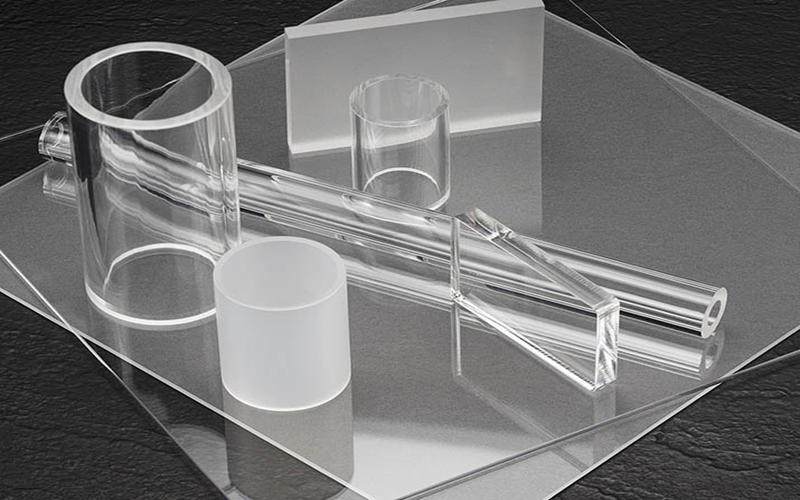

Polycarbonate and acrylic are two of the most widely used transparent plastics, each offering unique properties that make them suitable for a variety of applications, from industrial components to decorative designs.

While both materials share similarities, such as clarity and versatility, their differences in strength, durability, cost, and workability can significantly impact their suitability for specific projects.

This article provides a detailed comparison of polycarbonate and acrylic, exploring their material properties, applications to help readers make informed decisions when choosing between these materials.

What Is Polycarbonate?

Polycarbonate is a versatile thermoplastic polymer known for its excellent impact resistance and optical clarity.

Made from complex chemical compounds, it combines strength with lightweight properties, suitable for various applications.

Thanks to its scratch resistance and ability to withstand temperature changes, polycarbonate is widely used in demanding environments such as operator protection gear, bullet resistant windows, and outdoor signage.

Many polycarbonate products include UV grades that enhance durability against UV rays, making it a durable choice for indoor and outdoor print materials, skylights, and protective guards.

Its unique chemical properties and manufacturing processes set it apart from acrylic sheets, offering a strong, clear, and long-lasting material option.

What Is Acrylic?

Acrylic, also known as polymethyl methacrylate (PMMA), is a popular plastic material prized for its excellent clarity and lightweight nature.

It is produced through the polymerization of methyl methacrylate and methyl alcohol, resulting in a strong, transparent sheet that is widely used as a glass substitute.

Acrylic sheets are inherently UV resistant, making them suitable for both indoor and outdoor applications such as print materials, skylights, and protective guards.

This highly resistant material offers good scratch resistance compared to polycarbonate and is favored for its ease of fabrication, including thermoforming and cutting without a pre drying process.

Its versatility and durability make acrylic an excellent choice for a wide range of applications requiring clear, impact resistant plastic sheeting.

Key Property Comparison Between PC And Acrylic

When comparing polycarbonate vs acrylic, it’s essential to understand the unique properties that set these two polymers apart.

Polycarbonate is incredibly strong and impact resistant, making it ideal for applications requiring protection against heavy objects or high-impact forces.

It also performs well under high heat and is commonly used in environments that demand durability and toughness.

Acrylic sheets, often called Plexiglass, offer superior optical clarity and scratch resistance, making them a preferred choice for display cases, transparent shelves, and print materials indoor.

Both acrylic and polycarbonate sheets present UV grades that protect against excessive UV rays, ensuring longevity in outdoor signage and skylights.

Choosing between these two materials depends on balancing strength, clarity, scratch resistance, and cost for your specific project needs.

| Property | Polycarbonate | Acrylic (Plexiglass) |

|---|---|---|

| Impact Resistance | Excellent | Moderate |

| Optical Clarity | Good | Superior |

| Scratch Resistance | Poor | Excellent |

| Heat Resistance | High | Moderate |

| UV Resistance | Good with UV grades | Good with UV grades |

Differences Between Acrylic And Polycarbonate In Processing Methods

Acrylic and polycarbonate are manufactured using distinct processes that influence their characteristics and applications.

