Polyester is a widely used material, found in everything from clothing to industrial products, but a common question arises: is polyester plastic?

To answer this, we need to explore the composition, production, uses, and environmental impact of polyester, particularly its relationship to polyethylene terephthalate (PET), the most common form of polyester plastic.

This article delves into the science behind polyester fabric, its synthetic fibers, and the environmental implications of its widespread use, while addressing key concerns like microplastic pollution, greenhouse gas emissions, and recycling options.

What Is Polyester?

Polyester is a synthetic polymer, a category of materials that includes plastics.

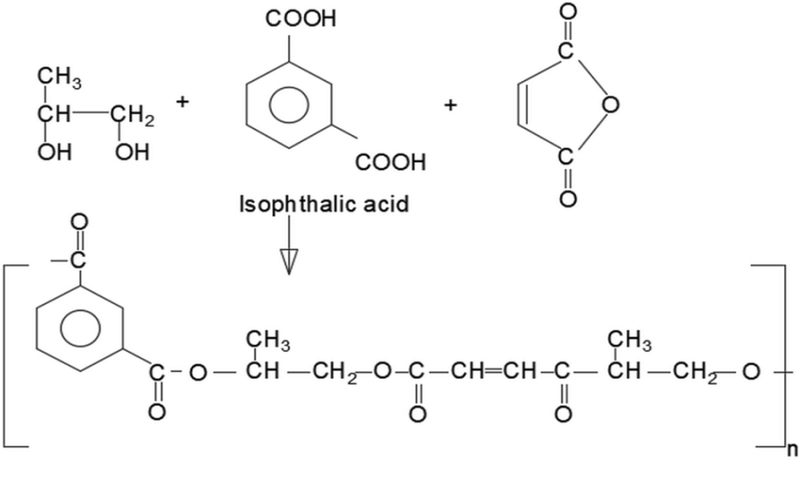

It is primarily made from polyethylene terephthalate (PET), a thermoplastic polyester formed through a chemical reaction between ethylene glycol and terephthalic acid.

These raw materials, derived from crude oil or fossil fuels, undergo a chemical process to create long chains of repeating molecular units, known as the repeat unit, connected by ester linkages.

This main chain structure gives polyester its durability and versatility, making it a staple in textile fibers and plastic reinforcements.

The term “polyester” encompasses a range of chemical compounds, including unsaturated polyesters used in resins and polyester fibers for textiles.

The most common form, polyethylene terephthalate (PET), is used in both polyester clothing and plastic products like bottles.

This dual nature is why people often ask, is polyester plastic?

The answer is yes—polyester is a type of plastic, specifically a synthetic fibre with petroleum-based origins, but its applications and properties vary depending on how it’s processed.

How Is Polyester Made?

The polyester production process begins with combining ethylene glycol (also called monoethylene glycol) and terephthalic acid to form glycol and terephthalic acid compounds.

These undergo a chemical reaction called polymerization, where long strands of molecules form long chains with ester functional groups.

The resulting synthetic materials can be extruded through tiny holes to create polyester fibers or molded into polyester products like containers.

The production process is energy-intensive, requiring high temperatures to reach the melting points of the materials, which contributes to energy consumption and greenhouse gas emissions.

Since polyester is derived from crude oil, its production is tied to fossil fuels, which release potent greenhouse gases during extraction and refining.

Additionally, the dyeing process for polyester fabric often involves hazardous chemicals, which can end up in wastewater treatment plants or natural water systems, posing risks to aquatic life and marine life.

Uses of Polyester

Polyester’s versatility makes it one of the most common fabrics globally. Its low cost, durability, and ability to be tailor-made for specific applications contribute to its popularity. Here are some key uses:

- Polyester Clothing: Polyester fibers are widely used in fast fashion due to their strength, resistance to wrinkles, and ability to hold vibrant dyes. They are often blended with natural fibers like cotton or used alone in athletic wear and outerwear.

- Industrial Applications: Polyester plastic, particularly polyethylene terephthalate (PET), is used in bottles, packaging, and plastic reinforcements for construction materials.

- Textiles and Home Goods: From carpets to curtains, polyester fabric is a go-to choice for its durability and affordability compared to other fibres.

- Specialized Products: Unsaturated polyesters are used in resins for coatings, adhesives, and composite materials.

This wide range of applications highlights why polyester is a cornerstone of modern manufacturing, but it also raises questions about its environmental cost.

