Polyvinyl chloride (PVC) is a material that we often see in our daily lives. It is used in water pipes, medical devices, packaging bags, and even some building materials.

PVC is widely used because it is durable, cheap, and flexible.

However, many questions were asked about the safety of PVC and, in particular, its impact on health and the environment.

So is PVC safe? In this article, we will talk about the safety of PVC, whether it poses a health risk, its impact on the environment, and what alternative materials can be considered.

What Is PVC ?

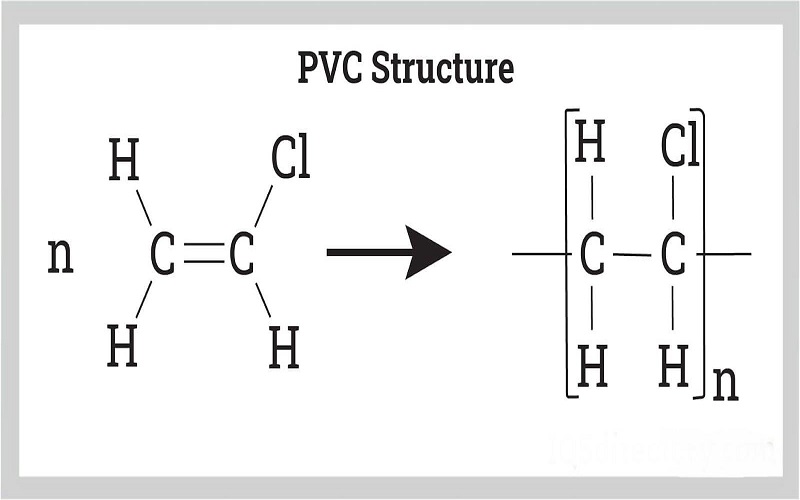

Polyvinyl chloride (PVC) is a common synthetic plastic, mainly made by polymerizing vinyl chloride monomer.

Vinyl chloride is an important chemical raw material, usually extracted and synthesized from chlorine and ethylene gases.

The wide application of PVC is due to its excellent physical properties, including chemical resistance, good mechanical strength, and adjustable flexibility.

| Physical Property | Value |

| Density (g/cm³) | 1.4 – 1.5 |

| Tensile Strength (MPa) | 40 – 60 |

| Elongation at Break (%) | 100 – 300 |

| Melting Point (°C) | 75 – 100 |

| Thermal Conductivity (W/m·K) | 0.14 – 0.19 |

| Temperature Range (°C) | -40 to 60 |

| Impact Strength (kJ/m²) | 5-15 |

The Composition of PVC: What’s Inside?

The main component of PVC is vinyl chloride monomer (C₂H₃Cl), which forms a long-chain molecular structure through polymerization reaction.

During the production process, additives such as plasticizers and stabilizers are usually added to enhance its flexibility, durability, and processing performance.

The molecular structure of PVC contains chlorine atoms, which gives it excellent flame retardancy and chemical corrosion resistance. Its repeating chain structure, with the molecular formula (CH₂-CHCl), makes PVC harder and has excellent chemical resistance and mechanical strength.

Therefore, PVC is particularly suitable for applications such as construction and pipelines that require high durability and fire resistance.

Phthalates: Are They Harmful?

Phthalates are very common plasticizers that are generally used to make PVC softer and more flexible.

However, studies have shown that this chemical can interfere with the human hormone system, hence its name as an endocrine disruptor.

Prolonged exposure to phthalates can lead to health problems such as reproductive effects, developmental abnormalities, and even association with certain cancers.

Lead and Cadmium: The Heavy Metal Threat

Lead and cadmium are two toxic heavy metals that were once widely used as stabilizers in polyvinyl chloride (PVC), mainly to enhance its heat resistance and durability.

However, these heavy metals are toxic and may seep into water sources or soil over time, causing serious environmental pollution.

For humans, long-term exposure to lead and cadmium can pose serious threats to health, including damage to the nervous system, kidneys and bones, and even increase the risk of certain diseases.

