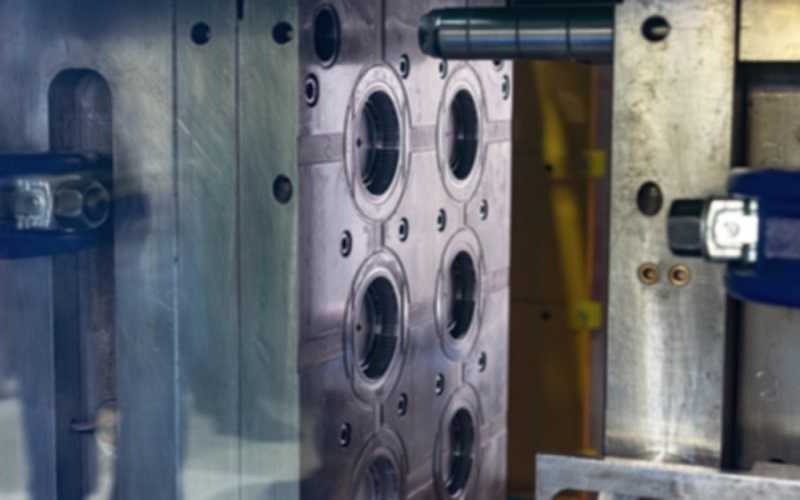

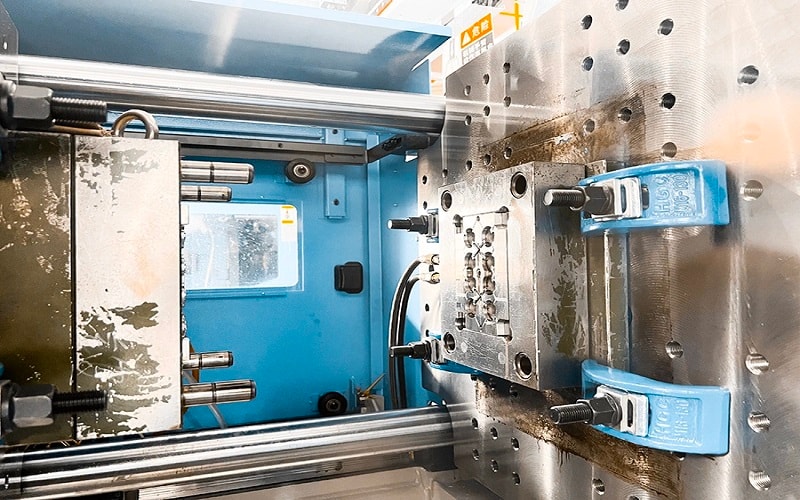

PBT injection molding is essential for producing strong, heat-resistant plastic parts. This process is favored in many industries for its durability and precision.

This article delves into the advantages, the molding process, and common challenges of using PBT.

Understanding PBT Resin

Polybutylene terephthalate (PBT) is a high-performance engineering polymer widely used in various industries due to its remarkable properties.

Known for its good dielectric strength, resistance to creep, heat, and UV light, PBT is a popular choice for applications requiring high durability and reliability. Its extensive use in electronics, automotive, and medical sectors showcases its versatility and superior mechanical and thermal properties.

In the electrical industry, PBT is extensively utilized for manufacturing components that require high thermal stability, often processed using an injection molding machine. The precision and reliability of PBT injection molded parts make them indispensable in sectors like electronics, automotive, and healthcare.

Understanding the full range of PBT’s advantages requires a closer look at its mechanical and electrical properties, along with its processing benefits.

Mechanical Properties

PBT is renowned for its high strength and stiffness, making it an ideal material for a variety of demanding industrial applications. Its superior impact resistance compared to PET makes it a robust choice for mechanical applications that require durability and toughness.

Moreover, PBT exhibits excellent dimensional stability under varying temperatures, ensuring that parts maintain their shape and performance, often validated through mold testing.

The rigidity of PBT molecules increases the likelihood of cracking under stress due to its high notch sensitivity, which can lead to a break in the material’s integrity. Polymer modification techniques can introduce flexible segments to enhance the material’s toughness.

This balance of strength, stability, and modified flexibility makes PBT a versatile material for automotive parts and other applications where mechanical properties are critical.

