Polycarbonate (PC) plastic is very common in our lives, such as food boxes, eyeglass lenses, and some medical supplies.

However, as people pay more attention to health and the environment, many people are beginning to worry about a component in polycarbonate, bisphenol A (BPA), because it may be harmful to the body.

So, “is polycarbonate safe?” This question has attracted the attention of many companies and consumers who make plastic products.

In this article, we will briefly explain the safety of polycarbonate, tell you whether it is harmful to humans, and also talk about whether it is safe when in contact with food, whether it has any impact on the environment.

Understanding Polycarbonate

What is Polycarbonate?

Polycarbonate (PC) is a strong and transparent plastic.

It is made through a chemical reaction that turns a chemical called carbonate into plastic. This chemical structure makes polycarbonate both heat-resistant and very strong and not easy to break.

In simple terms, the chemical structure of polycarbonate is a lot of small carbonate units connected together to form a large piece of plastic.

This structure allows it to remain stable even at high temperatures and has good transparency, making it suitable for a variety of uses such as eyeglass lenses, water bottles, and medical equipment.

Key Properties of Polycarbonate:

Polycarbonate (PC) has several particularly important properties:

1. high transparency

Polycarbonate is so transparent that you can see through it as clearly as glass. This makes it ideal for products that require transparency, for example glasses and transparent protective covers.

2. high strength

The plastic is strong and does not break easily. It is highly impact resistant and is therefore often used to make durable items such as car headlights and protective masks.

3. high temperature resistance

Polycarbonate resists high temperatures and does not deform easily in a high temperature environment. This makes it suitable for high temperature applications, such as components for high temperature equipment.

4. easy to process

It can be made of different shapes and sizes in different ways and is relatively simple to make. This means that we can manufacture all kinds of complex polycarbonate products.

These properties make polycarbonate very useful in our daily life and widely used in many different products.

Here are some other properties of polycarbonate:

| Property | Polycarbonate (PC) |

| Chemical Structure | Polycarbonate, synthesized from bisphenol A and phosgene |

| Density | 1.20-1.22 g/cm³ |

| Tensile Strength | 55-75 MPa |

| Flexural Strength | 80-100 MPa |

| Impact Strength | 30-40 kJ/m² |

| Transparency | Excellent (over 90% light transmittance) |

| Heat Resistance | High (glass transition temperature around 147℃) |

| Heat Deflection Temperature | 120-135℃ |

| Chemical Resistance | Good resistance to most acids, oils, and alcohols |

| Weather Resistance | Moderate, requires UV stabilizers to prevent yellowing |

Applications of Polycarbonate:

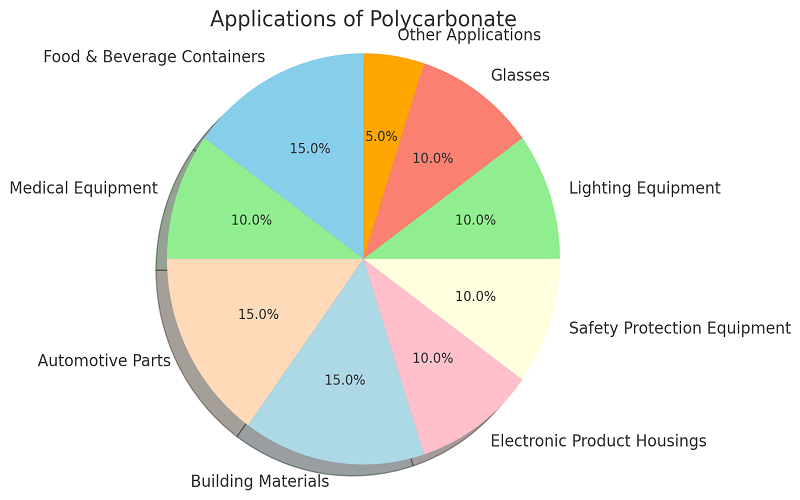

Polycarbonate is very practical in our life thanks to its strength, transparency and resistance to high temperatures:

1. glasses

The polycarbonate glass is very transparent and allows you to see clearly. In addition, they are lightweight and unbreakable, making them safer than glass glasses. In addition, they block harmful uv rays and protect your eyes.

2. food and beverage containers

Plastic is often used to make water bottles and food cans. It’s transparent so you can see what’s inside. In addition, it is also strong, does not break easily and resists high temperatures, so it can be washed in the dishwasher.

3. medical equipment

Polycarbonate is used in hospitals to make infusion boxes, vials and some surgical tools. It is transparent, so the doctor can see the fluid or medicine inside. In addition, it resists high temperatures and is suitable for sterilization.

4. auto parts

Polycarbonate for car shadows and dashboards. Strong and not easy to damage. It can withstand the impact of the moving car. In addition, it can make the light brighter and improve the safety of night driving.

In addition, polycarbonate is also widely used in building materials, electronic product housings, safety protection equipment, lighting equipment, etc.

How Polycarbonate is Processed and Manufacture?

There are two main methods of processing polycarbonate (PC) : injection molding and extrusion. These methods allow manufacturers to make objects of various shapes. Since polycarbonate can be reshaped after heating without losing its properties, it is ideal for precision parts.

