Molded furniture, crafted through techniques like injection and rotational molding, offers durable and versatile design options using plastic materials. If you’re considering furniture that combines practical functionality with innovative aesthetics, molded furniture might be your best bet.

This article will explore what molded furniture is, its types, benefits, and how it’s made.

Understanding Molded Furniture

Molded furniture refers to items created by shaping materials, typically plastics, using a mold. This manufacturing technique results in products with defined forms, allowing for a wide range of designs and functionalities.

The versatility of molded furniture is evident in the variety of products available, including sofas, armchairs, chairs, tables, and storage solutions, all designed to enhance both functionality and style. With the ability to produce intricate shapes and incorporate ergonomic designs, molded furniture meets diverse consumer needs with ease.

The production of molded furniture primarily utilizes two key techniques: injection molding and rotational molding. These methods not only determine the final shape and durability of the products but also influence their cost-effectiveness and production efficiency.

Understanding these techniques provides insight into why molded furniture is a popular choice for both residential and commercial settings.

Types of Molded Furniture

The versatility of molded furniture allows for a wide range of products, from plastic chairs and tables to innovative storage solutions. Each type of molded furniture serves a unique purpose and caters to different environments, whether it’s a cozy living room, a bustling office, or a well-organized storage area.

Key features such as collapsibility, functional design, and a variety of colors and finishes make molded furniture both practical and aesthetically pleasing. In the following sections, we will take a closer look at plastic chairs, plastic tables, and plastic storage solutions, exploring their specific benefits and uses.

Plastic Chairs

Plastic chairs are a quintessential example of molded furniture, embodying versatility and innovative design. The molds used to create plastic chairs provide the necessary shape and structure, enabling the production of a wide range of unique designs suitable for various settings, from homes to offices and schools. Whether it’s a simple dining chair or an ergonomically designed office chair, plastic chair molds can cater to diverse functional and aesthetic needs.

There are several types of plastic chair molds, each designed to meet specific manufacturing techniques and design requirements. For instance, some molds are optimized for injection molding, allowing for precise shape replication and high production speeds, while others are tailored for rotational molding, producing seamless and hollow chair designs. This versatility ensures that plastic chairs can adapt to any environment, providing both comfort and durability.

Plastic Tables

Plastic tables are renowned for their adaptability and strength, making them suitable for a variety of settings, from homes to commercial spaces. Their robust construction allows them to withstand heavy use and various environmental conditions, ensuring longevity and reliability.

Whether used as a dining table, a work desk, or a display stand, plastic tables cater to numerous functional needs while maintaining their aesthetic appeal.

Plastic Storage Solutions

Plastic storage solutions, including cabinets and shelves, are designed to facilitate easy organization of items in both residential and commercial spaces. These solutions are versatile, catering to various storage needs and allowing for modular configurations that can be customized as required. The functional design of plastic storage solutions helps streamline organization, making it easier to access items while maintaining an orderly space.

Constructed from durable materials like polyethylene and polypropylene, plastic storage solutions are built to last. These materials ensure that the storage units can withstand regular use and remain resilient against wear and tear. The combination of durability and flexibility makes plastic storage solutions an efficient choice for maintaining an organized and clutter-free environment.

Manufacturing Techniques for Molded Furniture

The manufacturing techniques used in producing molded furniture significantly influence the final product’s design, functionality, and durability. Two primary methods stand out: injection molding and rotational molding. Each technique offers unique advantages and is suited to different types of furniture, as we will explore in the following sections.

