Are you curious about what PA 12 (Nylon 12) is and why it’s popular in 3D printing? PA 12 is a type of polyamide known for its strength, durability, and versatility. As a favorite material in various industries, especially in 3D printing, it offers excellent mechanical properties and easy handling.

In this guide, we’ll dive into the key properties, applications, and printing processes for PA 12, helping you understand why it stands out.

Understanding PA 12 (Nylon 12)

PA 12, also referred to as Nylon 12, is a member of the polyamide family of polymers. This material is derived from fine polyamide powder, categorizing it under polyamide polymers.

When transitioning from traditional metal parts to PA 12, various factors must be considered to ensure performance parity:

- Operating conditions

- Loading cases

- Creep and fatigue levels

- Chemical resistance

- UV resistance

Notably, there are specialized formulations like EOS PA 2220 HighReuse, which is highly efficient and suitable for a range of applications.

These characteristics make PA 12 a highly adaptable and valuable material in the realm of 3D printing.

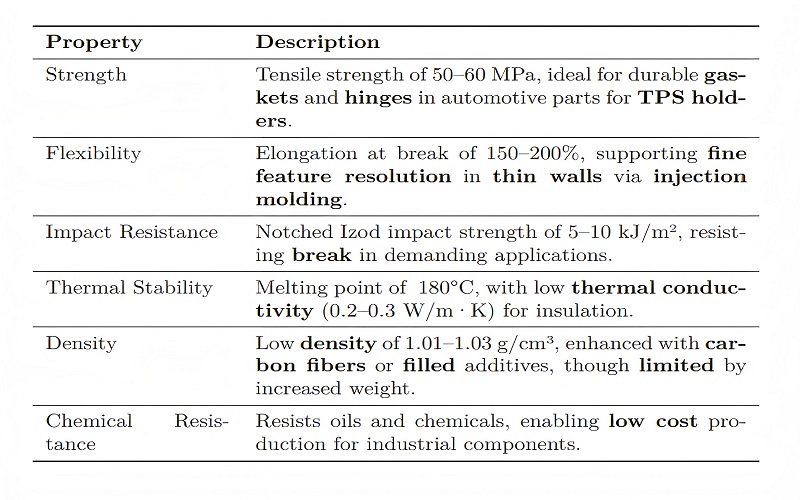

Key Properties of PA 12

One of the standout features of PA 12 is its high tensile strength, which, coupled with:

- excellent impact strength and flexibility, makes it ideal for creating functional parts and prototypes.

- low-friction characteristics that contribute to its durability, allowing it to perform well in demanding applications.

- excellent fatigue resistance, meaning it can withstand repeated stress without compromising its structural integrity.

PA 12’s low water absorption enhances its dimensional stability across various environments. This means that parts made from PA 12 remain consistent in size and shape, even when exposed to moisture, making it ideal for applications requiring fine feature resolution in intricate designs.

Its ability to maintain structural integrity also supports the creation of thin walls in components, ensuring precision and durability. These properties collectively make PA 12 a robust and reliable choice for a wide array of 3D printing applications.

Different Additive Manufacturing Processes for PA 12

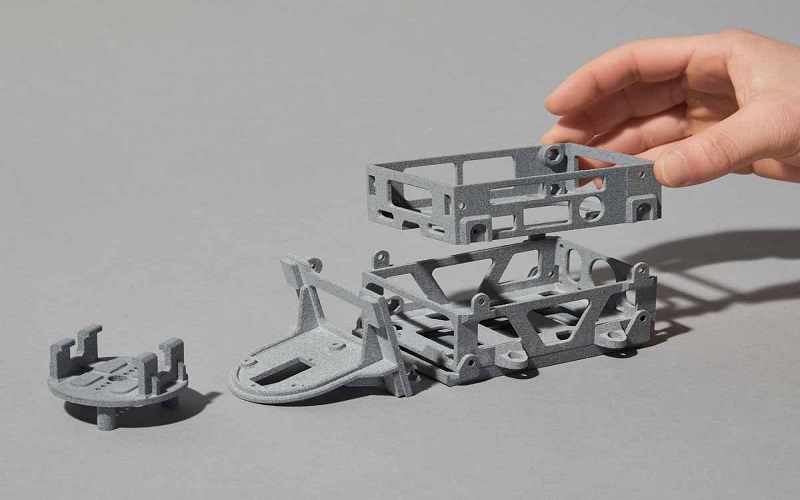

PA 12 is compatible with several established 3D printing methods, making it a highly versatile material in the field of additive manufacturing. These methods include Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Fused Deposition Modeling (FDM).

