With the development of science and technology, polyetheretherketone (PEEK) is widely used in aviation, medical, and automotive industries due to its toughness, high temperature resistance, and chemical corrosion resistance.

However, as its application increases, many people begin to pay attention to the safety of PEEK and its impact on health and the environment.

This article will briefly introduce the key characteristics and application of PEEK and analyze whether it is suitable for widespread use to help everyone better understand the safety of this type of material.

What Is PEEK Plastic?

PEEK is a semi-crystalline thermoplastic polymer composed of an aromatic group and a ketone group.

The colour is usually light brown or beige.

Its particular atomic structure provides the basis for the magical effects it produces.

Some of the outstanding properties of PEEK plastics include:

- High temperature resistance: PEEK can withstand temperatures up to 260°C (500°F) without melting or losing its structural integrity.

- Chemical resistance: PEEK does not break down when exposed to aggressive chemicals, acids, or solvents, making it ideal for harsh environments.

- Durability and abrasion resistance: it can handle prolonged exposure to wear and friction.

These qualities make PEEK plastic a base material for industries that need reliable and durable components.

Is PEEK Plastic Safe? Key Considerations for Safety

To determine whether PEEK plastic is safe, we can look at several aspects: first, whether its chemical composition is safe; second, how it performs at high temperatures.

Chemical Stability and Safety

PEEK plastic is considered safe in large part because of its stable chemical composition.

Unlike many common plastics, PEEK does not contain substances that are likely to cause concern, such as BPA (bisphenol A) or phthalates. These chemicals are often considered harmful to food or skin, but PEEK does not have such problems. Therefore, it is used in medical devices and food packaging, and people feel quite relieved.

In addition, PEEK has passed FDA safety testing and has been approved for use in medical and food-related items. This means that even if it comes into contact with the human body or food, it will not release harmful substances. Therefore, it is also popular in industries that have particularly high safety requirements.

Heat Resistance: Can PEEK Handle Extreme Temperatures?

One of the great features of PEEK is that it can maintain good performance at high temperatures. It can withstand temperatures up to 260°C (500°F), so industries such as aerospace and automotive that require high temperature resistance like to use it because many parts will work at high temperatures.

However, PEEK is not a panacea.

If the temperature exceeds its limit and is exposed for a long time, PEEK may decompose and release some gases or small particles.

This may be a bit risky in enclosed spaces or places with poor ventilation, but this situation generally only occurs in extreme industrial environments and is unlikely to occur under normal circumstances.

So as long as it is used within the recommended temperature range, PEEK is very safe.

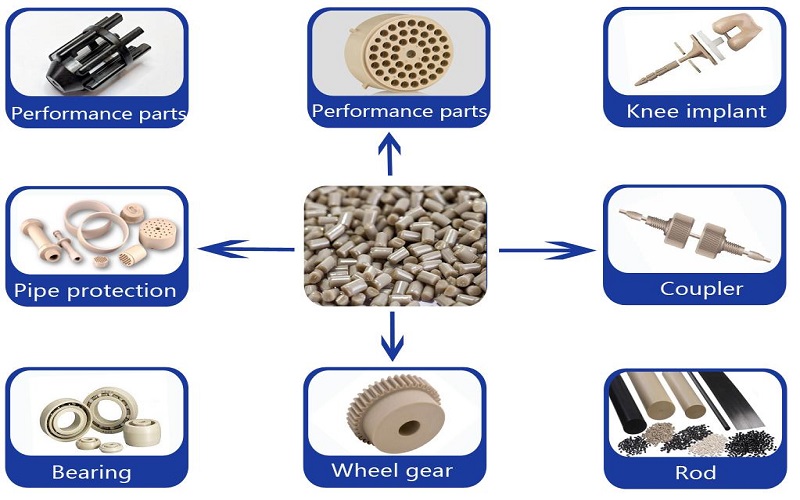

Applications of PEEK Plastic: Why Safety Is Critical

PEEK plastic is used in many industries, and safety and reliability are the most critical. We can look at where it is used and why each industry attaches so much importance to safety.

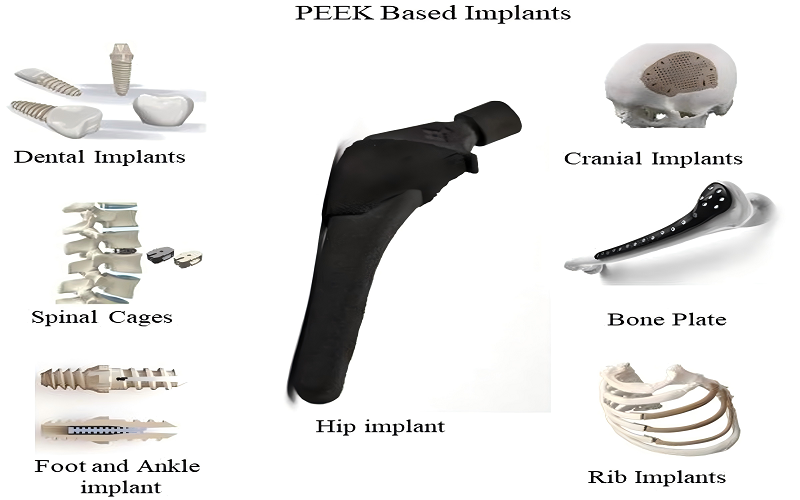

Medical Devices: Is PEEK Safe for Human Use?

PEEK plastic is very useful in the medical industry.

PEEK offers excellent strength and resistance to degradation. Its properties are very similar to those of bones and are suitable for implants that must remain in the body for a long time, such as spinal cages, bone screws, and dental implants.

