Nylon PA6 plastic material, also known as polyamide 6 (PA6), is a versatile engineering plastic renowned for its excellent mechanical properties, wear resistance, and chemical resistance.

As a semi-crystalline polymer, nylon 6 offers high tensile strength, thermal stability, and durability, making it a top choice across various industries like the automotive industry, consumer goods, and industrial applications.

This comprehensive guide explores the properties, structure, and common uses of nylon PA6, highlighting its performance in specific applications such as gears, bearings, and cable ties, while addressing its cost-effective benefits and behavior in humid environments.

What is Nylon PA6 Plastic Material?

Nylon PA6 plastic material is a cornerstone of engineering plastics, valued for its strength and stiffness and versatility.

Understanding its composition and properties is essential to appreciate its widespread use in many industries.

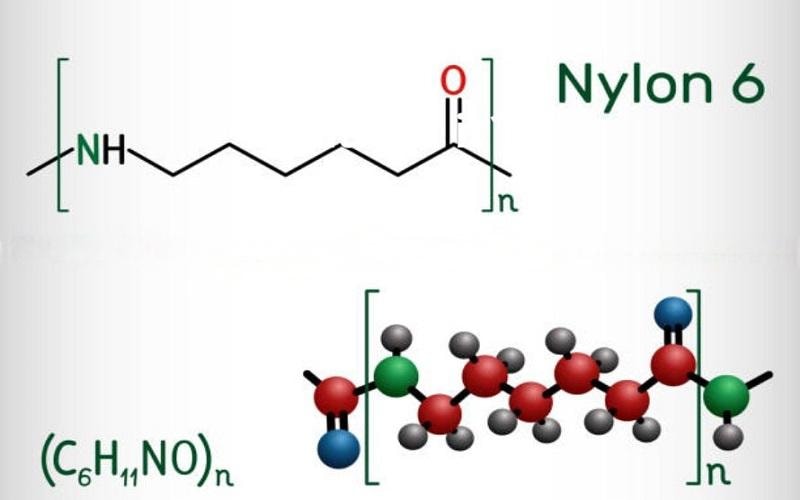

Composition and Molecular Structure of Polyamide 6

Polyamide 6 (PA6) is a semi-crystalline polymer composed of repeating units with six carbon atoms in its polymer chain, forming amide groups that contribute to its mechanical strength.

The molecular structure of nylon 6 creates a semi-crystalline structure, balancing crystalline and amorphous regions for toughness and flexibility.

This structure allows PA6 to absorb moisture, which can affect its dimensional stability but enhances its pliability in humid environments.

The semi-crystalline nature ensures high strength and good impact resistance, making nylon PA6 suitable for demanding applications.

Types and Modifications of Nylon 6

Nylon polymers, including PA6, can be modified with additives like glass fiber to enhance mechanical properties such as tensile strength and stiffness.

Glass fiber-reinforced PA6 offers excellent wear resistance and heat resistance, ideal for automotive parts or industrial components.

Food grade nylon variants meet safety standards for consumer goods like kitchenware.

These modifications allow manufacturers to tailor PA materials to meet performance requirements, ensuring cost-effective solutions for specific applications.

The versatility of nylon PA6 plastic material stems from its unique property profile, making it a preferred choice in industries requiring durability and performance.

Its structure and modifications enable customization for various projects.

Mechanical Properties of Nylon PA6

The mechanical properties of nylon PA6 make it a standout among plastics, offering high tensile strength, good impact resistance, and excellent wear resistance.

These properties drive its popularity in engineering applications.

Strength and Stiffness

Nylon 6 exhibits high tensile strength and stiffness, allowing it to withstand significant mechanical stress.

The semi-crystalline structure provides strength and stiffness, making PA6 suitable for components like gears, bearings, and engine parts.

Glass fiber reinforcement further enhances mechanical strength, increasing durability for high-performance applications in the automotive industry or industrial settings.

The low coefficient of friction ensures smooth operation in gears bearings, reducing wear.

Impact and Wear Resistance

Nylon PA6 offers good impact resistance, enabling it to absorb shocks without cracking, which is critical for consumer goods or industrial applications.

Its excellent wear resistance ensures longevity in components like cable ties or bearings, even under continuous use.

Compared to other plastics, PA6’s toughness and abrasion resistance make it ideal for parts exposed to friction or abrasive environments.

The mechanical properties of nylon PA6 ensure reliability in demanding applications, from automotive parts to household appliances, making it a go-to material for engineers and designers.

Chemical and Thermal Properties of Nylon 6

Nylon PA6 plastic material is valued for its chemical properties and thermal stability, enabling performance in challenging environments.

