TPE, thermoplastic elastomer, is a material we often come across, even if we don’t think about it.

Because it is flexible, strong, and easy to mold into different shapes, it is used in products such as automotive parts, children’s toys, and even medical equipment. But maybe you’re wondering, “Is that really safe?”

Well, the short answer is: yes, that’s for sure. TPE does not contain harmful chemicals like some other plastics, so it can be safely used around us when we come into daily contact.

What is TPE and Why Does It Matter?

TPE, or thermoplastic elastomer, is a polymer that combines the elasticity of rubber with the machinability of plastic.

This unique combination makes it a very versatile material that can be used in a range of products.

Whether it’s soft handles for the home, joints for automotive parts, or medical hoses, TPE is a material that offers a balance between flexibility and durability.

One of the main reasons TPE is so popular is that it is not only easy to form but also hypoallergenic, non-toxic, and often considered safe for various applications.

TPE’s Properties and Categories

TPE has become the material of choice in many industries due to its unique properties. The following table lists the key physical properties of TPE and their typical values to help you better understand its performance in different applications.

| Property | Typical Value/Range |

| Elasticity (Tensile Elongation) | 300% – 700% |

| Flexibility (Bend Radius) | Very High, Bend radius: 1-2 times the thickness |

| Hardness (Shore A) | 30 – 90 Shore A |

| Density | 0.89 – 1.3 g/cm³ |

| Temperature Resistance | -50°C to 120°C |

| Tear Strength | 10 – 50 N/mm |

| Soft Touch (Coefficient of Friction) | 0.6 – 0.9 |

| Elastic Modulus (MPa) | 1 – 100 MPa |

| Tensile Strength | 5 – 25 MPa |

| Abrasion Resistance (Volume Loss) | 30 – 120 mm³ |

| Compression Set | 10% – 30% |

| Thermal Conductivity | 0.15 – 0.35 W/m·K |

| Water Vapor Transmission Rate | 5 – 15 g/m²/day |

| Water Absorption | 0.1% – 0.4% |

| Flammability Rating | UL 94 HB, V-0 (customizable) |

| Heat Deflection Temperature | 80°C – 120°C |

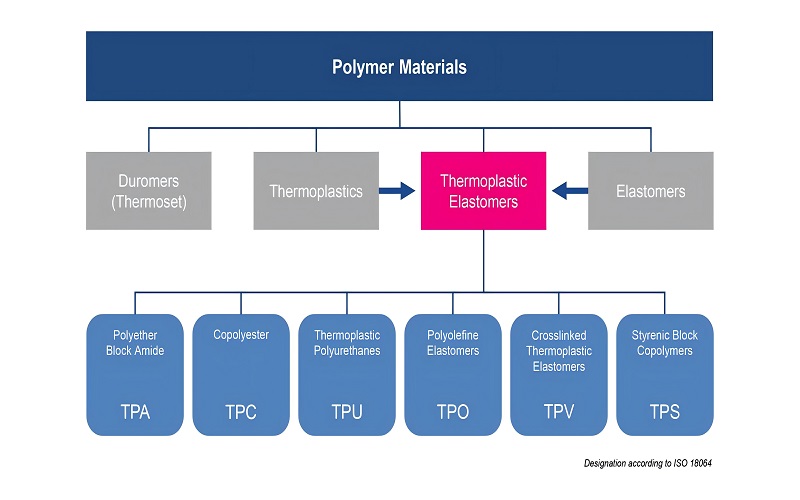

There are many different types of TPE, each with its own unique characteristics.

- For example, SBC/TPE-S is soft and flexible, so it is often used in toys and packaging.

- TPO/TPE-O is very popular in the automotive industry because it can remain durable in all weather conditions.

- TPV/TPE-V/EA can withstand high temperatures and is suitable for use in joints and pipes.

- TPU/TPE-U is particularly wear-resistant and chemical-resistant and is often found in electronic products and shoes.

- COPE/TEEE/TPE-E is very flexible and suitable for use as an engineering material.

- And PEBA/COPA/TPE-A is light, can withstand extreme temperatures, and is often used in sports equipment and medical devices.

The Manufacturing Process of TPE: How is it Made?

TPE is produced through injection molding and extrusion processes to create a variety of products.

These two methods can quickly process TPE into various shapes, which is very convenient.

