Nylon plastic is a highly durable and versatile material used in industries ranging from automotive to textiles. But what makes nylon plastic so essential?

This article will explore how it’s made, the different types available, its properties, and its wide array of applications.

How is Nylon Plastic Made?

Nylon plastic is a marvel of modern chemistry, born from the polymerization of adipic acid and hexamethylene diamine. This chemical reaction, known as condensation polymerization, forms a new polymer called nylons by linking the monomers into long chains. The process begins with the creation of a nylon salt, a crystalline substance formed when adipic acid and hexamethylene diamine react together, resulting in polyamide, dicarboxylic acid, nylon resins, nylon production, and nylon polymer.

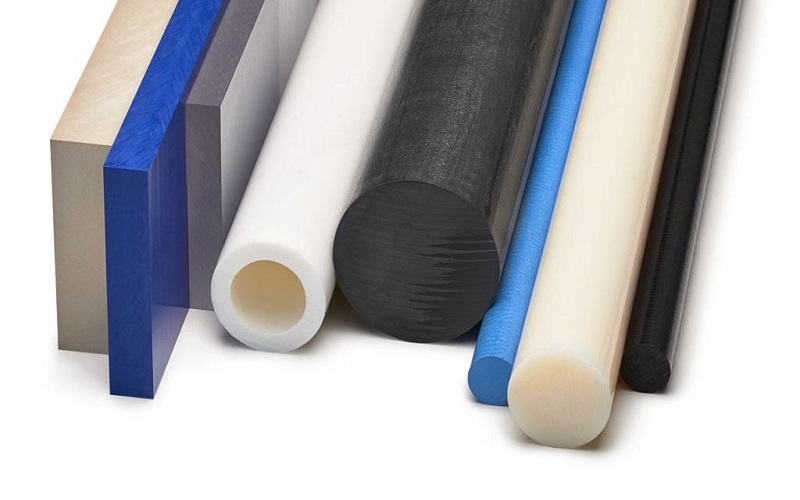

Next, the nylon salt is heated until it melts. This molten mixture is then extruded through a die to create continuous nylon filaments, forming various shapes from thin fibers to thick rods. The extrusion process’s versatility allows nylon to be molded into numerous shapes for diverse industrial applications.

After extrusion, the nylon is cooled to solidify, using methods such as water baths or air cooling systems to maintain its shape and structural integrity. Then, the nylon is typically cut into pellets, ready to be melted and molded into final products.

The manufacturing process of nylon plastic highlights both the complexity and precision involved, explaining why this material is so reliable and widely used. Each step, from the initial chemical reaction to the final cooling phase, is meticulously controlled to produce high-quality nylon parts.

Different Types of Nylon Plastic

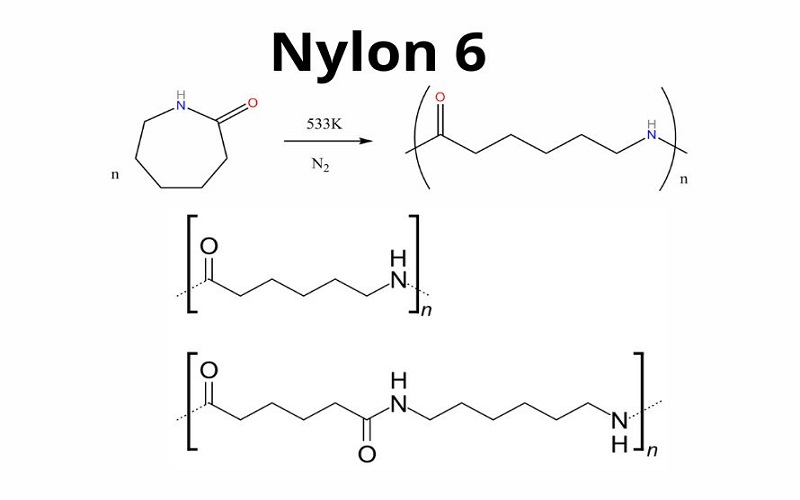

Nylon plastic is not a one-size-fits-all material; it comes in various types, each with unique properties tailored for specific applications. Among the most common types are Nylon 6, Nylon 6,6, and Nylon 4,6.

Nylon 6 is renowned for its strength, elasticity, and shiny appearance. It can withstand temperatures up to 150°C before melting, making it suitable for applications requiring high heat resistance. Nylon 6 is often used in textiles, carpets, and industrial applications where flexibility, durability, and nylon fabric are paramount, including synthetic fabrics.

