Nylon properties make this synthetic polymer highly versatile and essential in various industries. Known for its strength, elasticity, and durability, nylon stands out as a preferred material in textiles, automotive, and industrial applications.

This article will delve into the key physical, chemical, thermal, mechanical, and electrical properties of nylon, offering a comprehensive look at what makes it so valuable.

Key Physical Properties of Nylon

Nylon fibers, a synthetic polymer, boast a range of impressive physical properties that make nylon polymers, synthetic fabrics, synthetic material, and synthetic fiber invaluable across various industries. Its lustrousness, elasticity, strength, damage resistance, resiliency, moisture resistance, and quick-drying properties make nylon a highly versatile material.

High heat resistance and durability further enhance nylon’s appeal, making it notably stronger than other plastics due to its superior strength and temperature resistance.

Strength and Durability

Nylon’s strength and durability are among its most celebrated attributes. Exhibiting high tensile strength, it can endure significant impacts, making it suitable for demanding applications. From automotive parts to heavy-duty fabrics, nylon, derived from nylon salt as a key intermediate in its production, withstands prolonged exposure to temperatures up to approximately 120°C (248°F) without significant degradation.

This heat resistance is particularly advantageous in automotive and electrical components, where maintaining integrity under high temperatures is crucial.

Elasticity

Nylon’s excellent elasticity comes from the amorphous regions in its molecular structure, allowing it to stretch without permanent deformation. This unique ability to revert to its original shape makes nylon ideal for flexible products like clothing.

The amorphous molecular structure plays a key role in ensuring nylon maintains its form and functionality even after repeated use.

Abrasion Resistance

Nylon’s high abrasion resistance makes it suitable for products exposed to significant wear and tear. In industrial applications or everyday items like clothing and accessories, nylon withstands harsh conditions, ensuring longevity and reliability.

The robust molecular chains of nylon contribute to its high resistance to damage from wear and friction.

Chemical Properties and Environmental Exposure

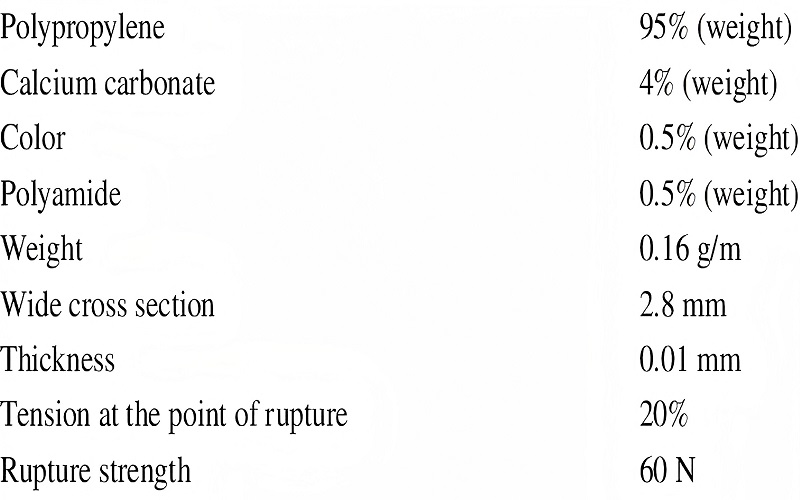

Nylon, composed of synthetic polymers known as polyamides and nylon resins, has unique chemical properties that influence its performance in various environments.

The polymerization process, involving diamine and dicarboxylic acids, results in nylon 66 with varying levels of chemical stability.

These chemical properties and reactions to different substances and environmental conditions determine nylon’s suitability for specific applications.

Chemical Resistance

Nylon’s exceptional chemical resistance enhances its utility in numerous applications. Its high resistance to various hydrocarbons, such as oils and fuels, makes it ideal for mechanical applications. This resilience against oils and solvents underscores its value as a versatile material.

Nylon maintains its integrity despite exposure to harsh chemicals, making it a preferred choice in many industries.

