When it comes to choosing the right plastic material for your project, understanding the key differences between nylon and polypropylene is essential.

Both nylon and PP are widely used synthetic polymers with their own unique properties, making them suitable for various applications across industries.

This comprehensive comparison will guide you through the essential characteristics, benefits, and typical uses of these two common plastics, helping you make an informed decision for your manufacturing and design needs.

What Is Nylon?

Nylon is a versatile synthetic polymer belonging to the polyamide family, known for its exceptional durability and strength.

It is composed of long polymeric chains formed by repeating amide linkages, which give nylon its high tensile strength and excellent resistance to abrasion.

This low friction material is well suited for manufacturing components that require both flexibility and toughness, such as gears, rollers, and seals.

What Is Polypropylene?

Polypropylene is a widely used synthetic polymer classified as a saturated polymer, composed of repeating propylene monomers with the chemical formula (C3H6)n.

Known for its lightweight nature and low density thermoplastic characteristics, polypropylene offers excellent chemical resistance and heat resistance, making it an ideal material for various manufacturing applications.

Thanks to its durability and resistance to physical stress, polypropylene is commonly used in producing plastic components such as lightweight buckles, chemical tanks, semiconductor components, and medical devices.

Basic Properties Comparison Of Nylon And Polypropylene

Nylon and polypropylene are two widely used synthetic polymers, each with distinct basic properties that influence their suitability for various applications.

Understanding these key differences in their basic properties is crucial for effective material selection in prototyping and manufacturing components.

Below is a Nylon and polypropylene’s performance comparison table:

| Property | Nylon | Polypropylene |

|---|---|---|

| Tensile Strength | High (60-80 MPa) | Moderate (30-40 MPa) |

| Durability | Excellent | Good |

| Abrasion Resistance | Superior | Moderate |

| Elasticity | Good | Limited |

| Heat Resistance | High (~220°C melting point) | Moderate (~160°C melting point) |

| Weight | Heavier | Lightweight |

| Chemical Resistance | Moderate | Excellent |

| Moisture Resistance | Poor (8-10% absorption) | Outstanding (<0.1% absorption) |

| UV Resistance | Moderate | Outstanding |

| Melt Viscosity | Higher | Lower |

| Impact Resistance | Excellent | Good |

| Flexibility | High | Lower |

Applications Of Nylon Material

Nylon is a highly versatile material with a wide range of applications across various industries due to its unique properties。

Automotive Industry

Nylon is commonly used for manufacturing gears, bearings, and engine components because of its high tensile strength and excellent abrasion resistance.

Electronics

Nylon’s excellent electrical insulation properties and high heat resistance make it an ideal choice for various electronic applications.

It is widely used in insulating electrical cables, manufacturing connectors, and components that require durability under thermal stress.

Additionally, nylon’s low friction and abrasion resistance contribute to the longevity and reliability of electronic parts, ensuring stable performance in demanding environments.

Consumer Goods

Nylon is widely used in consumer goods due to its durability, high strength, and excellent resistance to wear and tear.

Its low friction property makes it ideal for products like toothbrush bristles and fishing lines, where smooth performance is essential.

Additionally, nylon’s ability to withstand repeated stress without losing shape or function makes it a popular choice for sports equipment, apparel, and outdoor use items.

The material’s resistance to water absorption and UV degradation further enhances its suitability for outdoor applications, ensuring long-lasting performance even in harsh environments.

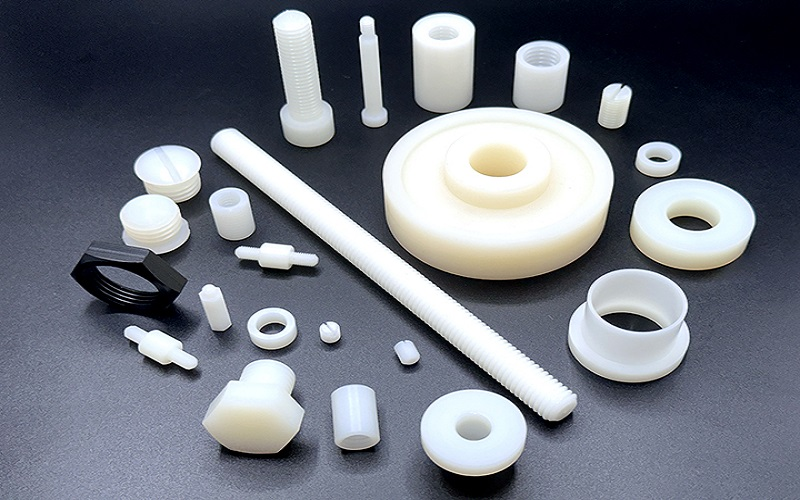

Industrial Applications

Nylon’s excellent durability, high tensile strength, and resistance to abrasion make it an ideal choice for various industrial applications.

It is widely used in producing seals, rollers, gears, and bearings that must withstand continuous mechanical stress and friction.

Its ability to maintain shape and performance under high temperatures and harsh chemical exposure further enhances its suitability for demanding manufacturing environments.

Prototyping

Nylon’s excellent malleability, combined with its ability to withstand higher temperatures, makes it an ideal material for prototyping and manufacturing components.

