Polyethylene, or PE, is one of the most common plastics in the world.

You see it all over the place, from plastic shopping bags and food containers to electronic goods and even medical devices.

It is used so widely because it is so widely useful and far more durable than other plastics.

But as plastics draw more and more attention, we have to ask if polyethylene is safe to have.

This article will explain what polyethylene is, what it is used for, and whether or not it can have any potential risks to human health and the environment.

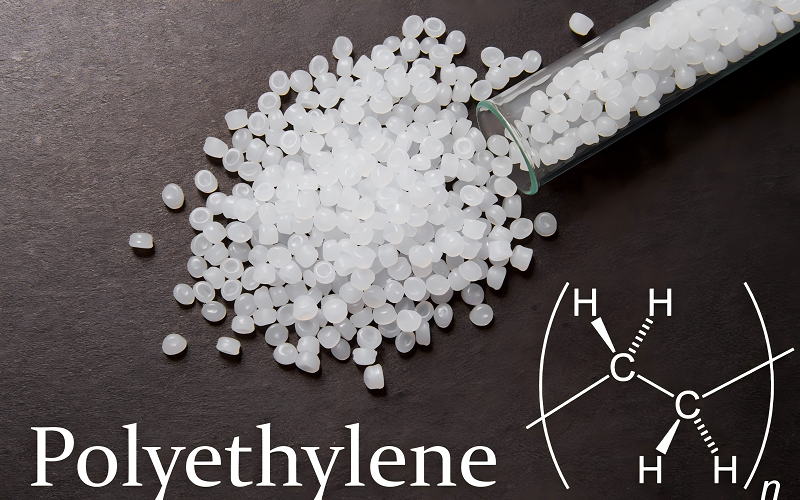

What is Polyethylene (PE)?

Polyethylene (PE) is a versatile plastic material produced through the polymerization of ethylene, a simple hydrocarbon gas.

In this process, ethylene undergoes chemical reactions that transform it into a plastic known for being lightweight, flexible, and durable.

Due to these excellent properties, polyethylene is widely used in daily life and industrial fields, such as food packaging, plastic bottles, pipes, and medical equipment.

Different Types of Polyethylene and Their Uses

There are several different types of polyethylene, each with its own characteristics and uses. Here are some common types of polyethylene and where they are commonly used:

- LDPE (Low-Density Polyethylene): This plastic is very soft and flexible and is often used to make plastic bags, plastic wrap, and some squeezeable bottles.

- HDPE (High-Density Polyethylene): Because it is resistant to chemicals and moisture, HDPE is often used to make food containers. It is also considered one of the safest plastics for contact with food.

- LLDPE (Linear Low-Density Polyethylene): This plastic is stronger than LDPE and is often used in stretch film and industrial packaging.

- MDPE (Medium-Density Polyethylene): MDPE has a good balance of strength and softness and is often used in gas pipes, packaging film, and shrink film. It’s not as hard as HDPE, but it’s also very durable.

- UHMWPE (Ultra-High Molecular Weight Polyethylene): This plastic is extremely strong and is often used in bulletproof vests, orthopedic implants, and some mechanical parts.UHMWPE is also safe for medical use because it’s strong and has no adverse effects on the human body.

Each of these different polyethylene plastics has its own advantages and is widely used in daily life and industry.

| Type | Density (g/cm³) | Tensile Strength (MPa) | Temperature Resistance(°C) | Melting Point (°C) | Elongation at Break (%) | Modulus of Elasticity (MPa) |

| LDPE | 0.91 – 0.94 | 8-10 | -50°C to 85°C | 105 – 115 | 400 – 600 | 100 – 300 |

| HDPE | 0.94 – 0.97 | 20 – 30 | -50°C to 120°C | 130 – 135 | 20 – 50 | 800 – 1600 |

| LLDPE | 0.91 – 0.94 | 10-15 | -50°C to 85°C | 122 – 125 | 500 – 800 | 200 – 400 |

| MDPE | 0.926 – 0.940 | 12-16 | -50°C to 100°C | 120 – 130 | 200 – 400 | 400 – 800 |

| UHMWPE | 0.930 – 0.935 | 40 – 50 | -150°C to 90°C | 130 – 136 | 300 – 600 | 700 – 1500 |

Polyethylene Plastic Production Safety

Polyethylene plastic can be made in many ways, such as injection molding, blow molding and extrusion.

Although polyethylene itself is non-toxic, there are still some safety hazards that need to be paid attention to during production and processing.

For example, some plastic additives and catalysts may be used in the injection molding process, which may sometimes be not so good for the environment and our health.

Therefore, it is important to take some protective measures in the production and processing of polyethylene to reduce the release of harmful substances and protect the safety of workers and the environment.

Is Polyethylene (PE) Safe ?

Studies have shown that polyethylene is non-toxic and non-carcinogenic, and does not pose a health threat under normal use. It does not contain harmful substances such as BPA or phthalates and is often used in food packaging and medical devices. Overall, polyethylene is one of the safest plastics in daily life.

