Want to master LLDPE injection molding?

In this article, we explore everything from the key properties of Linear Low-Density Polyethylene (LLDPE) to its advantages and best practices in injection molding.

Whether you are looking to improve product quality or production efficiency, we’ve got you covered.

Understanding Linear Low-Density Polyethylene (LLDPE)

Linear Low-Density Polyethylene (LLDPE) is a widely used commodity thermoplastic. It finds extensive application in the packaging industry.

Produced through the copolymerization of ethylene with alpha-olefins like butene, hexene, or octene, LLDPE’s unique molecular structure includes short branches that allow for better flexibility and elongation compared to Low-Density Polyethylene (LDPE).

The shorter branches in LLDPE contribute significantly to its physical properties, setting it apart from other types of polyethylene. These properties make LLDPE suitable for a wide range of applications, particularly in consumer and industrial packaging.

Additionally, its typical melt flow properties allow it to be processed through methods such as blow molding and film extrusion, further enhancing its versatility.

Compared to other polyethylene types, LLDPE offers advantages in terms of flexibility and elongation capabilities. Its distinct structure and polymerization process enable it to perform exceptionally well in environments where other polyethylenes might fall short.

Key Properties of LLDPE

| Property | Value/Description |

| Tensile Strength | ~20 MPa |

| Impact Strength | High (specific value not provided) |

| Density | ~0.915–0.925 g/cm³ |

| Melting Point | ~120–130°C |

| Elongation at Break | ~400–600% |

| Vicat Softening Point | ~90–110°C |

| Hardness (Shore D) | ~40–50 |

| Flexural Modulus | ~150–300 MPa |

The mechanical properties of Linear Low-Density Polyethylene (LLDPE) are what make it a standout material in plastic injection molding, thanks to its excellent mechanical properties and material properties.

With a tensile strength reaching approximately 20 MPa, LLDPE is strong enough to withstand various stresses while maintaining its integrity. This high tensile strength is complemented by its remarkable impact strength, making it suitable for applications that require durability and resilience.

Additionally, lldpe plastic is often chosen for its versatility in various manufacturing processes.

Despite these advantages, LLDPE does have its limitations. For instance, it lacks memory retention after being stretched, which can be a drawback in applications where shape recovery is crucial.

However, its combination of high tensile strength, good impact resistance, and effective environmental stress-cracking resistance makes it a versatile material for many uses.

Overall, the properties of LLDPE, including its high stiffness, tensile strength, and good toughness, position it as a highly valuable material in the injection molding industry.

These attributes ensure that LLDPE can meet the demands of various applications, from consumer products to industrial components, providing both performance and reliability.

Advantages of LLDPE in Injection Molding

Linear Low-Density Polyethylene (LLDPE) offers numerous advantages when used in injection molding, making it a preferred choice for many manufacturers. Key benefits include:

- Remarkable percentage of elongation, providing high extensibility

- Ideal for stretchable packaging films due to its flexibility

- Products made from LLDPE can stretch more easily without breaking

- Crucial for applications requiring durability and resilience

Another significant advantage of LLDPE in injection molding is its ability to withstand low temperatures without becoming brittle. This property enhances its performance in environments where other materials might fail.

Additionally, LLDPE exhibits excellent flow properties, which are crucial for achieving high-quality molded parts. Grades like M500026 and SABIC® M50022T are particularly noted for their excellent flow properties, low-temperature toughness, and stress crack resistance, making them ideal for injection molding applications.

Overall, LLDPE provides well-suited properties for various applications, making it a versatile choice for manufacturers. Its excellent flow properties, combined with its ability to withstand low temperatures and high extensibility, ensure that it can meet the diverse needs of different industries.

Optimal Conditions for LLDPE Injection Molding

Achieving optimal results in LLDPE injection molding requires careful control of several critical factors. One such factor is the mold temperature, which determines the crystallinity level in the polymer and can significantly enhance the surface finish of molded parts. Maintaining the correct mold temperature is essential for achieving the desired part quality and performance.