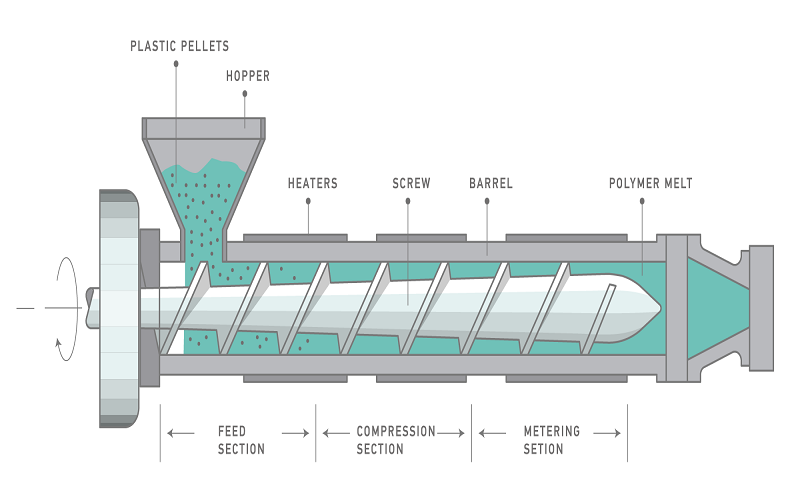

- Extrusion molding

This process is a bit like squeezing toothpaste. First, the TPE pellets are heated to a liquid state, and then extruded through a die to form a long strip or tube. This method is often used to make wire sheaths, pipes, and seals. The steps are as follows:

- Heat the TPE to a molten state.

- Extrude the molten TPE into a mold.

- Cool it with water or air to make it hard.

- It may need to be cut or punched, and it can be used after completion.

Extrusion molding is suitable for large-scale production and is efficient.

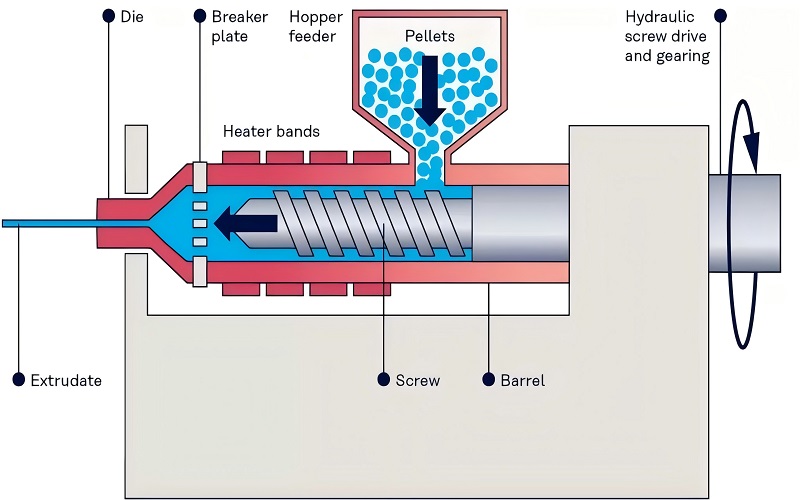

- Injection molding

This method is suitable for making small products with complex shapes. First, heat the TPE to a molten state, then inject it into the mold under high pressure, and cool it to get the desired shape. The steps are as follows:

- Heat the TPE to a molten state.

- Inject the molten TPE into the mold.

- The mold cools and the TPE is removed after solidification.

- Perform surface polishing and inspection, and use it after confirming that it is qualified.

Injection molding is suitable for making complex products such as mobile phone cases, automotive parts and toys.

The thermoplastic properties of TPE allow it to be melted and reshaped multiple times without losing properties. This flexibility makes TPE a cost-effective choice, reducing waste and energy consumption in the production process.

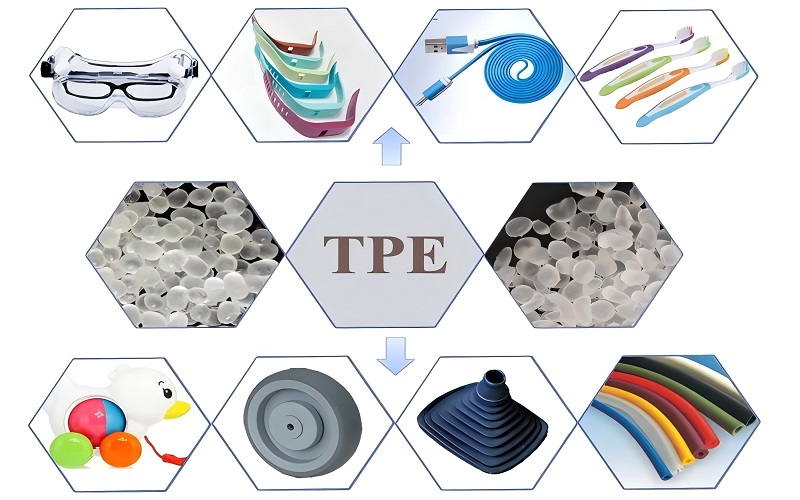

Applications of TPE

TPE’s versatility shines through in its wide range of applications. Some of the key areas where TPE is used include:

- Medical Applications

- Automotive Industry

- Consumer Goods

- Electronics

Is TPE Material Safe to Use?

TPE is safe and is used in many industries, especially in the medical and food fields.

