In the global plastic industry, plastic extrusion moulding is an essential manufacturing method recognized for its ability to produce consistent, high-volume components.

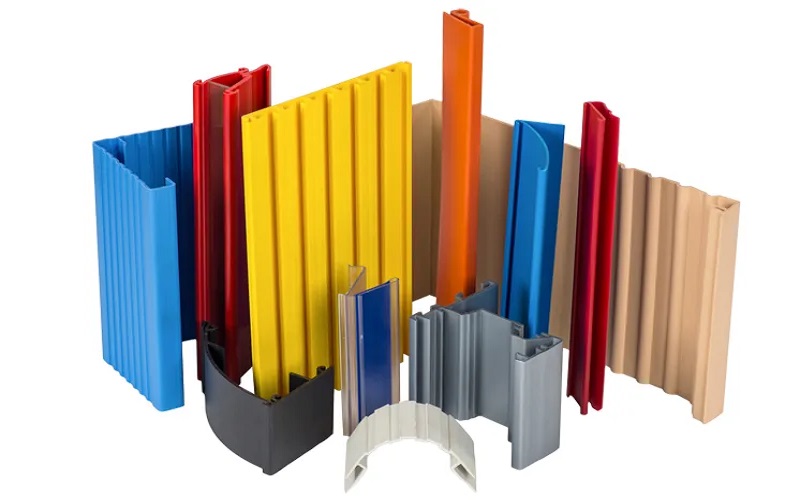

This high volume manufacturing process is used to create objects with a fixed cross-sectional profile, making it a cornerstone of modern production.

Remarkably, the extrusion molding process is widely used, producing over 60% of the plastic products in the world today.

The importance of extrusion molding lies in its ability to produce continuous lengths of plastic with consistent cross sections at a low cost.

Whether it is the drinking straws in your soda, the medical tubing used in hospitals, or the plastic sheets found in construction, most of these items started their life through the plastic extrusion process.

What is Plastic Extrusion Moulding?

Extrusion molding is a hot forming method in which molten polymer is continuously passed through a die having a predetermined shape.

Unlike injection molding, which is a batch process that produces discrete parts, plastic extrusion is a continuous operation. As long as the extrusion machine is fed raw material, it will continue to create a continuous profile.

Extrusion and Injection Molding: The Key Difference

Extrusion and injection molding,While both are vital plastic molding techniques, they serve vastly different roles in the manufacturing process:

Shape Complexity: Injection moulding can produce more complex three-dimensional shapes, whereas extrusion molding is generally limited to two-dimensional profiles and complex shapes with fixed cross sections.

Production Style: Extrusion is a continuous extrusion production process, while injection molding is a batch process that produces individual parts.

Initial Investment: Injection molding typically requires higher initial costs due to the need for intricate molds, while extrusion molding has lower setup costs and is generally more cost-effective for high volume manufacturing.

Surface Quality: The surface finish of products made by injection molding is generally superior to those produced by extrusion.

Thermal Stability: Extrusion molding imposes higher demands on the thermal stability of plastics.

This means that the same material is more prone to exhibiting “poor heat stability” during extrusion processing, whereas it performs relatively more reliably in injection molding processes.

The Plastic Extrusion Process: A Detailed Step-by-Step

The plastic extrusion process can be divided into four main steps: preparing, melting, shaping, and cooling.

Step 1: Material Preparation and Feeding

The process begins with the preparation of the base material, typically a thermoplastic or elastomer. Plastic pellets or plastic granules are loaded into the hopper of the extrusion equipment.

At this stage, it is crucial that the feed material is free of contaminants to ensure product quality.

