Plastic materials in engineering offer unmatched mechanical properties and chemical resistance, making them essential across industries such as automotive, aerospace, and electronics.

This article explores the types of engineering plastics, their key advantages, and why they are preferred over traditional materials.

Understanding Engineering Plastics

Engineering plastics are high-performance engineering thermoplastic polymers specifically designed for structural applications.

Unlike commodity plastics, which are commonly used for packaging and simple household items, engineered plastics offer a unique combination of properties such as:

- Better mechanical properties

- Dimensional stability

- Chemical resistance

- Durability

These unique characteristics make them well suited for demanding commercial applications across many industries, from automotive to aerospace, with several design considerations in mind, covering a broad range of highly resistant needs and tight tolerances in low volume applications, including typical applications and a wide spectrum of options.

High performance plastics, with excellent wear resistance and flame resistance, enhance their suitability for these uses.

The development of engineering plastics was driven by advancements in polymer technology, leading to materials that can perform effectively at temperatures ranging from over 90°C up to at least 150°C.

This capability sets them apart from traditional engineering materials, providing solutions that are not only high-performing but also versatile and adaptable to complex designs and manufacturing processes.

Key Properties of Engineering Plastics

The remarkable performance of engineering plastics can be attributed to their key material properties.

These materials, including polyvinyl chloride, possess excellent mechanical properties, thermal stability, and chemical resistance, making them suitable for a wide range of structural applications.

In the following subsections, we will explore these properties in greater detail, highlighting what makes engineering plastics stand out in the realm of material science.

Mechanical Properties

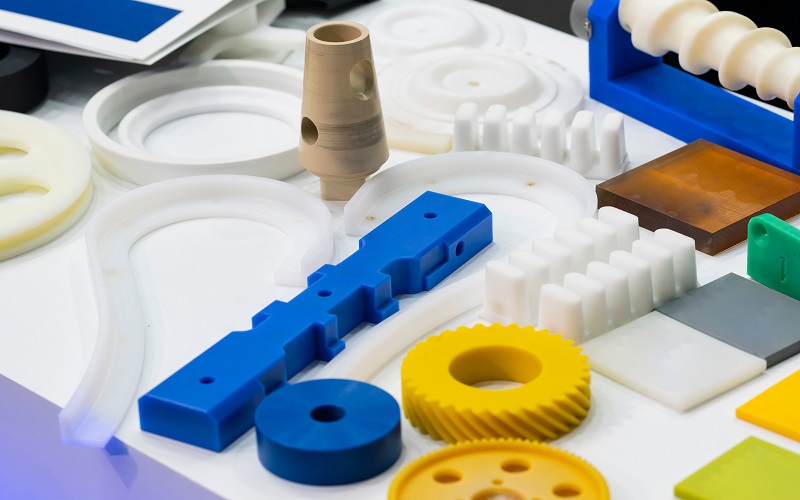

Engineering plastics serve as crucial components in various applications due to their strength and rigidity.

These materials are particularly valuable in creating mechanical parts that require precision and durability, such as cams, couplings, and gears. Their low coefficients of friction enhance performance in mechanical applications, ensuring smooth operation and reduced wear.

One of the standout features of engineering plastics is their impact resistance, which is essential for maintaining structural integrity under stress.

Polyoxymethylene (POM), for example, is known for its high dimensional stability and machinability, making it a preferred choice for manufacturing components that demand high precision and reliability.

These properties collectively contribute to the excellent mechanical strength performance of engineering plastics in various high-stress applications.

Thermal Stability

Thermal stability is a critical property of engineering plastics, allowing them to function effectively in high-temperature environments.

Some engineering plastics, including high density polyethylene, can endure operating temperatures exceeding 220°C while still maintaining their mechanical properties and good dimensional stability, making them suitable for applications that involve extreme temperatures.

Modified Polyphenylene Oxide (PPO), for instance, has a heat distortion resistance range above 100°C up to 195°C, showcasing its good thermal performance and high heat resistance with minimal thermal expansion.