The Safety of PVC, Is It Toxic?

This is a question that many people are concerned about.

PVC is made from vinyl chloride, which is a carcinogen, but its content in PVC products is usually low enough to be considered safe.

The problem lies mainly in additives, such as phthalates, which are plasticizers that may affect human hormones. Long-term exposure may cause fertility problems and even increase the risk of cancer.

In addition, when PVC is processed or incinerated, toxic substances such as hydrochloric acid and dioxins are released, which are harmful to both health and the environment.

This is why PVC is called “toxic plastic.”

Is PVC Safe for Building Materials?

PVC is safe for building materials because of its excellent strength and durability.

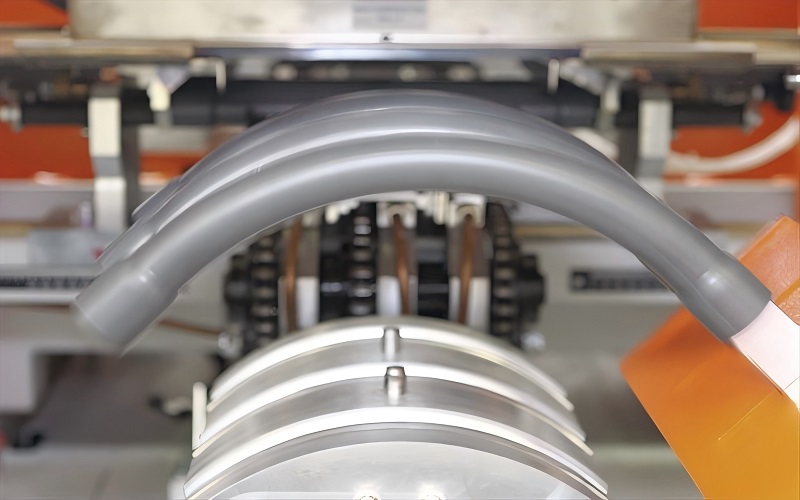

It is not easy to rust, has a long service life, and has good fire resistance. PVC pipes and window frames are often used in many construction projects because they are strong, durable, and not easily corroded by water and chemicals.

However, PVC may release some harmful gases at high temperatures, so care should be taken to avoid high temperature operations during construction.

In daily use, as long as the PVC material meets safety standards, the risk is relatively small.

Is PVC Safe for Use in the Automotive Industry?

Polyvinyl chloride (PVC) is widely used in the automotive industry, mainly for interior decoration, such as seats, floors, and dashboards.

Because PVC is durable, easy to clean, and can resist sunlight and moisture, it can keep the interior of the car in good condition.

However, like in building materials, PVC may also release some harmful substances at high temperatures, so in automobile production and use, it is necessary to ensure that the PVC materials used meet safety standards to reduce potential risks.

Is PVC Safe for Human Body?

Polyvinyl chloride (PVC) is common in everyday life, but its safety for humans is a concern.

Take toys, for example. Although many countries have safety standards, old toys can contain harmful chemicals. It is therefore best to look for a certified product when purchasing.

In food packaging, PVC can emit hazardous substances at high temperatures, so its use is restricted in many places.