Unlike PVC, which contains harmful chemicals, TPE does not have those dangerous additives and will not cause allergies like latex, so both manufacturers and those of us who use it can rest assured.

TPE does not contain harmful things such as phthalates, BPA, or latex, which makes it particularly suitable for places with high safety requirements. Whether it is kitchen supplies, hospital equipment, or children’s toys, TPE is a reassuring choice that is not only good for us but also good for the environment.

TPE in the Medical Industry: Safety and Usability

TPE is an incredibly importation material for the medical industry due to it being safe and simple to fabricate.

To begin with, TPE does not contain any harmful substances, such as harmful chemicals—or harmful to the body—so that the patient won’t feel hurt when they use medical devices, which is beneficial for patients with latex allergies. The use of TPE makes allergies less likely. Also, some TPE material can add antibacterial ingredients to stop infections, which is important in atmospheres like hospitals.

In addition to that, TPE has a good tolerance for the chemical drugs used in medical care and doesn’t react with the drugs.

The most convenient, the TPE can be easily manufactured into many shapes through simple other treatment methods to enable quick but cost-effective medical device manufacturing.

TPE and Consumer Health: Is There a Risk?

TPE is a suitable material for kitchen utensils. It is very safe to use because it contains no harmful chemicals, including BPA or phthalates, making it safe for everyone to use, including people with allergies, although allergies usually do not happen.

Some TPE materials can even contain antibacterial elements that can help inhibit bacterial growth to keep the kitchen clean. It resists high temperatures, which makes it a very excellent material for pot mats and spatulas.

It also feels good in hand and is very easy and comfortable to hold. Importantly, TPE has a very smooth surface, which does not stick to food or debris and is really easy to clean.

Overall, TPE kitchen utensils are safe to use and effective to work with. When using TPE kitchenware, you can experience less anxiety during the cooking process and keep the kitchen clean.

TPE in Children’s Products: Safety Considerations

TPE is widely used in children’s products, mainly for its safety and comfort.

First, TPE does not contain harmful chemicals such as phthalates and bisphenol A, so parents can reassure their children to use it. In addition, TPE is generally non-allergenic and suitable for sensitive children.

Secondly, TPE is soft and elastic; it is very suitable for making toys and cutlery. It feels very comfortable to use. Wear-resistant, resists children’s play, not easy to break. TPE also has the characteristics of heat and cold resistance. It is suitable for various environments. Some materials can also add antibacterial ingredients to maintain the hygiene of toys.

In summary, the use of TPE in children’s products is safe and convenient, reassuring for parents and children. Children can play and eat with the products made of TPE.

TPE’s Environmental Impact: A Green Choice?

TPE is regarded as an eco-friendly material with numerous perks.

For one, the manufacturing process of TPE is more energy efficient than traditional rubber since TPEs do not need several chemical processes, resulting in less energy consumption and carbon footprint.

Moreover, TPEs are reusable. You can heat it, remelt it, and remodel it so that production waste is not wasted but reused.

Additionally, TPE does not produce many harmful volatile organic compounds (voc) in its manufacture, which makes it better for the environment and the health of workers.

While TPE itself is not degradeable in a natural manner, being recyclable means that manufacturers can reuse it and reduce their use of new materials. New technologies are also available to manufacture TPEs from renewable/rebio resources, which is yet another means of reducing the environmental impact of TPEs.

In sum, TPE is environmentally friendly in many respects.

TPE vs. PVC and Silicone: A Comparative Analysis

When TPE is compared to PVC and silicone, it excels in the following areas:

Safety: TPE does not contain harmful phthalates or bisphenol A, both of which can be found in PVC. While silicone is also safe, the manufacturing of TPE allows for more flexibility, and recycling face has also increased strong support for this compared to silicone.

Recyclability: TPE can be recycled and processed into another form. Silicone is not typically recyclable. Because of toxic additives, PVC is definitely an incurable environmental issue.

Flexibility and durability: TPE has comparable flexibility, is much cheaper, and costs less to process than silicone.

Regulations and Standards: Ensuring the Safety of TPE

Strict guidelines, including the following, apply to TPE products used in food and medical applications:

- FDA Approval: In the U.S., the FDA regulates TPE for food contact and medical use to ensure it is free of harmful chemicals.

- REACH Compliance: In the EU, TPE is subject to REACH regulations, which control the use of hazardous substances in manufacturing.

These regulations help ensure that TPE is safe for consumers and meets the highest standards in industries that prioritize safety.

Conclusion: Is TPE Safe?

In summary, TPE is a safe and flexible material that works well in many areas. You’ll find it in medical devices, car parts, and everyday items.

What’s great about TPE is that it’s durable and non-toxic, which makes it a smart choice for both manufacturers and consumers.

So, is TPE safe? Definitely! It’s not just safe; it’s also one of the most versatile and green materials out there today.