Another popular type is Nylon 6,6, which boasts:

- High strength and toughness

- Ideal use for wear pads, slide bearings, and other components subjected to significant mechanical stress

- A higher melting point of 252°C compared to Nylon 6, making it suitable for even more demanding applications.

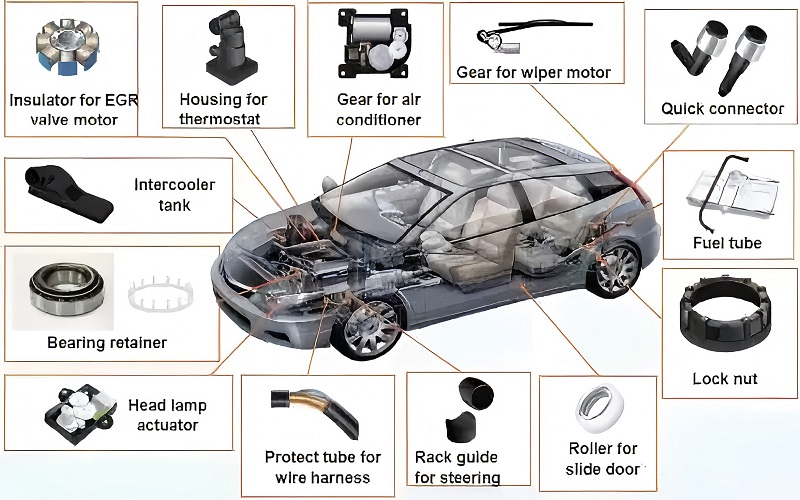

Nylon 4,6 is engineered to endure higher temperatures than both Nylon 6 and Nylon 6,6. This type is particularly useful in the automotive industry for components like transmissions and brakes, where high-temperature stability is crucial.

Nylon 510, while more expensive to produce, is celebrated for its strength and durability. It is used in small production batches for industrial applications that require these specific properties.

Nylon 11 and Nylon 12 offer:

- Excellent resistance to impact and abrasion

- Durability against chemicals

- Excellent flexibility

- Minimal moisture absorption

These various properties make them ideal for a range of applications from automotive to consumer products, including steel.

Understanding the different types of nylon reveals the material’s versatility and its capacity to meet diverse industrial needs. Each type offers unique properties, ensuring a suitable option for nearly any application.

Common Manufacturing Processes for Nylon Plastic

The manufacturing processes for nylon plastic are as diverse as the material itself. Among the most commonly used methods are CNC machining, injection molding, and 3D printing.

CNC machining is a highly precise method used to produce intricate nylon parts, such as gears and bushings. This process involves using computer-controlled machines to cut and shape the nylon material, ensuring high accuracy and consistency. CNC machining is particularly beneficial for producing components that require tight tolerances and complex geometries, including various machine parts.

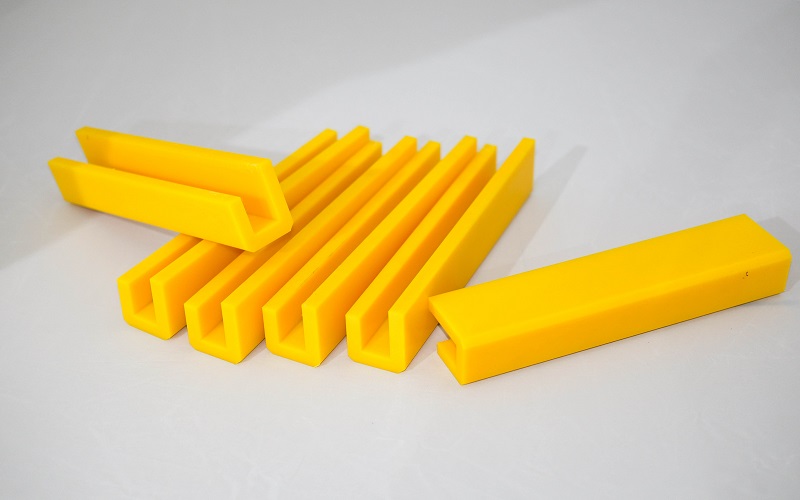

Injection molding is another popular method due to its ability to produce durable and heat-resistant nylon parts in large quantities. In this process, molten nylon is injected into a mold, where it cools and solidifies into the desired shape. Injection molding is favored for its efficiency and capability to produce high-strength parts with excellent surface finish.

