LSR injection molding is a process used to create durable, precise parts from liquid silicone rubber.It’s valued in industries like healthcare and automotive for its efficiency and ability to produce intricate shapes.

This article covers the essential techniques and best practices for mastering LSR injection molding.

Understanding Liquid Silicone Rubber (LSR)

Liquid silicone rubber (LSR) is a versatile material known for its exceptional flexibility, allowing the creation of intricate shapes with minimal waste. Its biocompatibility and chemical inertness make it an ideal choice for medical implants and prosthetics, minimizing allergic reactions and ensuring safe interactions with human tissue.

Additionally, liquid silicone rubber molding, thermoplastic injection molding, and liquid silicone molding enhance the manufacturing process, further optimizing the use of this innovative material.

Additionally, LSR can withstand extreme temperatures, functioning effectively from -60°C to 250°C, making it suitable for applications that demand durability in extreme temperatures. The chemical resistance of LSR further enhances its longevity, enabling it to perform reliably in harsh environments and resist extreme temperatures.

Its low viscosity allows for the creation of parts with detailed features and intricate designs. These electrical properties make LSR an attractive material across various industries, including healthcare, aerospace, and consumer goods, where its insulating properties also benefit electronic components.

The LSR Injection Molding Process

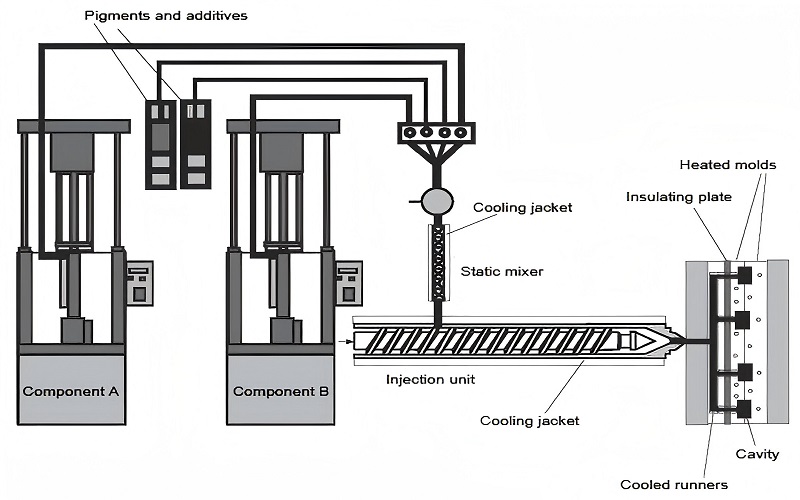

The LSR injection molding process begins with:

- Preparation of uncured liquid silicone in two separate containers: one for the base and the other for the catalyst.

- Mixing process of these materials in equal proportions using intensive distributive mixing to ensure a uniform blend.

- Keeping the mixture at a low temperature before injection to maintain its properties.

The LSR injection molding process involves the following steps:

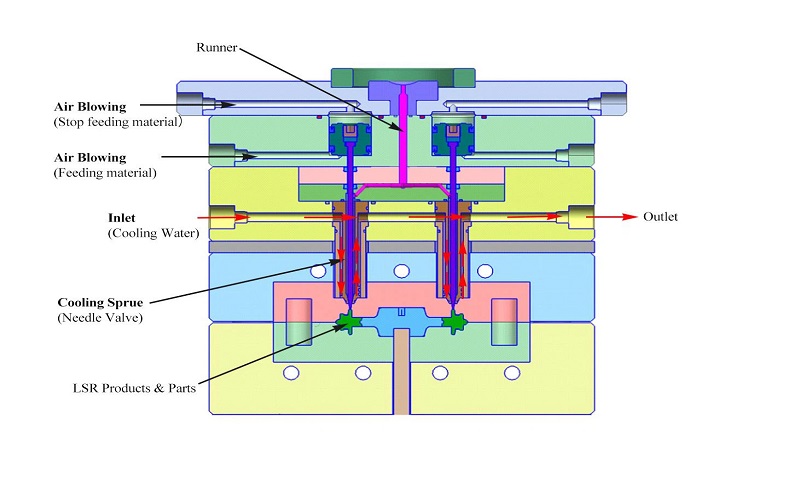

- A high-temperature mold is crafted using CNC machining, which is crucial for the process.

