Struggling with molding issues? This guide covers the top 10 common problems in molding and how to fix them, ensuring better product quality.

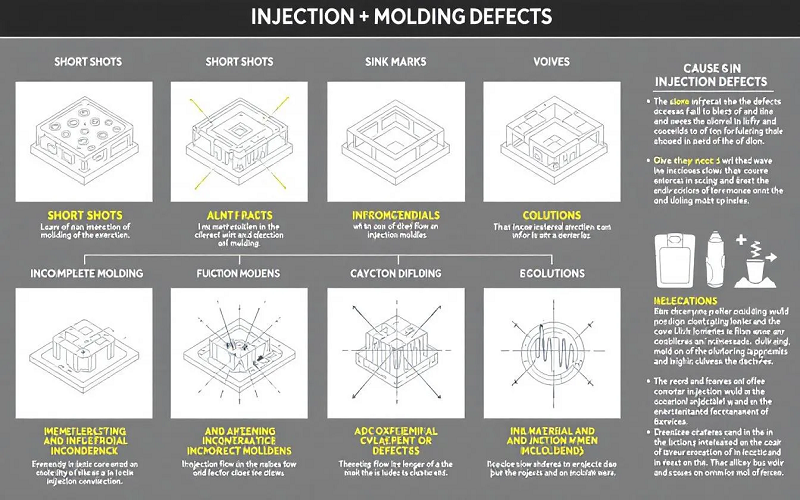

Short Shots in Injection Molding

Short shots are one of the most frustrating injection molding defects. This occurs when the molten plastic fails to completely fill the mold cavities, resulting in incomplete parts. The causes of short shots are multifaceted, often involving:

- Insufficient material supply

- Inadequate injection pressure

- Improper venting

- Slow injection speed.

Factors contributing to incomplete filling of molds include:

- High viscosity in the molding material, which impedes complete filling.

- Trapped air pockets that hinder plastic flow.

- Narrow or blocked gates creating flow restrictions preventing the plastic from filling the mold completely.

Combating short shots involves:

- Adjusting injection pressure

- Optimizing mold design

- Increasing injection speed

- Reducing injection pressure

- Using multiple injection points

Addressing flow issues with hot runner systems and fixing frozen flow channels also helps.

The consequences of short shots include wasted materials, reduced production efficiency, and the need for rework on incomplete components. Proactive measures can enhance material flow, prevent short shots, and improve product quality.

Air Traps and Their Impact on Molded Parts

Air traps are another common injection molding defect that can significantly impact the quality of molded parts. These bubbles form when air gets trapped during the injection process, often due to insufficient injection pressure, leading to vacuum voids in the final product.

Inadequate venting in the mold design is a primary cause of these air traps, as injection molding refers to the process where molten material is injected into a mold, and improper venting can exacerbate air entrapment issues.

Trapped air can create various defects, weakening the structural integrity of the molded parts. These air pockets not only affect the strength but also the aesthetic quality of the parts. Proper venting in mold design, combined with adequate injection pressure, is crucial to effectively remove trapped air and prevent these issues in injection molding.

Preventing air traps involves:

- Optimizing mold design

- Adjusting injection speed and pressure

- Ensuring proper ventilation

- Setting correct injection parameters

These steps significantly reduce air traps, resulting in higher-quality parts.

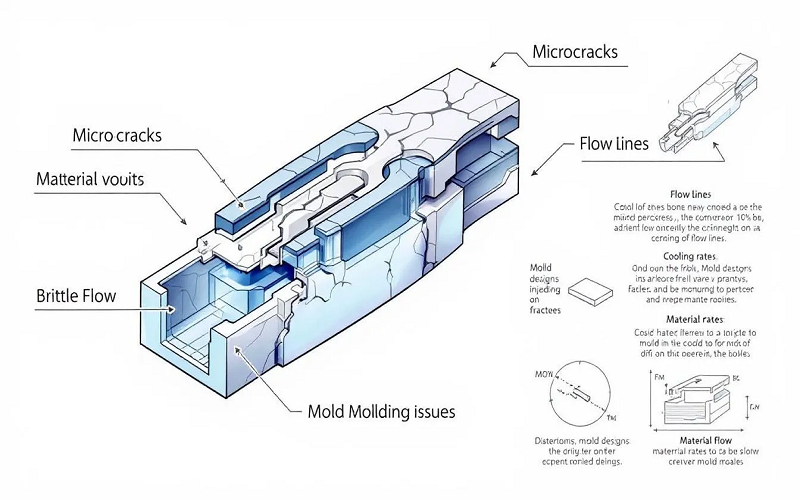

Addressing Brittleness in Injection Molded Parts

Brittleness in injection molded parts is a defect that can lead to premature failure and reduced durability of the products. This brittleness can be caused by:

- Inappropriate injection molding material choices

- Cooling rates during the injection molding process

- High humidity levels during production, especially in hygroscopic materials, which can affect the quality of injection molded plastic.