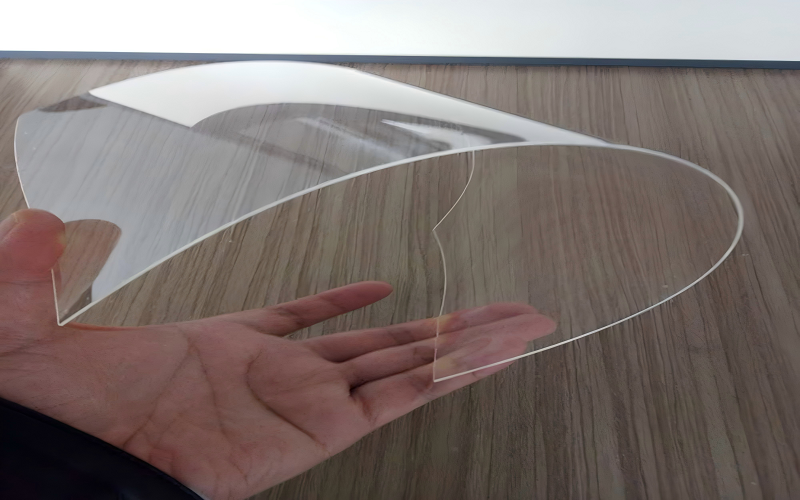

Medical devices such as infusion tubes and blood bags use flexible PVC, but it can also emit harmful substances, especially for children, so hospitals now prefer to use phthalate-free materials.

Environmental Impact of PVC

Beyond its direct impact on human health, PVC also has significant environmental consequences, both during its production and disposal.

Pollution During PVC Production

During the production of PVC, some harmful chemicals are released, such as dioxins and vinyl chloride. Dioxins are persistent organic pollutants that easily accumulate in the food chain and may cause serious health problems, such as affecting fertility and development.

These substances not only pose a great threat to our human health, but also pollute the air and water, causing long-term ecological problems.

Wild animals exposed to dioxins will also have various health problems. Therefore, it is particularly important to ensure safety and environmental protection when producing and using PVC.

Disposal and Recovery Issues

Polyvinyl chloride (PVC) is difficult to degrade naturally and may remain in the environment for hundreds of years.

Burning PVC produces harmful gases and pollutes the air.

Although PVC is marked as recyclable “03,” it is not easy to actually recycle it because it contains additives.

When processed at high temperatures, PVC releases harmful gases.

Recycled rigid PVC requires a lead-free protective layer and can usually only be used for the same purpose.

Are There Safer Alternatives to PVC?

Depending on the application, several safer and more sustainable materials can replace PVC.

Polyethylene (PE) and Polypropylene (PP)

Polyethylene (PE) and polypropylene (PP) are widely used alternatives to PVC.

These materials are durable, flexible, and resistant to moisture, making them suitable for a range of applications, from packaging and plumbing to automotive parts.

Unlike PVC, PE and PP do not require harmful plasticizers like phthalates, making them safer choices for food and medical applications.

Silicone and Thermoplastic Elastomers (TPE)

In applications that require flexibility, such as medical tubing or consumer goods, silicone and thermoplastic elastomers (TPE) are gaining popularity as safer alternatives to PVC.

Silicone is particularly prized for its heat resistance and durability, making it ideal for use in high temperature environments.

Additionally, TPE is phthalate-free and considered safe for both medical and food-contact applications.

How the Rules Govern PVC Safety?

Governments and regulatory bodies have implemented stringent measures to ensure the safety of PVC, particularly in applications that involve close human contact or environmental exposure. These regulations help minimize the risks associated with PVC’s use.

- European Union Regulations

The European Union is at the forefront of regulating the use of PVC.

It bans the use of certain dangerous stabilisers, such as lead and cadmium, and limits the use of phthalates in children’s toys and materials intended to come into contact with foodstuffs.

In addition, the EU has set recycling targets to reduce the environmental impact of PVC during its production and disposal.

- U.S. Regulations

In the United States, the use of PVC is governed by numerous regulations.

The environmental protection agency (EPA) limits harmful substances released during manufacture, while the consumer product safety commission (CPSC) focuses on children’s toys and household products and limits harmful additives such as phthalates.

The US Food and Drug Administration (FDA) guarantees the safety of PVC materials in contact with food.

In addition, some states have their own PVC recycling policies to encourage better use of resources.

Conclusion: Is PVC Safe?

In general, PVC is safe in many cases, provided it meets modern safety standards and is used properly.

Although there are some additives, such as plasticizers, strict controls have been put in place in many places to reduce the impact on health and the environment.

Recycling PVC is difficult but can reduce the risk of hazardous substances if the method is correct.

In conclusion, in order to ensure the safe use and recycling of PVC, we must focus on regulatory and environmentally friendly materials for a sustainable future.