Electrical Properties

PBT’s electrical properties are equally impressive, with a dielectric strength of 23.7 kV/mm, making it a highly effective electrical insulator.

This high dielectric strength is crucial for materials used in electrical applications, as it indicates the maximum voltage a material can withstand without breaking down. As a result, PBT is suitable for electrical applications where insulation is critical for safety and performance.

These properties make PBT an excellent choice for manufacturing electrical connectors and other components that require both good mechanical properties and superior electrical insulation. Its ability to maintain these properties under heat further enhances its suitability for demanding electrical environments.

Processing Advantages

One of the standout features of PBT is its ease of processing, which contributes to efficient production workflows. PBT is favored for precision injection molding due to its ability to maintain fine details and surface quality.

This means that components molded from PBT not only meet functional requirements but also have a superior aesthetic finish.

The stability and flow characteristics of PBT make it ideal for applications requiring precision in mold design. The ease of processing and superior surface finish quality achieved with PBT lead to aesthetically pleasing and highly functional components, making it a preferred material in many industries.

Benefits of PBT Injection Molding

Polybutylene terephthalate (PBT) offers numerous advantages when used in injection molding, making it a favored material for producing high-quality plastic parts.

One of the key benefits is its rapid crystallization during the injection molding process, which can significantly reduce cycle times and enhance production efficiency.

PBT’s unique properties and benefits include:

- Strong UV resistance

- Availability of FDA compliant grades

- Excellent heat resistance

- High dielectric strength

These features make it increasingly preferred in injection molding applications.

The benefits of PBT in injection molding are manifold. Its strong UV resistance ensures durability under sunlight, making it ideal for outdoor applications. Certain grades of PBT are specifically designed to meet FDA standards for safe applications, ensuring compliance with stringent food safety regulations.

Additionally, PBT’s excellent heat resistance allows it to withstand higher temperatures, making it suitable for demanding environments like automotive applications. Lastly, its high dielectric strength supports superior electrical insulation, which is essential for electrical components.

UV Resistance

PBT retains its color well when exposed to sunlight, minimizing fading and maintaining its visual clarity and color stability even after prolonged sunlight exposure.

This strong UV resistance, combined with flame retardant properties, makes PBT ideal for applications that require durability under sunlight exposure, such as outdoor electrical enclosures and automotive components, with cooling time playing a key role in processing.

These properties help ensure that PBT parts maintain their aesthetic and functional quality over time, making them suitable for various applications where exposure to UV light is a concern. Whether it’s for a car part that needs to withstand years of sunlight or an outdoor electrical box, PBT’s UV resistance ensures long-lasting performance.

FDA Compliance

Certain grades of PBT are specifically designed to meet FDA standards for food contact applications. This compliance is crucial for ensuring the safety and suitability of PBT in food-related uses, where materials must adhere to stringent safety regulations.

Meeting these standards allows PBT to be confidently used in the manufacturing of food processing and packaging equipment.

Heat Resistance

PBT can withstand service temperatures significantly higher than many common plastics, exhibiting significant resistance to deformation under heat. This property enhances its usability in high-temperature applications, such as automotive parts that are exposed to engine heat and other high-temperature environments.

The ability to maintain its shape and function under higher temperatures makes PBT an excellent choice for applications where thermal stability is crucial. Its excellent heat resistance ensures that parts remain durable and reliable, even in demanding conditions.

Dielectric Strength

The dielectric strength of Polybutylene terephthalate (PBT) is 23.7 kV/mm, which makes it a preferred material for electrical applications requiring excellent insulation properties. PBT’s superior insulation properties are further enhanced by its low moisture absorption, which helps maintain its dielectric strength.

Due to its excellent insulating properties and thermal stability, PBT is often chosen for manufacturing electrical components such as connectors and switches. These properties ensure that PBT parts provide reliable performance in electrical applications, contributing to the overall safety and efficiency of electrical systems.

Challenges in PBT Injection Molding

While PBT injection molding offers numerous advantages, it also presents certain challenges that can impact part quality. Notable challenges include notch sensitivity, warping, and low hydrolysis resistance. Addressing these challenges is crucial for optimizing the injection molding process and ensuring the production of high-quality parts.

