Medical plastic injection molding is a cornerstone of medical device manufacturing, enabling the production of high quality parts for medical devices such as surgical implants, dental implants, and test tubes.

This manufacturing process combines precision, biocompatible materials, and strict quality standards to ensure patient safety and optimal performance.

By leveraging medical injection molding techniques like insert molding, two shot molding, and liquid silicone injection molding, the medical device industry achieves cost efficiency and high volume production.

This guide explores the injection molding process, materials, techniques, and applications, providing insights into creating medical device components that withstand harsh environmental conditions.

Understanding Medical Plastic Injection Molding

Medical plastic injection molding is a specialized manufacturing process that produces plastic components with tight tolerances and excellent mechanical properties for the healthcare industry.

Understanding its fundamentals is key to appreciating its role in medical device manufacturing.

What is Medical Injection Molding?

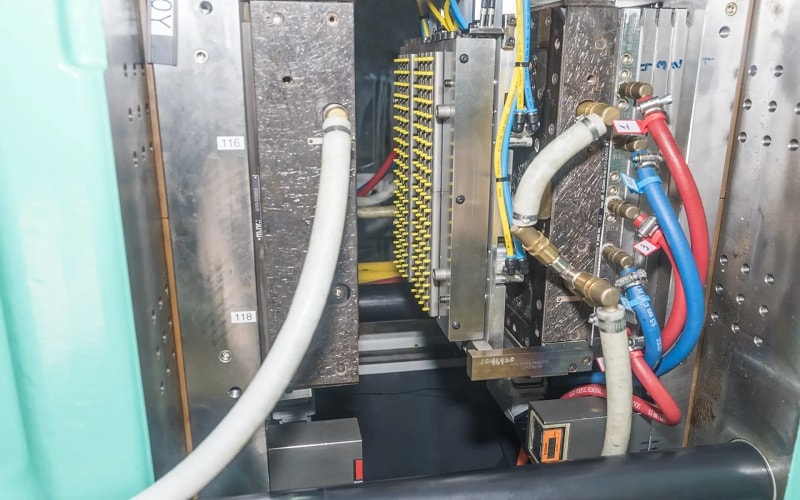

Medical injection molding involves molding medical grade plastics into precise shapes using an injection molding machine.

The process heats plastic or thermoset plastics until melted, then injects them into a mold to form injection molded parts like medical device components that offer exceptional mechanical properties.

This method ensures high precision, consistent quality, and excellent dimensional stability, making it suitable for critical components such as implantable devices or test tubes.

The medical injection molding process operates in a controlled environment, often a cleanroom environment, to meet FDA regulations and maintain strict quality standards.

Importance in the Medical Device Industry

Medical plastic injection molding is vital to the medical device industry, enabling high volume production of medical components that demonstrate compliance with regulatory standards.

Unlike general plastic injection molding, medical molding prioritizes biocompatible medical grade plastic to ensure patient safety and avoid adverse reactions.

Techniques like scientific molding optimize process control, ensuring injection molded plastics and manufacturing injection molded parts meet tight tolerances for medical applications like surgical implants.

The precision and reliability of medical injection molding make it a preferred cost efficient manufacturing method for medical devices.

Its ability to produce high volumes of high quality thermoplastic parts supports the healthcare industry’s demand for durability and performance.

Benefits of Medical Plastic Injection Molding

Medical plastic injection molding offers significant advantages for medical device manufacturing, from cost efficiency to exceptional mechanical properties.

These benefits drive its adoption in the medical industry.

Cost Efficiency and High Volume Production

Medical injection molding is a cost efficient manufacturing method, minimizing labor costs through automated processes.

It supports high volume production, enabling injection molders to produce high volumes of medical device components like test tubes or dental implants with consistent quality.

This efficiency reduces costs while maintaining strict quality standards, making medical molding ideal for large-scale medical applications.

Exceptional Mechanical Properties and Durability

Medical grade plastics used in injection molding offer exceptional mechanical properties, including chemical resistance and excellent dimensional stability.

These materials can withstand harsh environmental conditions, such as sterilization processes, ensuring durability for medical equipment or implantable devices.

The injection molded parts maintain tight tolerances, critical for patient safety and optimal performance in medical devices.

Precision and Regulatory Compliance

Medical plastic injection molding ensures high precision through scientific molding, delivering injection molded plastics with consistent quality.

The process adheres to FDA regulations, using biocompatible materials to prevent adverse reactions in the human body.

Injection molders operate in a cleanroom environment to demonstrate compliance, ensuring medical grade products meet strict quality standards for medical applications.

Key Techniques in Medical Injection Molding

The medical injection molding process employs advanced techniques to produce high quality parts.

These methods enhance manufacturing efficiency and product quality for medical devices.

Insert Molding for Complex Components

Insert molding involves molding plastic around a secondary component, such as metal or another plastic, to create complex medical device components.

