Introduction

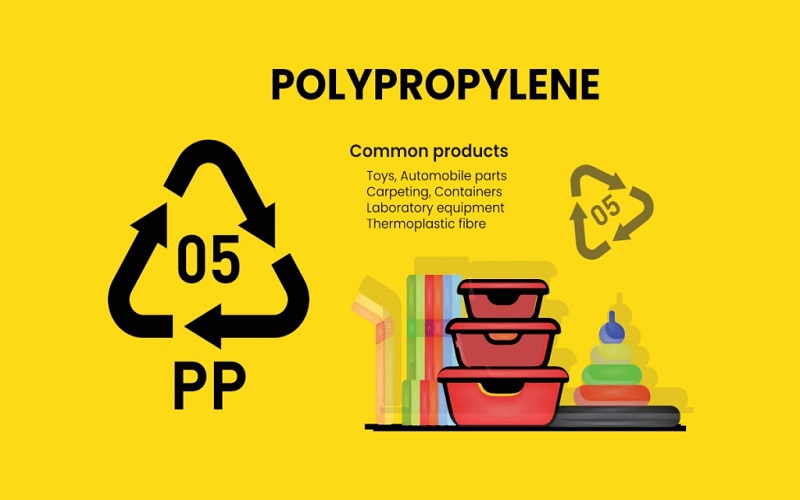

Polypropylene (PP) is a very common plastic used for packaging food, medical equipment, household products, etc. It has excellent physical and chemical properties and is widely used in various places. But with the increase in the use of plastic, people started worrying about their safety.

This applies especially in areas with high safety requirements, such as food and medical equipment. Therefore, the properties, use and safety of PP should be studied in detail to see how it behaves in different situations.

This article provides scientific evidence and official certification to help everyone gain a more comprehensive understanding of PP safety and how to use it properly.

What is Polypropylene (PP) Plastic?

Polypropylene (abbreviated PP) is a thermoplastic material produced by polymerization of propylene monomer. It is a milky white substance, tasteless, odorless and harmless to the human body. PP is easy to process and is widely used in consumer packaging materials, plastic hinges and waterproof insulation materials.

With a density of approx. 0.90 g/cm3 to 0.91 g/cm3, PP is one of the lightest plastic materials available today and is suitable for high temperature environments up to 100 degrees Celsius. However, it should be noted that PP is brittle at low temperatures, has poor wear resistance and tends to age over time.

In summary, PP, a polyolefin material, occupies an important position in plastic manufacturing processes due to its excellent mechanical and thermal properties.

Benefits of Polypropylene (PP) Include:

| Advantage | Description |

| Lightweight | Low density, only 0.90-0.91 g/cm³ |

| High Strength | Good mechanical properties |

| Chemical Resistance | Resistant to acids, alkalis, and organic solvents |

| Heat Resistance | Can be used at high temperatures |

| Non-toxic and Odorless | Safe for food and medical applications |

| Easy to Process | Suitable for various processing methods |

| Good Electrical Insulation | Excellent electrical properties and high-frequency insulation |

Disadvantages of Polypropylene (PP) Include:

| Disadvantage | Description |

| Brittle at Low Temperatures | Becomes brittle at low temperatures |

| Poor Wear Resistance | Easily worn out |

| Ages Easily | Deteriorates with prolonged sun exposure |

| Non-biodegradable | Difficult to degrade in natural environments |

| Difficult to Bond | Hard to adhere to other materials |

| Poor Flame Resistance | Requires flame retardants to improve |

| Environmental Impact | Dependent on petroleum resources, complex recycling processes |

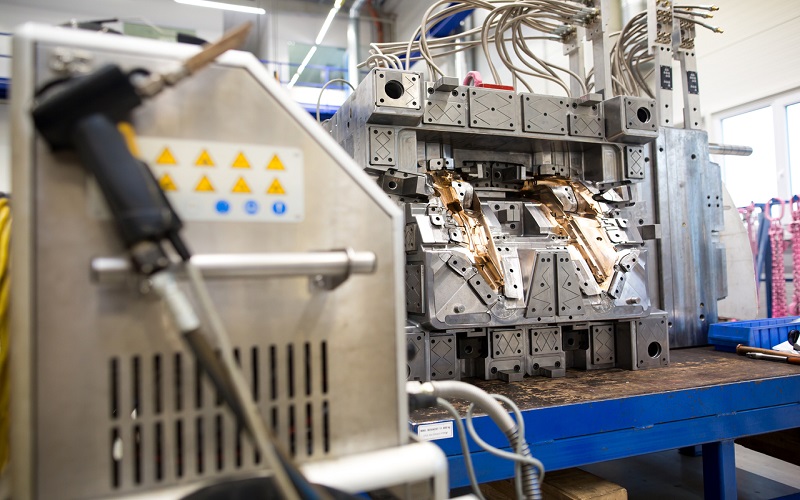

Injection Moulding of Polypropylene(PP)

Polypropylene (PP) is generally stable during the injection molding process and does not release large amounts of hazardous substances, but you must be aware of the possible dangers in certain situations.

First, PP is rated as a relatively safe material because volatile organic compounds (VOC) do not degrade or release within the injection temperature range (180°C to 240°C).

However, if the processing temperature exceeds 240℃, PP may thermally degrade and release small amounts of volatile organic compounds and propylene monomer, which may be harmful to health. Therefore, the processing temperature must be strictly controlled and monitored.

In addition, PP products often contain additives such as flame retardants and plasticizers, which can release harmful substances at high temperatures. For applications in contact with food, ingredients must be selected that especially meet safety standards.

To reduce the risk, injections should be performed in a well-ventilated environment, and equipment should be regularly maintained to ensure normal operation of the temperature control system and the exhaust system to prevent equipment failure that could cause overheating or release of hazardous substances.

