PVA is a special synthetic material that can be used to make textiles and food packaging.

One of its characteristics is that it is soluble in water, which makes it more popular and more environmentally friendly in many cases.

Recently, many people have been concerned about the impact of materials on the environment and health. Is PVA safe in daily life?

So in this article we will introduce PVA to you, hoping that you can have a more comprehensive understanding of this material.

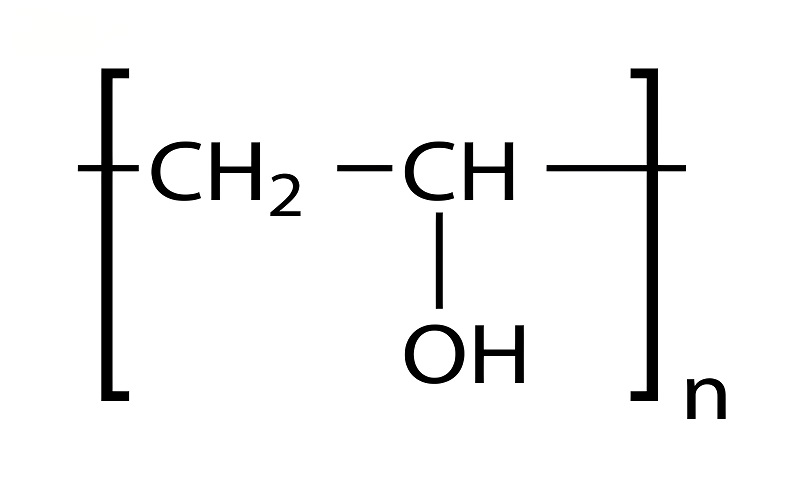

What is Polyvinyl Alcohol (PVA)?

PVA (polyvinyl alcohol) is a synthetic polymer widely used in products that need to be water-soluble.

It is made by a chemical process where a substance called vinyl acetate is polymerized to form a viscous liquid, which is then converted into polyvinyl alcohol by adding water.

How does PVA Differ from Traditional Plastics?

There are several significant differences between polyvinyl alcohol (PVA) and traditional plastics like polyethylene and polypropylene.

First, PVA dissolves in water, whereas most traditional plastics are waterproof and don’t break down easily. This means that PVA will degrade relatively quickly after use, leaving less of an impact on the environment, whereas traditional plastics can sit out there for hundreds of years and create a lot of pollution.

Second, PVA is generally softer, which makes it suitable for products that need to release their contents quickly, such as dissolvable laundry pods and drug capsules. In contrast, traditional plastics are stronger and are suitable for use in packaging and building materials where durability is required.

Finally, PVA is made differently than traditional plastics. PVA is made by polymerizing vinyl acetate and treating it with water, whereas traditional plastics are made using different processes. These characteristics make PVA more environmentally friendly in some ways, but it may not be as durable as traditional plastics.

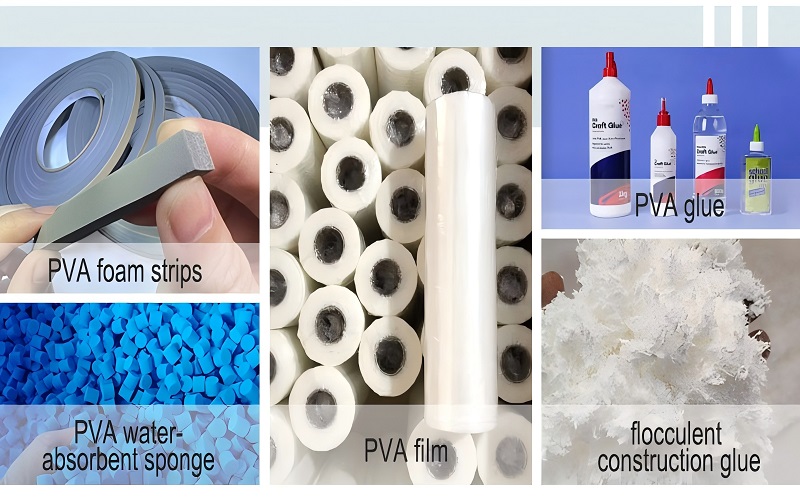

Common Uses of PVA

Polyvinyl alcohol (PVA) has many common uses:

- Soluble laundry balls: PVA is often used to make soluble laundry balls, which dissolve quickly when washing clothes, releasing detergent, and are easy to use.

- Drug capsules: In the pharmaceutical industry, PVA is used to make water-soluble drug capsules, which can quickly release drugs and are easy to take.

- Food packaging: PVA’s environmentally friendly properties make it a packaging material for some foods, which can degrade faster in the environment and reduce pollution.

- Glues and adhesives: PVA is a good adhesive and is often used to bond wood, paper, and cloth.

- Textiles: In the textile industry, PVA is used as a sizing agent to increase the strength and gloss of fabrics.

- Cosmetics: PVA is used as a thickener and film-forming agent in some cosmetics to help the product work better.

