Nylon is a significant synthetic material extensively utilized in major fields like automobiles, electronics, textiles, and industrial production, which is attributed to its excellent durability and mechanical properties in almost all fields in which it is used.

As technology has developed, the types of nylon have also grown, and currently, we have nylon 6, nylon 66, nylon 11, nylon 12 and many other variations of nylon.

Each type of nylon material has its own dictates with regards to physical and chemical properties and one important factor is the physical property of melting point. The melting point of nylon is a critical factor that directly impacts the nylon material performances at elevated temperatures.

When it comes to selecting a specific type of nylon material, it is useful to understand the differences between melting points of various types of nylon.

For example, the difference between the melting point of nylon 6 and the melting point of nylon 66 has a direct bearing on their applications in high-temperature environments. Similarly, the melting point of nylon 11 and the melting point of nylon 12 will also have implications on their performance and application effects under specific conditions with temperature variation.

Knowing this information will help you better accurately select the nylon material best suited to use in your practical applications giving you the best opportunity to take advantage of its unique properties.

What Is Nylon?

Basic Concepts Of Nylon

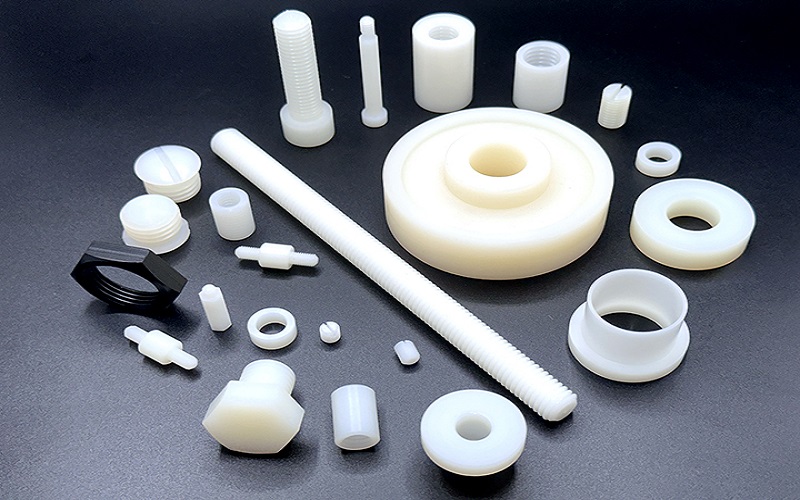

Nylon is a type of synthetic polyamide material. It is a material produced from petrochemical products, which was developed by DuPont in the 1930s. Various types of nylon, such as nylon 6, nylon 66, nylon 11, and nylon 12, have been produced since then. Nylon is incredibly durable, does not wear, and can endure high pressure and is suitable for long-term parts use, such as gears, bearings and sliding parts.

Nylon has excellent chemical resistance. Nylon is resistant to a range of oils, solvents, alkalis and selected acids and can be used in industrial applications where chemical exposure is a risk. Nylon also exhibits heat resistance characteristics. Thermal resistance will vary depending on the type of nylon chosen as each type possesses a specific melting point and will perform differently in high temperature environments.

Nylon can be easily molded and shaped. It can be produced into different shapes and sizes through a number of processes such as injection molding, extrusion and blow molding. This flexibility has popularized nylon in the automotive, electronics, textile and industrial supply industries.

Overall, nylon’s strength, chemical resistance, and simple processing make it a great material in a wide range of applications.

Classification Of Nylon

| Nylon Type | Chemical Formula |

| Nylon 6 | (C₆H₁₁NO)n |

| Nylon 66 | (C₁₂H₂₂N₂O₂)n |

| Nylon 12 | (C₁₂H₂₃NO)n |

| Nylon 11 | (C₁₁H₂₁NO)n |

| Nylon 6/12 | (C₁₈H₃₄N₂O₂)n |

| Nylon 6-10 | (C₁₆H₃₀N₂O₂)n |

| Nylon 46 | (C₁₀H₁₈N₂O₂)n |

| Nylon 610 | (C₁₂H₂₂N₂O₂)n |

| Nylon 12,12 | (C₂₄H₄₄N₂O₂)n |

What Is The Melting Point Of Nylon?