- The prepared mold receives the liquid silicone mixture under high pressure, ensuring it fills all the mold features.

- Heating initiates the curing process, converting the liquid silicone into solid rubber.

- The curing duration varies based on the complexity and size of the part, with larger volumes taking longer. This process is often enhanced through silicone rubber injection molding, silicone injection molding, the liquid injection molding process, and the lsr molding process.

Post-curing, the parts are cooled and extracted from the molds. The molded state of LSR is permanent and irreversible.

This precise thermoset process ensures the final parts meet exact specifications and maintain high quality. Combining high pressure, precise temperature control, and meticulous mixing produces durable, create flexible silicone parts suitable for various applications.

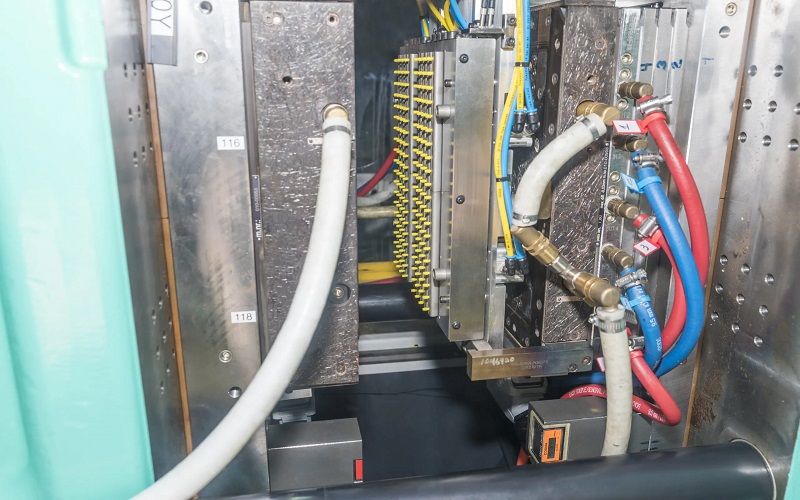

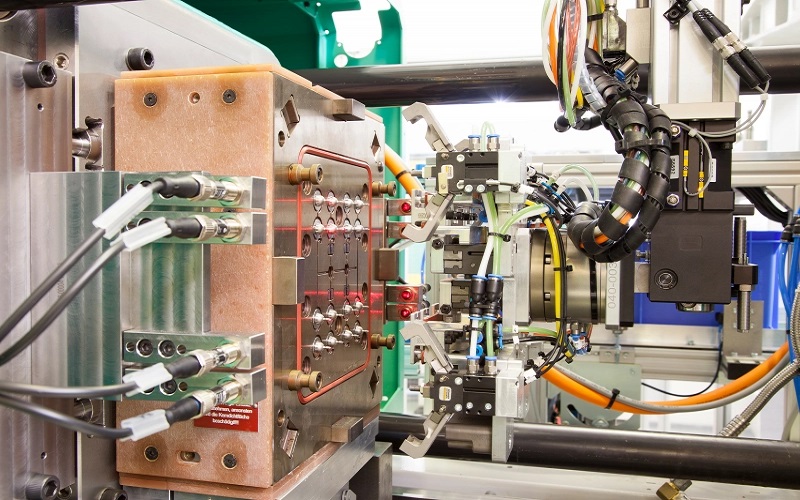

Key Equipment for LSR Injection Molding

Key equipment in LSR injection molding includes:

- Mixers: Blend the two components—base-forming silicone and platinum catalyst—ensuring a uniform mixture before injection, often using a static mixer.

- Injectors: Deliver the pressurized liquid silicone into the mold, with adjustable pressure and injection rates for precision.

- Metering units: (mentioned as key equipment but not further described in the text).

Key components and their functions include:

- Metering units: crucial for a pumping system that mixes the two liquid components in specific ratios, allowing for accurate mixing and consistent part quality.

- Mold clamp: secure the mold halves together during the injection process to prevent leakage.

- Automatic shut-off valve in the nozzle: helps to prevent leaks and overfilling, along with several mechanical components that enhance the overall system efficiency.

