Polyamide fiber and nylon materials are increasingly being used in many industries because of their excellent performance, toughness, and versatility.

The two materials polyamide and nylon are often used interchangeably, but they are not actually the same. Simply put, nylon is a subcategory of aliphatic polyamides. You may be confused, but don’t worry.

Let’s compare polyamide and nylon. In this article, we will define and compare nylon plastic and polyamide fabric, help you understand the differences between the two materials, and help you choose the right material for your products.

What Are Polyamide Fabrics?

Simply put, polyamide is a natural or synthetic material known for its durability, strength, and elastic structure.

DuPont developed and patented this material in the mid-1930s as a replacement for women’s stockings. Polyamides have excellent crystallinity, heat resistance, and chemical resistance due to hydrogen bonding. Therefore, polyamides are widely used in many industries.

Natural polyamides include wool, silk, collagen, and keratin. Synthetic polyamides can be divided into three categories: aliphatic polyamides such as nylon 6 and nylon 6/6, aromatic polyamides and semi-aromatic polyamides. Synthetic polyamides are used in the aerospace, automotive, consumer, construction, and textile industries. However, the largest consumer of polyamides is the transportation sector, which accounts for 35% of polyamide consumption.

What Are Polyamides Used For?

Polyamide is not only durable and flexible, but also has the ability to absorb moisture, resist certain chemicals and remain stable under the influence of heat. Thanks to these special properties, polyamide materials are suitable for various industries and applications. Here are some examples:

- Workwear and fireproof clothing: Polyamide has excellent heat resistance, making it an ideal material for workwear and fireproof clothing.

- Automotive industry: The automotive industry is one of the main consumer industries for polyamide materials, which are typically used to make airbag containers, intake manifolds, car interiors, engine covers and other parts.

- Cable protection systems: Cable protection systems made of polyamide materials are widely used in the railway and transport industry. It is lighter than PVC-coated metal pipe, saves fuel, reduces work time and ensures safety.

- Food and beverage packaging: Thin polyamides are also used in packaging materials such as films and containers due to their excellent high barrier properties. This will protect your food from environmental factors, preserve its freshness, preserve its taste and extend its shelf life.

- Food processing equipment: Some food processing equipment is made of polyamide materials, such as conveyor belts and seals. They are generally non-reactive, wear-resistant and have low friction, making them ideal for this application.

What is Nylon?

Nylon is obtained from crude oil. It is therefore a fully synthetic material, more precisely a polymer, and is the trade name given to a group of aliphatic polyamides by the chemical company DuPont.

Nylon comes in a variety of qualities, some of which can be processed into fabrics. Not all types of nylon have the same molecular structure and polymerization technique.

Nylon polymers are made up of chains of carbon-based molecules, called monomers, that bond together to form long chains and make up the structure of nylon material. This is important because it means the material is durable, less likely to break under tension, and has good toughness and abrasion resistance.

Nylon is currently one of the most popular engineering thermoplastics, and like other thermoplastics, nylon can be melted and molded at high temperatures to create parts in processes such as injection molding, extrusion, and 3D printing.

Where is Nylon Used?

Nylon products have advantages such as light weight, high mechanical strength, wear resistance and corrosion resistance, and are widely used in various fields as an important substitute for metals such as steel, iron and copper.

- Mechanical parts: bearings, gears, pump impeller.

- Medical field: surgical sutures, medical catheters, stents, equipment parts.

- Civil engineering: door and window seals, pipe insulation sleeves.

- Textile: Clothing, socks. Industrial supplies: ropes for tires, industrial fabrics, ropes, conveyor belts.

What is the Strength of Nylon?

Nylon is one of the strongest engineering plastics in the world due to the strong bonds in the molecular structure of the material. It has high tensile and impact strength, as well as high lubricity.

Depending on the grade, nylon 6 has a tensile strength of around 80 MPa, while nylon 66 can reach tensile strengths of over 120 MPa. High tensile strength can be achieved by using fillers such as glass-infused nylon.

Due to its strength, nylon is widely used in fields such as medical and industrial products, furniture, decorations, and sporting goods.

What Are the Differences Between Polyamides and Nylons?

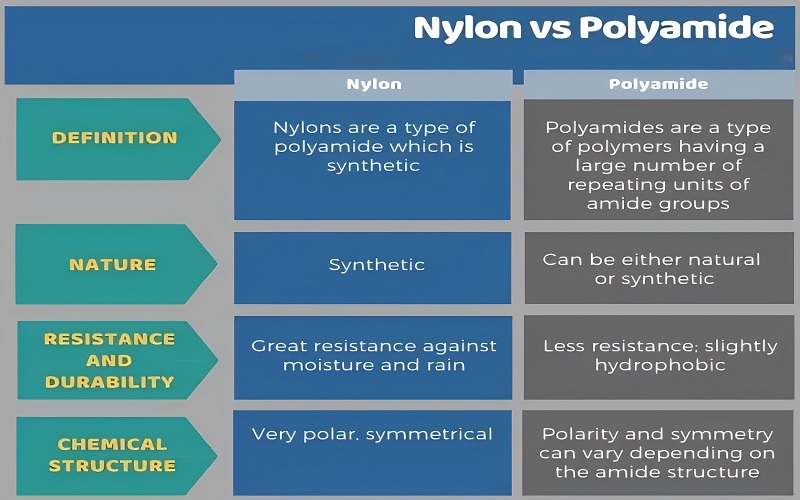

Simply put, nylon is a type of polyamide. Just as air conditioners and fans are a category of household appliances, nylon is actually a subcategory of polyamide. However, there are some differences. The main difference is that polyamides are either natural or synthetic, while nylon materials are fully synthetic.