Water Absorption

Nylon’s hygroscopic nature means it can absorb moisture from the air, though not as much as natural fibers like wool or cotton. Its quick-drying properties are particularly beneficial in clothing and outdoor gear. However, nylon’s elastic modulus can be influenced by absorb moisture, potentially lowering its rigidity.

Despite this, water does not penetrate all the way through thicker nylon parts, preserving its structural integrity.

UV Resistance

Nylon’s UV resistance is crucial for outdoor applications, ensuring materials retain integrity and durability despite prolonged sunlight exposure.

This resistance helps maintain the color, strength, and functionality of nylon products, making it ideal for items like fishing lines and tent fabrics.

The ability to withstand harsh sunlight exposure significantly enhances the performance and lifespan of these products.

Thermal Properties of Nylon

Nylon’s thermal properties are vital in its application across various industries. Its ability to withstand high temperatures without significant degradation makes it a reliable material for many uses. The melting point of nylon 6 is 428°F (220°C), while nylon 66 has a melting point of 285°C (545°F) during its formation.

These high melting points contribute to the material’s thermal stability and suitability for high-temperature applications.

Melting Point

Nylon’s melting point is a pivotal factor in its selection for products and industries requiring robust performance under elevated temperatures. With a melting point reaching up to 200°C, nylon maintains integrity and performance even in heat-intensive environments such as automotive and aerospace applications.

This thermal stability is a key reason why nylon is a widely used synthetic polymer valued for high-temperature applications.

Glass Transition Temperature

The glass transition temperature of nylon, typically around 50°C (122°F), impacts its flexibility in different environmental conditions. This temperature range influences how nylon performs under varying climate factors.

Understanding the glass transition temperature helps users anticipate the material’s behavior and select the right nylon type for specific applications.

Heat Resistance

Nylon’s strong thermal properties allow it to withstand high temperatures without degrading, ensuring reliability in various applications. Its relatively high melting point makes it suitable for applications requiring heat resistance, such as automotive and electrical components.

The glass transition temperature indicates where nylon maintains flexibility, contributing to its effectiveness in fluctuating environments.

Mechanical Properties of Nylon

Nylon’s mechanical properties are integral to its versatility. Its inherent strength makes it suitable for applications that endure impacts and stress. With a unique balance of strength and flexibility, nylon is used in a wide array of applications, from textiles to industrial components.

Variants filled with glass or carbon fibers further enhance its mechanical performance in high-load scenarios.

Stiffness and Flexibility

Nylon exhibits a unique balance between stiffness and flexibility, making it versatile for numerous applications. With stiffness ranging between 20-40 gm/density, nylon provides the right balance, allowing for flexibility in various applications.

Impact Resistance

Nylon’s molecular structure enables it to absorb shocks effectively, making it an excellent choice for protective gear and sports equipment. Its high tensile strength and durability allow it to withstand significant impacts.

This shock-absorbing ability ensures that nylon products are both safe and reliable.

Elastic Modulus

The elastic modulus of nylon indicates its level of rigidity, allowing it to respond effectively to varying stress and strain conditions. With a breaking extension of 20-40%, nylon can stretch and return to its original shape, handling stress without permanent deformation.

Electrical Properties of Nylon

Nylon’s electrical properties make it suitable for various electronic applications. Its excellent electrical insulation prevents electrical leakage and protects components in cables and connectors.

The semi-crystalline structure of nylon contributes to its high temperature, chemical, and electrical resistance, enhancing its performance in electronic applications.

Insulation Properties

Nylon is an effective insulator, preventing electrical leakage and protecting components in cables and connectors. These properties enable its use in various electronic applications, where minimizing electrical conductivity is crucial.

Static Electricity

Nylon is prone to static electricity, which can lead to clinging and sparks. The structure of nylon can cause the accumulation of static charges, affecting its performance in electronic devices.

This tendency to accumulate static charges could interfere with sensitive electronic devices.

Environmental Impact of Nylon

Nylon’s environmental impact is a growing concern. The monomers for nylon are extracted from crude oil, indicating its derivation from fossil fuels. A significant disadvantage is that nylon is non-biodegradable, contributing to long-term waste issues.