The material’s low thermal conductivity (0.2–0.3 W/m·K) ensures stable processing in these methods, minimizing heat-related distortions. Additionally, incorporating carbon fibers can enhance PA 12’s strength for applications requiring durability, similar to injection molding processes used for high-precision parts.

Each of these processes has its unique advantages and is suited for different applications, ensuring that PA 12 can meet a wide range of performance and resolution requirements, such as fine feature resolution and thin walls in complex designs for TPS holders.

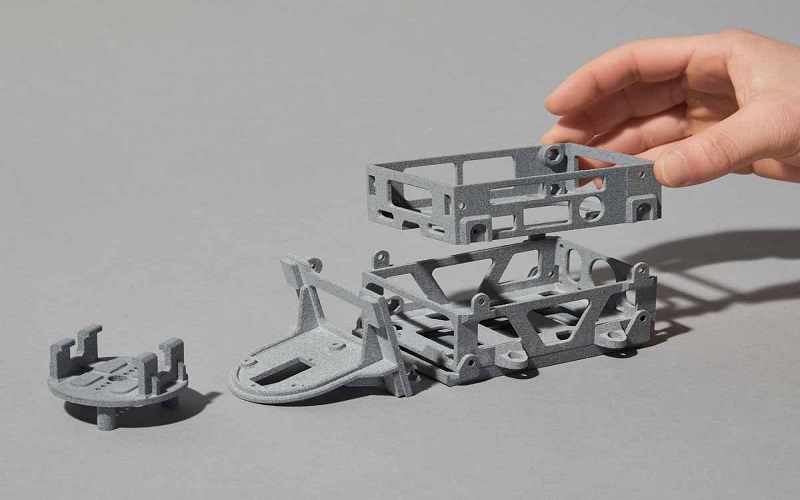

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a popular method for 3D printing with PA 12, utilized by companies like Sculpteo. The process involves:

- Using a focused laser beam to selectively melt the PA 12 powder layer by layer to form the final part.

- Sintering thin layers of PA 12 powder together, creating robust parts with excellent mechanical properties.

- Applying typical layer heights ranging from 100 to 120 microns, or even as thin as 60 microns for finer details.

This method is particularly beneficial for producing parts that require low water absorption, such as those used in injection molded parts and other demanding applications.

SLS offers the advantage of creating complex geometries without the need for support structures, making it a go-to process for high-performance and detailed 3D printed components.

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) is another advanced 3D printing process suitable for PA 12. This technology:

- Uses a binding agent to join layers of PA 12 powder

- Results in high-resolution parts with excellent surface finish

- Offers a faster production rate compared to traditional 3D printing methods

These features make MJF an efficient choice for both prototyping and manufacturer production.

This process ensures that the final parts are robust and ready for direct use, often eliminating the need for extensive post-processing.