Liquid injection molding machines are specifically designed to handle LSR materials, featuring:

- Supply drums

- Metering units

- static or dynamic mixer

- Other essential components to ensure efficient and precise molding

This specialized equipment is integral to achieving high-quality results in LSR injection molding.

Designing for LSR Injection Molding

Designing for LSR injection molding requires careful consideration of mold design, tolerances, and draft requirements. Molds can be single, multi-cavity, or family molds, each suited to different production needs. Tolerances for mold cavities are typically +/- 0.005 inches, with an additional +/- 0.002 inches per inch for shrink rate.

The lsr molding tool is critical in achieving these precise tolerances, ensuring compatibility with materials like body fluids and chemical solutions in applications such as medical devices.

Draft requirements for LSR parts are similar to those for plastic injection molding, with shallow components sometimes utilizing zero draft. The use of a dynamic or static mixer in the injection process ensures consistent material flow and homogeneity, which is crucial for optimizing the injection molding process and ensuring high-quality parts.

Optimizing Part Design

Optimizing part design in LSR injection molding involves several key considerations:

- Wall thickness should be even to prevent sinks and voids.

- Rib thickness should be between 0.5 and 1.0 times the thickness of adjacent walls.

- Incorporate draft angles to facilitate easier part ejection from molds and improve manufacturability.

- Align parting lines with the parting surface in gaskets and seals to enhance fit and functionality.

- Minimize parting lines to produce cleaner parts and save time.

Gate placement on LSR components should be on non-critical smooth surfaces or in recessed locations to avoid affecting part aesthetics and functionality. The material’s flexibility allows for the easy creation of parts with undercuts, assisting with part removal.

By considering these design elements, manufacturers can achieve optimal performance and quality in their LSR-molded components.

Material Selection Considerations

Selecting the right LSR materials is crucial for meeting specific application requirements and ensuring performance. Factors to consider include:

- Chemical compatibility

- Wear resistance

- Environmental performance

- Durometer range (typically 10 to 80 durometer shore), which affects elongation and modulus properties and falls within the hardness range

- Temperature resistance

- Mechanical properties

- Durability, especially for applications exposed to extreme conditions

Understanding shrinkage rates is essential for establishing guidelines in the design stage. Material shrinkage can be influenced by mold temperature and pressure in the mold cavity. Using mold simulations and prototypes can help identify the precise shrinkage rate of silicone materials, ensuring accurate final dimensions.

These considerations are vital for selecting the best materials for LSR injection molding applications.

Advantages of LSR Injection Molding

LSR injection molding offers several advantages that make it a superior choice for modern manufacturing needs:

- Shorter molding cycles, leading to greater efficiency and higher production output

- Ease of processing

- High-volume production

- Consistent part quality

- Improved productivity

- Low viscosity of liquid silicone facilitates the creation of intricate designs and complex geometries

- Ability to produce precise parts with exact dimensions

Another advantage is the cost-effective production of complex parts in high volumes, minimizing waste and reducing overall manufacturing costs. The versatility, efficiency, and design flexibility of LSR injection molding appeal to manufacturers across various industries.

Applications of LSR Injection Molding

The versatility of liquid silicone rubber makes it suitable for a wide range of applications:

- In the medical field, LSR’s biocompatibility is crucial for creating safe and effective implants, prosthetics, and other medical devices.

- The automotive industry uses LSR to produce components such as oil seals, O-rings, and parts for cooling-water systems.

- Household appliances like vacuum cleaners and food processors utilize LSR for its durable and flexible properties.

LSR is also employed in the agricultural sector for creating efficient and environmentally friendly solutions. Its ability to bond without primers allows for overmolding with thermoplastics and metals, enhancing its application scope through lsr molding.

Furthermore, LSR’s high heat resistance and non-odorous, non-tasting properties make it ideal for food safety applications. These diverse applications highlight the material’s adaptability and effectiveness across industries.

Prototyping and Testing in LSR Injection Molding

Prototyping is crucial for developing liquid injection molded parts, allowing manufacturers to evaluate form, fit, and functionality before mass production. Technologies like CNC machining and 3D printing, including Fused Deposition Modeling (FDM) and Stereolithography (SLA), are commonly used.

These methods offer conceptual models and functional testing capabilities, identifying performance or production process issues early. The injection unit plays a key role in ensuring precise material delivery, while the heated cavity maintains optimal molding conditions to minimize material waste.