Research is underway for bio-based nylon alternatives to reduce dependence on fossil fuels and lower production emissions.

Production and Pollution

Nylon is mainly produced from polyamide monomers derived from crude oil, making it reliant on fossil fuels. The manufacturing process and polymerization techniques for creating Nylon 6 and Nylon 6,6 demand significant energy, increasing the carbon atoms footprint.

Nitrous oxide, released during the production of adipic acid for Nylon 6,6, is a greenhouse gas with a warming potential far greater than carbon dioxide. The production of nylon generates hazardous emissions, including nitrous oxide.

Recycling and Sustainability

Nylon production raises environmental concerns, including raw materials, energy use, waste production, and its biodegradability. One negative consequence of nylon’s synthetic nature is that it is not biodegradable, taking hundreds of years to decompose.

However, recycled nylon lends itself well to recycling, offering potential solutions to mitigate its environmental footprint. Proper disposal methods are crucial to improving nylon’s environmental impact.

Common Uses of Nylon

Nylon is used in various industries such as textiles, automotive, electrical components, industrial applications, packaging, and sports equipment. Its versatility and durability make it a preferred material in many applications, including nylon fabrics.

Textile Industry

Nylon is used in a wide range of nylon clothing items, including lingerie, nylon stockings,swimwear, and cycling wear. Nylon fabric is commonly used in tights, yoga pants, and other form-fitting bottoms. One desired aspect of nylon in sportswear is its elasticity.

After World War II, due to material shortages, nylon fabric was sometimes repurposed from parachute material for civilian clothing. The introduction of nylon in clothing reduced silk imports from Japan.

Automotive and Industrial Applications

Nylon is utilized in various industrial applications, including gears and bearings. Its low friction and durability make it an ideal material for machine parts such as screws, nuts, and bolts.

In the automotive industry, nylon contributes to the manufacturing of lightweight and durable components, enhancing fuel efficiency. Nylon’s strength and flexibility offer significant advantages over metal for various industrial tools.

Consumer Goods

Nylon’s durability and versatility make it a popular choice in everyday items. It is used in medical applications such as catheters, bandages, hospital beds, walkers, and syringes. Nylon plastic also plays a role in the production of packaging materials like plastic bags and films.

Its widespread use in various consumer goods highlights nylon’s practical value in different industries.

Summary

Nylon’s exceptional properties make it an invaluable material in numerous applications. Its strength, durability, elasticity, and resistance to abrasion, chemicals, and UV light ensure its reliability and longevity.

While its environmental impact poses challenges, ongoing research and recycling efforts offer hope for more sustainable use. Whether in textiles, automotive parts, or everyday consumer goods, nylon continues to prove its worth.

Understanding these properties allows us to appreciate the versatility and importance of this remarkable synthetic polymer. Let us embrace sustainable practices and innovative solutions to ensure that nylon remains a valuable resource for future generations.

Frequently Asked Questions

What makes nylon so durable?

Nylon is exceptionally durable due to its high tensile strength and resistance to impacts and high temperatures. These properties make it suitable for various demanding applications.

How does nylon’s elasticity benefit its applications?

Nylon’s elasticity enhances its applications by enabling it to stretch and revert to its original shape, which is particularly beneficial for flexible products such as clothing. This characteristic contributes to durability and comfort in various uses.

Why is nylon resistant to abrasion?

Nylon’s robust molecular chains contribute to its high level of abrasion resistance, making it an ideal choice for products that undergo significant wear and tear.

What are the environmental concerns associated with nylon production?

Nylon production poses serious environmental concerns due to its reliance on fossil fuels, which leads to hazardous emissions and the creation of non-biodegradable waste. This underscores the need for more sustainable materials and processes in the textile industry.

How is nylon used in the automotive industry?

Nylon is utilized in the automotive industry for manufacturing lightweight and durable components, thereby improving fuel efficiency and overall performance. This material’s strength and versatility make it an essential choice for various applications in vehicles.