ABS is another engineering plastic valued for its excellent heat resistance and ability to withstand various environmental conditions.

The ability to maintain stability over a wide temperature range ensures that engineering plastics can be relied upon in diverse thermal environments, enhancing their usability in industries that demand high-performance materials under challenging conditions.

Chemical Resistance

The chemical resistance of engineering plastics is a key factor in their widespread adoption across various industries.

These materials, including polyethylene terephthalate, can endure exposure to a variety of harsh chemicals, such as acids and solvents, without significant degradation.

This robust chemical resistance and good resistance enable engineering plastics to maintain functionality and integrity in challenging applications, such as automotive, medical, and electrical components, while reducing operating costs.

In environments where chemical exposure is common, the ability of engineering plastics to resist degradation, along with their chemical properties and chemical stability, is crucial for ensuring long-term performance and reliability.

This property not only extends the lifespan of the components made from these materials but also enhances safety and efficiency in demanding industrial applications.

Common Types of Engineering Plastics

Engineering plastics encompass a wide range of plastic materials, each with its unique set of properties and applications.

Examples include Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), and Polyoxymethylene (POM).

These plastics, featuring carbonate groups and skeleton functions, are designed to have superior mechanical, chemical, optical, and thermal properties compared to standard plastics, making them suitable for specific machining processes and applications, including the creation of various shapes.

PC plastic is one of the notable examples in this category, alongside various types of plastic material.

Polycarbonate (PC)

Polycarbonate is renowned for its toughness, rigidity, and durability. It exhibits excellent impact strength and can be optically transparent in some grades, making it a versatile material for various applications.

Its good thermal and electrical properties further enhance its suitability for a range of uses, from protective shields to optical properties discs.

Common applications of polycarbonate include motorcycle helmets, bumpers, and optical discs. In the realm of electrical plastic parts, polycarbonate is used to make connectors and relays, showcasing its adaptability and high performance in different sectors.

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a widely used engineering plastic composed of acrylonitrile, styrene, and polybutadiene. It offers key properties such as:

- Heat resistance

- Flame retardancy

- Chemical resistance

- Electrical insulation

- Impact strength These properties make it a preferred material for various applications.

ABS is commonly used in automotive parts like dashboard trims, wheel covers, and car bumpers. Its low production cost and suitability for CNC machining and 3D printing further enhance its appeal in manufacturing processes, making it a cost-effective and versatile material.

Polyoxymethylene (POM)

Polyoxymethylene (POM) stands out for its high wear resistance, rigidity, and hardness, making it ideal for applications that require durable and high-performance parts.

This engineering plastic is commonly used in the production of gear wheels, fasteners, auto parts, and ball bearings, highlighting its versatility in various mechanical applications.

POM is easily processed into various high-performance parts, offering excellent machinability and dimensional stability. These attributes make it a preferred choice for the manufacturing process of components that demand precision and durability.

Applications of Engineering Plastics

Engineering plastics are critical in numerous sectors, including aerospace, electronics, and consumer goods, where they provide improved performance compared to traditional engineering plastic materials.

Their high strength-to-weight ratio, resistance to corrosion, and ability to be processed into complex shapes make them ideal for a wide range of applications.

Automotive Parts

In the automotive industry, engineering plastics have revolutionized the design and performance of vehicles. Their benefits include:

- Lightweight nature, which allows for reduced vehicle weight

- Improved fuel efficiency and reduced energy consumption

- Enhanced impact resistance of automotive components, contributing to safer vehicle designs.

The use of engineering plastics in automotive parts includes lightweight and impact-resistant bumpers, engine components, and interior trim, showcasing their versatility and importance in modern vehicle manufacturing.