Early quality checks, including visual inspections and material testing, ensure high-quality LSR parts. Prototypes help optimize and refine designs, reducing potential production costs and times.

Identifying issues related to part performance and production processes beforehand ensures final products, such as those incorporating cushioning pads, meet all specifications and quality standards.

Full-Scale Production and Quality Control

Full-scale production of LSR parts involves pilot production, where near-production quality samples are created to finalize design elements and production processes. Quality control testing includes evaluating tensile properties using ASTM D412 standards, along with visual inspections and functional testing to ensure high-quality parts.

Adhering to ISO-certified practices further ensures consistent production quality. The use of a metered pumping device ensures precise delivery of materials, including thermoplastic elastomers, enhancing process efficiency.

Automation significantly impacts high-volume production by reducing human interaction and minimizing contamination risks. Automated systems usually handle part removal post-cooling. Selecting a partner that adheres to ISO quality standards helps maintain rigorous quality throughout the production process. This approach ensures that the final products meet all required specifications and maintain high-quality standards.

LSR vs. HCR Injection Molding

There are notable differences between Liquid Silicone Rubber (LSR) and High Consistency Rubber (HCR) in injection molding. These distinctions are important to consider:

- LSR is favored for high-volume production due to its lower viscosity, allowing for easier processing and faster production rates.

- HCR requires labor-intensive processing methods and is generally associated with slower production rates.

- The choice between LSR and HCR often depends on the specific application’s requirements for material properties such as flexibility and hardness.

HCR injection molding is characterized by higher viscosity, different curing systems, and longer cure times compared to LSR. The most commonly used curing process in HCR is peroxide curing, which contributes to its high viscosity and slower curing times. Common molding processes for HCR include compression molding and transfer molding.

However, HCR processing presents higher part variability compared to LSR, making LSR a more consistent and efficient choice for many applications.

Choosing the Right LSR Injection Molding Partner

Choosing the right LSR injection molding partner is crucial for ensuring the quality and performance of molded parts. A partner with expertise in LSR can effectively address the unique material characteristics and challenges presented by liquid silicone rubber.

Implementing a thorough vetting process for potential partners can prevent costly mistakes and delays in production. This process enhances production efficiency and reliability, leading to successful project outcomes.

When selecting a partner, consider:

- Their experience with LSR injection molding

- Their adherence to quality standards

- Their ability to provide comprehensive support throughout the production process

A well-chosen partner will contribute to the overall success of your LSR injection molding projects, ensuring high-quality, reliable parts.

Summary

Mastering LSR injection molding offers numerous benefits, including efficiency, high-quality production, and versatility across various applications.

By understanding the material properties, optimizing part designs, selecting the right equipment, and choosing a reliable partner, manufacturers can achieve exceptional results.

Embrace the potential of LSR injection molding to enhance your manufacturing processes and produce superior products that meet the highest standards of quality and performance.

Frequently Asked Questions

What are the main advantages of LSR injection molding?

The main advantages of LSR injection molding include shorter molding cycles, high-volume production, consistent part quality, and the capability to produce intricate designs with minimal waste. These benefits make it a highly efficient choice for manufacturing.

What industries benefit from LSR injection molding?

Various industries, including healthcare, automotive, consumer goods, agriculture, and food safety, benefit significantly from LSR injection molding due to its versatility and enhanced properties. This technology is pivotal in producing high-quality and durable components across these sectors.

How does prototyping help in LSR injection molding?

Prototyping significantly aids in LSR injection molding by enabling manufacturers to assess design aspects such as form, fit, and functionality, while also identifying potential performance issues. This process ultimately reduces costs and production times prior to mass production.

What is the difference between LSR and HCR injection molding?

The primary difference between LSR and HCR injection molding is that LSR features lower viscosity, enabling easier processing and quicker production, whereas HCR has higher viscosity, necessitating more labor-intensive methods and resulting in slower curing times.

What should I consider when choosing an LSR injection molding partner?

When selecting an LSR injection molding partner, it is crucial to evaluate their expertise in LSR, adherence to quality standards, and experience, as well as their capability to offer comprehensive support throughout the production process. These factors collectively ensure a reliable and efficient collaboration.