3D printing, or additive manufacturing, is making significant strides in the production of nylon components. This process involves building up layers of nylon material to create a part, offering advantages in flexibility and design complexity. However, it requires handling high temperatures to ensure the material’s integrity.

Effective nylon manufacturing also considers specific design factors, such as maintaining appropriate wall thickness and corner radii. Wall thickness should range between 0.030 to 0.115 inches to avoid issues like warping, while corner radii larger than 0.5 mm help prevent stress concentrations. These considerations ensure the final product’s durability and performance.

Understanding these manufacturing processes provides insight into how nylon parts are created from raw materials and highlights the material’s adaptability to different production methods.

Material Properties of Nylon Plastic

Nylon plastic stands out due to its remarkable material properties, making it a popular choice across various industries. One of its most notable characteristics is high tensile strength, which allows it to withstand significant stress without breaking. This makes nylon ideal for applications requiring durable and long-lasting materials.

Nylon also offers excellent wear and abrasion resistance, ensuring that parts made from this highly durable material maintain their integrity even under constant friction. This property is particularly useful in mechanical components, such as gears and bearings, where impact resistance and wear resistance are crucial.

Chemical resistance is another key attribute of nylon. It is resistant to many chemicals, oils, and solvents, which broadens its range of applications. However, it’s worth noting that certain substances like phenol can dissolve nylon, so it’s important to consider the chemical environment in which the nylon will be used.

Heat resistance varies among different types of nylon, with melting points around 215°C for Nylon 6 and 252°C for Nylon 6,6. This high-temperature tolerance and high temperature resistance make nylon suitable for temperature resistant applications involving high heat, such as automotive and industrial components.

Finally, nylon’s elasticity allows it to stretch and return to its original shape without permanent deformation. This property, combined with its durability, makes nylon an excellent choice for products that require flexibility and resilience.

These unique properties explain why nylon makes such a versatile material and widely used material, capable of meeting the demands of various applications.

Industrial Applications of Nylon Plastic

Nylon plastic’s unique properties make it indispensable in a wide range of industrial applications. In the automotive industry, for example, glass-reinforced nylon is used to replace heavier metal parts, enhancing fuel efficiency. Common components include:

- Gears

- Bearings

- Engine covers

- Fuel lines This use of nylon not only reduces weight but also improves the overall performance and efficiency of vehicles.

In the aerospace sector, synthetic polymer nylon is used to manufacture lightweight components that contribute to better aircraft performance. Its strength and durability are crucial in this high-stakes industry, where material failure is not an option.

The electronics industry values nylon for its excellent insulating properties and compliance with fire safety regulations. It’s used in various components, including connectors and housings, where these properties are essential for safe and reliable operation.

Nylon’s durability and aesthetic qualities also make it a popular material choice in consumer products. From sports equipment to kitchen tools, nylon stockings, and food packaging, nylon fabrics are favored for their resistance to wear and ability to maintain their appearance over time. Additionally, the ability to produce rapid prototypes through 3D printing and large-scale production runs via injection molding further demonstrates nylon’s versatility in manufacturing processes.

These examples highlight the broad spectrum of industries that rely on synthetic polymer nylon, showcasing its widespread use and the critical role it plays in modern manufacturing industry.

Advantages and Disadvantages of Nylon Plastic

Nylon plastic offers numerous advantages that make it a preferred material in various applications. Its strength and durability, first recognized during World War II for applications like parachutes, are perhaps its most significant benefits, ensuring that nylon parts can withstand substantial stress and wear over time. Additionally, nylon’s versatility allows it to be used in a wide range of products, from automotive components to consumer goods like hair combs.

However, nylon is not without its drawbacks. One of the most notable disadvantages is its hygroscopic nature, meaning it can absorb moisture from the air through tiny holes in its structure. This moisture absorption can affect nylon’s dimensions and properties, potentially leading to performance issues. In applications requiring precise tolerances, this dimensional change can be problematic.

Another drawback is nylon’s susceptibility to UV light. Prolonged exposure to UV rays can lead to a loss of strength and cause the material to develop a yellow tint. This makes nylon less suitable for outdoor applications unless it is treated with UV stabilizers.

Nylon’s glass transition temperature can also be lowered due to its hygroscopic nature, making the material behave more brittle under certain conditions. Additionally, nylon is known for its lack of breathability and propensity to shrink, which can be a disadvantage in certain applications, particularly in the textile industry.