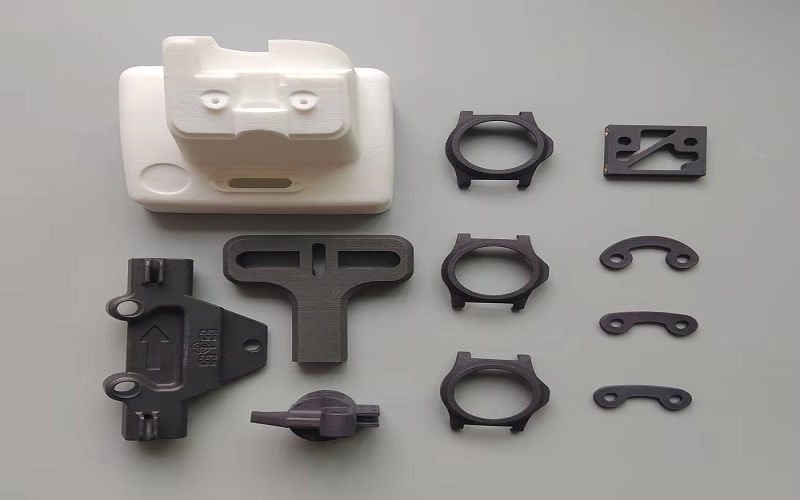

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a widely used method for printing with PA 12, utilizing a specialized filament known as FDM Nylon 12TM. This process involves extruding the filament through a heated nozzle to build up the part layer by layer.

FDM is particularly suitable for creating functional prototypes and industrial production parts due to its low cost and ability to produce durable, high-strength components that resist break under stress. This makes it ideal for applications like hinges in automotive or medical devices for TPS holders, ensuring robust performance with fine feature resolution.

One of the challenges with FDM is the need for support structures, especially for overhanging features. Key points include:

- Water-soluble PVA is typically used as the support material.

- PVA can be easily dissolved after printing.

- This process leaves the final part clean and ready for use.

This makes FDM a flexible and practical choice for various 3D printing applications.

Applications of PA 12 in Various Industries

The versatility of PA 12 makes it an invaluable material across multiple industries. Its unique properties, such as high tensile strength, impact resistance, and low water absorption, enable its use in applications ranging from automotive components to aerospace structures and medical devices.

Each sector leverages these properties to enhance the performance, reliability, and efficiency of their products.

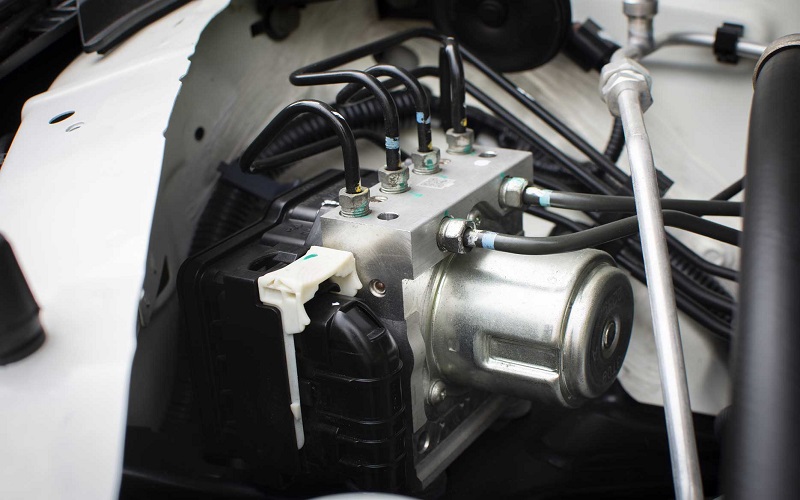

Automotive

In the automotive industry, PA 12 is commonly utilized for producing components like engine parts, seals, and fuel lines due to:

- Its high durability and resistance to extreme conditions

- Minimal water absorption, ensuring stable performance even in humid environments

- Excellent chemical resistance, crucial for parts exposed to harsh conditions such as oils and hydraulic fluids

Manufacturers favor PA 12 for its lightweight nature compared to traditional materials. This reduction in weight without compromising strength and durability helps improve fuel efficiency and overall vehicle performance. From gears and assemblies to intricate plastic components, PA 12 continues to play an essential role in advancing automotive engineering.

Aerospace

The aerospace industry greatly benefits from the lightweight and durable nature of PA 12. This material is crucial for creating efficient aircraft components that contribute to fuel savings and enhanced performance. PA 12’s ability to maintain structural integrity while being lightweight makes it ideal for internal parts that require both strength and reduced weight.

PA 12 is often used in aerospace applications where components must meet strict performance standards. Its robustness and low weight are critical for parts that face high stress and need to withstand abrasion and exposure to chemicals. This makes PA 12 a preferred material for various aerospace assemblies and engineered solutions.