Injection pressure is another crucial parameter in the LLDPE injection molding process. Key points include:

- The typical injection pressure range for LLDPE molding is between 50-160 MPa.

- High packing pressure helps to counteract cavity pressure drops, especially for higher molecular weight resins.

- Properly managing injection pressure ensures that the material flows correctly into the mold, filling all cavities and producing high-quality parts.

Melt temperature also plays a vital role in the injection molding process, influencing the viscosity of the polymer as it enters the mold.

For LLDPE, the adjustable temperature range is between 200 °C to 260 °C, which impacts the flowability and processing characteristics of the material, including the melt index.

Additionally, mold shrinkage, which occurs primarily during cooling, can affect the dimensional accuracy of the final part, highlighting the importance of adequate cooling time.

By carefully controlling these conditions, manufacturers can optimize their LLDPE injection molding processes and achieve consistent, high-quality results.

Common Applications of Injection Molded LLDPE

The versatility of Linear Low-Density Polyethylene (LLDPE) makes it suitable for a wide range of applications in various industries. In the consumer sector, LLDPE is commonly used for molded components such as:

- Lids

- Containers

- Caps These components benefit from the material’s excellent puncture resistance and durability, ensuring that products made from LLDPE can withstand the rigors of everyday use.

In industrial applications, LLDPE’s environmental stress-crack resistance makes it ideal for packaging solutions. Shipping sacks, produce bags, can liners, and carrier bags are just a few examples of how LLDPE is utilized in industrial packaging.

Additionally, the agricultural tanks sector benefits from LLDPE in the rotational molding of tanks, trash containers, and chemical drums, where durability and resistance to harsh conditions are crucial.

Smaller applications for LLDPE include pipe linings and wire and cable coatings, where its flexibility and toughness are advantageous. Typical applications for injection molded LLDPE also encompass enclosures, caps, snap fits, and lids, highlighting the material’s broad utility and adaptability to different general purpose applications, including outdoor applications.

Challenges and Solutions in LLDPE Injection Molding

While LLDPE offers many benefits, it also presents certain challenges in the injection molding process. One key challenge is that LLDPE does not recover its shape after stretching, which can lead to potential issues in part design. This limitation requires careful consideration during the design phase to ensure that the final product meets the desired specifications.

High mold shrinkage associated with LLDPE can lead to warpage, a common defect in molded parts. Effective communication between designers and engineers is crucial for optimizing the injection molding process and addressing such challenges during production. By collaborating closely, teams can identify potential issues early and implement solutions to mitigate them.

Quality assurance protocols implemented by experienced providers play a vital role in maintaining high standards throughout the injection molding process.

These protocols ensure consistent quality in the final product, helping to overcome the challenges associated with LLDPE injection molding and achieve reliable, high-quality results.

Comparison with Other Polyethylenes

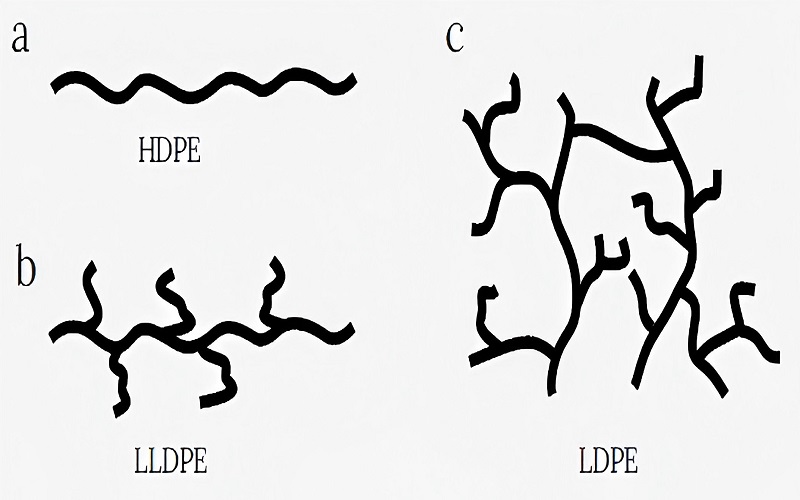

Comparing Linear Low-Density Polyethylene (LLDPE) with other polyethylenes like Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) reveals distinct differences in their properties and applications.