While nylon offers significant benefits in terms of durability and versatility, it is essential to consider these drawbacks when selecting materials for specific applications. Balancing the advantages and disadvantages will help in making informed decisions about using nylon plastic.

Post-Processing Techniques for Nylon Plastic

Post-processing techniques enhance the quality and performance of nylon plastic components. Annealing, for example, relieves internal stresses in nylon parts, preventing warping or cracking. This process involves heating the nylon to a specific temperature and then slowly cooling it for structural stability.

Surface treatment is another crucial post-processing technique. It can enhance the adhesion of coatings, paints, or adhesives on nylon parts, making them suitable for various applications. Techniques like sandblasting can modify the friction characteristics of nylon surfaces, improving grip and usability in specific contexts.

Dyeing is also a popular post-processing technique for nylon. It not only tailors the appearance of nylon parts but also improves their resistance to UV radiation. This is particularly useful for products that will be exposed to sunlight, ensuring they maintain their dyed color and integrity over time.

Machining processes such as CNC milling, turning, and grinding are commonly used to achieve the desired shape and finish for nylon parts. These techniques allow for high precision and customization, ensuring the final product meets specific requirements.

By employing these post-processing techniques, manufacturers can enhance the properties and performance of nylon plastic, ensuring it meets the demands of various applications.

Design Considerations for Nylon Plastic Parts

Designing nylon plastic parts requires careful consideration of several factors to ensure optimal performance and durability. One of the first steps is choosing the right type of nylon based on the application’s specific requirements. Different types of nylon offer varying properties, such as heat resistance, strength, and flexibility, making it crucial to select the appropriate type for the intended use.

Key design considerations for molding include:

- Maintaining uniform wall thickness to prevent issues such as warping, sink marks, or voids.

- Ensuring structural integrity of the part, especially in applications where mechanical strength is critical.

- Incorporating draft angles into the design to facilitate easy ejection from the mold and reduce the risk of damage during manufacturing.

- Using draft angles typically between 0.5° and 1°.

Drying nylon before machining is crucial due to its hygroscopic nature, which can lead to significant dimensional changes. Key points to consider include:

- Keeping the material dry before machining helps maintain precision and accuracy.

- Accounting for dimensional changes during cooling.

- Adjusting part dimensions accordingly to prevent issues during final assembly.

These design considerations are crucial for creating functional parts and durable nylon parts that meet specific application requirements. By addressing these factors, engineers and designers can optimize the performance and longevity of nylon components.

Summary

Nylon plastic is a cornerstone of modern manufacturing, offering a unique combination of strength, durability, and versatility.

From its intricate production process to its diverse applications across industries, nylon has proven to be an essential material. Understanding its various types, manufacturing processes, material properties, and design considerations provides a comprehensive view of why nylon is so widely used.

Despite its drawbacks, such as moisture absorption and UV susceptibility, nylon’s advantages far outweigh its disadvantages. Its ability to be tailored through post-processing techniques further enhances its appeal, making it suitable for a wide range of applications. As industries continue to innovate, the role of nylon plastic will undoubtedly remain significant, driving advancements and shaping the future of manufacturing.

Frequently Asked Questions

What is the primary chemical reaction involved in making nylon plastic?

The primary chemical reaction in making nylon plastic is the polymerization of adipic acid and hexamethylene diamine to form nylon salt, which is subsequently melted and shaped.

What are the different types of nylon plastic, and where are they commonly used?

Different types of nylon plastic include Nylon 6, Nylon 6,6, Nylon 4,6, Nylon 510, Nylon 11, and Nylon 12. These materials are commonly utilized in textiles, automotive components, industrial machinery, and consumer products.

What are the key manufacturing processes for nylon plastic?

The key manufacturing processes for nylon plastic are CNC machining, injection molding, and 3D printing, each offering distinct advantages like precision, scalability, and design flexibility. Understanding these processes is essential for effective nylon production.

What are some advantages and disadvantages of using nylon plastic?

Nylon plastic offers high strength, durability, and versatility, making it a valuable material in many applications. Conversely, it is prone to moisture absorption, UV light degradation, and potential dimensional changes, which may limit its use in certain environments.

What is the primary chemical reaction in making nylon fabric?

Polymerization of adipic acid and hexamethylene diamine forms nylon salt, which is melted and extruded into fibers for nylon fabric.