The term melting point refers to the point at which a material metamorphizes from a solid state to a liquid state. For example, the melting point of high polymer materials like nylon is very important because it dictates the material’s capability to be processed and function within temperature limits. From a materials science perspective, melting point is a primary property affecting the mechanical performance and heat resistance of a material.

Nylon polymers are classified as polyamide-type, synthetic materials, and the melting characteristic can differ due to the assortment of molecular structures. The melting point of nylon 6 is around 220°C, while the melting point of nylon 66 is near 260°C, making nylon 66 more thermally tolerant. The melting point of nylon 11 is 188°C, while the melting point of nylon 12 is 178°C, making these nylons more flexible with notable chemical resistance capacity.

In addition, nylon 6/12 has a melting point positioned between nylon 6 and nylon 12 depending on the ratios of each component in the material. Knowing what is the melting point of nylon allows for a material that is reliable. Different applications require the use of nylon due to mechanical and thermal performance under different treatments and temperature ranges.

In conclusion, the melting property of nylon is a valuable and relevant consideration for the correct selection and performance of materials designed for various environments.

Melting Points And Applications Of Different Nylons

Nylon is a polyamide synthetic material with different melting points depending on its type. Understanding the melting point of nylon is essential for choosing the right material for various applications. Here’s a clear overview of the melting points for various types of nylon:

- Melting point of nylon 6 is about 220°C. This temperature range makes it suitable for applications requiring moderate heat resistance, such as textiles and automotive parts.

- Melting point of nylon 66 (also known as melting point of nylon 6.6) is around 260°C. This higher melting point allows it to perform well in high-temperature environments, making it ideal for components like electrical connectors and machinery.

- Melting point of nylon 12 is approximately 178°C. This nylon variant is known for its good chemical resistance and low moisture absorption, making it effective for applications exposed to chemicals and moisture, such as automotive fuel lines.

- Melting point of nylon 11 is about 188°C. This nylon has similar moisture resistance and additionally provides flexibility making it ideal for use in systems like fuel systems and other chemical containment systems.

- Melting point of nylon 6/12 falls between that of nylon 6 and nylon 12,usually around 200-220°C, influenced by its specific formulation. It offers a balance of properties from both types, used in applications requiring such a mix.

- Melting point of nylon 6-10 is approximately 245°C. This type provides a good combination of strength and flexibility with enhanced resistance to moisture and chemicals compared to other nylons.

- Melting point of nylon 46 is about 295°C. This nylon provides a much higher melting point suited for very high temperature applications makes it more thermally stable.

- Melting point of nylon 610 is around 220°C, combining properties of nylon 6 and nylon 66, making it versatile for both textile and industrial uses.

- Melting point of nylon 12,12 falls between that of nylon 12 and other nylons, often cited around 190-200°C, providing a balance of chemical resistance and mechanical properties for specialized engineering applications.

| Nylon Type | Melting Point |

| Nylon 6 | 220°C |

| Nylon 66 | 260°C |

| Nylon 12 | 178°C |

| Nylon 11 | 188°C |

| Nylon 6/12 | Between Nylon 6 and Nylon 12,usually around 200-220°C |

| Nylon 6-10 | 245°C |

| Nylon 46 | 295°C |

| Nylon 610 | 220°C |

| Nylon 12,12 | Between Nylon 12 and other nylons,often cited around 190-200°C |

Significance Of Melting Point In Nylon Performance

The melting point of nylon is incredibly important for the use in various applications in industry. The melting point of nylon affects performance and reliability in textiles and heat resistance, mechanical strength for automotive components, insulation for electronics, and durability for industrial applications producing consumer and industrial products.