LLDPE molecules do not entangle as easily as those of LDPE and HDPE, which contributes to its unique characteristics. The molecular structure of LLDPE as a copolymer enhances its resistance to harsh environments over LDPE, a homopolymer.

The different types of polyethylene can be characterized as follows:

- LLDPE (Linear Low-Density Polyethylene): Notably more flexible than LDPE, offering greater tensile strength and conformability.

- HDPE (High-Density Polyethylene): Recognized for its high strength and chemical resistance, making it less flexible compared to LLDPE and LDPE.

- MDPE (Medium-Density Polyethylene): Provides a balance between strength and flexibility, being stronger than LDPE but less commonly used.

When selecting polyethylene grades, factors such as flexibility, chemical resistance, durability, and thermal performance should be carefully evaluated.

HDPE’s tight molecular structure allows it to excel in applications requiring UV resistance and durability, while LLDPE’s flexibility makes it ideal for applications demanding high elongation and toughness.

Tips for Enhancing Production Efficiency

Enhancing production efficiency in LLDPE injection molding is crucial for maximizing productivity and minimizing costs. Effective material handling practices are essential; using automated systems can minimize waste and ensure consistent material flow during the injection molding process. This approach helps maintain steady production rates and reduces the likelihood of defects.

Expert support in design and prototyping can significantly enhance the efficiency and success of LLDPE injection molding projects. By leveraging the expertise of professionals, manufacturers can optimize their designs, reduce production time, and improve the overall quality of the final product. This collaboration is particularly valuable in the early stages of product development.

Combining effective material handling with expert support creates a robust strategy for optimizing production efficiency in LLDPE injection molding. These practices ensure that the production process runs smoothly, from material preparation to the final product, ultimately leading to increased productivity and cost savings.

Choosing the Right Grade of LLDPE

Selecting the appropriate grade of Linear Low-Density Polyethylene (LLDPE) is critical for achieving the desired performance and quality in injection molding applications.

LLDPE grades vary in properties such as density and the presence of additives like slip agents and anti-block, affecting their usage in different applications. Understanding these variations helps manufacturers choose the right material for their specific needs.

For example, SABIC® 220HT is designed for blown film applications, showcasing specific grade suitability for certain uses. Using high-quality LLDPE materials that are specially formulated with higher viscosity can enhance efficiency by reducing defects and improving the final product’s integrity.

By selecting the right grade, manufacturers can ensure that their intended optimal performance and reliability in injection molding projects.

Expert Design and Support Services

Utilizing expert design and support services is essential for optimizing LLDPE injection molding projects. Benefits include many advantages:

- Advanced technology for CAD and prototyping allows for better design validation before mass production.

- Ensures that the final product meets all specifications.

- Helps identify potential issues early in the design process, saving time and resources.

A provider’s experience in your specific industry can typically improve the quality and reliability of the molded products. Experienced providers understand the unique challenges and requirements of different industries, enabling them to offer tailored solutions that enhance product performance and durability.

One-stop service offered by providers can streamline the process, encompassing product design, mold manufacturing, and injection molding.

This comprehensive approach ensures that all aspects of the project are managed efficiently, resulting in high-quality products and an easy flow in the production process, especially for injection molders.

Summary

Mastering LLDPE injection molding requires a thorough understanding of the material’s properties, optimal processing conditions, and common challenges.

By leveraging the advantages of LLDPE, such as its flexibility, excellent flow properties, and durability, manufacturers can produce high-quality products that meet the demands of various industries.

With the insights provided in this guide, you are well-equipped to harness the full potential of LLDPE in your injection molding projects, driving innovation and success in your manufacturing endeavors.