If you’ve ever worn sports shoes, used a yoga mat, or bought toys for your children, you’ve probably been in contact with a material called EVA.

EVA stands for ethylene vinyl acetate; it is lightweight, soft, and shock absorbent, so it is often used in sports goods, household products, and toys.

However, many people are also worried: is this plastic safe?

This article will help you answer this question. We will briefly present the composition of EVA, the areas where it is commonly used, the health risks it may present, the relevant safety regulations, and its impact on the environment.

The Basics of EVA Plastic

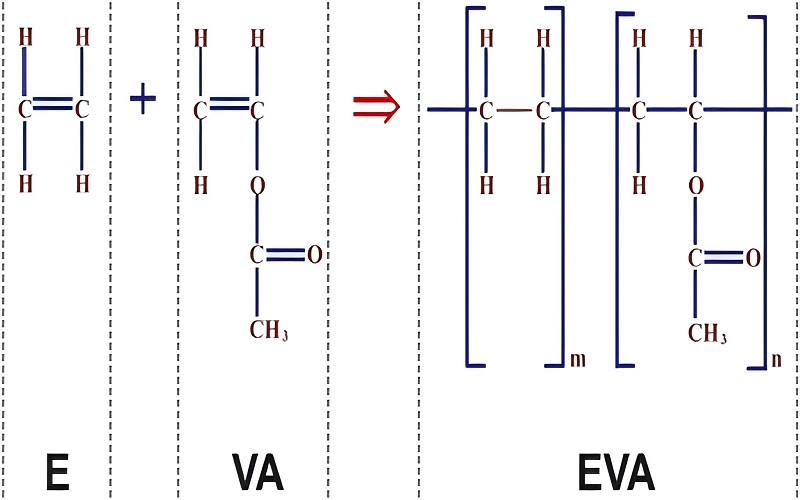

EVA is a plastic material; its full name is ethylene vinyl acetate, which is synthesized by a special chemical reaction between two main components: ethylene and vinyl acetate.

It is an extremely elastic material that can be processed like other thermoplastics.

This material has low temperature toughness, resistance to stress cracking, and resistance to UV radiation.

Key Properties of EVA

EVA plastic has many key properties. Here are some of the main features of EVA:

- Flexibility and durability: EVA can be easily molded into various shapes, and it feels soft and durable.

- Shock absorption: EVA can absorb shock well.

- Waterproofness: EVA is waterproof and does not absorb water.

- Wear resistance: EVA has strong wear resistance and is not easy to damage.

- Good processability: EVA can be made into products of different shapes and sizes through a variety of processing methods, including injection molding, extrusion, hot pressing, etc., which is convenient for manufacturing various personalized products.

Common Applications of EVA

EVA plastic is suitable for many common products in our daily life because it is light, comfortable, safe and durable:

- Shoes

- Toys

- Sports equipment

- Packaging materials

- Building materials

- Automobiles

- Medical supplies

- Household items

EVA Production in Injection Molding

Different EVA production methods result in different final product forms. EVA plastic is made by mixing ethylene and vinyl acetate under high temperature and high pressure and then extruding or injection molding; EVA foam is made by adding a foaming agent to the plastic and heating it to form foam. During the production process, the temperature, pressure, raw material quality and the use of foaming agents need to be strictly controlled to ensure that chemical residues are within a safe range.

During the EVA injection molding process, the EVA material first changes from solid to liquid and then is molded into the desired plastic part by cooling.

This process usually needs to be carried out at a temperature between 180°C and 230°C. Too high a temperature may cause material degradation, while too low a temperature will affect fluidity, which in turn affects the molding quality.

In addition, if the EVA raw material contains moisture, bubbles or cracks may occur during injection molding, so it is necessary to ensure that the raw material is completely dry.

Is EVA Plastic Safe? Potential Health Concerns

EVA plastic is generally very safe, but during the production process, some chemicals may have some impact on health, such as:

1.Formamide

Formamide is used to make EVA softer, which can make the material more elastic. Contact with formamide may cause skin allergies or breathing discomfort.

2. Acetophenone

Acetophenone may also be produced during the production of EVA. Although its content is very low and its toxicity is not high, long-term contact will also cause skin or respiratory discomfort.

3. Other chemicals

In addition to formamide and acetophenone, EVA may also contain some other chemical ingredients, such as stabilizers, plasticizers, etc. Usually, the content of these ingredients in products produced by regular manufacturers is very low and will not cause much impact on health.