Medical Devices

PA 12’s biocompatibility and high durability make it an excellent choice for medical devices. It is particularly favored for creating precise surgical guides and customized orthopedic devices that need to be sterilized and withstand rigorous use. The material’s compatibility with sterilization processes ensures that medical devices remain safe and functional.

3D printed prostheses are another notable application of PA 12 in the medical field. The ability to customize and rapidly produce tailored prosthetics significantly improves patient outcomes.

Companies like Koovea utilize PA 12 for developing temperature monitoring devices, showcasing its versatility and resilience in creating reliable medical tools.

Cost Considerations and Sustainability

The cost and sustainability aspects of PA 12 are crucial factors for its widespread adoption in 3D printing. The production method directly influences the cost structure of PA 12 materials, with design complexity and production volume being critical factors. Moreover, the environmental benefits of PA 12, such as reduced CO2 emissions during production, make it an eco-friendly choice.

Additionally, heat treatment through annealing can enhance the mechanical strength and impact resistance of PA 12 components, adding to its value.

Material Costs

Design complexity significantly impacts the pricing of PA 12 materials. Complex designs often lead to higher production costs due to the increased material waste and time required for manufacturing.

However, as production volume increases, the cost per unit of PA 12 typically decreases, making it a more cost-effective option for large-scale projects. Both design complexity and production volume are critical elements that influence the overall costs of PA 12 materials.

Sustainability

The sustainability profile of PA 12 is enhanced by:

- The ability to recycle unsintered powder in the SLS process, significantly reducing waste.

- Utilizing recycled PA 12 to help lower the environmental impact by decreasing the need for new resources.

- Supporting sustainable production and contributing to a lower carbon footprint.

These factors make PA 12 an environmentally friendly choice for 3D printing.

PA 12 offers substantial environmental benefits, particularly in additive manufacturing. The reduced material waste and the use of recycled materials highlight its cost-effective and sustainable nature.

These attributes make PA 12 a robust and viable option for industries looking to minimize their ecological footprint while maintaining high performance and durability.

Post-Processing Techniques for PA 12

Post-processing is a crucial step in the 3D printing workflow to enhance the appearance and performance of PA 12 parts. Finishing options for PA 12 include:

- Dyeing

- Polishing

- Painting

- Chemical smoothing

Techniques like Color Touch and Color Resist offer aesthetic enhancements. These methods not only improve the visual appeal but also provide additional protective layers to the light parts.

Techniques such as tumbling, sanding, and bead blasting can significantly enhance the surface quality of PA 12 parts. For instance, spray painting can provide a continuous and protective finish, enhancing both the appearance and durability of the parts. A well-executed post-processing regimen can transform a standard 3D printed part into a high-quality, aesthetically pleasing component.

Moreover, painting not only adds to the visual appeal but also impacts the surface durability, making the parts more resistant to wear and tear. This comprehensive approach to post-processing ensures that PA 12 components meet the desired performance and aesthetic standards required by various industries.

Design Guidelines for PA 12 Parts

Designing parts with PA 12 requires careful consideration to optimize the 3D printing process and the performance of the final parts. Key considerations include:

- Ensuring proper venting for internal cavities to avoid trapping excess powder during printing.

- Recognizing that PA 12 maintains good dimensional stability across varying temperatures.

- Utilizing PA 12 for precise applications due to its stability.

Additionally, managing warping in FDM prints through careful temperature control is necessary to achieve the desired results. Post-print machining can also be conducted on PA 12 parts to achieve tighter tolerances and improved surface finishes.

Minimum Wall Thickness

For PA 12 parts, maintaining a minimum wall thickness is crucial to ensure structural integrity. The recommended minimum wall thickness for PA 12 parts is 0.8 mm. For designs that require more rigidity, a wall thickness of 2 mm is advised.

Additionally, avoiding large flat surfaces in designs can help prevent warping during the printing process. These guidelines ensure that the final parts are robust and meet the desired performance criteria in smooth geometry.

Tolerances

Achievable tolerances for PA 12 parts are approximately ±0.3% in dimensions. For parts exceeding 100 mm, a tolerance of ±0.5% is typically achievable. When designing complex geometries, additional spacing may be required to ensure the removal of unsintered powder.