Notch sensitivity in PBT can lead to a crack, especially at points with sharp geometrical features or design flaws. Warping occurs due to uneven shrinkage during the cooling phase, which can be minimized by ensuring consistent wall thickness and controlling mold temperature and injection speed. Additionally, addressing potential cracks can further enhance the integrity of the design.

Additionally, PBT’s low hydrolysis resistance makes it susceptible to degradation from hot water and strong acids, impacting its durability.

Notch Sensitivity

PBT exhibits high notch sensitivity, meaning it is prone to stress concentrations that can lead to cracking under stress.

Reinforcing PBT with fillers like glass fibers can significantly enhance its structural integrity and minimize the risk of cracking associated with its inherent notch sensitivity.

Warping

Warping in injected molded PBT is caused by stress imbalances during the cooling phase. To minimize warping, it is essential to:

- Control mold temperature

- Control injection molding speed

- Ensure that the cooling process is uniform

- Ensure the part maintains its intended shape

The use of glass-filled PBT can help reduce warping caused by stress imbalances during the cooling phase.

This approach enhances the dimensional stability of the parts, ensuring they meet the required specifications and performance standards.

Hydrolysis Resistance

PBT has low hydrolysis resistance, making it susceptible to degradation from hot water, diluted acids, and strong mineral acids.

This characteristic can impact the durability and longevity of PBT parts, particularly in applications exposed to moisture and harsh chemical environments.

Key Applications of PBT Injection Molding

PBT injection molded parts are utilized in a variety of sectors such as consumer electronics, automotive, and medical, thanks to their excellent properties and versatility.

The material’s resistance to chemicals, high melting point, and exceptional toughness even at low temperatures make it suitable for a broad spectrum of applications.

PBT’s combination of mechanical strength, temperature resilience, and chemical resistance makes it a preferred material for many industries. Its excellent weatherability further enhances its suitability for outdoor applications, ensuring long-lasting performance in various environments.

Electrical Components

PBT is widely used in the electrical industry due to its thermal stability and excellent impact resistance.

Components such as electrical connectors and switches benefit from PBT’s heat deflection temperature of 150ºC and continuous service temperature range of 80ºC to 140ºC, ensuring reliable performance in various electrical environments.

Automotive Parts

PBT is employed in automotive applications for its lightweight and durable properties, making it an ideal material for various automotive parts.

Modified PBT is commonly used for manufacturing car window motor housings, motorcycle motor parts, and automotive transmission gearboxes, thanks to its strength and dimensional stability.

The excellent dimensional stability of PBT ensures that automotive components maintain their shape even under extreme temperature fluctuations. This reliability is critical for parts that experience significant stress and temperature changes, such as those found in engine compartments and transmission systems.

The durability and lightweight nature of PBT contribute to overall vehicle performance and efficiency.

Medical Devices

Certain grades of PBT are compliant with FDA regulations, making them ideal for use in medical device production. These grades ensure the safety and reliability of medical equipment, meeting stringent standards necessary for healthcare applications.

By using FDA-compliant PBT, manufacturers can produce medical devices that are both safe and dependable, ensuring patient safety and product longevity.

Design Considerations for PBT Injection Molding

Designing for PBT injection molding involves several critical considerations to ensure the production of high-quality parts. Maintaining consistent wall thickness is essential to avoid defects and ensure structural integrity. Additionally, utilizing processing guidelines specific to PBT is crucial for achieving superior molded parts.

High injection speed is necessary to ensure the mold is fully filled, thus avoiding weld lines and poor surface finishes. Adjusting the injection speed also helps minimize the risk of air entrapment during the molding of PBT components, leading to higher quality and more reliable parts.

Partnering with experienced production partners can provide essential design for manufacturing (DFM) support, enhancing the quality of PBT components and part design.

Wall Thickness

Maintaining consistent wall thickness in PBT injection molded parts is crucial to avoid defects like internal voids and sink marks. Consistent thickness ensures uniform cooling and reduces the risk of warping, leading to structurally sound and reliable parts.

This consideration is vital for achieving high-quality results in PBT injection molding.

Shrinkage Rates

The shrinkage rate for unfilled PBT ranges from 0.5% to 2.2%, which can be reduced to a range of 0.2% to 1% by incorporating fillers.

Understanding and controlling shrinkage rates is essential for maintaining dimensional accuracy and reducing cycle times, ultimately lowering production costs and enhancing part quality and part size.