For example, in textiles, nylon is converted into nylon thread and nylon filament. The melting point is key considerations in both nylon thread and nylon filament. The melting point of nylon will determine if the nylon fiber may still have strength at the high manufacturing temperatures if there is an arbitrary amount of flexibility. The high melting point of nylon 66, for example, allows this nylon material to be manufactured to be flexible and durable fiber while still retaining high resistance at higher processing temperatures.

In summary, color or material selection of nylon with different melting point can be correctly chosen to give best performance in the application required.

Comparison Of High Melting Point And Low Melting Point Nylon

Nylons with a High Melting Point: The thermal stability and prominence of heat loading of nylon 6 and nylon 66, also known as the melting point of nylon 6 and melting point of nylon 66, are appropriate for automotive parts and industrial environments. The durability under precision loading and anticipated wear and stability in high temperature and stress environments makes them a suitable choice for serviceable plastic applications.

Nylons with Low Melting Point: The thermal stability and prominence of heat loading of nylon 11 and nylon 12, also known as the melting point of nylon 11 and melting point of nylon 12 , are not as favorable, but are suitable for low temperature environments and chemically limiting environments, such as in chemical pipelining and fuel lines in automobiles where their performance is flexible and resistant to damage.

Nylons for Compound Properties: The thermal stability and prominence of heat loading of nylon 6/12 hybridizes the properties of the high and low melting nylons and is suitable for usage that require moderate stability and chemical use; for example, utilizing the nylon 6/12 in consumer goods and electronics.

In conclusion, nylon stability and the melting point of nylon are key determining factors for determination of the best nylon for best use. High melting point nylons are suitable for high heat and high stress environments, while lower melting point nylon is suitable for flexible, chemically limiting environments.

How Environmental Factors Affect Nylon Melting Points?

Nylon is an engineering material frequently employed, and its melting point and performance can be affected by the environmental temperature and humidity.

- Effect of the Temperature of the Environment

The melting point of nylon may soften or deform when exposed to high temperatures. For instance, Nylon 66 has a melting point of 260 degrees Celsius, yet its strength may start to decrease in an environment over 200 degrees Celsius.

When temperatures are low, nylon can become brittle, especially high melting point nylons, which can break due to coldness. Therefore, selecting the appropriate type of nylon is crucial to ensure stable performance across different temperature ranges.

- Effect of Humidity

Nylon is known to be hygroscopic. In an environment of high humidity, nylon can swell or settle, thus causing a reduction in strength. Humidity may not directly affect the melting point of nylon, yet it can have some effect on nylon’s performance when under load.

- Effects of other environmental factors

- Additives and Fillers: Melting points of nylon may be influenced by chemical additives and fillers. Some types can raise the melting point of nylon, while others actively lower it or change the melting point.

- Crystallinity: The crystallinity of nylon creates a different melting point. Nylons formed with more crystallinity have higher melting points, because more energy will be needed to break down it’s crystallinity.

- Molecular Weight: The melting point of nylon can also be affected by the molecular weight. Nylons with greater molecular weight correspond to higher melting points, as well as it’s molecular weights distribution will play a role in the melting point stability.

Conclusion

The performance of nylon at different temperatures is influenced by its melting point, which can be affected by the temperature, humidity, additives, crystallinity, and molecular weight. Understanding these factors can assist in selecting the correct nylon type so it will perform at a stable or constant way at a variety of conditions.

Learning about these factors that affect the melting point of nylon also leads to improved decisions and also improved reliability and durability of the materials being considered.

FAQs

What Specifically Is Crystallinity In Nylon And How Is It Associated With Melting Point?

The crystallinity of nylon is specific to the crystalline structure within the nylon polymer down below the macroscopic level. Nylons which are more highly crystalline will generally have higher melting points as the crystalline structure requires greater amounts of energy to break.

What Is The Association Of Melting Point With Heat Resistance In Nylon?

Generally speaking, higher melting points usually is an indication that the material remains solid at a higher temperature, which means the material has better short term heat resistance. Different types of nylon have different melting points and heat resistances to their different chemical structures.