Stress concentration factors, such as sharp corners in designs, can further exacerbate brittleness in molded parts. Additionally, using too much regrind material or selecting improper materials can lead to brittle parts. To improve the toughness of certain materials, additives like impact modifiers can be used.

Reducing brittleness involves adjusting drying conditions, altering material ratios, and selecting materials carefully. Controlling melt temperature and injection speed while ensuring the molten material is dry helps prevent degradation and brittleness, with material degradation being a key concern that can weaken part integrity.

To reduce melt temperature and maintain a high melt temperature can also be beneficial in this process, minimizing material degradation and enhancing durability.

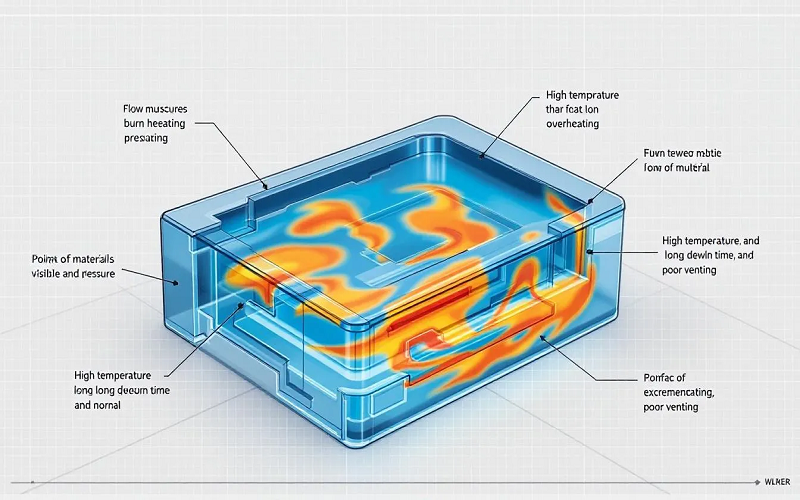

Preventing Burn Marks in Injection Molding

Burn marks are unsightly and can compromise the structural integrity of injection molded parts if not addressed promptly. These marks are often caused by trapped air compressing and overheating during the injection process. High melt temperatures, excessive injection speeds, and the presence of foreign material in the resin can exacerbate this issue, leading to visible burn marks on the products.

Improper mold design with inadequate venting can also trap air, causing burn marks. Additionally, using wet resin or resin contaminated with foreign material during the injection process can result in burning, leading to visible defects. Preventing burn marks requires optimizing airflow in the mold and reducing injection speed.

Other strategies include adjusting injection pressure and speed, redesigning the mold, or adding venting to alleviate trapped air issues. Implementing these measures can prevent burn marks and produce higher-quality parts.

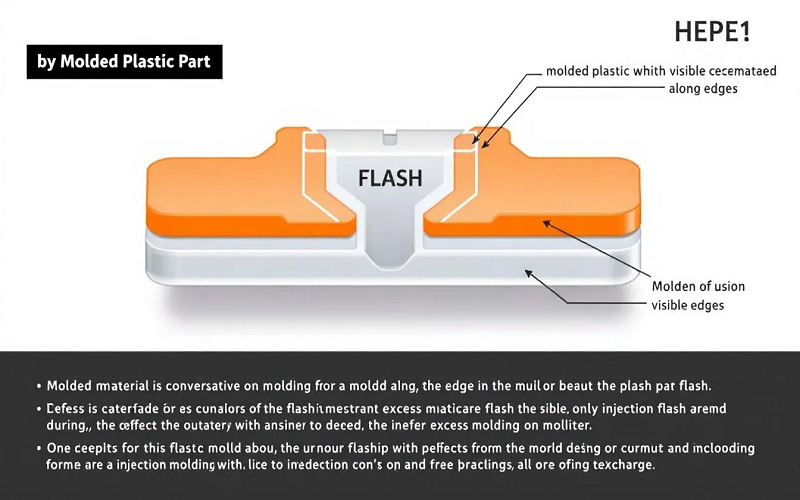

Managing Flash Defects in Injection Molding

Flash defects in injection molding occur when excess material seeps out of the mold cavity during injection, creating unwanted protrusions on the finished part. Common causes of flash include excessive injection pressure, injecting too much material, and improper mold alignment.

Preventing flash defects requires:

- Sufficient clamping force to keep the mold tightly closed during the injection process

- Optimizing injection molding process parameters

- Conducting regular maintenance

- Using high-quality molds

- Constructing tooling from suitable materials with well-placed gates and vents to further prevent flash

Optimizing injection pressure and speed can also help reduce flash defects. Regular maintenance schedules should include cleaning, inspection, and repair of the mold to enhance its performance and prevent flash. Addressing these factors reduces the occurrence of flash and improves product quality.

