Polyethylene (PE) plastic material is a versatile polymer used in countless applications. In this article, we’ll explore its properties, types, and uses, explaining why PE plastic is essential in modern manufacturing.

Understanding Polyethylene (PE)

Polyethylene, often abbreviated as PE, is a key player in the family of synthetic polymers. Derived from ethylene monomers, which are obtained from crude oil and natural gas, polyethylene is a thermoplastic polymer with the chemical formula (C2H4)n.

This formula indicates a repeating unit structure where each unit consists of two carbon atoms bonded with four hydrogen atoms, forming long pe chains. The process involves breaking the double bonds of ethylene molecules and linking them together, often distinguishing it from polymers like vinyl chloride which has a different monomeric base. This results in a highly versatile polymer composed of repeating units, including ethylene copolymers such as medium density polyethylene.

This simplicity in structure belies its incredible utility. Polyethylene can be found in an array of products ranging from plastic bottles to high-strength industrial applications.

Its ability to be reshaped and reused upon heating, due to its melting point typically ranging between 105°C to 135°C depending on its density, classifies it as a rigid thermoplastic polymer, making it a preferred choice for various manufacturing processes.

This basic chemistry lays the foundation for exploring its different types and unique properties.

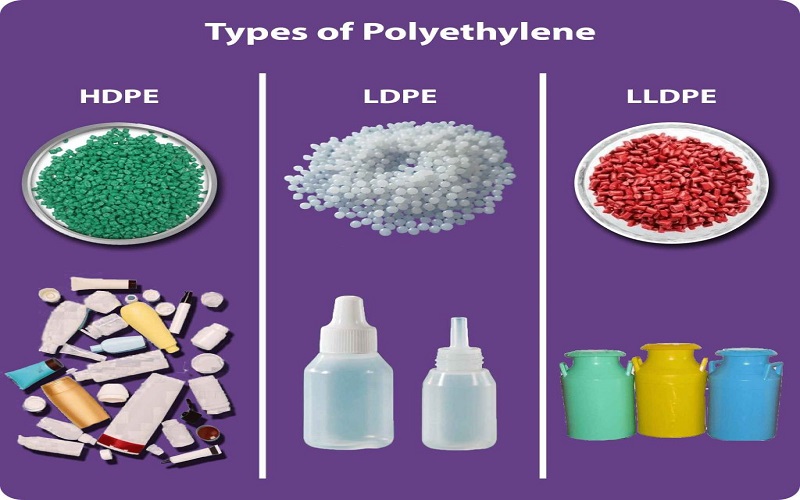

Types of Polyethylene

Polyethylene is not a one-size-fits-all material. It comes in several forms, each tailored for specific uses. The four most common types of polyethylene are:

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Linear Low Density Polyethylene (LLDPE)

- Ultrahigh Molecular Weight Polyethylene (UHMWPE)

Each type has distinct properties that make it suitable for particular applications, from flexible plastic bags to bulletproof vests.

These variations help in selecting the right material for specific needs. Here’s a breakdown of each type.

Low Density Polyethylene (LDPE)

Low Density Polyethylene (LDPE) is characterized by its highly branched molecular structure, which results in a material that is both flexible and soft. Due to its lower crystallinity and high degree of branching, LDPE is not as dense as other forms of polyethylene.

This makes it ideal for products that require flexibility, such as plastic bags, food packaging, and frozen food bags. Its chemical composition primarily consists of carbon and hydrogen with a formula (C2H4)n, while its chemical structure features long chains with significant side branching, contributing to its unique properties.

The primary processing method for LDPE is extrusion, although it can also be used in injection molding for making various consumer goods. Its versatility, ease of processing, and stress resistance (capable of withstanding moderate tensile stress up to 10-20 MPa) make it a staple in the packaging film industry.

High Density Polyethylene (HDPE)

High Density Polyethylene (HDPE) is the most popular form of polyethylene, known for its impressive tensile strength and minimal branching.

This minimal branching allows HDPE to be denser and more durable, making it ideal for applications requiring rigidity and toughness, such as rigid containers. Common uses include detergent bottles, milk jugs, and food containers.