Step 2: Melting and Plastification

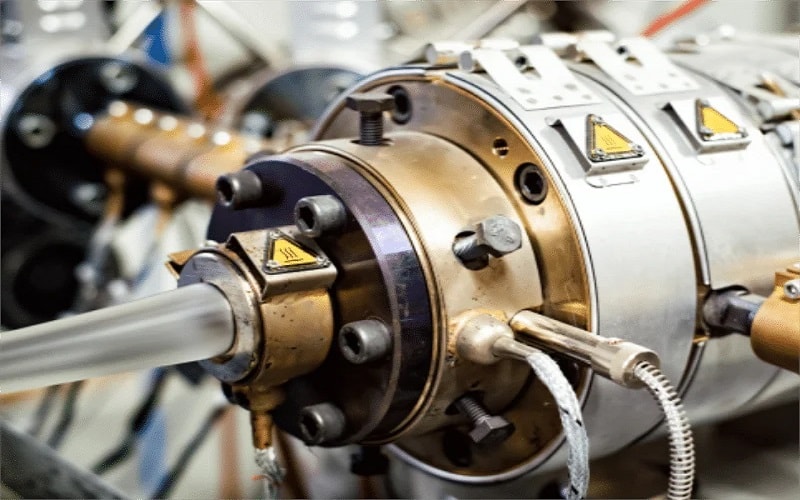

As the material enters the barrel, it is moved forward by a rotating screw.

The primary function of the extruder is to plasticize the solid material into a homogeneous molten plastic and pressurize the viscous fluid.

This plastification extruding is achieved through external heaters and the frictional forces generated by the screw speed.

Step 3: Shaping Through the Extrusion Die

The molten material is forced through a shaped opening or extrusion die.

The die design is critical because the die opening determines the desired shape and specific shape of the extruded materials.

The extrusion force must be uniform to prevent defects.

Step 4: Cooling and Solidification

Once the material exits the die to create its profile, it enters the cooling stage.

Cooling systems are essential to ensure the extrudate solidifies into the final shape and size.

This is often achieved using a water bath or several cooling rolls—particularly in sheet extrusion to maintain consistent wall thickness.

Step 5: Post Processing

After materials cure into their final shape, post-processing is typically required.

Unlike injection-molded parts, which are usually complete upon demolding, extruded materials often require additional steps such as cutting to specific lengths, precision punching, or surface treatment to meet the quality standards of the plastics industry.

Essential Plastic Materials and Their Properties

The choice of materials and their mechanical properties significantly affect the extrusion methods and the final form of the product.

Polyethylene (PE): Recognized for its flexibility and chemical resistance, it is commonly used in packaging films and containers.

Polypropylene (PP): A widely used plastic due to its low cost and high flexural strength.

Nylon (PA): This tougher material has a high strength-to-weight ratio and performs well in high-temperature environments, making it suitable for automotive engines components.

Acrylic: Known for its clarity and light transmission, it is a popular choice for applications requiring transparency.

ABS: A tough plastic known for its good abrasion resistance and waterproof surface.

Polycarbonate (PC): A transparent thermoplastic known for its impact resistance and optical clarity.

Polystyrene (PS): Often used in construction for its excellent insulation properties and is commonly used to produce insulation boards.

Industrial Applications of Extrusion Molding

Plastic extrusion molding is used in various industries because it can produce parts with high consistency and large output.

Construction and Infrastructure

Extrusion molding is employed in the production of insulation materials for construction, such as extruded polystyrene.

It is also used to produce a wide variety of products including plastic sheets, films, and protective covers.

Automotive and Transportation

In the automotive sector, extrusion is used for producing components like reservoirs, tubes, and interior trim.

The process can also be used for part of the thermosetting plastic molding process in specific vehicle parts.

Medical and Healthcare

Extrusion molding is a key process in the production of medical devices, particularly for medical tubing and other critical components.

The continuous operation allows for high-precision tubing that meets strict healthcare standards.

Food and Consumer Goods

Common applications include the manufacturing of drinking straws, hoses, and rods.

Interestingly, the process is also used in the food industry for producing items like pasta and snacks through extrusion cooking.

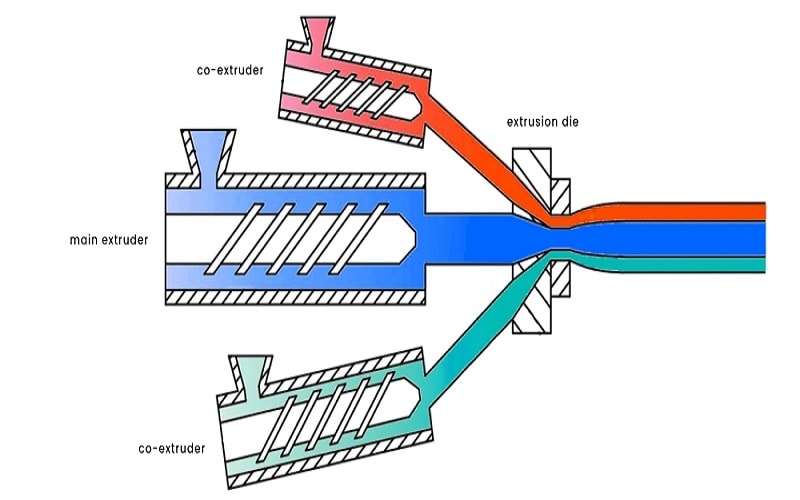

Special Extrusion Process: Co-extrusion and Coating

To enhance product quality, the plastic industry often employs specialized extrusion methods:

Co-extrusion: A technique that allows for the simultaneous processing of multiple layers of materials to combine properties, like a rigid core with a flexible outer seal.

Extrusion Coating: Used to apply a layer of molten plastic onto an existing base material, such as adding a protective film to paper or foil.

Common Issues in Extrusion Processes:

The parameters of the extrusion process, such as melt temperature, pressure, and flow rate, need to be strictly controlled.

Common problems can include poor dimensional stability, wall thickness variations, and surface defects.

Thermal Degradation: Material degradation can occur if the melt temperature is too high, leading to a decline in product quality.

Inconsistent Cooling: Inconsistent cooling rates can result in warping or twisting of the final shape.

Poor Flow: Poor material flow can lead to blockages in the extrusion machine, which can halt production and require maintenance.

Decomposition: Improper temperature control can lead to bubbling and poor surface quality.

Components of Extrusion Equipment:

The extrusion molding equipment is composed mainly of the extruder, head and die, auxiliary and control systems.

The Extruder: The main function is to plasticize the solid material into a homogeneous melt and pressurize it through the die.

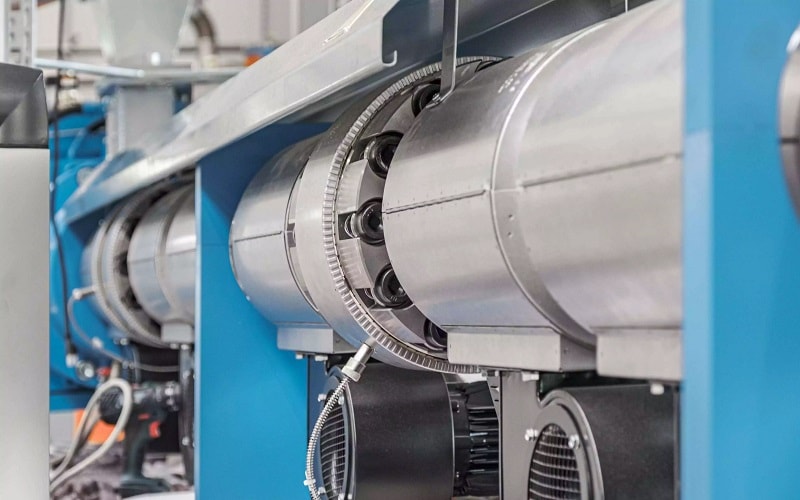

Single-Screw vs. Twin-Screw: Different types of extruders, including single-screw and twin-screw extruders, can be used depending on the molding material.

Screw Extruder: The most popular extrusion equipment, consisting of the screw, barrel, transmission parts, and heating/cooling systems.

Sustainability and Economic Efficiency

Plastic extrusion minimizes waste as excess plastic or thermoplastic scrap can often be re-melted and reused.

While the upfront investment in plastic extrusion moulding can be significant, it is ideal for high volume manufacturing because of its low per-unit cost over long runs.

Why Choose Extrusion?

- Continuous Profile: Ideal for long shapes like drinking straws and pipes.

- Low Cost: Efficient for large quantities of simple shapes.

- Versatility: Can produce a wide variety of pieces with different cross sections.

Conclusion

Plastic extrusion moulding remains the backbone of the plastic industry because it provides a continuous operation that is relatively simple yet capable of producing a wide variety of pieces.

By forcing molten plastic through a die design to create a specific shape, manufacturers can achieve a low-cost, high-speed output that other processes cannot match.

Whether you are seeking tensile strength, chemical resistance, or transparency, the extrusion molding process offers a manufacturing method that can be tailored to meet the needs of nearly any sector.

As we move forward, the focus on strictly controlling parameters like traction rate and melt temperature will continue to drive product quality to new heights.