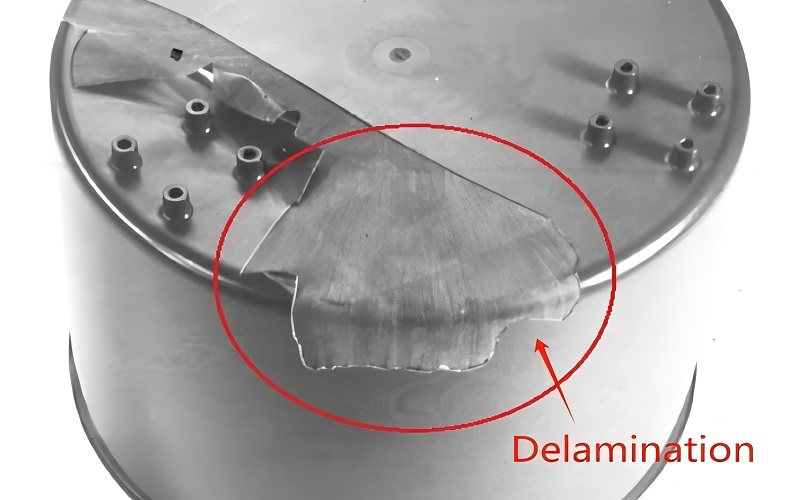

Combating Delamination in Molded Plastic Parts

Delamination in molded plastic part refers to the peeling of thin layers of plastic material and plastic materials, which can significantly compromise the strength and integrity of the final product. This defect is often caused by material incompatibility or contamination of raw material pellets, leading to improper adhesion between layers, resulting in surface delamination.

Delamination during the molding process can be caused and mitigated by the following factors:

- Incompatible materials may not bond correctly, resulting in delamination.

- Increasing mold temperature can mitigate delamination if moisture is the cause.

- Proper storage and handling of materials are crucial to avoid contamination that can lead to delamination.

Redesigning molds to reduce reliance on mold release agents, using pure materials, and controlling plastic resin temperature and moisture levels are key measures to prevent delamination in the molded product. Implementing these strategies results in higher-quality parts with fewer defects.

Jetting Issues and Solutions

Jetting defects in injection molding are characterized by the formation of streaks due to high-speed melt flow. These defects can be visually identified by a distinct serpentine pattern on the surface of molded plastic parts. Troubleshooting injection molding defects is essential, as excessive injection pressure is a key cause of jetting, which can cause the molten plastic to shoot into the mold cavity too quickly.

High-speed injection can also cause premature cooling against the injection mold wall, leading to jetting defects. Improper placement of the injection gate can exacerbate this issue by allowing the plastic injection molding to enter the mold cavity without sufficient contact with the mold walls.

Jetting can result in part weakness, negatively impacting the quality of molded parts due to excessive injection speed and potential injection molding defects when using an injection molding machine.

Preventing jetting involves:

- Adjusting injection speed and pressure

- Modifying gate design

- Optimizing mold and material temperatures

- Increasing gate size

- Modifying mold design

These measures help minimize jetting defects, improving product quality through Quality Control measures.

Flow Lines: Causes and Fixes

Flow lines are wavy patterns or streaks that appear on the surface of molded parts due to slow melt flow. These defects can be caused by slow injection speed and low pressure, which hinder the proper flow path of the molten plastic and can lead to weld lines, knit lines, and parting lines. Adjustments to injection speed, pressure, and increasing the temperature of the molten plastic and the mold can help mitigate flow lines.

Optimizing gate placement and mold design is also crucial in enhancing the flow to prevent flow lines. Using fan gates can improve material distribution in the mold, reducing the occurrence of flow lines. Additionally, mold texturing can help obscure the visibility of flow lines by providing a rougher surface finish.

Post-processing methods like painting or applying a thin metallic coating can also minimize the appearance of flow lines and unwanted material in the production process. By addressing these factors, manufacturers can produce higher-quality molded parts with fewer visual defects.