HDPE is particularly well-suited for injection molding, a process that allows for continuous and batch production of a wide range of products. Its strength and durability make it a preferred material for both hdpe consumer goods and industrial applications.

Linear Low Density Polyethylene (LLDPE)

Introduced in 1968, Linear Low Density Polyethylene (LLDPE) combines the properties of both high-density and low-density polyethylene, offering superb tensile strength and stretchability. Its structure features a linear backbone with open branches, making it more flexible than traditional LDPE.

LLDPE is produced through copolymerization, which enhances its strength and flexibility. This makes it popular for applications such as stretch films and plastic bags. Additionally, its properties can be tailored by altering the ingredients used in its production, providing a wide range of uses.

Ultrahigh Molecular Weight Polyethylene (UHMWPE)

Ultrahigh Molecular Weight Polyethylene (UHMWPE) stands out due to its exceptionally long polymer chains and high molecular weight polyethylene, which grant it unparalleled abrasion resistance and strength. Its stiffness and tensile strength are many times that of steel, making it suitable for high-performance applications.

UHMWPE is known for its low coefficient of friction and toughness, making it ideal for industrial purposes such as bulletproof vests and other high-stress environments. It is typically processed through sintering and compression molding.

Manufacturing Processes of PE

The production of polyethylene involves various manufacturing processes, each influencing the material’s properties and applications. One common method is free radical polymerization, which requires high temperatures and pressures to link ethylene molecules into polymer chains.

This process, pioneered by Imperial Chemical Industries, results in polyethylene with different degrees of crystallinity and mechanical properties depending on the conditions used.

Another significant method is Ziegler-Natta polymerization, which employs specific catalysts to produce polyethylene at lower pressures and low temperatures. These catalysts play a crucial role in determining the molecular weight and branching of the resulting polymer, including the production of cross linked polyethylene.

Controlling factors such as catalyst type and reaction conditions allows manufacturers to tailor polyethylene properties to meet specific needs.

Applications of Polyethylene

Polyethylene’s versatility makes it indispensable across various industries. It is extensively used in manufacturing containers and fuel tanks for chemicals, foods, and fuels, thanks to its excellent chemical resistance.

In healthcare, polyethylene’s biocompatibility makes it suitable for medical equipment and components. Additionally, its use in automotive components like interior parts and under-the-hood applications showcases its durability.

Polyethylene’s excellent dielectric properties make it ideal for electrical insulator applications in electrical components insulation and wiring sheaths. Its plasticity also makes it suitable for consumer products like toys and household items, even under extreme temperatures where chlorinated polyethylene variants offer enhanced flexibility and fatigue resistance.

The wide range of applications highlights polyethylene’s versatility and adaptability as a versatile material and utility.

Environmental Impact and Recycling

Polyethylene is recyclable, and recycling it helps reduce plastic waste in landfills, thereby lessening environmental pollution. Both low-density polyethylene (LDPE) and high-density polyethylene (HDPE) are recognized for their recyclability, contributing to lower greenhouse gas emissions compared to producing new plastic from raw materials.

Recycled polyethylene can be transformed into new products such as outdoor furniture, construction materials, and household items. However, challenges in recycling include difficulties in collecting and sorting different types of polyethylene and potential quality degradation over multiple recycling cycles, exacerbated by exposure to chlorinated solvents and organic solvents during processing.

Innovative recycling technologies aim to improve the quality of recycled polyethylene, addressing concerns about material performance, particularly by managing its higher melting point variations that arise from repeated processing.

Comparing PE with Other Plastics

Polyethylene has distinct advantages and limitations compared to other plastics like polyvinyl chloride (PVC), polypropylene (PP), and polystyrene (PS). For instance, polyethylene is generally more flexible than polypropylene, which has better heat resistance.

Polypropylene’s density usually sits between high-density polyethylene (HDPE) and low-density polyethylene (LDPE) among various pe grades. This positioning highlights its unique physical properties relative to these two materials.

While polyethylene offers excellent chemical resistance and ease of processing, it may not perform as well in terms of mechanical strength compared to some other plastics, potentially requiring reinforcements. These differences guide the selection of the right material for specific applications.