Environmental Impact of Polyester

While polyester’s versatility and low cost make it appealing, its environmental impact is significant.

The reliance on fossil fuels for polyester production contributes to greenhouse gas emissions, exacerbating climate change.

The chemical process also generates byproducts that can harm ecosystems if not properly managed. Below are some key environmental concerns:

Microplastic Pollution

When polyester clothing is washed, it sheds microplastic pollution—tiny fragments of synthetic fibers that enter waterways and harm aquatic life.

These microplastics are difficult to filter out in wastewater treatment plants and can accumulate in marine life, entering the food chain and potentially affecting human health.

Unlike natural fibers like cotton, which biodegrade, polyester fibers persist in the environment for hundreds of years.

Energy Consumption and Emissions

The production process for virgin polyester is energy-intensive, requiring high temperatures to melt and shape the material.

This contributes to significant energy consumption and greenhouse gas emissions.

Additionally, the extraction of crude oil for raw materials releases potent greenhouse gases, further increasing polyester’s environmental footprint.

Hazardous Chemicals

The dyeing process and other stages of polyester production often involve hazardous chemicals that can cause skin irritation in humans and harm ecosystems if released untreated. These chemicals can contaminate water sources, affecting both human health and aquatic life.

Fast Fashion and Waste

Polyester’s role in fast fashion exacerbates its environmental toll.

The rapid production and disposal of polyester clothing contribute to textile waste, much of which ends up in landfills.

Unlike natural fibers, polyester products do not biodegrade, adding to long-term environmental issues.

Recycling Polyester: A Sustainable Option?

To address these concerns, recycled polyester has emerged as a sustainable option.

Made from recycled materials like plastic bottles, recycled polyester reduces the demand for virgin polyester and helps divert waste from landfills.

There are two main recycling methods:

- Mechanical Recycling: This involves shredding and reprocessing polyester products into new polyester fibers. While effective, it can degrade the quality of the fibers over time.

- Chemical Recycling: This breaks down polyester plastic into its original components, like ethylene glycol and terephthalic acid, allowing for the creation of high-quality new polyester fibers. Chemical recycling is more resource-intensive but produces better results.

Recycled polyester reduces energy consumption and greenhouse gas emissions compared to virgin polyester, but it’s not a perfect solution.

The recycling process still requires energy, and microplastic pollution remains a concern when recycled polyester is used in clothing.

Polyester vs. Other Materials

Compared to natural fibers like cotton, polyester has advantages in durability and cost but falls short in environmental sustainability.

Cotton is biodegradable but requires significant water and pesticides to grow, creating its own environmental cost.

Meanwhile, synthetic fibers like polyester are more durable and resistant to wear but contribute to microplastic pollution and rely on fossil fuels.

Other synthetic materials, such as nylon or acrylic, share similar environmental challenges, but polyester’s dominance in textile fibers makes its impact more pronounced.

Developing tailor-made solutions, such as blending polyester fibers with natural fibers or improving recycling technologies, could help balance performance and sustainability.

Toward a Holistic Approach

Addressing the environmental impact of polyester requires a holistic approach.

Innovations in chemical recycling, improved wastewater treatment plants, and the development of bio-based polyesters could reduce reliance on fossil fuels and hazardous chemicals.

Consumers can also play a role by choosing recycled polyester products, supporting sustainable brands, and reducing consumption of fast fashion.

Additionally, advancements in polyester production—such as lowering melting temperatures or using renewable energy—could decrease energy consumption and greenhouse gas emissions.

Research into alternative raw materials, like bio-based ethylene glycol, could further reduce polyester’s petroleum-based origins.

Conclusion

So, is polyester plastic? Yes, polyester, particularly polyethylene terephthalate (PET), is a type of synthetic polymer that falls under the plastic category.

Its long chains of ester linkages, derived from ethylene glycol and terephthalic acid, make it versatile for use in polyester fabric, polyester clothing, and plastic reinforcements.

However, its environmental impact—from microplastic pollution to greenhouse gas emissions—poses significant challenges.

While recycled polyester and improved production processes offer hope, the reliance on fossil fuels, hazardous chemicals, and the persistence of synthetic fibers in the environment highlight the need for change.

By adopting a holistic approach that combines innovation, recycling, and conscious consumer choices, we can mitigate the environmental cost of polyester and move toward a more sustainable option for the future.