Introduction

In the plastics world, polycarbonate(PC) and acrylonitrile-butadiene-styrene (ABS) are two widely used engineering plastics. Both are thermoplastics and are similar in many ways, but have significant differences in properties and applications. Polycarbonate(PC) is generally processed by methods such as injection molding or thermoforming and is suitable for applications that require high impact strength and excellent optical transparency.

In comparison, ABS is widely used in injection or extrusion and is harder than polycarbonate(PC) and suitable for places that require high toughness and heat resistance. For injection molding suppliers, the choice between these two materials for part production can present some challenges.

The purpose of this article is to provide a comprehensive look at the properties, processing methods and applications of these two materials to help injection molding contractors make decisions.

Material Overview

Polycarbonate (PC) :

Polycarbonate (PC) is a thermoplastic polymer synthesized from bisphenol A and phosgene (COCl₂). The main manufacturing method is melt polycondensation, which is to react bisphenol A with diphenyl carbonate to form polycarbonate(PC). In addition, polycarbonate(PC) can be prepared by transesterification, but the conversion rate is not high.

Because of its amorphous structure, polycarbonate(PC) is particularly suitable for use in places that need to withstand impact and have local plastic deformation. Compared with semi-crystalline materials, PC’s polymer chains are loosely arranged and can absorb more energy, so it is more impact-resistant. PC is also suitable for making things that require high transparency because of its irregular structure and good transparency, and light can pass through the gaps between polymer chains.

In addition,polycarbonate(PC) is very suitable for use in high temperature environments because of its high glass transition temperature. PC can be manufactured by many processing methods, such as bending, injection molding, extrusion, 3D printing and machining. However, when extruding PC with a 3D printer, special equipment and high temperature are required.

In short, polycarbonate(PC) is becoming more and more popular among engineering plastics because of its unique structure and good performance, and is one of the fastest growing general-purpose materials.

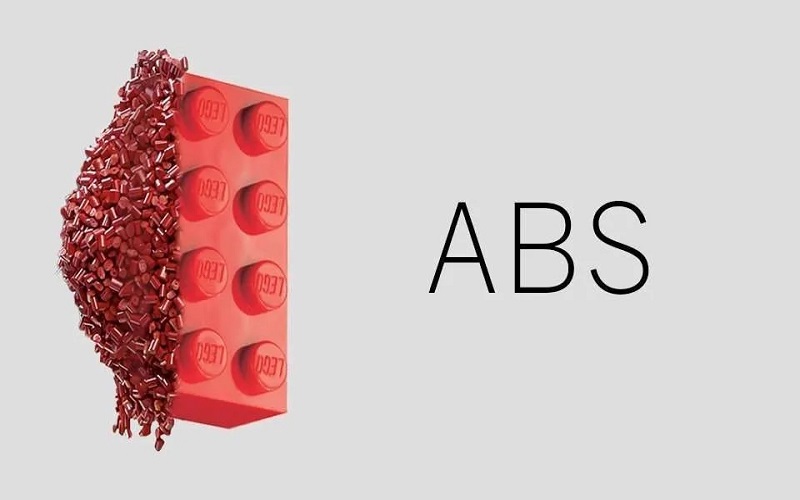

Acrylonitrile Butadiene Styrene(ABS):

ABS is a super strong plastic , It is usually a yellowish or off-white granular substance that is not as tightly structured as crystals. The most special thing about ABS is its composition, which includes a copolymer of acrylonitrile-butadiene-styrene and a mixture of copolymers of butadiene and styrene.

These polymers are mixed in a certain ratio and then some organic solvents and plasticizers are added to form ABS. This blend ensures that ABS not only has strong impact resistance, but also has the advantages of polypropylene hardness and polystyrene heat resistance.

ABS can be used to make many things such as toys, electrical appliances and car parts because it is strong and the surface looks smooth and is not easily scratched. It can keep its shape and does not deform in a wide range of temperatures. If it needs to be stronger, glass fiber can be added to it. In addition, ABS can be matte and glossy and can also be dyed in different colors.

In terms of manufacturing, ABS is usually produced by injection molding and 3D printing. Especially in the 3D printing process, no special high-temperature equipment is needed, so it is very convenient to use it for rapid production of prototypes and special custom items.

In short, ABS is one of the most common and popular plastics today because of its high performance and wide range of uses.

