Nylon is not naturally UV resistant and can degrade when exposed to sunlight.

This article answers ‘is nylon UV resistant’ by exploring how UV radiation affects nylon, comparing it with other plastics, and discussing ways to enhance its UV resistance.

UV Resistance in Plastics

UV resistance in plastics refers to the material’s ability to withstand the damaging effects of ultraviolet light. UV light, a potent component of sunlight, can cause significant degradation in many plastics. Exposure to UV rays can lead to discoloration, loss of mechanical strength, and ultimately, structural failure.

This is particularly concerning for outdoor applications, where materials are constantly exposed to sunlight. Choosing UV-resistant plastics that are also resistant to UV helps maintain their appearance and functionality over time, improving UV resistance, preventing frequent replacements, and ensuring safety and reliability in outdoor applications, including plastic toys.

Not all plastics are created equal when it comes to UV resistance. Many degrade quickly without specific treatment, leading to brittleness and structural failure. For instance, common plastics like polyethylene and polypropylene can suffer significant damage under prolonged UV exposure due to their low UV resistance. This is where UV stabilizers come into play.

These additives, often including carbon black, preserve the physical properties of plastics despite prolonged sunlight exposure, acting as a shield against UV rays. UV stabilizers can be mixed into the base polymer during manufacturing to improve UV resistance significantly, alongside enhancing temperature resistance.

Selecting UV-resistant materials is not just about durability; it also leads to economic benefits by reducing maintenance costs. Whether it’s high-density polyethylene used for playground equipment or fluorinated ethylene propylene in chemical tank liners, UV-resistant plastics are essential for applications exposed to high-intensity UV radiation. Integrating UV stabilizers and protective layers allows manufacturers to produce materials that maintain functionality and durability.

How UV Radiation Affects Nylon

When it comes to UV radiation, nylon and nylons, despite their many benefits, fall short of being naturally resistant to UV-resistant properties. Exposure to UV radiation can generate free radicals within nylon, compromising its structural properties over time.

This degradation is particularly pronounced within the UV wavelengths range of 290 to 315 nanometers, where nylon is most sensitive. This sensitivity leads to both mechanical weakening and noticeable color fading, which can be detrimental in applications where appearance and strength are critical, such as with colored lenses.

Prolonged UV exposure can cause nylon parts to weaken and change color, an issue compounded by environmental conditions such as humidity and pollutants that accelerate degradation over a prolonged period. The once robust and resilient nylon, when subjected to continuous UV radiation, can quickly become brittle and lose its functional integrity. This accelerated degradation underscores the importance of enhancing UV resistance in nylon for outdoor applications, often achieved by incorporating carbon black pigments.

The effects of UV light on nylon are not just surface-level. Over extended periods, UV light can penetrate deeply into the material, causing internal damage that compromises the entire structure. The use of nylon with low melt viscosity can facilitate the addition of UV stabilizers during processing, further aiding in mitigation. Understanding the limitations of nylon in direct sunlight and finding mitigation strategies are essential to ensure the material remains reliable and durable in various environments.

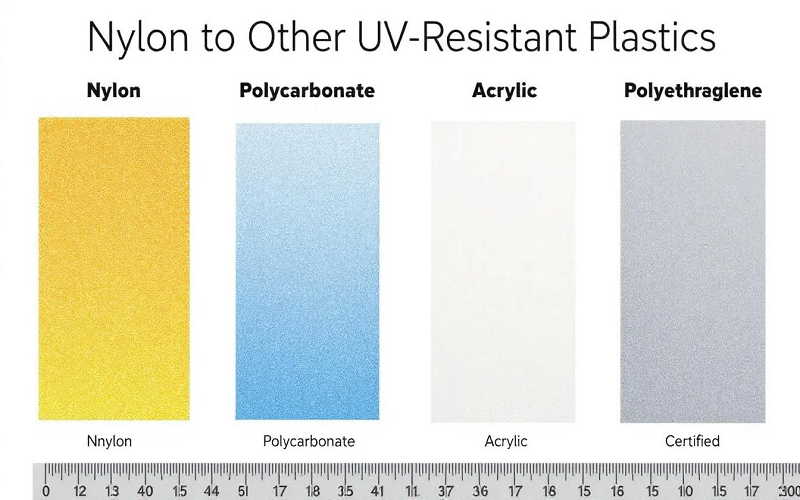

Comparing Nylon to Other UV-Resistant Plastics

Nylon, though versatile and widely used, is generally not considered UV-resistant, which limits its suitability for many outdoor applications. In contrast, other plastics exhibit much higher UV resistance, making them more reliable for prolonged outdoor use.

For instance, plastic products like acrylic are known for their clarity and durability. It experiences minimal degradation (about 3%) over a decade. This makes acrylic an excellent choice for outdoor signs and light fixtures.

