Parting line in injection molding is a critical aspect that influences both the functionality and aesthetics of injection molded parts.

Understanding the parting line location and how mold halves meet during the molding process can significantly impact the quality, production cost, and overall success of your injection molding project.

This essential guide will explore the types of parting lines, and explain how to design parting line, and guides the importance of parting line in injection molding.

What Is The Parting Line In Injection Molding?

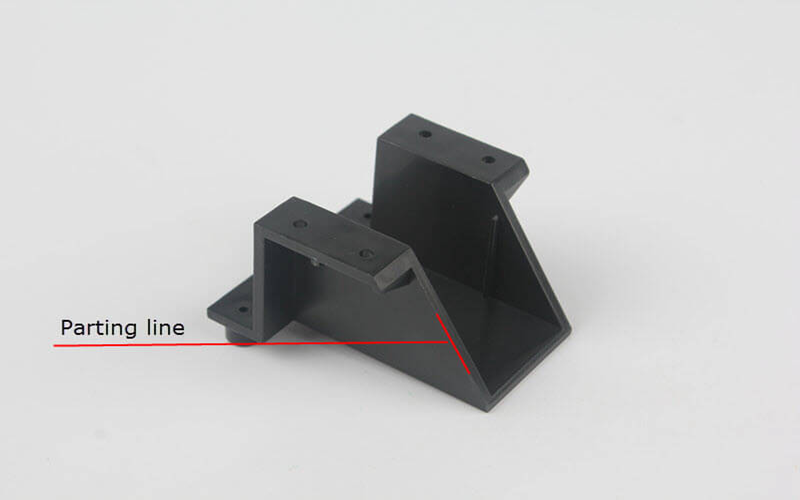

The parting line in injection molding is the visible line or seam that forms where the two halves of the mold meet and separate during the injection molding process.

It runs along the entire perimeter of the molded plastic part and marks the junction between the mold core and mold cavity.

This line is an inevitable result of the mold design and the way the mold opens and closes within the injection molding machine.

The location of the parting line is crucial because it affects the appearance of the final product, the presence of flash or excess material, and the ease of part ejection using ejector pins.

Properly planning the parting line based on the shape and complexity of the plastic part can minimize defects and ensure functional features are accurately formed.

Types Of Injection Molding Parting Lines

In injection molding, understanding the different types of parting lines is essential for optimizing mold design and part quality.

Vertical Parting Line

The vertical parting line is the most common and straightforward type used in injection molding.

It runs perpendicular to the mold opening direction, making it easier to design and manufacture.

This parting line type is ideal for simpler parts where the mold halves can separate smoothly without complex mechanisms.

Curved Parting Line

Curved parting lines are specifically designed to follow the natural contours of parts with rounded or irregular surfaces.

This type of parting line is essential for more complex parts where a straight or vertical line would not effectively separate the mold halves.

By aligning the parting line with the curve of the part, manufacturers can minimize the visibility of vestiges left on the surface after the mold separates, enhancing the final product’s aesthetic quality.

Beveled Parting Line

A beveled parting line features a sloped or angled edge where the two mold halves meet, rather than a straight vertical line.

This design helps create a better sealing surface between the mold halves, which is essential for preventing flash—excess molten plastic that can seep out during the injection molding process.

This type of parting line is especially useful for intricate or detailed part designs where maintaining tight tolerances and clean edges is critical.

Stepped Parting Line

The stepped parting line is designed to manage situations where a large force is exerted on one side of the mold during the injection molding process.

This type of parting line features a stepped shape that helps balance the injection force, preventing excessive wear and deformation of the mold halves.

Comprehensive Parting Line

A comprehensive parting line combines elements of vertical, curved, beveled, and stepped parting lines to accommodate the complexities of intricate injection molded parts.

This type of parting line is carefully designed to optimize mold functionality, ensuring smooth mold opening and closing while minimizing flash and other defects.

By integrating multiple parting line styles, it allows for better distribution of injection force and improved sealing surfaces, which is especially important for parts with complex geometries and multiple features.

Why Parting Line Location Matters In Injection Molding Process?

The location of the parting line in the injection molding process plays a vital role in several key aspects of the final product and manufacturing efficiency.

Affects Mold Opening Direction

The parting line determines how the mold halves separate during mold opening, directly influencing the draft direction, the ease of part ejection, and the overall efficiency of the molding process.

A well-planned parting line ensures smooth mold opening and closing, reduces the risk of part damage during ejection, and helps maintain dimensional accuracy of functional features.

Impacts Flash Formation

Improper parting line location can cause excessive flash—excess molten plastic that escapes the mold—leading to additional finishing costs, compromised part aesthetics, and potential interference with part assembly or sealing.

Careful consideration of the parting line location helps minimize flash, ensuring cleaner edges and reducing the need for secondary operations, which ultimately improves both the quality and cost-effectiveness of the injection molding process.

Influences Mold Design Cost

A well-chosen parting line can significantly simplify the mold structure, reducing the need for complex side actions or sliders.

This simplification not only lowers production costs but also shortens mold manufacturing time and enhances mold durability.

Facilitates Efficient Ejection Process

Proper alignment with ejector pins and positioning on the mold core side ensures smooth and efficient ejection of parts, minimizing potential damage and improving cycle times.

This careful placement reduces the risk of part deformation or sticking during the ejection process, contributing to higher quality injection molded parts and enhanced production efficiency.

How To Design Parting Line?

Designing an effective parting line in injection molding requires careful consideration of several factors to ensure optimal part quality, ease of manufacturing, and cost efficiency.

First, the parting line should be positioned at the largest contour of the plastic part to simplify mold opening and reduce the need for complex mold components such as sliders or side actions.

It is essential to align the parting line with the mold opening direction, allowing smooth separation of mold halves and facilitating efficient ejection of the part, usually favoring placement on the mold core or B side for better ejection.

Additionally, the parting line location should minimize visible vestiges and flash by placing it along edges or less conspicuous areas, such as sharp edges or recessed surfaces.

Utilizing CAD programs can help visualize and optimize parting line placement, allowing designers to simulate mold separation and detect potential issues early.

For parts subjected to high injection forces, incorporating features like wedge shaped inserts can improve mold stability and reduce wear.

Ultimately, a well-designed parting line balances functional requirements, aesthetics, and manufacturability, leading to higher quality injection molded parts with reduced production costs.

Conclusion

In summary, the parting line in injection molding is a fundamental aspect that directly influences the quality, functionality, and cost-effectiveness of injection molded parts.

Understanding the different types of parting lines, such as vertical, curved, beveled, stepped, and comprehensive, and their impact on mold design and mold opening direction is crucial for optimizing the injection molding process.

Often, the parting line runs along the middle of the part, serving as a natural division point for the mold halves.

Proper parting line location minimizes flash and excess material, facilitates efficient ejection with ejector pins, and ensures that functional features are accurately formed.

By carefully designing the parting line using tools like CAD programs and considering factors like injection force and mold complexity, manufacturers can produce high-quality parts while reducing production costs and improving overall manufacturing efficiency.