Draft Angles and Radii

Applying draft angles is critical in PBT injection molding because:

- They ease the ejection of parts from molds.

- A draft angle of 1° is typically recommended for every inch of cavity depth.

- This facilitates part ejection and reduces the likelihood of part failures during the molding process.

Utilizing the recommended draft angles ensures smoother production and higher quality parts.

Optimizing the PBT Molding Process

Optimizing the PBT molding process involves careful management of temperature, moisture, and injection settings.

PBT can rapidly crystallize during the injection process, which may lead to defects if not managed properly. Continuous monitoring of temperature during the molding process is critical for maintaining the desired mechanical properties of PBT.

Effective management of melt flow can enhance the quality of molded PBT parts, ensuring high throughput rates and efficient production. Adhering to specific processing guidelines and employing rigorous quality assurance protocols are crucial for successful PBT injection molding.

By optimizing these parameters, manufacturers can produce high-quality PBT parts with excellent surface finishes and dimensional accuracy.

Moisture Control

Thorough drying of PBT is crucial to ensure the quality and performance of the molded parts. Key points to consider are:

- PBT should be dried at a temperature of 120ºC.

- The drying duration should be 2-4 hours prior to molding.

- This process removes any moisture content.

- Failure to dry PBT adequately can lead to defects such as bubbles in the final product.

- These defects affect the structural integrity and appearance of the molded parts.

Moisture control is essential to avoid splay and visual defects, which can compromise the overall quality of PBT parts. Careful management of moisture content ensures that the final products meet the desired specifications and performance standards, leading to reliable and high-quality parts.

Temperature Settings

The ideal injection temperature range for PBT is between 240ºC and 280ºC. Maintaining appropriate temperatures during molding can help prevent brittleness in PBT parts, ensuring that they retain their mechanical properties and structural integrity.

Consistent temperature settings are crucial for achieving high-quality molded parts with minimal defects and constant results.

Injection Speed and Pressure

The recommended injection pressure range for PBT during molding is between 60 MPa and 90 MPa, while glass-filled grades require a pressure range of 80 MPa to 100 MPa.

PBT has the advantage of flowing easily with lower injection pressures, allowing for more flexible injection speed settings during the molding process. Injection pressure is crucial for ensuring that the PBT material flows adequately through the mold, preventing defects in the final product.

By optimizing both the injection speed and pressure, manufacturers can achieve high-quality molded parts that exhibit excellent surface finish and dimensional accuracy. These optimizations are essential for producing reliable and aesthetically pleasing PBT components.

Quality Assurance in PBT Injection Molding

Quality assurance is a critical aspect of PBT injection molding, ensuring that the final products meet the highest standards of quality and performance. Key points include:

- Excess moisture in PBT can lead to splay and visual defects, compromising the quality of the parts.

- PBT should be dried before molding to minimize moisture-related defects.

- Proper drying ensures consistent quality in the final products.

Quality assurance involves thorough monitoring and control throughout the manufacturing process. This includes regular quality control checks during production stages and final inspections to verify part dimensions and overall quality.

By adhering to rigorous quality assurance protocols, manufacturers can reduce defects and enhance overall product reliability.

Raw Material Quality

The quality of raw materials used in PBT injection molding is crucial as it directly affects the quality of the final PBT products.

Consistent quality of raw materials is vital in maintaining the performance and characteristics of PBT products, ensuring that they meet the desired specifications and standards.

Stable suppliers are essential for guaranteeing the consistency of raw material quality in PBT injection molding.

In-Process Monitoring

In-process monitoring is a crucial aspect of injection molding that ensures consistent quality during production. Timely adjustments identified through in-process monitoring are essential for maintaining the desired quality of molded parts.

Effective in-process monitoring leads to reduced defects and improved overall efficiency in injection molding.

Final Inspections

Final inspections are critical to verify part dimensions and overall quality of PBT molded products.

The use of advanced inspection technologies, such as coordinate measuring machines and laser scanners, ensures that PBT parts meet stringent quality and dimensional standards, making inspection a vital tool in the process.

These inspections help ensure that the final products are reliable and meet the required specifications.

Alternatives to PBT

While PBT offers numerous advantages, it may not be suitable for all applications, particularly those involving prolonged exposure to moisture due to its low hydrolysis resistance.