Additionally, nylon’s compatibility with additive manufacturing techniques and injection molding processes enables rapid iteration and customization, reducing development time and costs.

This versatility in prototyping applications highlights nylon’s unique properties compared to polypropylene, which, despite its lower melt viscosity and lightweight nature, is less suited for intricate design prototypes requiring high strength and heat resistance.

Applications Of Polypropylene Material

Polypropylene is a versatile and widely used synthetic polymer with numerous applications across various industries, thanks to its unique combination of properties.

Automotive Industry

In the automotive industry, polypropylene is highly valued for its lightweight material properties, which contribute significantly to weight reduction and improved fuel efficiency.

It is commonly used in manufacturing high resistance equipment such as battery cases, interior trims, and chemical tanks.

Additionally, polypropylene’s low melt viscosity allows for efficient injection molding of complex shapes, supporting cost-effective production of durable automotive components.

This combination of strength, chemical resistance, and lightweight nature makes polypropylene a preferred material alongside other materials in modern vehicle manufacturing.

Medical Devices

Polypropylene plays a crucial role in the medical field due to its excellent chemical resistance, biocompatibility, and ability to withstand repeated sterilization processes without degrading.

These properties make it an ideal material for manufacturing a wide range of medical devices, including syringes, surgical instruments, diagnostic components, and laboratory equipment.

Packaging

Polypropylene is extensively used in the packaging industry due to its excellent chemical resistance, moisture barrier properties, and lightweight nature.

These characteristics make it ideal for producing food packaging, containers, and plastic films that help preserve freshness and extend shelf life.

Additionally, polypropylene pellets enable efficient manufacturing through injection molding, allowing for cost-effective and versatile packaging solutions that meet diverse industry needs.

Consumer Goods

Polypropylene is extensively used in the consumer goods sector due to its lightweight nature, excellent chemical resistance, and durability.

It is a preferred material for manufacturing various plastic components such as lightweight buckles, household appliances, and toys.

Its outstanding resistance to UV light and moisture makes it particularly well suited for outdoor applications, ensuring products maintain their strength and appearance over time.

Key Differences Between Nylon And PP In Cost

When considering nylon and pp, cost is a significant factor influencing material selection.

Generally, polypropylene is more cost-effective than nylon due to its simpler manufacturing process and lower raw material expenses.

This makes polypropylene an attractive choice for applications requiring good durability without high strength demands.

On the other hand, nylon, with its superior tensile strength and abrasion resistance, tends to be more expensive but offers enhanced performance for demanding applications.

The price difference between these two materials often reflects their unique properties and suitability for specific uses, so balancing budget constraints with performance requirements is essential when choosing between nylon and polypropylene.

Which Is Better, Nylon Or PP?

Choosing between nylon and polypropylene depends largely on the specific requirements of your project, as both materials offer distinct advantages.

Nylon excels in applications requiring high tensile strength, excellent abrasion resistance, and the ability to withstand higher temperatures, making it ideal for demanding industrial components, prototyping, and manufacturing components that face significant physical stress.

On the other hand, polypropylene offers excellent chemical resistance, outstanding moisture resistance, and a lightweight nature, which makes it well suited for outdoor applications, medical devices, packaging, and plastic components where weight reduction and resistance to diluted bases or mineral spirits are important.

Both polypropylene and nylon have their own unique properties, so the best choice hinges on balancing factors such as durability, cost, heat resistance, and exposure to chemicals or UV light.

Conclusion

In summary, both nylon and polypropylene are versatile synthetic polymers with distinct advantages that make them suitable for different applications.

When considering applications polypropylene offers, it excels in automotive parts, chemical tanks, and semiconductor components due to its strength and resistance.

In the polypropylene vs nylon comparison, polypropylene is generally more cost-effective and better suited for applications requiring excellent chemical resistance and lightweight material benefits.

When choosing between nylon vs pp, consider factors such as cost, mechanical properties, environmental exposure, and specific application requirements to select the ideal material for your project.

Frequently Asked Questions

What Are The Key Advantages And Disadvantages In The Polypropylene vs Nylon Comparison?

Polypropylene offers excellent chemical resistance, lightweight properties, and cost-effectiveness, but has lower strength and heat resistance; nylon provides higher tensile strength, better abrasion resistance, and heat tolerance, though it is generally more expensive and absorbs moisture.

What Are The Most Common Applications Polypropylene Is Used For In Various Industries?

Polypropylene is widely used in industries such as automotive, medical devices, packaging, and consumer goods due to its lightweight nature, excellent chemical resistance, and durability.

Can Nylon And Polypropylene Be Used For Prototyping And Manufacturing Components?

Yes, both nylon and polypropylene can be used for prototyping and manufacturing components, with nylon favored for its malleability and heat resistance, and polypropylene valued for its lower melt viscosity and durability.

Which Material Is Better For Outdoor Applications?

Polypropylene is generally better for outdoor applications due to its superior resistance to UV light, moisture, and chemicals compared to nylon.

Are Nylon And Polypropylene Safe For Use In Medical Devices?

Yes, both nylon and polypropylene are safe for use in medical devices as they are available in FDA-compliant grades suitable for such applications.