In addition, there are other treatment techniques. Thermoforming consists of heating the polycarbonate sheet until it is softened and moulded to the desired shape. This method is commonly used to manufacture automotive dashboards and other complex components.

3D printing is a new technology used for the rapid production of prototypes and small series of parts. Since polycarbonate is very durable and stable, it is particularly suitable for this type of printing.

Whether it’s thermoforming or 3D printing, polycarbonate is important in the automotive and medical sectors where precision and durability are needed.

Is Polycarbonate Recyclable?

Polycarbonate (PC) is recyclable, but because it contains BPA, it is more complicated to recycle than other plastics. You need special equipment to handle it to prevent BPA from contaminating other recycled materials. This is why the recycling rate of polycarbonate is much lower than that of plastics like polypropylene (PP) or PET.

Also, it takes a lot of energy to recycle polycarbonate, which makes people start to worry about its environmental protection. Recycled polycarbonate is often only used for some lower-quality things, such as construction materials, instead of being used in higher-end products, such as food storage.

So, people are now working to improve recycling technology and are also looking for safer alternatives that do not contain BPA.

Is Polycarbonate Safe?

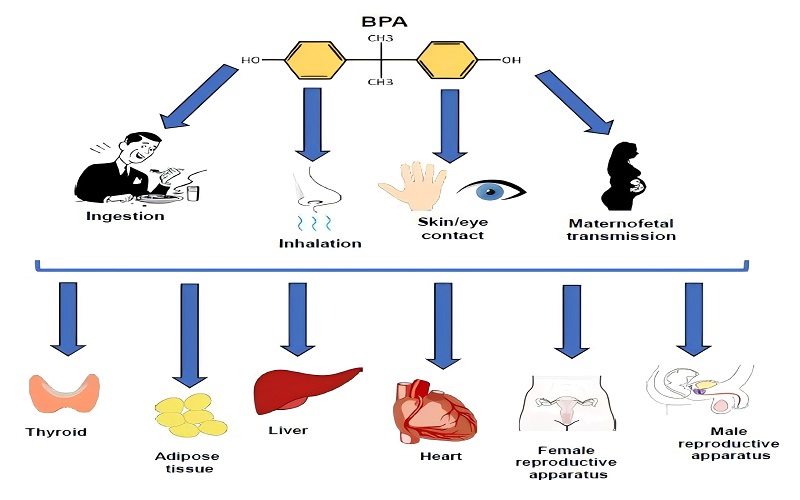

Polycarbonate itself is not toxic, but a chemical called BPA is used in its production. BPA may affect human hormones, and long-term exposure may have an impact on health.

For example, some studies say that BPA may reduce the number of sperm in men and make it more difficult for women to get pregnant.

For pregnant women, exposure to BPA may affect the development of the baby, such as causing behavioral problems in the child or early puberty.

Some people also say that long-term exposure to BPA may increase the risk of breast cancer or prostate cancer, but more research is needed to confirm this.

Is Polycarbonate Safe for Food Contact?

Many people have discussed the safety of polycarbonate food containers.

Although organizations like the FDA say it can be used to hold food, we still have to be careful.

For example, polycarbonate may release chemicals such as BPA into food or drinks when heated, so it is best not to use such containers for microwave heating or hot water. Also, be careful when cleaning, and don’t use a brush that is too hard, because that may scratch the container and make it easier for BPA to enter the food.

Also, acidic foods such as tomatoes and oranges may cause BPA to seep in more, so it is best to use glass or stainless steel containers when holding these foods.

Now many manufacturers have also made BPA-free polycarbonate containers, which will be more reassuring to use.

Is Polycarbonate Safe for the Health of Different Groups of People?

Some people are more vulnerable to BPA than others, especially infants, children, and pregnant women.

Even small amounts of BPA can have a big impact on their health, which is why many countries now don’t allow BPA in baby bottles and other children’s products.

In addition, although it’s not often mentioned, some studies have shown that BPA may also be bad for the elderly, such as worsening memory or causing heart problems.

Pregnant women exposed to BPA may be harmful to their babies and may cause obesity or other health problems in the future.

For safety, these people are advised to use BPA-free products or choose safer materials such as glass and stainless steel.

Is Polycarbonate Safe for Recycling?

When polycarbonate (PC) is recycled, its quality may decrease, so BPA may leak out more easily.

Therefore, it is generally not recommended to use recycled polycarbonate for food containers.

Recycled polycarbonate is usually used in things that are less exposed to people, such as outdoor furniture or industrial materials. For example, it can be used to make building materials, such as soundproof walls, because these materials have little chance of contact with people.

It can also be used in cars, such as interior decoration or headlight housings, which also do not come into direct contact with people.

Although recycling technology may be safer in the future, you still have to be careful when using recycled polycarbonate for products that come into direct contact with people.

Conclusion

Polycarbonate (PC) is a great material because it is strong and transparent. However, it used to have a problem that the BPA in it may have an impact on health.

However, many manufacturers are now making BPA-free polycarbonate, so the safety has improved a lot.

In general, as long as we use it properly, such as not using it to heat food or store acidic drinks, polycarbonate is still relatively safe.

There may be better alternative materials in the future, but for now, as long as we understand these and make wise choices, we can use polycarbonate products with peace of mind.