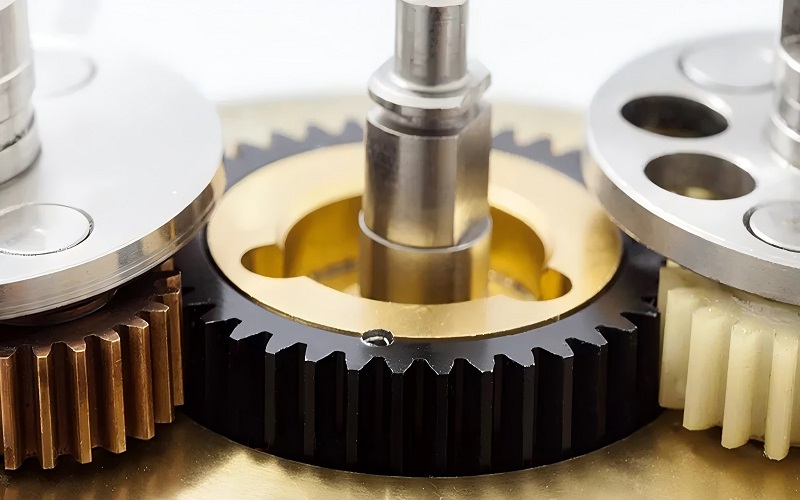

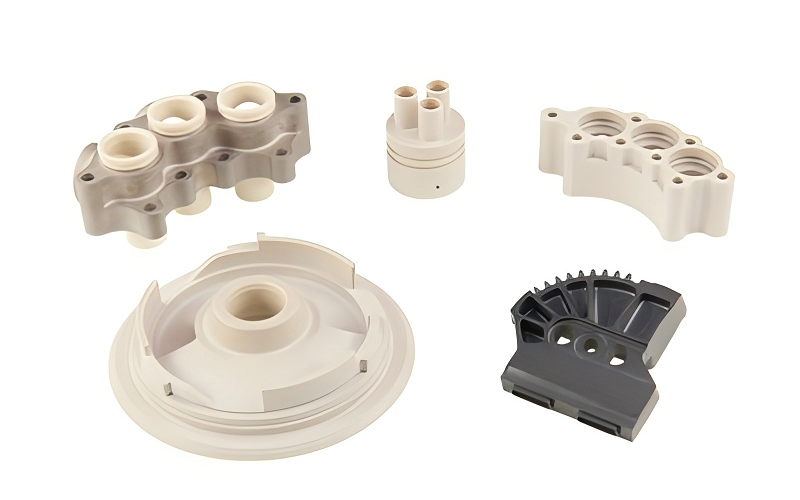

Because of its low friction, it is suitable for gears, bearings, automotive parts, and medical devices. It is also resistant to chemical corrosion and has good electrical insulation, making it suitable for complex engineering projects.

However, Delrin’s performance may be affected in particularly humid or acidic environments.

Properties of Delrin:

Here are the ten most important properties of Delrin:

| Property | Value | Unit |

| Density | 1.41 | g/cm³ |

| Melting Point | 175 | °C |

| Tensile Strength | 70-100 | MPa |

| Tensile Modulus | 3000-3500 | MPa |

| Elongation at Break | 20-40 | % |

| Flexural Strength | 90-120 | MPa |

| Impact Strength (Unnotched) | 80-130 | kJ/m² |

| Heat Deflection Temperature (1.82 MPa) | 110-120 | °C |

| Coefficient of Friction | 0.10-0.25 | – |

| Hardness (Shore D) | 85-90 | – |

How Strong and Durable Is Delrin?

Delrin is very strong and durable, which is one of the reasons why it is widely used. It has a high tensile strength and can withstand a lot of pressure without breaking easily, which makes it particularly suitable for heavy-duty parts such as automotive parts and industrial machinery.

In addition to its strength, Delrin is also very wear-resistant, especially in parts that need to move frequently, such as gears and bearings.

Because it has low friction and less wear, parts made of Delrin generally have a longer life and do not need to be replaced frequently.

In addition, Delrin can remain stable in extreme temperatures. Whether it is a cold -40°C or a hot 120°C, it can work normally without bending or losing strength.

Overall, Delrin’s strength, durability, and versatility make it a good choice for many projects that require high strength and long-term use.

What About Chemical Resistance?

Delrin has very good chemical resistance.