Injection Molding

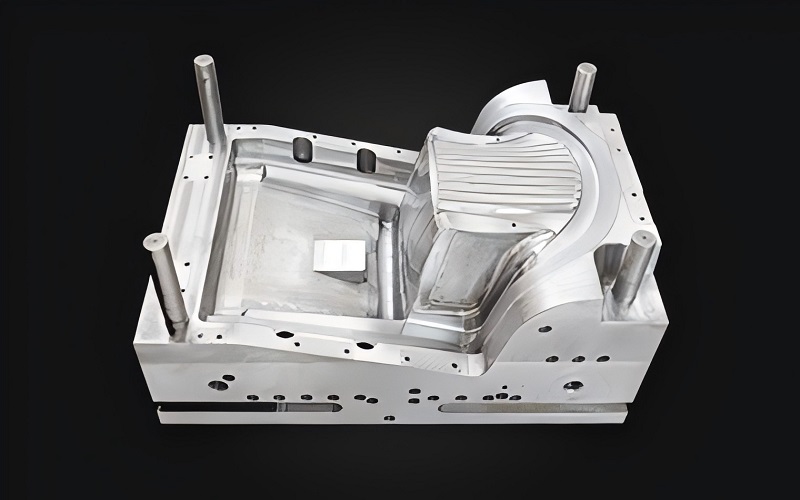

Injection molding is a popular manufacturing process in the furniture industry, involving heating plastic pellets until they liquefy and then injecting the molten plastic into a mold to form furniture components. This method allows for precise shape replication and high production speeds, making it ideal for large-scale production runs. One of the key advantages of injection molding is its cost-effectiveness, as the initial investment in the mold can be offset by the ability to manufacture thousands of identical parts efficiently.

Additionally, injection molding provides significant design flexibility, enabling the creation of complex shapes and intricate designs that would be challenging to achieve through other methods. The process ensures a high-quality finish, enhancing both the functionality and aesthetic appeal of the furniture. This versatility makes injection molding a preferred choice for manufacturing a wide range of molded plastic furniture.

Rotational Molding

Rotational molding, or rotomolding, is another essential manufacturing technique for plastic furniture. This process involves a heated mold that is rotated around two axes, allowing for uniform material distribution and the creation of seamless, hollow furniture pieces. Rotational molding is particularly beneficial for producing durable and lightweight items, making it a cost-effective option in the furniture industry.

The ability to create seamless designs ensures that the furniture pieces are not only aesthetically pleasing but also structurally sound and easy to clean. This makes rotational molding an excellent choice for producing items that need to withstand rigorous use and varying environmental conditions, enhancing the overall durability and functionality of molded plastic furniture.

Advantages of Molded Furniture

Molded furniture is highly favored for its lightweight and durable characteristics, making it suitable for various applications in both homes and commercial environments. The robust durability of molded furniture ensures that it can withstand regular use without significant wear, providing a long-lasting solution for high-traffic areas.

For instance, durable plastic furniture is often made from strong polyethylene, which resists deterioration from high traffic and spills, making it an ideal choice for busy settings where a dropdown open furniture menu can help customers easily explore available options.

The injection molding process enables mass production, leading to lower production costs per unit and making molded furniture an economically feasible option for manufacturers and consumers alike. Additionally, plastic furniture is gaining popularity in environments that require high hygiene standards, as it is resistant to germs and bacteria, providing a longer lifespan compared to cloth-based furniture.

Customization Options in Molded Furniture

Customization is one of the standout features of molded furniture, thanks to the precision and flexibility offered by manufacturing techniques like injection molding. Advanced technology allows for the creation of custom molds that meet specific design requirements with high accuracy and consistency. Manufacturers like FOW Mould collaborate closely with clients to develop tailored designs that enhance both aesthetics and functionality.

Customization options can include selecting materials, adjusting dimensions, and integrating unique design features to meet client specifications. Molded plastic furniture can also be personalized with unique colors, textures, and branding to fit specific therapeutic or aesthetic needs.

This level of customization ensures that the furniture not only meets functional requirements but also aligns with the overall design and decor of the space.

High-Quality Materials Used in Molded Furniture

High-quality materials are crucial in the production of molded furniture, ensuring strength, durability, and aesthetic appeal. Common materials used in injection molding include polypropylene, polystyrene, and polyethylene, all known for their robust and flexible properties.

Polypropylene, in particular, is a lightweight yet strong thermoplastic widely utilized in the furniture industry. Other thermoplastics such as acrylonitrile butadiene styrene (ABS) and polycarbonate are also employed in the production of molded furniture, offering enhanced durability and resistance to wear.

The use of eco-friendly materials in rotational molding adds an element of sustainability to the production process. This method can incorporate recycled materials, reducing environmental impact and aligning with sustainability goals. Choosing high-quality plastics and sustainable materials ensures that molded furniture meets both functional and environmental standards.