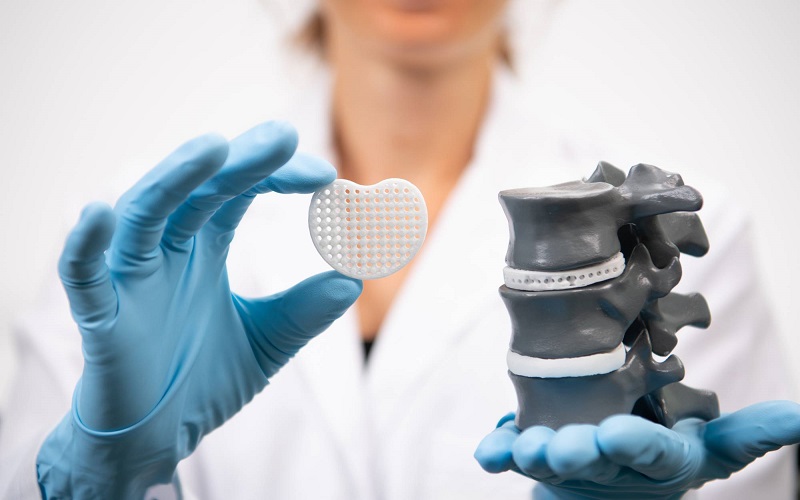

Medical Devices

The healthcare industry relies heavily on engineering plastics for various applications, including surgical instruments, medical devices, and implantable materials. These materials are chosen for their biocompatibility, ensuring they are safe for use in medical applications.

Autoclavable plastics are particularly valuable in medical environments as they retain their mechanical properties and dimensions under steam sterilization, enhancing their usability and reliability in critical medical applications.

Electrical Components

Engineering plastics are widely used in electrical components due to their excellent electrical resistance and electrical insulation properties.

They provide high dielectric strength, making them ideal for insulating components in electrical applications and ensuring safety and reliability.

The structural integrity of engineering plastics ensures durability in demanding electrical component applications, further highlighting their importance in the structural components of the electronics industry.

Advantages Over Traditional Materials

Engineering plastics offer several advantages over traditional materials:

- Exceptional resistance to corrosion environments, making them suitable for harsh applications where metals might fail.

- Dimensionally stable plastics, including semi crystalline types like polyphenylene sulfide, can achieve performance levels comparable to metals.

- Excellent mechanical features such as strength and stability.

Moreover, the low density of advanced engineering plastics contributes to significant weight reduction advantages in various applications.

Their malleability allows for greater design flexibility compared to traditional materials, enabling the creation of complicated shapes and innovative designs, including those with low moisture absorption.

Challenges in Using Engineering Plastics

Despite their many advantages, the use of engineering plastics comes with certain challenges. While manufacturing processes for plastics are often more efficient and cost-effective than those for metals and ceramics, the initial investment in specialized equipment and technology can be high.

Summary

Engineering plastics have transformed numerous industries with their exceptional properties and versatility.

From automotive parts to medical devices and electrical components, these materials offer unique advantages over traditional materials, including improved performance, durability, and design flexibility.

As we look to the future, the continued development and adoption of engineering plastics will play a crucial role in driving innovation and sustainability.

By leveraging the latest advancements in material science and technology, we can unlock new possibilities and create a better, more efficient world.

Frequently Asked Questions

What are engineering plastics?

Engineering plastics are advanced thermoplastic polymers specifically developed for structural applications, providing enhanced mechanical, thermal, and chemical properties compared to conventional plastics.

What are the key properties of engineering plastics?

Engineering plastics are characterized by their exceptional mechanical properties, thermal stability, and chemical resistance, ensuring their effectiveness in demanding industrial applications. These properties make them a preferred choice in various engineering fields.

What are some common types of engineering plastics?

Common types of engineering plastics are Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), and Polyoxymethylene (POM), each offering distinct properties and applications suitable for various industries.

How are engineering plastics used in the automotive industry?

Engineering plastics play a crucial role in the automotive industry by minimizing vehicle weight, thereby enhancing fuel efficiency and safety while also improving aesthetics. Components such as bumpers, engine parts, and interior trims exemplify their diverse applications.

What are the future trends in plastic engineering?

The future of plastic engineering will be marked by a strong emphasis on sustainability, the integration of smart materials, and the application of AI to enhance material development and optimize formulations. These trends will significantly shape the industry’s direction moving forward.