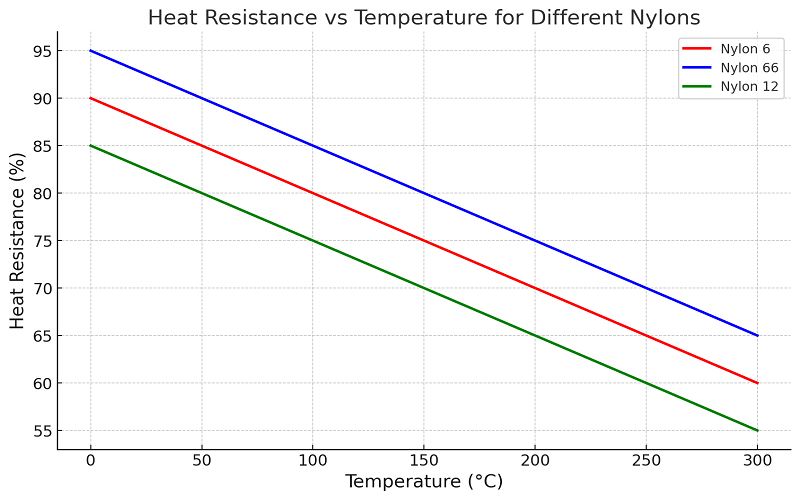

This figure shows how the heat resistances of different types of nylon (Nylon 6, Nylon 66 and Nylon 12) change as the treatment temperatures increase.

The slope of the curve in the figure shows that as temperature increases, the heat resistance decreases gradually, however, the heat resistance of nylon 66 (blue line), has a higher melting point exhibited high heat resistance at higher temperatures. The heat resistance of wires for nylon 12 (green line) decreases significantly at lower temperatures as indicated by the slope.

This indicates that the melting point of nylon had direct impact on heat resistance. The higher the melting point, the better the heat resistance of a material at high temperatures.

How Can The Melting Point Of Nylon Be Measured?

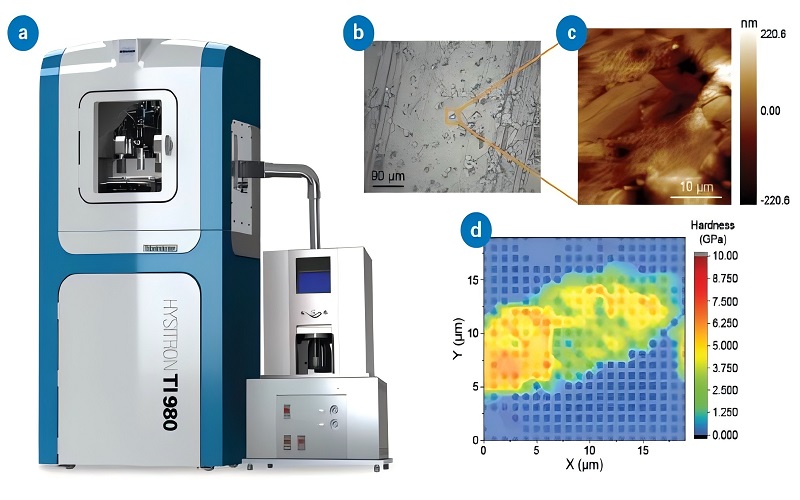

There are multiple methods to measure the melting point of nylon, most importantly include differential scanning calorimetry (DSC), melting point instrumentation, thermomechanical analysis (TMA ), thermogravimetric analysis (TGA), and also using heating stages in scattering microscopes.

The most common and most accurate method overall is differential scanning calorimetry as it is the best for easily determining the temperature at which a bulking polymer melts.

Does The Melting Point Of Nylon Change?

The melting point for nylon does not change over time, except in rare cases where a polymer undergoes a phase change at elevated temperatures/ humidities or loses weight from thermal degradation.

However, an environment with elevated temperatures or elevated humidities for long-periods will change the physical characteristics of nylon, thus resulting in the performance around the melting point to alter, in some cases only slightly.