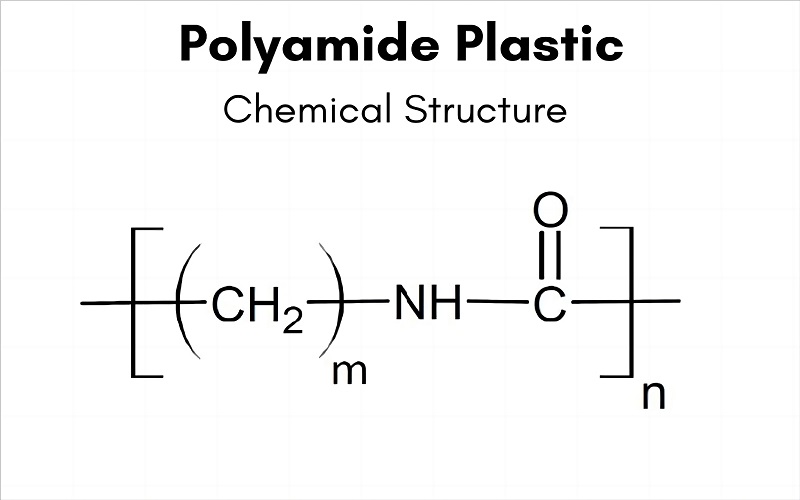

The chemical structures of the two materials are also different. The chemical structure of nylon is highly polar and symmetrical. In the case of polyamides, it depends on the specific arrangement of each part within the molecule (the smallest unit of the compound).

Nylon does not form an entire class of polymers, but it is cheaper, easier to process and has better balanced properties than aromatic and semi-aromatic polyamides. Aromatic polyamide (aramid for short), unlike nylon, the most common polyamide, has excellent heat resistance and tensile strength and is widely used in many fields.

How to Distinguish Polyamide or Nylon?

The best way to determine whether a material is polyamide or nylon is through laboratory data or sample testing. There is no obvious visual difference between nylon fabric and polyamide, so it is difficult to easily distinguish them with the naked eye without the help of technology or equipment.

For example, nylon feels very soft and cannot be judged by feel, but the same is true for other polymers such as polytetrafluoroethylene. This method is not accurate enough to completely determine the type of polyamide.

The dissolution method is a relatively simple identification method. We put the two materials into a 37% concentrated hydrochloric acid solution at 20°C and observe after 30 minutes. The material that can be dissolved is nylon. This method can be used to identify a variety of daily clothing materials.

Another identification method is to test the melting point or density, but these methods do not provide enough information to determine which nylon grade the material belongs to. Some types of nylon are made by mixing other types of nylon, making it difficult to identify. Therefore, the best option is to send the sample to a laboratory.

Frequently Asked Questions About Polyamide and Nylon

Definition of Fibers and Their Main Types

Fibers are durable, long, flexible yarn-like substances that can be spun into yarn and used to make fabrics. Fibers are divided into natural fibers and synthetic fibers. Cotton, wool and silk are considered natural fibers obtained directly from plants and animals.Man-made fibers with many repeating units, such as nylon or rayon, are often called synthetic fibers because they are made using various chemical methods in a laboratory with petroleum sources.

What Are the Main Types of Polyamide and Nylon?

There are 8 different varieties of nylon: nylon 6、nylon 6,6、nylon 4,6、nylon 6,9、nylon 6,10、nylon 6,12、nylon 11、nylon 12. And four categories of polyamide: PA – 6 or polyamide 6( this is also referred to as nylon 6)、PA – 11 or polyamide 11、PA – 12 or polyamide 12、PA – 66 or polyamide 66.

What Are the Disadvantages of Polyamide Fabric?

The advantages of polyamide fabrics are that they are strong, durable and resistant to abrasion. They are also resistant to most solvents and chemicals, allowing them to remain stable in extreme environments. The disadvantages of polyamide fabrics are that they are less breathable than other fibers, making them less convenient to wear in hot weather.

Is Polyamide Toxic to Skin?

Can polyamide cause skin irritation? Some fibers, often including natural fibers (such as wool), can rarely cause sensitization when in contact with the skin. However, in general, polyamide synthetic fibers do not cause allergic reactions or skin irritation and are safe and harmless to the skin.

Conclusion

Polyamide vs Nylon, Which is Better?

Nylon is a synthetic fiber or material composed of polyamide. In summary, the difference between polyamide and nylon is related to the specific properties of a wide variety of man-made polymers. The common amide chains offer excellent mechanical properties and are suitable for use in a variety of industries.

Whether used in materials, automotive parts, plastics design, sporting goods and more, the superior properties of polyamides and nylons continue to drive progress and innovation in all fields. Which of the two compounds you choose depends largely on the application and specific requirements, as the performance characteristics of both are equivalent.

However, if you are looking for a material that is easy to work with and has balanced properties at a reasonable price, nylon is a good choice. Feel free to visit our website for more information or request a free quote.