This technique is used for surgical implants or dental implants, where precision and durability are essential.

Insert molding ensures tight tolerances and excellent mechanical properties, integrating components seamlessly for optimal performance in the human body.

Two Shot Molding and Liquid Silicone Injection Molding

Two shot molding combines two materials in a single mold, creating medical components with multiple properties, such as a rigid base and a flexible surface.

Liquid silicone injection molding uses silicone for flexible, biocompatible parts like seals or gaskets in medical equipment.

Both techniques enhance product quality, offering chemical resistance and excellent dimensional stability for critical components.

The versatility of medical injection molding techniques allows injection molders to meet diverse medical device design needs.

By selecting the right method, manufacturers can achieve high precision and cost efficiency in production.

Material Selection for Medical Injection Molding

Material selection is a critical aspect of medical plastic injection molding, ensuring biocompatibility and performance in medical applications.

The right materials are essential for patient safety.

Medical Grade Plastics and Biocompatibility

Medical grade plastics, such as polycarbonate, polyethylene, and polypropylene, are chosen for their biocompatibility and chemical resistance.

These high quality thermoplastics offer exceptional mechanical properties, ensuring durability in harsh environments like sterilization or body fluids.

Medical grade products like test tubes or implantable devices must demonstrate compliance with FDA regulations to avoid adverse reactions, ensuring safety in the human body.

Thermoset Plastics and Specialty Materials

In addition to thermoplastics, thermoset plastics and liquid silicone are used in medical molding for specific applications.

Thermoset plastics provide excellent dimensional stability for surgical implants, ensuring plastic parts maintain their desired shape under stress.

Silicone offers flexibility for other medical components like catheters, accommodating dynamic medical needs.

Proper material selection ensures injection molded parts meet strict quality standards and withstand harsh environmental conditions.

The choice of materials in medical injection molding directly impacts product quality and patient safety. Injection molding experts guide manufacturers in selecting biocompatible materials for optimal results.