These properties expand its common uses across industries.

Chemical Resistance

Nylon 6 exhibits good resistance to chemicals, including oils, greases, and some solvents, making it suitable for automotive and industrial applications.

Its chemical resistance protects components like engine parts or cable ties from degradation in harsh conditions.

However, PA6 can absorb moisture in humid environments, which may affect dimensional stability but does not compromise its chemical properties in most applications.

Heat Resistance and Thermal Stability

With a melting point around 220°C, nylon PA6 offers good temperature resistance, allowing it to perform at elevated temperatures in automotive or electrical components.

Its thermal stability ensures durability in household appliances or industrial parts exposed to heat.

Glass fiber-reinforced PA6 enhances heat resistance, making it ideal for engine parts or gears requiring performance under thermal stress.

The chemical resistance and thermal stability of nylon PA6 make it a reliable material for specific applications, ensuring longevity and performance in many industries.

Manufacturing Processes for Nylon PA6

Nylon PA6 plastic material is produced using advanced processes that leverage its semi-crystalline structure and mechanical properties.

These methods ensure cost-effective production for various industries.

Injection Moulding and Extrusion

Injection moulding is a common process for nylon 6, where pellets are melted and injected into a mold to form components like gears, bearings, or cable ties.

Extrusion creates continuous shapes, such as filaments or tubes, used in electrical or consumer goods applications.

Both processes utilize PA6’s thermal stability and melt properties, ensuring precision and durability.

Additives like glass fiber can be incorporated to enhance strength and stiffness.

Additive Manufacturing and Other Methods

Additive manufacturing, such as 3D printing, uses nylon PA6 for prototyping or complex components due to its high strength and flexibility.

The semi-crystalline polymers allow PA6 to be processed into filaments with excellent mechanical properties, making it suitable for industrial applications.

Other methods, like casting, support production of custom parts with dimensional stability.

The manufacturing processes for nylon PA6 ensure cost-effective production while maintaining high performance, making it widely used in engineering and consumer products.

Common Uses of Nylon PA6 in Various Industries

Nylon PA6 plastic material is widely adopted in many industries due to its durability, mechanical strength, and cost-effective property profile.

Its versatility supports specific applications across sectors.

Automotive Industry Applications

In the automotive industry, nylon 6 is used for automotive parts like engine parts, gears, and bearings due to its excellent wear resistance and heat resistance.

Glass fiber-reinforced PA6 enhances strength and stiffness, ensuring performance in demanding environments.

Cable ties and clips benefit from PA6’s toughness and chemical resistance, making it a reliable material for vehicle components.

Consumer Goods and Household Appliances

Nylon PA6 is commonly used in consumer goods like household appliances, kitchenware, and sporting goods due to its good impact resistance and aesthetic versatility.

Food grade nylon ensures safety in kitchen products, while PA6’s durability supports long-lasting appliances.

Its low coefficient of friction makes it ideal for moving parts in appliances.

Industrial and Electrical Applications

Industrial applications leverage nylon PA6 for gears, bearings, and conveyor components due to its excellent wear resistance and mechanical strength.

In electrical applications, PA6’s thermal stability and resistance to chemicals make it suitable for insulators or housings.

Its ability to perform in humid environments ensures reliability in outdoor or industrial settings.

Challenges and Considerations for Nylon PA6

While nylon PA6 plastic material offers numerous benefits, challenges like moisture absorption must be addressed to ensure optimal performance.

Understanding these considerations is critical for successful use.

Moisture Absorption and Dimensional Stability

Nylon 6 can absorb moisture in humid environments, which may affect dimensional stability and mechanical properties.

This property can soften PA6, making it more pliable but potentially reducing stiffness.

Manufacturers can mitigate this by using coatings or additives to enhance resistance, ensuring reliability in applications like automotive parts or electrical components.

Cost and Processing Challenges

While nylon PA6 is cost-effective compared to other engineering plastics, processing at elevated temperatures requires precision to avoid degradation.

The melting point and thermal stability demand controlled production processes.

Additives like glass fiber can increase costs, but they enhance performance for high-strength applications.

Conclusion

Nylon PA6 plastic material, or polyamide 6, is a versatile engineering plastic with excellent mechanical properties, wear resistance, and chemical resistance, making it ideal for various industries.

Despite challenges like moisture absorption, nylon 6’s cost-effective property profile and processability make it a preferred material for high-performance products.

By understanding PA6’s properties and common uses, manufacturers and designers can leverage its strength and stiffness for specific applications.