Polycarbonate vs. ABS: Physical Properties

| Property | Polycarbonate (PC) | Acrylonitrile Butadiene Styrene (ABS) |

| Chemical Structure | Polycarbonate, synthesized from bisphenol A and phosgene | Copolymer of acrylonitrile, butadiene, and styrene |

| Density | 1.20-1.22 g/cm³ | 1.04-1.06 g/cm³ |

| Tensile Strength | 55-75 MPa | 40-60 MPa |

| Flexural Strength | 80-100 MPa | 65-90 MPa |

| Impact Strength | 30-40 kJ/m² | 15-30 kJ/m² |

| Transparency | Excellent (over 90% light transmittance) | Generally opaque, but can be made translucent |

| Heat Resistance | High (glass transition temperature around 147℃) | Moderate (glass transition temperature around 105℃) |

| Heat Deflection Temperature | 120-135℃ | 80-100℃ |

| Chemical Resistance | Good resistance to most acids, oils, and alcohols | Good resistance to many acids, alkalis, and oils, but less resistant to solvents |

| Weather Resistance | Moderate, requires UV stabilizers to prevent yellowing | Poor, degrades easily under sunlight |

Polycarbonate vs. ABS: Applications and Uses

Polycarbonate (PC) and Acrylonitrile Butadiene Styrene (ABS) are two superplastic materials that can be used to make many things.

Polycarbonate (PC) is like super glass, it is transparent and not easy to break. Therefore, it can be used to create a transparent roof for skylights.Polycarbonate (PC) can also be used as food containers. It is heat resistant and has passed food safety tests, so it can be used to make microwave ovens, kettles, etc.

ABS is also special! The smooth surface facilitates cleaning, which makes it particularly suitable for furniture parts, sinks, bathtubs, etc. In addition, ABS can block ultraviolet rays, so it can be used as a material to protect electronic components in electronic devices. ABS is also used in many sports equipment because it is impact resistant and durable, allowing it to be used for a long time.

In other words, Polycarbonate (PC) and ABS each have their own unique properties and uses, allowing them to meet the needs of different products. If you want transparency and resistance to high temperature, choose PC. If you want scratch resistance and UV protection, choose ABS! Choosing the right plastic can help you create better products!

Take A Suitcase For Example:

Take luggage for example. Polycarbonate (PC) and ABS are relatively light and can be used as raw materials for luggage. If you don’t have a big budget, you can consider ABS luggage. ABS is generally cheap, so the price of luggage is not high either. But at the same time, ABS luggage is subject to scratches and wear. If you have enough budget, Polycarbonate (PC)l luggage is a better option. Polycarbonate luggage is usually used in the high-end market. Although it is more expensive, it is almost indestructible and has a longer life.

Is Polycarbonate (PC) More Environmentally Friendly Than ABS?

There are many factors involved in comparing polycarbonate (PC) and ABS as being more environmentally friendly, and a simple comparison can be made based on their recyclability and environmental impact.

The first is reusability.polycarbonate (PC) recycling is more complex and requires specialized equipment and skills, making it more expensive. Recycling ABS is relatively easy and cheap, and the recycled plastic can be reused to make household appliances and toys.

Then there is the environmental impact. Although polycarbonate (PC) have a long life and can reduce the waste of resources, they are not good for the environment because they consume a lot of energy and generate some harmful substances during the manufacturing process.

In contrast, the ABS manufacturing process consumes less energy, uses fewer chemicals, and has a relatively lower overall environmental impact. ABS is therefore better than Polycarbonate (PC) from an environmental point of view. Because it is easy to produce, consumes less energy, is easy to recycle, is economical and more in line with modern requirements for sustainable development.

However, the specific type of plastic used will depend on the specific use and product requirements. If you need a very strong material with a long life, Polycarbonate (PC)may be more suitable. If it is disposable or needs to be replaced frequently, ABS is more environmentally friendly.

Blending of Polycarbonate(PC) and ABS

Polycarbonate (PC) and acrylonitrile-butadiene-styrene copolymer (ABS) are mixed together to make a plastic called PC/ABS alloy. This alloy combines the strong impact resistance of PC with the easy processing of ABS, so it is often better than using PC or ABS alone. They also add a plastic called SAN, so that the PC will wrap around the SAN, and the SAN will wrap around the grafted rubber, which forms a very complex structure.

PC/ABS alloy has many benefits, such as strong impact resistance and easy processing. It has better fluidity than PC alone and is not easily deformed by strong forces. Compared with ABS alone, PC/ABS alloy is stronger and has better heat and fire resistance. Therefore, it is widely used in the manufacture of automotive interiors, electronic equipment, home appliances and lighting products.

Overall, PC/ABS alloy is a great plastic that combines the strength and transparency of PC with the easy processing and toughness of ABS, making it suitable for making many different types of things.

Conclusion

Through the above content, we have a deep understanding of the material properties of polycarbonate and ABS, and also understand their uses and environmental performance. If you want to know more about polycarbonate and ABS, you can go to our website, where you can find more information and get a free quote!