Polycarbonate is another standout material, boasting durability and impact resistance that is 200 times stronger than glass. This makes it ideal for applications requiring both high UV resistance and mechanical strength, such as in protective barriers and outdoor shelters. High-Density Polyethylene (HDPE) is renowned for its durability and UV stability, often utilized in heavy duty products like playground equipment and outdoor furnishings. Its ability to withstand UV radiation without significant degradation ensures longevity and safety in these applications.

Polyamide-Imide (PAI), a hybrid of nylon and polyimide, offers excellent resistance to UV and chemicals, outperforming nylon in durability. This makes PAI suitable for demanding environments where both chemical and UV resistance are paramount. PTFE, on the other hand, is notable for its excellent flexibility and resistance to UV damage, making it advantageous for various outdoor applications.

Polyvinyl chloride (PVC), often enhanced with additives like titanium dioxide, also demonstrates superior UV resistance compared to nylon, making it a popular choice for outdoor piping and window frames. Comparing these materials to nylon highlights the need for enhancing nylon’s UV resistance to compete with these more durable options.

While nylon can be molded into various shapes and two forms, its natural UV resistance is significantly lower than these other plastics, including two plastics. By understanding the strengths and limitations of each material and using chemical techniques such as incorporating titanium oxide, one can make informed decisions about which plastic to use for specific outdoor applications, ensuring both performance and longevity through injection molding.

Enhancing UV Resistance in Nylon

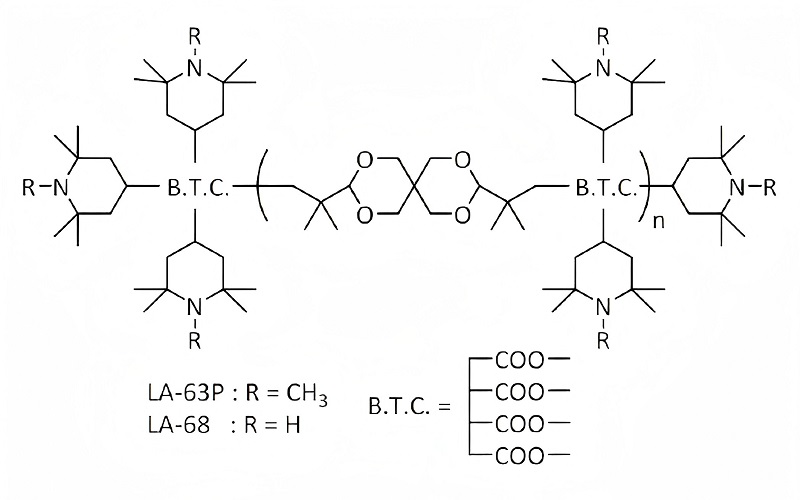

Various methods can enhance nylon’s UV resistance, with stabilizers being a particularly effective approach. These stabilizers help mitigate the harmful effects of free radicals generated by UV exposure in nylon. For example:

- Hindered amine light stabilizers (HALS) act as radical scavengers

- They interrupt the photo-oxidation cycle in nylon

- This process enhances nylon’s UV resistance

Benzophenone derivatives, as UV stabilizers, provide the following benefits:

- Convert harmful UV radiation into harmless heat, protecting the nylon.

- Products like EuroPlas Anti-UV Additive combine UV absorbers and antioxidants to significantly improve nylon’s resistance to UV degradation and absorb uv light.

- Incorporating various additives and uv resistant additives during the manufacturing process greatly enhances nylon’s longevity and durability.

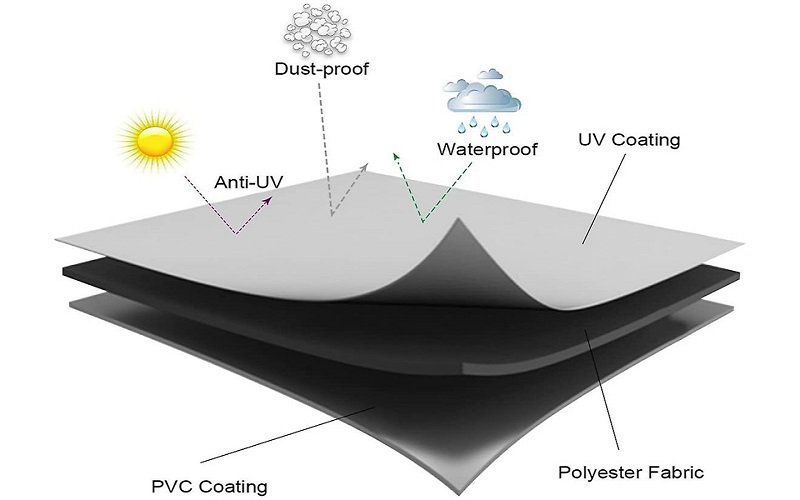

In addition to chemical additives, coatings offer another layer of protection. Acrylic coatings provide a transparent shield that protects nylon from UV radiation while also improving its appearance. Epoxy coatings create a durable protective layer that guards against UV damage and enhances adhesion, including the benefits of zinc oxide. Additionally, polyvinylidene fluoride (PVDF) coatings can be applied to nylon, offering exceptional UV resistance and chemical stability, making them ideal for long-term outdoor exposure.