PEEK is biocompatible; that is, it does not produce adverse effects and remains stable after implantation. After extensive testing, PEEK has proven safe for long-term use.This is why PEEK is popular in the medical field.

Aerospace: Ensuring Safety in Extreme Conditions

In the aerospace industry, safety is paramount, and materials must be able to work reliably under extreme pressures, temperatures, and stresses.

PEEK plastic is a good material for this and is often used in insulation materials and engine parts because it can withstand the high temperatures and various harsh chemicals in the aviation environment.

PEEK’s low flammability and resistance to chemical degradation are also important, which means that it does not pose a major safety hazard even in high-risk applications such as aircraft engines.

Because of this, PEEK plastic can be safely used in some of the most challenging aerospace conditions.

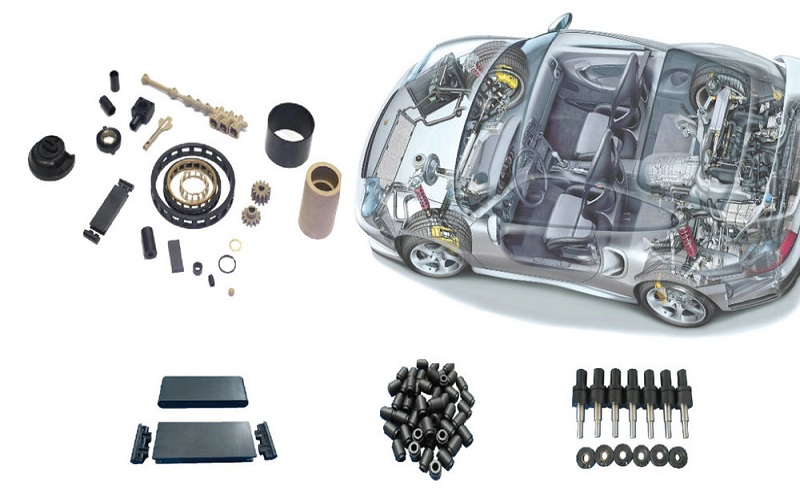

Automotive: PEEK’s Role in Vehicle Safety

In automotive manufacturing, PEEK plastics are widely used in parts that need to resist high temperatures and chemicals, such as seals, gaskets, and bearings.

The safety of PEEK in automotive parts is very important because these parts directly affect the overall reliability and safety of the vehicle.

Even under the hood of a car, PEEK plastics can maintain structural integrity. The environment there is harsh, and parts are often exposed to high temperatures and engine oil.

However, PEEK does not easily degrade, which ensures that the vehicle’s critical systems can operate safely and stably.

Overall, PEEK is a very reliable material in the automotive industry.

Health Concerns: Is PEEK Plastic Safe for Long-Term Use?

Is PEEK safe for everyday use? What are the concerns about its toxicity or long-term exposure?

Non-Toxic and Non-Carcinogenic

In short, PEEK plastic is safe for daily use. The answer is yes.

It is considered non-toxic and non-carcinogenic, so it is particularly suitable for places that come into direct contact with the body or food. Whether in medical devices, food containers, or industrial applications, PEEK’s chemical stability ensures that no harmful substances will be released under normal circumstances.

This means that products made of PEEK will not affect health during normal use. You can rest assured to use it in hospitals for implants or use it in food packaging in the kitchen. In short, PEEK provides strength and durability while ensuring safety, making it a trustworthy choice.

Potential Risks in Extreme Conditions

Although PEEK plastic is generally considered safe, it can present some risks in rare cases if misused or in extreme conditions.

For example, if PEEK is exposed to temperatures above its ability to withstand for an extended period of time, it may begin to degrade, releasing gases that could be harmful to inhale in an enclosed space.

However, these risks are very low and usually occur only in specific industrial environments. For most of us, PEEK plastic is very safe for everyday use, and few people worry about its long-term health effects.

Environmental Impact of PEEK: Is PEEK Environmentally Safe?

While PEEK plastic is safe for humans, we also need to consider its impact on the environment.

Like many high-performance materials, PEEK is not easily biodegradable.

However, its durability and long service life make it more sustainable in certain industries.

PEEK’s durability means that products made from it don’t need to be replaced as often, such as parts in the aerospace and automotive fields, which have a much longer service life than other materials, which helps reduce waste.

In addition, PEEK is light and strong and often replaces heavier metal materials, reducing the weight of vehicles and aircraft, improving fuel efficiency, and reducing carbon emissions.

So, although PEEK is not easy to degrade, its durability also has many benefits in terms of environmental protection.

Best Practices for Handling and Using PEEK Plastic Safely

Although PEEK plastics are safe under normal conditions, they must be handled with care during manufacture and use. Here are some tips to help you use PEEK safely:

- Use protective equipment: remember to wear appropriate protective equipment (ppe) when cutting or treating PEEK to prevent inhalation of dust or particles.

- Monitor temperature: Always monitor PEEK’s operating temperature to ensure it is in the safety range to prevent material degradation.

- choice of certified material: for important applications such as medical devices or food packaging, it is essential to choose a certified PEEK to ensure it meets safety standards.

By following these tips, you can use PEEK plastic safely and reliably in various applications.

Conclusion: Is PEEK Plastic Safe?

Overall, PEEK plastic is considered one of the safest, most reliable high-performance materials available today.

Its chemical stability, heat resistance, and biocompatibility make it very popular in industries such as medical, aerospace, and automotive.

While there may be some risks in using PEEK in extreme conditions, these risks are largely avoided by following some simple handling and temperature recommendations.

For most applications, PEEK plastic is a safe and durable choice.