Processing Methods for PE

Methods like injection molding, extrusion, and blow molding can be used to process polyethylene, each offering unique advantages and applications. For instance, extrusion is commonly used to produce pipes and tubing for fluid transfer and delivery systems.

These processing methods allow manufacturers to create a wide range of products with specific properties tailored to their intended use. The manufacturing process depends on the desired characteristics of the final product, like flexibility, strength, and durability.

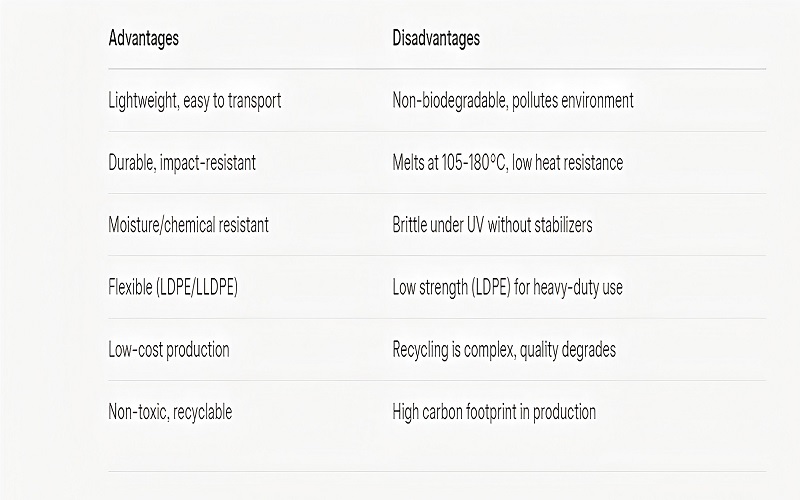

Advantages and Disadvantages of PE

Durability, high malleability, and impact resistance make polyethylene suitable for applications requiring high abrasion resistance. Its versatility and ease of processing further enhance its utility across different industries, including the production of automotive parts such as fuel tanks and interior components.

However, polyethylene also has its drawbacks. It has a slow degradation rate and relies on petroleum for production, which raises environmental concerns.

Additionally, challenges in recycling, potential quality degradation over multiple cycles, and susceptibility to stress cracking under prolonged tension are significant issues that need to be addressed. The process of copolymerizing ethylene with other monomers can mitigate some of these issues by improving toughness and resistance.

Balancing these pros and cons is essential for making informed decisions about using polyethylene.

Summary

Polyethylene is a versatile and essential material in modern life, offering a wide range of applications from packaging to industrial uses. Its different types, such as LDPE, HDPE, LLDPE, and UHMWPE, each have unique properties that make them suitable for specific purposes.

The commercial production of polyethylene, which began in the 1930s, has evolved significantly, with types like LLDPE showcasing a linear structure that enhances strength and moisture resistance. The manufacturing processes and recycling challenges highlight the complexity and significance of this material.

As we move towards a more sustainable future, understanding the properties, uses, and environmental impact of polyethylene is crucial. By making informed choices, we can maximize the benefits of this versatile polymer while minimizing its drawbacks.

Frequently Asked Questions

What is polyethylene made from?

Polyethylene is primarily produced from ethylene, a petrochemical derived from crude oil and natural gas.

What are the different types of polyethylene?

The four main types of polyethylene are Low Density Polyethylene (LDPE), High Density Polyethylene (HDPE), Linear Low Density Polyethylene (LLDPE), and Ultrahigh Molecular Weight Polyethylene (UHMWPE). Each type serves different applications based on its properties.

How is polyethylene recycled?

Polyethylene is recycled by collecting, cleaning, and processing it into granules, which can then be transformed into new products like outdoor furniture and construction materials. This process not only conserves resources but also reduces environmental impact.

What are the applications of high-density polyethylene (HDPE)?

High-density polyethylene (HDPE) is essential for producing durable and rigid items like detergent bottles, milk jugs, and food containers. Its toughness makes it a popular choice across various industries.

What are the environmental impacts of polyethylene?

Polyethylene’s recyclability can mitigate plastic waste, but its environmental impact is significant due to challenges in collection, sorting, and quality degradation through multiple recycling cycles.