Combining additives with protective seals is recommended for optimal protection, ensuring nylon remains resilient and reliable in high pressure applications and outdoor applications, such as decorative panels used in architectural settings.

Applications of UV-Resistant Nylon

UV-resistant nylon has found its way into various outdoor applications, proving its capability to withstand UV radiation effectively. One of the most common uses is in outdoor furniture, where its durability and UV resistance make it ideal for long-lasting use. Whether it’s patio chairs or garden tables, completely UV-resistant nylon ensures these products remain attractive and functional over time, even when exposed to organic compounds in the environment.

Playground equipment is another area where UV-resistant nylon is frequently used. Its tensile strength, bolstered by its high melting point, and ability to withstand UV degradation make it a reliable choice for components that need to endure rough use and constant exposure to sunlight. From slides to climbing frames, UV-resistant nylon helps maintain the safety and integrity of these structures.

In the automotive industry, UV-resistant nylon is often used for exterior parts to enhance lifespan and performance. Components like bumpers and trim benefit from nylon’s UV resistance, ensuring they remain durable and aesthetically pleasing despite constant exposure to sunlight. Nylon’s versatility, allowing it to be molded into various shapes and forms, makes it suitable for a wide range of outdoor applications.

Factors Affecting UV Resistance in Nylon

Several factors influence the UV resistance of nylon:

- The chemical structure of the nylon itself is a primary factor.

- Nylon is especially susceptible to UV radiation in the 290-315 nm wavelength range.

- This sensitivity impacts its durability and longevity.

- The sensitivity necessitates the use of additives such as UV stabilizers to enhance its resistance to degradation.

Environmental conditions also play a significant role. Factors such as humidity, temperature, and exposure to pollutants can accelerate the degradation of UV-resistant plastics like nylon. The chemical compatibility of the nylon with these conditions, as well as its mechanical properties like strength and flexibility, are crucial in determining its suitability for outdoor applications.

Choosing the Right Nylon for Outdoor Use

When selecting nylon for outdoor use, it’s essential to consider the specific type of nylon and its UV resistance. Different nylon types exhibit varying levels of UV resistance, with nylon 6/6 being less resistant than nylon 6 or nylon 12. The choice of nylon type should be based on the specific outdoor environment and application requirements, including semiconductor equipment and manufacturing industry settings where precision is critical.

Nylon 6 and nylon 12 offer better UV resistance compared to nylon 6/6, making them more suitable for outdoor applications. Whether it’s for outdoor furniture, playground equipment, or other open-air infrastructure, selecting both nylon types can make a significant difference in the product’s longevity and performance, as well as in laboratory equipment environments requiring durability.

Considering the environmental conditions and the specific requirements of the application is crucial. Understanding the differences in UV resistance among various nylon types helps in making informed decisions, ensuring that the chosen material will perform reliably under prolonged exposure to sunlight.

Summary

In summary, UV resistance is a critical factor in the longevity and performance of plastics used in outdoor applications. While nylon offers many benefits, it is not naturally UV-resistant and requires enhancements to withstand prolonged UV exposure. By incorporating UV stabilizers, additives, and protective coatings, the UV resistance of nylon can be significantly improved.

Understanding the specific requirements of the application and selecting the right type of nylon is essential for ensuring durability and reliability. As technologies and materials continue to advance, the future of UV-resistant plastics looks promising, offering even greater protection and longevity for outdoor products.

Frequently Asked Questions

What makes a plastic UV-resistant?

Plastic becomes UV-resistant through the inclusion of stabilizers and additives that protect it from the damaging effects of UV radiation, ensuring its properties remain intact over time.

Why is nylon not naturally UV-resistant?

Nylon is not naturally UV-resistant because it can generate free radicals when exposed to UV radiation, which causes structural degradation and color fading. This sensitivity makes nylon susceptible to damage from prolonged sunlight exposure.

How can the UV resistance of nylon be improved?

Improving the UV resistance of nylon can be achieved by incorporating stabilizers such as HALS, using UV absorbers, and applying protective coatings. These methods effectively enhance the material’s durability against UV degradation.

What are some common applications of UV-resistant nylon?

UV-resistant nylon is widely utilized in outdoor furniture, playground equipment, and automotive parts, owing to its exceptional durability and ability to withstand UV degradation. This makes it an ideal choice for various outdoor applications.

How do environmental factors affect the UV resistance of nylon?

Environmental factors like humidity, temperature, and pollution significantly impact the UV resistance of nylon by accelerating its degradation, which ultimately reduces its longevity and performance. Therefore, it is crucial to consider these factors when assessing the durability of nylon in UV-exposed applications.