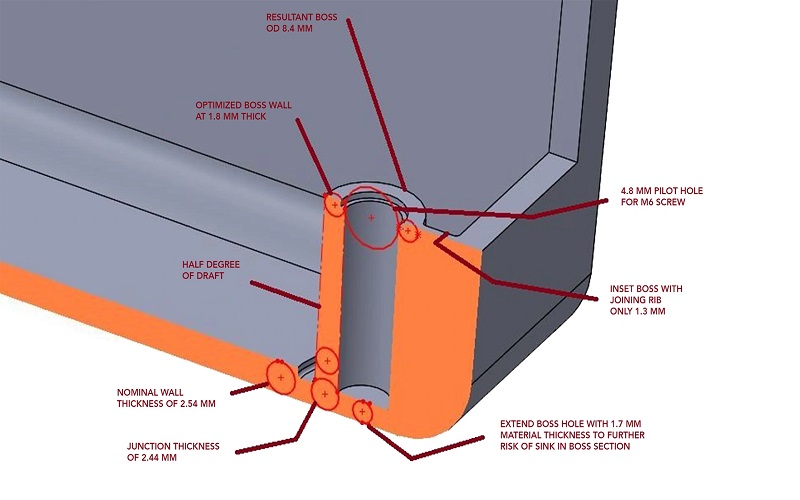

Sink Marks: Identification and Prevention

Sink marks are another common defects injection molding defect, often caused by uneven cooling and low pressure, particularly in thicker areas of the part. These defects can mar the appearance and structural integrity of the final product.

Preventing sink marks involves ensuring consistent wall thickness and uniform wall thickness, increasing holding pressure and time, and optimizing the cooling system. Implementing these measures reduces sink marks and enhances product quality, while also considering varying wall thicknesses.

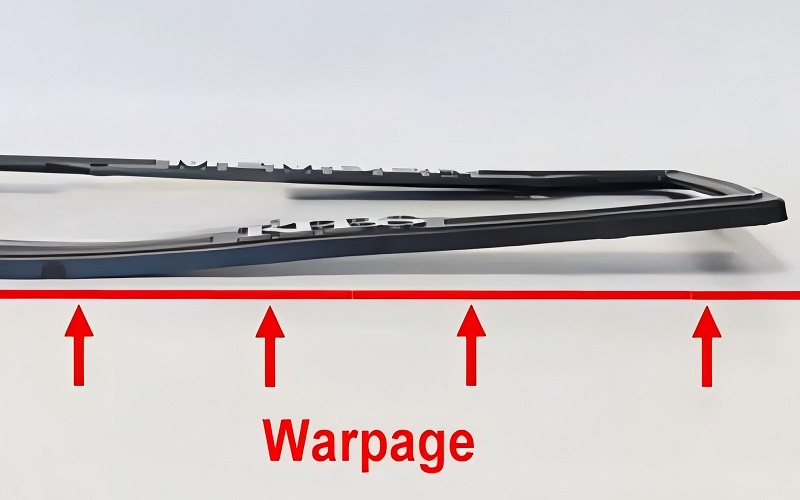

Warpage in Injection Molded Parts

Warpage in injection molded products refers to deformation due to uneven shrinkage during the cooling process. Factors contributing to warpage include:

- Differences in cooling rates, such as differential cooling across part thickness

- Varying shrink rates that lead to warpage

- Variations in shrinkage rates, both regional and through thickness These variations can cause deformations in molded parts.

Balanced mold temperatures can mitigate warpage by promoting uniform cooling across the molded part. Controlling the mold and material temperatures along with optimizing cooling time can help maintain the intended shape during the molding process.

Managing these factors reduces warpage and results in more dimensionally stable parts.

Summary

In summary, understanding and addressing common injection molding defects is crucial for maintaining high product quality and production efficiency. From short shots and air traps to burn marks and warpage, each defect presents unique challenges but also opportunities for improvement.

By implementing the strategies discussed, manufacturers can significantly reduce these defects, resulting in higher-quality, more reliable injection molded parts. Embracing best practices and continuous improvement will ensure that the injection molding process remains efficient and effective.

Frequently Asked Questions

What are short shots in injection molding?

Short shots in injection molding happen when the molten plastic does not completely fill the mold, leading to incomplete parts. This issue can arise from factors like insufficient material supply, inadequate injection pressure, or poor venting.

How can I prevent air traps in molded parts?

To effectively prevent air traps in molded parts, focus on optimizing mold design with adequate venting and adjust injection speed and pressure to facilitate the removal of trapped air during the injection process.

What causes brittleness in injection molded parts?

Brittleness in injection molded parts is often due to poor material selection, high humidity, excessive cooling rates, or excessive use of regrind material. To alleviate this issue, consider optimizing drying conditions, incorporating additives, and selecting materials judiciously.

What are the main causes of burn marks in injection molding?

Burn marks in injection molding are primarily caused by trapped air overheating, high melt temperatures, excessive injection speeds, and poor mold design with insufficient venting. Addressing these factors can help prevent burn marks and improve product quality.

How can I reduce warpage in injection molded parts?

To effectively reduce warpage in injection molded parts, focus on controlling mold and material temperatures, optimizing cooling times, and ensuring balanced mold temperatures. These strategies will help manage shrinkage rates and enhance the final part quality.