These design considerations are essential to achieve the desired dimensional accuracy and mechanical properties in the final parts.

Venting and Powder Removal

Incorporating vents in designs is crucial for facilitating powder removal from internal cavities. To effectively remove excess powder from PA 12 parts, consider the following:

- Strategically place vents to allow powder to escape.

- Design vent holes to prevent trapped powder.

- Ensure that the final parts are clean and functional by using vents appropriately.

For interlocking components, a minimum clearance of 0.5 to 0.6 mm is recommended to guarantee proper functionality. These guidelines ensure that the parts are free of powder residue and meet the desired specifications.

Case Studies: Successful Implementations of PA 12

PA 12 has been successfully implemented in various projects, showcasing its versatility and effectiveness. From customizable robotics to durable consumer products and innovative prototyping, PA 12 proves to be a valuable material for diverse applications.

These case studies highlight the material’s adaptability and high performance in real-world scenarios.

Customizable Robotics

The Berkeley Humanoid Lite, a 3D printed robot developed by UC Berkeley, is a prime example of how PA 12 can be used to create affordable and customizable robotic components.

Customizable robotics are revolutionizing the manufacturing sector by offering adaptive and tailored solutions, and PA 12 plays a key role in this transformation.

The material’s flexibility and strength make it ideal for developing complex robotic parts that require precision, durability, toughness, and rigid plastics.

Durable Consumer Products

PA 12’s excellent mechanical properties, including high fatigue resistance, make it a choice material for durable consumer products. In the automotive industry, PA 12 is utilized for producing components that can withstand rigorous conditions due to its durability.

The aerospace sector frequently employs PA 12 in components where lightweight and durability are critical to performance and safety. Medical devices also benefit from PA 12’s biocompatibility and strength, allowing the creation of reliable and long-lasting products.

Innovative Prototyping

Using PA 12 for rapid prototyping offers several advantages:

- Allows for quick iterations, which is crucial in developing new products efficiently.

- Significantly shortens the development cycle for new products.

- Enables the production of complex prototypes that can be tested and modified quickly, reducing product development time.

These properties make PA 12 suitable for creating intricate geometries that traditional methods may not achieve. The material’s mechanical properties ensure that functional prototypes can be tested under real-world conditions.

Summary

PA 12, or Nylon 12, stands out as a versatile and high-performance material in the world of 3D printing. Its unique properties, compatibility with various additive manufacturing processes, and wide-ranging applications across industries make it a preferred choice for engineers and manufacturers.

From automotive and aerospace to medical devices and consumer products, PA 12 continues to drive innovation and efficiency.

By understanding its properties, cost considerations, sustainability benefits, and design guidelines, you can harness the full potential of PA 12 for your next 3D printing project.

Frequently Asked Questions

What is PA 12, and why is it preferred for 3D printing?

PA 12, or Nylon 12, is a polyamide polymer favored in 3D printing for its high tensile strength, impact resistance, and low water absorption. Its versatility in various additive manufacturing processes further enhances its appeal for producing durable and high-quality parts.

What are the key properties of PA 12?

PA 12 is characterized by high tensile strength, excellent impact resistance, flexibility, low water absorption, and good fatigue resistance, making it ideal for demanding functional parts and prototypes.

How is PA 12 used in the automotive industry?

PA 12 is utilized in the automotive industry for its high durability and excellent chemical resistance, making it ideal for components such as engine parts, seals, and fuel lines. Its properties contribute to enhanced vehicle performance by reducing weight while maintaining structural integrity.

What post-processing techniques are available for PA 12?

Post-processing techniques for PA 12, such as dyeing, polishing, painting, chemical smoothing, tumbling, sanding, and bead blasting, significantly improve the surface quality, aesthetic appeal, and durability of the final parts. Employing these methods can enhance the overall performance and look of your products.

How does PA 12 contribute to sustainability?

PA 12 enhances sustainability by enabling the recycling of unsintered powder during the SLS process, which significantly minimizes material waste. Additionally, its production has a lower carbon footprint, positioning it as an environmentally friendly option for 3D printing.