When you think of plastic, you might picture a stiff water bottle or a rigid storage bin. When you think of nylon, you likely imagine a lightweight jacket or nylon stockings.

This leads to a fundamental question often debated in the textile industry: Is nylon made of plastic?

The short, technical answer is yes. Nylon is a man-made, polymer-based material derived from petroleum. It is classified as a synthetic thermoplastic polyamide (PA) known for high tensile strength, wear resistance, and a low friction coefficient.

However, unlike common plastics, nylon is uniquely engineered to be pulled into thin nylon fibers or molded into high-strength engineering plastic components.

In this comprehensive guide, we will dive deep into the nylon production process, its historical roots in World War II, and why its thermal stability makes it a favorite in numerous industries.

The Chemical Foundation: What Makes Nylon?

To understand if nylon is plastic, we must look at its polymer chain. Nylon is a family of synthetic polymers characterized by amide linkages, typically connecting aliphatic or semi-aromatic groups. It belongs to a group of synthetic polymers known as polyamides.

The Composition and Polymerization

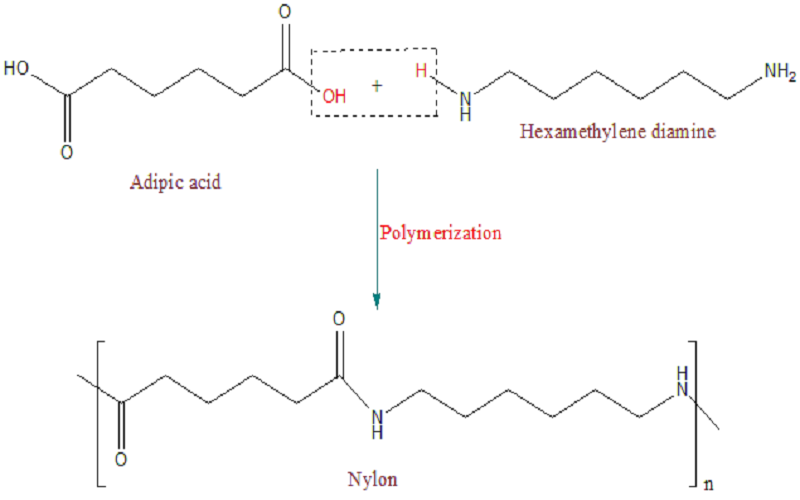

Nylon is produced from polyamide monomers extracted from crude oil, making it a synthetic plastic. The manufacturing process typically involves a reaction between two types of polyamide monomers: adipic acid (a dicarboxylic acid) and diamine acid.

Nylon Salt: Nylon is produced through a chemical reaction between diamine and dicarboxylic acid, resulting in a polymer known as nylon salt.

The Reaction: Specifically, Nylon 6,6 is produced by mixing hexamethylenediamine with adipic acid, resulting in a crystallized polymer that is then heated to form nylon.

Polymerization: The production involves a process called polymerization, where monomers are combined to form long chains of nylon.

The Birth of Nylon

Nylon was invented by Wallace Carothers at DuPont in the early 1930s and publicly announced in 1938.

The first nylon, nylon 66, was synthesized on February 28, 1935.

Built from carbon-based molecules and long-chain polymer molecules, it became one of the earliest successful synthetic fibers.

Marketed as the world’s nylon, it was called a “miracle fiber”—as strong as steel yet as fine as a spider’s web—though its production involved handling several toxic chemicals.

Commercial Development of Nylon in World War II

Before World War II, the world relied heavily on silk imports from Asia. When the war disrupted these supply lines, the United States needed a replacement.

During World War II, nylon was primarily used for military applications, including parachutes and ropes. It was also used in flak jackets and tire cords.

Post-war, the fashion industry exploded. Nylon was showcased at the 1939 New York World’s Fair, where it was marketed as a replacement for silk in women’s stockings.

The result was legendary: Nylon stockings became an instant commercial success, with 64 million pairs sold in their first year on the market after being released in 1940.

Interestingly, the name ‘nylon’ was derived from a modification of the term ‘no-run’, intended to market the fabric’s resistance to runs.

Why Nylon is an Engineering Powerhouse?