These uses show the multiple functions and environmental characteristics of PVA, making it popular in many industries.

Is PVA Safe for Human Health?

PVA is FDA-approved for use in food packaging and pharmaceutical capsules due to its safety.

With its water-soluble nature, PVA quickly breaks down in the body, isn’t absorbed or accumulated, and is expelled without leaving residue.

This property makes PVA ideal for drug delivery systems, allowing medications to be safely transported into the body without lingering.

Additionally, its low toxicity and biocompatibility make PVA popular in medical and cosmetic fields.

Industrial Safety of PVA

In factories, polyvinyl alcohol (PVA) is a relatively safe material with low toxicity.

It is often used in the manufacture of paper and adhesives and generally does not pose major problems.

However, in some hot work, such as casting or extrusion, PVA can release fumes. If large amounts of smoke are inhaled, slight irritation of the respiratory system may occur.

To protect workers, many factories are taking measures to reduce exposure, such as the use of air filters and the requirement for workers to wear protective equipment.

Although PVA is not considered hazardous, prolonged exposure to large amounts of fine particles can cause mild coughing or irritation of the respiratory tract, especially in sensitive individuals.

Does PVA Pose Risks to Water Safety?

Polyvinyl alcohol (PVA) is a water-soluble plastic commonly used in products such as laundry balls and dishwasher tablets.

Although PVA is usually decomposed by microorganisms in wastewater treatment plants, thus reducing the impact on water sources, untreated PVA may not be completely degraded after entering natural water bodies. This may cause harm to the ecological environment.

The decomposition of PVA is affected by factors such as water temperature, salinity, and microorganisms, so we need to pay more attention to its use and treatment to protect water sources and ecological health.

Although studies have shown that PVA is less toxic to aquatic organisms, its excessive accumulation should still be avoided.

Microplastic Problems with PVA

The issue of polyvinyl alcohol (PVA) microplastics is gaining increasing attention.

As a water-soluble plastic, PVA is widely used in packaging, textiles, and medical products, but improper handling may lead to the formation of microplastic particles smaller than 5 mm in the environment.

These microplastics can come from a variety of sources, including plastic bottles, bags, and clothing.

They may cause harm to aquatic life and ecosystems and may affect human health through the food chain.

Although studies have shown that PVA particles do not accumulate in the body, they may still persist in the environment for a long time, affecting the ecological balance and absorbing harmful chemicals.

Are PVA’s Degradation Products Harmful?

PVA (polyvinyl alcohol) is a synthetic material that is soluble in water and degrades under appropriate conditions. Its degradation process mainly takes place in water.

First, PVA dissolves in water, and over time, water molecules gradually break its molecular chain, turning it into small molecules. These small molecules, such as ethanol and acetic acid, are generally considered safe and have little effect on aquatic organisms.

However, if the degradation is incomplete, some intermediate compounds may be left behind; the safety of these substances has not been fully confirmed and may have an impact on water quality.

For human health, PVA is generally safe and is usually not absorbed by the body. The small molecules produced during the degradation process will not pose a threat to health in small doses, but exposure to high concentrations of PVA dust or solution may cause skin irritation or respiratory discomfort.

In terms of the environment, although the main degradation products of PVA are generally safe, if some intermediate products accumulate in soil or water, they may have an impact on the ecology.

In general, under appropriate conditions of use, the products produced after PVA degradation are mostly safe, but we still need to pay attention to possible intermediate products to ensure that they are not harmful to people and the environment.

A Green Alternative to PVA

As people become more concerned about environmental issues, they are looking for alternatives to traditional plastics. Here are some common alternatives, along with their pros and cons:

Polylactic acid (PLA)

PLA is a plastic made from plants such as corn and sugar cane. It can degrade under certain conditions, but it is not soluble in water. However, PLA tends to deform at high temperatures, so it is not very suitable for hot food.

Starch-based plastics

These plastics are made from natural starch and are easily degraded, making them ideal for disposable food packaging and tableware. They are low-cost and widely available, but they tend to lose their shape in humid environments.

Cellulose-based film

This material is often used in food packaging and can degrade naturally and decompose quickly. It can keep food fresh. However, some chemicals may be used to make cellulose film, which may affect its environmental friendliness.

In contrast, polyvinyl alcohol (PVA) has a unique water solubility, which is particularly suitable for products that need to release contents quickly, such as dissolvable laundry balls and drug capsules. PVA degrades quickly and has a low impact on the environment, but may not be as durable as these alternative materials.

In general, although these alternative materials have their own advantages and disadvantages, none of them can completely replace the water solubility of PVA.

In Summary: Is PVA Safe?

In short, PVA is a safe and environmentally friendly high-performance material with the characteristics of being non-toxic, odorless, and soluble in water.

It is widely used in key areas such as food packaging, drug capsules, and soluble laundry balls. It does not pose a threat to human health and environmental safety.

If you want to use PVA materials in your new project, please contact Otivic! We will provide you with the most cost-effective customized production solutions to ensure that your needs are met.