Applications of Medical Plastic Injection Molding

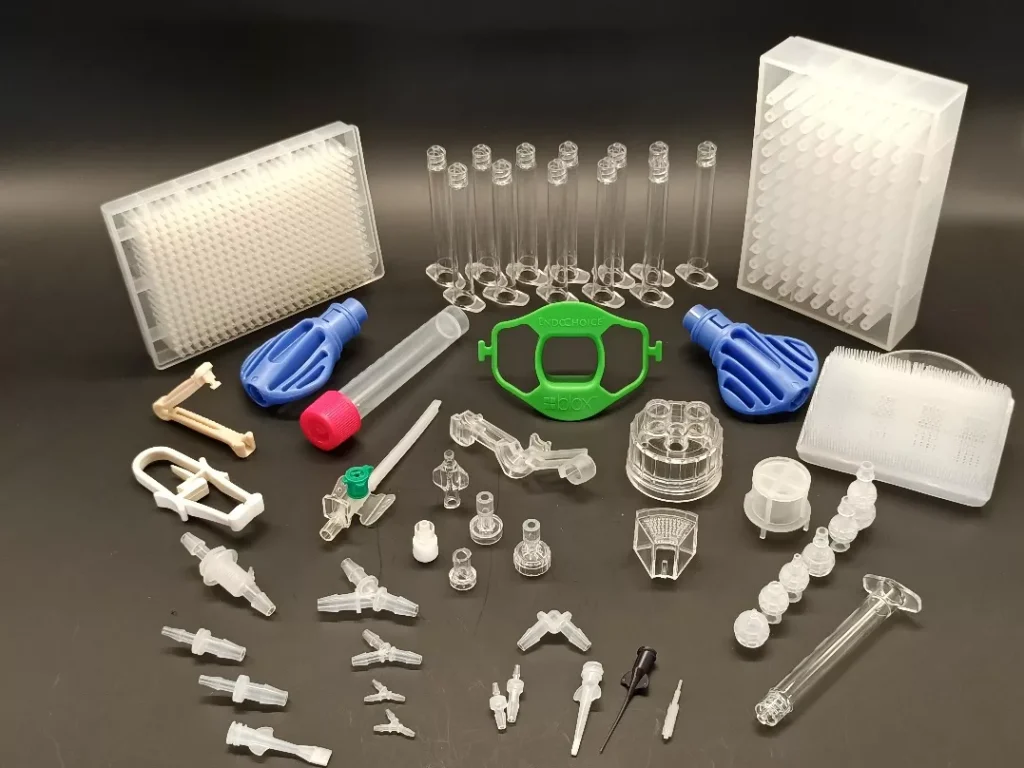

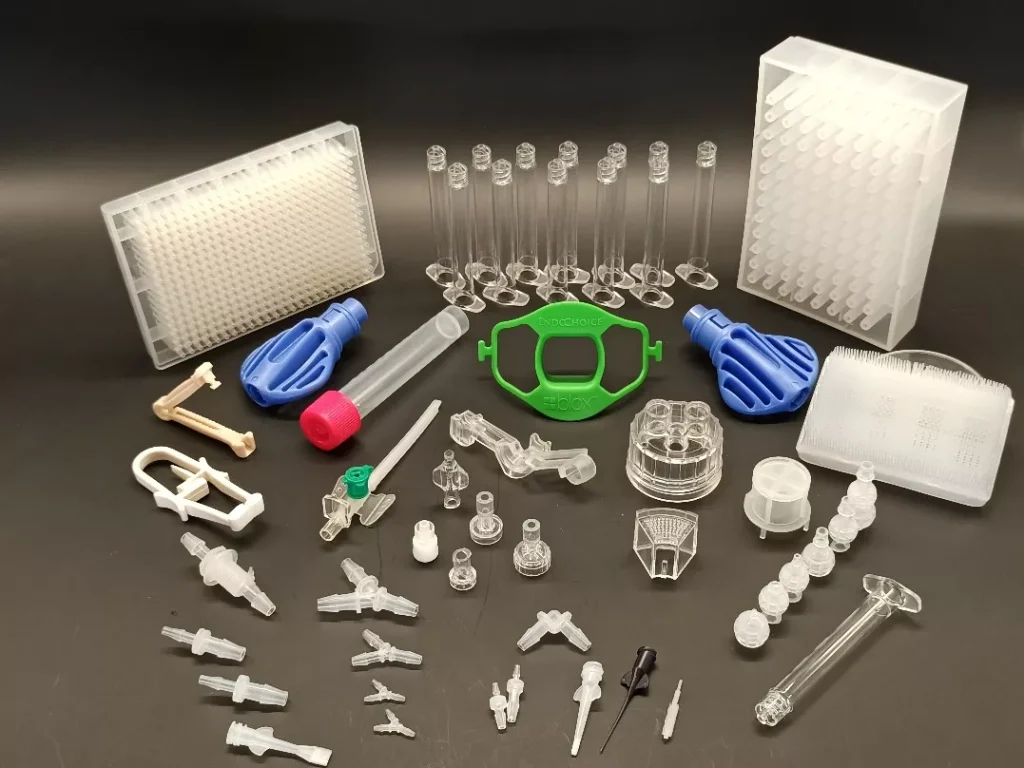

Medical plastic injection molding supports a wide range of applications in the healthcare industry, producing critical components with high precision.

Its versatility drives its adoption.

Medical Devices and Surgical Implants

Medical device injection molding produces surgical implants, dental implants, and implantable devices with tight tolerances and biocompatible materials.

These injection molded parts ensure patient safety and optimal performance, leveraging excellent mechanical properties to withstand harsh environments in the human body.

The process supports custom plastic injection for unique medical device designs.

Test Tubes and Other Medical Components

Medical molding creates test tubes, syringes, and other medical components used in diagnostics or medical equipment.

These plastic components offer chemical resistance and excellent dimensional stability, ensuring consistent quality in high volume production.

Medical injection molding ensures cost efficiency while maintaining strict quality standards for healthcare applications.

Medical Equipment and Functional Parts

Medical plastic injection molding produces functional parts for medical equipment, such as housings or connectors, using high quality thermoplastics.

Techniques like two shot molding or insert molding enable complex designs, enhancing durability and performance.

These parts are critical for medical applications, ensuring reliability in controlled environments.

Challenges in Medical Injection Molding

While medical plastic injection molding offers advantages, challenges must be addressed to ensure product quality and regulatory compliance.

These considerations are essential for success.

Maintaining Strict Quality Standards

Medical injection molding requires process control to maintain strict quality standards.

Injection molders must operate in a cleanroom environment to prevent contamination, ensuring medical grade products are safe for patient use.

Scientific molding techniques optimize manufacturing efficiency, but variations in material or process can affect tight tolerances, requiring expert oversight.

Regulatory Compliance and Patient Safety

FDA regulations mandate biocompatibility and chemical resistance for medical devices to avoid adverse reactions.

Injection molding experts must demonstrate compliance through rigorous testing, ensuring injection molded plastics are safe for the human body.

Material selection and process control are critical to meet these standards, particularly for implantable devices or surgical implants.

Conclusion

Medical plastic injection molding is an essential manufacturing process for the medical device industry, producing high quality parts like surgical implants, test tubes, and medical equipment with tight tolerances and excellent mechanical properties.

Techniques like insert molding, two shot molding, and liquid silicone injection molding enable cost efficient high volume production while ensuring patient safety and regulatory compliance.

By using medical grade plastics and biocompatible materials, injection molders create plastic components that withstand harsh environmental conditions and deliver optimal performance.

For manufacturers seeking custom plastic injection or medical device design, partnering with an injection molding expert ensures consistent quality and cost efficiency.