It can withstand many common chemicals, such as fuel, fat, alcohol, and some weak acids and weak bases. This makes it good in places such as cars, industrial machinery, and electronic devices that are regularly exposed to various chemicals. It is important to maintain stable performance.

However, when it encounters particularly strong chemicals, such as strong acids and strong bases, Delrin may be less durable.

Especially in a humid environment or with prolonged exposure to these chemicals, their chemical resistance can be compromised. So if you are planning to use delrin in these harsh chemical environments, it is best to inquire in advance about the specific conditions of use.

Overall, Delrin’s chemical resistance is reliable for most daily USES, but you should always be careful in extreme chemical environments.

Delrin’s Safety in Different Applications

Delrin is widely used in the food and medical fields, mainly because it is safe and reliable.

Delrin in Food Contact

In the food industry, Delrin is often used to make gears and parts in processing equipment. It has passed the US FDA’s food contact safety certification, which means that it will not release harmful substances into food, so it is safe to use in food processing.

Delrin in Medicine

Delrin is also popular in medical devices. It is used in surgical tools, dental equipment, and other medical devices because it is durable and harmless to the human body and will not cause adverse reactions. Delrin is not only strong, but also maintains stable performance when used in complex medical equipment.

Delrin in Electronics and ESD-Sensitive

Delrin is relatively safe in electronic and electrostatically sensitive (ESD) areas. It blocks current and is not easy to conduct electricity, so it is widely used in electronic devices, such as insulating parts and connectors.

Even better, Delrin can also be made into an anti-static version, which can prevent static electricity from damaging sensitive electronic components. Therefore, Delrin is a good choice in some places where static electricity needs to be avoided.

However, it should be noted that Delrin’s performance may be affected in extremely hot or humid environments. So when choosing a material, it is best to consider the actual use environment.

In general, as long as it is used properly, Delrin is reliable in electronic and ESD-sensitive areas and can protect electronic components.

Delrin vs. Other Engineering Plastics: Why Choose It?

Delrin is a great choice when it comes to engineering plastics. Compared to POM-C, nylon, and ABS, Delrin has some special advantages.

First, Delrin is stronger and more wear-resistant than POM-C, making it suitable for places that bear heavy loads. In addition, Delrin has a low coefficient of friction, which makes it particularly good for use in gears and bearings.

As for Nylon, Delrin performs better in wet environments. It does not absorb water like nylon and remains stable. At the same time, Delrin is resistant to many chemicals, making it particularly suitable for automobiles and industrial equipment.

Although Delrin may cost more than ABS, because it is durable, long-term use can save money on repairs and replacements. For example, many automakers use Delrin in engine parts because it performs well under high temperatures and pressures. In addition, in medical equipment, Delrin is an ideal choice because it is non-toxic.

In short, Delrin is often the material of choice for engineers because of its durability and wide range of applications.

Watch Out for Environmental Stress Cracking (ESC)

Although Delrin is very resistant to wear, there is one problem to watch out for: environmental stress cracking (ESC).

In simple terms, ESC is a phenomenon in which cracks can occur when the material is subjected simultaneously to chemical and mechanical stresses, which can eventually cause material failure. Delrin has good resistance to ESC and is generally stronger than some other plastics, such as HDPE or LDPE.

However, that doesn’t mean it’s safe in all environments. Especially when Delrin is exposed simultaneously to aggressive chemicals and stress, such as strong acids and strong oxidants, you should always be careful.

In order to reduce the risk of ESC, it is recommended to take a few simple steps when using Delrin:

- Avoid exposure to strong acids or aggressive chemicals.

- Designed to avoid tension concentrations as much as possible and to optimize the shape of the parts.

- If use in a hostile environment is really necessary, the use of a pom-c copolymer may be considered, which in some cases may be more resistant to cracking under ambient stress.

Overall, Delrin is a durable material that still has to pay attention to environmental stress cracking during its use, especially when it has to be subjected to additional pressure or chemicals. This will help ensure that Delrin continues to function well and safely in various applications.

Conclusion: Is Delrin Safe for Your Project?

Delrin is a very safe material, especially for the manufacture of mechanical parts, automotive parts, electronics, and medical devices.

It is strong and not easy to break. In addition, it resists many chemicals and high temperatures, making it very reliable to use. Therefore, it is used by many industries and can even be found in food processing.

However, like any material, Delrin has its limitations. For example, it is not suitable for use with strong acids, strong oxidants, or in applications requiring antistatic properties.

Overall, Delrin is a versatile and safe material. In most cases, it can be used safely without worrying about problems.