Is Polyethylene Safe for Food Contact?

Polyethylene (PE) is a very common food packaging material that everyone considers safe.

Because its chemical nature makes food ingredients difficult to penetrate into the package, we don’t have to worry about polyethylene packaging when storing food in the refrigerator or at room temperature. In addition, polyethylene does not contain harmful substances such as bisphenol A and phthalates, making it quite reassuring to use.

However, if you want to store very hot food, small amounts of chemicals can migrate into food. Although this amount is small and generally does not cause any damage, it is best to use glass or stainless steel containers to store hot food for safety reasons.

Overall, polyethylene remains very safe as food packaging under normal conditions of use.

Is Polyethylene Safe for Medical Use?

Polyethylene (PE) is generally considered safe for medical use and is widely used in the manufacture of medical devices and products such as catheters, syringes, and implants. Its advantages are that it is nontoxic, durable, and nonirritating to the human body.

For example, ultra-high molecular weight polyethylene (UHMWPE) is often used in surgical implants such as joint replacements because it is both wear-resistant and biocompatible and is not easily rejected by the human body.

In addition, polyethylene does not release harmful substances during long-term use and does not contain chemicals such as bisphenol A, further ensuring its safety.

In short, in the medical field, as long as polyethylene products are strictly quality controlled and produced in compliance with regulations, they are generally safe to use and will not cause health hazards.

Is Polyethylene Safe for Industrial Use?

Polyethylene (PE) is very safe for industrial applications, mainly because of its chemical resistance, non-toxicity, and good strength. It can resist a wide range of chemicals and is often used for storing and handling chemicals.

Low-density polyethylene (LDPE) and high-density polyethylene (HDPE) both have different strengths and toughness, suitable for various industrial uses such as pipes, packaging, and containers.

However, when using polyethylene in high-temperature or high-pressure environments, make sure to meet safety standards to avoid deformation or breakage of the material. Overall, polyethylene is very reliable in industrial applications.

Polyethylene and Health: What You Need to Know?

Can Additives in Polyethylene Cause Harm?

Although polyethylene itself is safe, manufacturers often add chemical additives during the production process to improve the properties of the plastic.

These additives can make polyethylene more flexible, stronger, or heat-resistant. However, when polyethylene is used in food containers or medical products, additives may cause some concerns.

For most food-grade and medical-grade polyethylene, manufacturers need to ensure that these additives are safe and will not harm us.

But if you use polyethylene containers to store hot or oily foods, some chemicals may seep out. This is why it is often recommended not to heat food in plastic containers in the microwave, even those made of safer materials.

To be safe, using glass or stainless steel containers may be a better choice.

What is Leaching and Offgassing?

When chemicals in plastics get into food or liquids, we call this leaching.

Even though polyethylene is safer than many other plastics, leaching can still happen, especially if it’s exposed to high temperatures or when storing acidic or fatty foods.

Degassing is when plastic releases gases into the air.

Luckily, polyethylene doesn’t let out harmful gases when used normally, and it has a low deflation rate. Still, to be safe, it’s best not to keep polyethylene in hot places for too long.

Is Polyethylene Safe for the Environment?

The environmental impact of polyethylene (PE) is a bit complicated. Although it is safe when used, it can cause problems if not handled properly. Polyethylene is not biodegradable and may take hundreds of years to decompose, which contributes to the problem of plastic pollution.

But the good news is that polyethylene can be recycled, and low-density polyethylene (LDPE) and high-density polyethylene (HDPE) can be reprocessed into new products to help reduce waste. However, not all polyethylene can be recycled, and a lot of it is still thrown into landfills.

In addition, some chemicals may be used in the production process of polyethylene, which may pollute the air and water if not handled properly. Therefore, it is important to pay attention to environmental protection when producing and using polyethylene.

In short, polyethylene is relatively safe when used properly, but the impact on the environment when not properly managed needs our attention. Reducing the use of single-use plastic and recycling them well are both good ways to protect the environment.

Can You Use Alternatives to Polyethylene?

If you want to reduce the use of polyethylene in plastic mold production, there are some alternative materials to choose from.

For example, fiberglass and stainless steel are both very durable options that can withstand high temperatures and chemicals without releasing harmful substances.

In addition, composite materials are also a good choice.

They combine the advantages of multiple materials and are usually lighter and stronger, suitable for a variety of production needs.

There are also biodegradable plastics, such as polylactic acid (PLA), which may not be as durable as polyethylene but can also meet the needs well in short-term use.

Conclusion: Is Polyethylene Safe?

Yes, polyethylene is considered a very safe plastic.

It is corrosion-resistant, strong, and widely used in food packaging, medical devices, and construction materials.

It is non-toxic and does not cause cancer. However, avoid heating plastic containers during use, and make sure to recycle them when possible.

In short, as long as safety standards are followed, polyethylene is safe and durable for various applications.