Application Field of Polypropylene(PP)

Food contact material

Polypropylene (PP) is widely used in food packaging and tableware such as yogurt boxes, beverage bottles and lunch boxes, as well as disposable tableware such as forks, knives, spoons, plates and cups, as well as microwaveable containers,oven and frozen foods.

Medical and pharmaceutical fields

Polypropylene (PP) is widely used as a packaging material for medical devices and drugs, including syringes, test tubes, surgical instrument handles, vials, vials, blister packs, drug storage containers, and intravenous fluid bags.

Daily necessity

PP material is widely used in the production of furniture, storage boxes and toys. For example, PP chairs, tables, cabinets and shelves are popular in homes and offices because they are durable and easy to clean.

PP is strong, can withstand heavy objects and can be used for a long time, so it is often used to make storage boxes, boxes and organizers.

In addition, various children’s toys such as assembly kits, puzzles, models and plastic cars are produced using PP. PP is non-toxic, odorless and impact resistant, making it not only safe but also very durable.

Is Polypropylene(PP) Safe to Use in Food?

PP plastic is considered a very safe material in contact with food because it has several advantages:

First, it does not emit toxic substances and has no taste or smell, so it does not affect the taste or safety of food. It maintains stability even at high temperatures, such as in a microwave oven, and does not degrade or release harmful substances.

Second, PP has very strong resistance to chemicals and does not react with ingredients in food, which ensures the purity and safety of food.

In addition, PP is recyclable and relatively environmentally friendly, which meets current requirements for sustainable development.

PP receives FDA approval. The US FDA and the EU EFSA have strict regulations to ensure the safety of PP materials when they come into contact with food. These certifications give greater confidence to those using PP material in food packaging and cutlery because it has been thoroughly tested to ensure safety and reliability.

Effects of PP on Human Health: Is Polypropylene BPA-Free?

What is BPA?

BPA (Bisphenol A) is a substance commonly used in the production of plastic products that are closely related to our daily lives, such as water bottles and baby bottles. BPA can enter our body through contact and use of these products, which is not good for our health. It disrupts the endocrine system, affects development and in severe cases can potentially lead to cancer.

Why is Polypropylene(PP) Safe for Humans?

Polypropylene(PP) is a relatively safe material for humans, and some children’s toys are also made of PP, so it is not only safe for adults, but also for children. Here are a few reasons about its safety:

First, because polypropylene does not contain harmful substances such as bisphenol A (BPA) or phthalates, it does not emit dangerous chemicals when used in food packaging, tableware, medical devices, etc.

Second, PP is stable even under high temperatures such as microwave heating or high temperature sterilization. There are no chemical changes or the release of harmful substances, therefore it is suitable for microwave containers for food, medical devices, etc., which makes it highly safe.

In addition, polypropylene (PP) resists most chemicals and is biocompatible, so it is gentle on human tissue and has no side effects. Therefore, it is widely used in medical devices.

Although PP is relatively safe, proper usage guidelines must be followed to maintain the stability and safety of the structure. Above all, long-term use at high temperatures should be avoided.

The Environmental Impact of the PP Materials

Polypropylene is a type of plastic that is obtained from petroleum. We know that oil is a non-renewable resource, so refining polypropylene has a significant impact on the environment. The extraction and processing of oil releases a large amount of greenhouse gases, which can negatively affect climate change and disrupt ecosystems.

Polypropylene is naturally difficult to break down, especially in the ocean. Discarded polypropylene plastic breaks down into small plastic particles and enters the food chain, endangering marine life and causing serious problems to the entire ecosystem, ultimately affecting human health.

In order to reduce the impact of polypropylene on the environment, its life can be extended by recycling. Mechanical recycling is a method by which discarded polypropylene can be turned into new products. There is also chemical recycling, which is a more expensive but effective way of disposing of polypropylene waste. Pyrolysis is also an option that can help mitigate some of the negative environmental impacts of polypropylene.

In conclusion, we can say that each of us can use these methods to protect the environment and reduce the negative effects of polypropylene.

How to Use Polypropylene (PP) Correctly?

These recommendations for polypropylene (PP) products are very important, especially if you pay attention to detail in use to keep the product in good condition and extend its life.

1. Temperature regulation. Polypropylene can be safely used in a relatively wide range of temperatures from -20 degrees to 100 degrees Celsius. Especially when heating with a microwave oven, make sure that the temperature does not exceed 100 degrees to avoid negative effects on the structure and performance of the product. At the same time, avoid sudden shocks in a low-temperature environment to avoid damage to the polypropylene material.

2. Chemical contact. Although polypropylene is highly resistant to most household chemicals, it is best to avoid contact with strong acids, strong bases or strong oxidizing agents to avoid damage or discoloration of the product due to possible chemical reactions.

3. Reasonable load and use. Be careful not to overload or pull with excessive force on polypropylene products, as this may deform or damage the product, affecting its life and appearance.

4. Be careful not to expose yourself to sunlight for too long. Prolonged exposure to sunlight can cause polypropylene materials to become brittle, increasing brittleness and brittleness.

5. It is also important to keep the product clean and maintained. Cleaning with mild soapy water and a soft cloth can effectively remove dirt. Do not use cleaning agents containing strong acids, strong bases or solvents to avoid damaging the smooth and clean polypropylene surface.

These suggestions can help you better care for and maintain your polypropylene products, extend their life, and keep them in good condition and functionality.

Summarize

So polypropylene (PP) is an all-purpose material! which is very safe and harmless to the human body.

It can be used to make a variety of items at home, including food packaging and medical devices. It does not contain harmful Bisphenol A or phthalates and can withstand high temperatures.

If you need a good PP plastic supplier, contact us now! Our company provides high-quality materials and is definitely your trustworthy partner!