Nylon isn’t just for synthetic fabrics. In the world of engineering design, it is a high-performance engineering plastic that delivers exceptional mechanical properties.

Thermal Stability: Nylon materials demonstrate excellent thermal stability with continuous use temperatures of 80-110°C for PA6 and 120-140°C for PA66. It has a high melting point, typically between 220°C and 260°C.

Strength: Nylon exhibits excellent tensile strength, high torsional strength, and exceptional stiffness, making it ideal for precision mechanical components. Furthermore, nylon can be blended with additives to significantly increase its strength and stiffness.

Friction and Wear: Nylon has a low coefficient of friction, making it suitable for moving parts like gears and bearings. It is also known for its excellent wear resistance and durability.

Chemical Resistance: Nylon is resistant to oils, fuels, and many solvents, but can be attacked by strong acids.

Good Electrical Insulator: It has good electrical integrity, and is one of the commonly used electrical integrity materials in the plastics process, which has excellent performance under dry conditions.

Types of Nylon and Their Industrial Applications

Nylon polymers are classified based on their molecular structure and monomer composition, with common types including PA6 and PA66.

Versatility Across Industries Nylon is used in a variety of applications including textiles, automotive components, and food packaging films.

Automotive: Nylon is widely used in the automobile industry, especially in the engine compartment, due to its durability and heat resistance. High-grade nylon resins are molded into nylon parts that must survive a wide temperature range.

Consumer Goods: Nylon is used in the production of a wide range of consumer goods, including toothbrushes, machine screws, hair combs, and food packaging. Note that the first commercial use of nylon was in a nylon-bristled toothbrush developed in 1938.

Fashion and Sports: Nylon is often used in sportswear for its elasticity and lightness, despite its moisture-wicking properties being inferior to other fabrics. It is also less absorbent than cotton, which can lead to discomfort in hot or humid conditions.

Environmental Impact and Sustainability

While nylon’s versatility is unmatched, its footprint is a significant concern. Nylon is derived from petrochemicals or crude oil extracts, making its production environmentally harmful.

Pollution and Waste

Climate Change: The production of nylon releases nitrous oxide, a greenhouse gas that is 300 times more potent than carbon dioxide.

Energy and Waste: The production of nylon fabric is an energy intensive process and generates significant nylon waste, contributing to environmental pollution.

Microplastics: Nylon releases microplastics into the environment, which can enter the food chain and potentially harm human health.

Marine Life: Nylon waste contributes to ocean pollution, particularly through discarded fishing nets, which harm marine life. Nylon is not biodegradable and can take hundreds of years to decompose.

Recycled Nylon

To combat this, the industry is turning to recycled nylon made from used fishing nets and textile scraps. This reduces the reliance on virgin crude oil and helps clear the oceans of discarded fishing nets.

How is Nylon Fabric Made?

To turn a thermoplastic polymer into nylon fabric, the molten substance must be processed through an extruder.

Extrusion: The molten nylon is extruded through a spinneret, which forms fibers that harden upon exposure to air. It passes through tiny holes to form the nylon fibre.

Drawing: The fibers produced from nylon are then drawn to increase their strength and elasticity before being wound onto spools. This creates a parallel structure in the polymer chain.

Blending: To reduce drawbacks and create mixed textiles, nylon is often blended with other fibers like cotton and polyester to enhance its properties.

Nylon vs. Other Materials

Nylon’s production process is more expensive than that of polyester, resulting in a higher price point for nylon products.

However, nylon is more durable and weather-resistant than polyester, making it suitable for outdoor apparel. Unlike brittle plastics, nylon offers the toughness required for demanding applications.

It is important to remember that nylon is hygroscopic and will absorb or desorb moisture as a function of the ambient humidity, affecting its dimensions and properties.

This is a key factor in material selection for engineering design.

Conclusion

Is nylon made of plastic? Undeniably. It is a specialized, high-performance thermoplastic polymer that has shaped numerous industries.

From the silk stockings replacement of the 1930s to modern automotive components and industrial machinery, nylon remains a miracle of chemistry.

While its energy intensive process and environmental impact remain challenges, the rise of recycled nylon offers a sustainable future for this popular fabric.

Whether in women’s fashion or industrial applications, nylon’s strength, thermal stability, and durability ensure it will remain a vital part of our world for years to come.