In general, as long as the EVA products you choose meet the relevant safety regulations, they pose little risk to health, so don’t worry too much.

Regulatory Measures Ensuring EVA Plastic Safety

EVA plastics are subject to regulations that ensure that the products are safe for consumers, especially children and people with health problems.

EU REACH Regulation

In the EU, REACH requires manufacturers to ensure that their products do not contain harmful chemicals. For example, REACH regulates the amount of formalin used in children’s toys with the goal of reducing health risks.

U.S. Consumer Product Safety Commission (CPSC)

In the United States, the CPSC sets safety standards for children’s products, including EVA plastic toys. EVA products must undergo rigorous testing to ensure that they do not release harmful chemicals, even after long-term use.

Safety Certification and Labeling

In addition to regulatory requirements, some manufacturers also add safety certification labels to their products, such as OEKO-TEX or CE marks, to further ensure the safety of EVA plastic products.

EVA in Children’s Toys

EVA is considered a safer material for children’s toys.

It is non-toxic and does not contain harmful chemicals such as phthalates and heavy metals, which is much better than many common plastics.

In addition, EVA material is soft and comfortable, making it very suitable for children’s toys, cushions, or puzzles. Its softness can effectively reduce the impact force and reduce the risk of children falling or getting injured while playing.

EVA is also not easy to absorb water and has a smooth surface, which is easy to clean, which is especially important for children because they often put toys in their mouths or touch them with their hands.

EVA in the Medical Field

EVA is widely used in the medical field, such as infusion bags, catheters, medical hoses, disposable surgical equipment, blood bags and drug delivery devices.

The reason why EVA is popular in the medical field is that it does not cause adverse reactions when it comes into contact with human tissues or body fluids, has good biocompatibility, and meets medical-grade standards.

Secondly, EVA does not contain harmful plasticizers, such as phthalates, which avoids possible health risks.

Furthermore, EVA can be easily treated by conventional sterilization methods such as gamma rays, ethylene oxide or high-pressure steam without losing its performance, so it is particularly suitable for disposable medical supplies.

Finally, EVA is also very durable, has strong chemical resistance, low water absorption, stable temperature, and can work reliably under various conditions, reducing the risk of equipment failure or contamination.

Environmental Impact: Is EVA Eco-Friendly?

EVA does not contain toxic chemicals, such as phthalates and heavy metals. Compared with some plastics (such as PVC), it does not release harmful hydrogen chloride gas when burned, and it also pollutes the air less.

Therefore, EVA is considered to be more environmentally friendly than some traditional plastics.

But its main problem is that it is not completely degradable. In the natural environment, EVA will not decompose like some bioplastics and may form microplastics that exist for a long time, posing a potential threat to the ecosystem.

Although EVA can be recycled, recycling is not popular enough at present, and most EVA waste will eventually be incinerated or landfilled. Incineration and landfilling not only occupy land but also may pollute the environment.

Final Thoughts: Is EVA Safe?

In general, EVA plastic is safe in most cases, as long as it comes from a regular manufacturer and meets safety standards.

Although EVA is not easy to recycle, there are some environmentally friendly alternatives being developed, and everyone can choose a more environmentally friendly product.

If you want to learn more about EVA, welcome to visit our company’s website.

FAQs

1.Does EVA have any Smell?

Generally, good EVA products have no smell. If there is a particularly strong smell, it is probably a quality problem and it is best not to use it.

2. Does EVA Cause Allergies?

EVA is very skin-friendly and not easy to cause allergies. Many products, such as baby mats and hospital supplies, use it.

3. Can EVA be Used Outdoors?

Yes, EVA is a very durable material and is not afraid of the sun. It is often used in things like sandals and sports mats.

4. Is EVA Afraid of High and Low Temperatures?

No. EVA can withstand both high and low temperatures, but they have different properties. Generally speaking, EVA is easy to age at high temperatures, but at low temperatures it can maintain its elasticity and is not easy to break.

EVA performance in high and low temperatures:

| Aspect | High Temperature | Low Temperature |

| Shape Stability | Softens above 90°C, loses shape | Maintains shape, no hardening |

| Flexibility | Increased flexibility, less durable | Retains flexibility, impact-resistant |

| Aging | Accelerated aging (hardening, cracks) | Minimal aging, stable properties |

5.How Long does EVA Last?

The service life of EVA is generally 3-10 years, but in actual use, it is affected by factors such as UV rays, ambient temperature and humidity.