Choosing the Right Molded Furniture for Your Space

Selecting the right molded furniture involves careful consideration of the space’s specific requirements, including size, aesthetics, and functionality. Accurate measurements of the intended space are crucial to ensure that the furniture fits properly around fixed features like windows and doors. Additionally, aligning the furniture with the current decor style is essential, whether you prefer modern designs for a contemporary look or traditional pieces for a classic interior.

Another factor to consider is the weight and mobility of the furniture, especially in environments where reconfiguration is necessary. Molded furniture is available in diverse styles and can be customized in color and design to blend with or enhance the existing decor of a space.

Ensuring the durability of the furniture is also important, particularly for high-traffic areas where the furniture will undergo regular use. Timely delivery can reduce the overall lead time, which is particularly important for businesses needing quick turnaround on furniture orders.

Leading Manufacturers of Molded Furniture

Leading manufacturers play a crucial role in shaping the molded furniture market by focusing on quality and innovation. Here are some notable companies:

- FOW Mould, established in 1978, specializes in providing high-quality chair molds and has built a strong reputation in the molding industry.

- Taylor Made Wood & Plastic, operating since 1990, emphasizes durability and eco-friendliness by creating outdoor furniture from recycled plastic.

- Flow Furniture, founded in 2002, is known for its innovative designs and high-quality production of plastic chairs and tables.

Other notable manufacturers include Krahn Outdoor, a family-owned business since 1986, specializing in premium poly furniture designed for comfort and aesthetic appeal. Uma Plastics Limited, based in India and established in 1999, is recognized for high-quality molded plastic products and a commitment to international standards.

Chairplan, founded in the UK in 1996, is renowned for its innovative chair designs and collaboration with major suppliers. These manufacturers highlight the importance of innovation and eco-friendliness in their product offerings, contributing to a more sustainable industry.

Fast Delivery and Customer Service

Excellent customer service plays a significant role in ensuring a positive shopping experience for molded furniture buyers. Fast delivery is critical to meet customer expectations and enhance satisfaction when purchasing molded furniture.

Companies that prioritize quick turnaround times and efficient logistics can significantly improve the customer experience, ensuring that the furniture arrives promptly and in perfect condition.

Moreover, a wide array of shopping assistance options, such as detailed product information, customization services, and responsive customer service shopping assistance, can help address any concerns or inquiries buyers may have during the purchasing process. Comprehensive customer service helps companies build trust and loyalty, encouraging repeat business and positive word-of-mouth recommendations.

Summary

In summary, molded furniture offers a blend of durability, functionality, and aesthetic appeal that makes it a versatile choice for various settings. From plastic chairs and tables to storage solutions, the range of products available meets diverse consumer needs.

The innovative manufacturing techniques, including injection and rotational molding, ensure high-quality and cost-effective production. With numerous advantages, customization options, and high-quality materials, molded furniture is a smart investment for both residential and commercial spaces.

Leading manufacturers and excellent customer service further enhance the appeal of molded furniture, making it a reliable and practical choice.

Frequently Asked Questions

What is molded furniture?

Molded furniture is crafted by shaping materials, usually plastics, within a mold, yielding products with distinct forms and versatile designs. This technique allows for innovative and functional furniture solutions.

What are the primary manufacturing techniques used for molded furniture?

The primary manufacturing techniques for molded furniture are injection molding and rotational molding, which significantly affect the design, functionality, and durability of the products. Utilizing these methods ensures high-quality and efficient production of molded furniture.

What are some common materials used in molded furniture?

Molded furniture commonly utilizes polypropylene, polystyrene, polyethylene, ABS, polycarbonate, and eco-friendly recycled plastics due to their strength, flexibility, and sustainability. These materials are ideal for creating durable and functional furniture designs.

How can I choose the right molded furniture for my space?

To choose the right molded furniture for your space, prioritize size, aesthetics, and functionality by taking accurate measurements and ensuring alignment with your decor style. Select durable and lightweight options to facilitate easy rearrangement.

Why is fast delivery and customer service important in the furniture industry?

Fast delivery and customer service are crucial in the furniture industry as they directly meet customer expectations and enhance satisfaction, while also addressing inquiries and building trust, ultimately fostering customer loyalty.