Adding hydrolysis stabilizers can slow down the degradation of PBT when exposed to moisture, but alternatives like polypropylene (PP) and polyethylene terephthalate (PET) may be more suitable for certain applications.

PP and PET each have their own set of advantages and disadvantages. Understanding these alternatives can help in selecting the right material for specific applications, ensuring optimal performance and durability.

Polypropylene (PP)

Polypropylene is softer than PBT, which affects its processing and end-use performance. Both PBT and polypropylene exhibit poor hydrolysis resistance, but PP has a lower density, contributing to its lightweight characteristics.

This makes PP suitable for applications where weight is a critical factor, though its mechanical properties might not match those of PBT.

Despite its lower impact resistance compared to PBT, PP’s lightweight nature and cost-effectiveness make it a viable alternative for less demanding applications. Its versatility and ease of processing offer significant advantages in various industries.

Polyethylene Terephthalate (PET)

Comparison of PBT and PET:

- PBT has higher impact resistance than PET, making it more suitable for applications requiring durability and toughness.

- PET offers greater clarity and gloss compared to PBT, making it preferable for applications where aesthetics are important.

- PET has a slightly higher glass transition temperature than PBT, which can be beneficial in certain thermal conditions.

PET may be the better choice for applications where visual appeal and surface finish are critical. Conversely, PBT is preferred for applications requiring superior mechanical properties and impact resistance.

Partnering for Success in PBT Injection Molding

Partnering with experienced injection molders is crucial for successful PBT projects. Their expertise ensures manufacturing-ready design and production, optimizing all aspects of the process for quality and efficiency.

Qualified production partners provide comprehensive knowledge, product analysis, and on-site production management, significantly reducing the risk of defects during both the prototyping and production phases, making them capable of delivering high-quality results.

Collaboration with qualified injection molders ensures that the design for manufacturing (DFM) support is available, enhancing the overall quality of PBT components. This partnership helps achieve the best possible outcomes for PBT injection molding projects, delivering high-quality, reliable parts and assembly.

Summary

Optimizing PBT injection molding is crucial for producing superior plastic parts that meet high-performance standards.

Understanding the unique properties of PBT, including its mechanical and electrical properties, and leveraging its processing advantages can significantly enhance product quality. The benefits of PBT, such as UV resistance, FDA compliance, heat resistance, and dielectric strength, make it a preferred material in various industries.

Addressing challenges like notch sensitivity, warping, and low hydrolysis resistance is essential for optimizing the injection molding process. By considering key design aspects and partnering with experienced injection molders, manufacturers can achieve high-quality, reliable PBT parts.

In conclusion, optimizing the PBT injection molding process involves a combination of understanding the material’s properties, addressing potential challenges, and leveraging the expertise of qualified partners. By doing so, manufacturers can produce superior plastic parts that meet the highest standards of quality and performance.

Frequently Asked Questions

What are the key advantages of PBT injection molding?

The key advantages of PBT injection molding include strong UV resistance, FDA compliance, excellent heat resistance, and high dielectric strength, making it ideal for applications in automotive, electronics, and medical sectors. These properties ensure durability and reliability in demanding environments.

How can the challenges of notch sensitivity in PBT be addressed?

Addressing notch sensitivity in PBT can be effectively achieved by incorporating reinforcement fillers, such as glass fibers, which significantly strengthen the material and diminish the likelihood of cracking. This approach enhances the overall durability and performance of PBT in applications prone to stress concentrations.

What is the ideal injection temperature range for PBT?

The ideal injection temperature range for PBT is 240ºC to 280ºC. Adhering to this range is crucial for preventing brittleness and ensuring the production of high-quality parts.

Why is moisture control important in PBT injection molding?

Moisture control is essential in PBT injection molding because excess moisture can cause defects like bubbles and splay, negatively impacting the quality and performance of the final product. Ensuring thorough drying of PBT prior to molding is critical for achieving optimal results.

What are some alternatives to PBT for injection molding?

Consider using polypropylene (PP) for its cost-effectiveness and lightweight properties, or polyethylene terephthalate (PET) for enhanced clarity and gloss in aesthetic applications. Each alternative offers distinct advantages depending on your specific requirements.