Acrylic sheets are produced primarily through bulk polymerization, where methyl methacrylate monomers react in molds under controlled heat and pressure, resulting in clear, rigid sheets with excellent optical clarity and scratch resistance.

This process can be done in batch cells for thicker sheets or continuous polymerization for thinner ones. Polycarbonate sheets, on the other hand, are commonly made by extrusion, where polycarbonate pellets are melted and forced through a die to form sheets.

This extrusion method allows polycarbonate to retain its superior impact resistance and flexibility. Unlike acrylic, polycarbonate can be cold-formed without heating, making it easier to fabricate for applications requiring complex shapes.

These differences in manufacturing processes contribute to the unique properties of polycarbonate and acrylic sheets, helping determine their suitability for various uses such as bullet resistant windows, skylights, and transparent materials in both indoor and outdoor settings.

Applications Of Polycarbonate

Polycarbonate’s unique combination of strength, transparency, and versatility makes it a preferred material across various industries.

Architecture

Polycarbonate is widely employed in architectural applications such as greenhouses, skylights, roofing panels, and exterior windows due to its exceptional durability, lightweight nature, and availability in UV-resistant grades.

These properties make it an ideal choice for outdoor signage, doors, and skylights where exposure to excessive UV light and weathering is common.

Its excellent impact resistance and scratch resistant surface ensure longevity and safety, while maintaining high light transmittance for bright, clear environments.

Automotive Industry

Polycarbonate is widely used in the automotive industry for applications including headlight lenses, interior components, windshields, and clear visors.

Its combination of lightweight material and superior impact resistance enhances vehicle safety and performance.

With its outstanding clarity, scratch resistance, and ability to be easily molded through injection molding, polycarbonate offers a versatile and reliable alternative to traditional glass and other plastic materials in automotive manufacturing.

Electronics

Polycarbonate is extensively used in electronic device housings, LED diffusing panels, and electrical insulators thanks to its excellent flame retardancy, high impact resistance, and outstanding electrical properties.

Its durability and lightweight nature make it a preferred material for protecting sensitive components in a wide range of industrial settings and consumer electronics, ensuring reliable performance and safety.

Medical Devices

Polycarbonate is extensively used in medical devices, including surgical instruments and medical equipment housings, due to its exceptional toughness, sterilizability, and chemical resistance.

Its durability and ability to withstand repeated sterilization processes make it an ideal choice for critical healthcare applications requiring reliable performance and safety.

Applications Of Acrylic

Acrylic, often referred to as Plexiglass, is a versatile and transparent plastic valued for its exceptional optical clarity, lightweight nature, and ease of fabrication.

Its wide range of applications spans multiple industries due to its aesthetic appeal and functional properties.

Displays

Acrylic sheets are extensively used for indoor and outdoor signage, retail displays, point-of-sale stands, and diffusing panels due to their exceptional glass-like clarity, lightweight material, and ease of cutting and polishing.

These transparent materials provide superior light transmittance and excellent scratch resistance, making them ideal for crafting visually appealing transparent shelves and display cases across a wide array of applications, including DIY projects and outdoor signage Craft.

Acrylic’s inherent UV resistance ensures long-lasting durability and color stability when exposed to excessive UV rays, making it a preferred choice for outdoor signage, print materials, and light fixtures.

Aquariums

Polycarbonate is extensively used in large aquariums and protective enclosures because of its remarkable strength, excellent optical clarity, and superior resistance to water-related wear and impact.

Compared to standard glass, polycarbonate sheets offer a lightweight yet highly durable alternative that ensures enhanced safety and longevity for both public and private aquatic displays.

Its outstanding chemical resistance and ability to withstand temperature variations make it ideal for long-term exposure to aquatic environments.

Furniture

Polycarbonate and acrylic sheets are increasingly used in modern furniture design, including transparent chairs, tabletops, and art installations.

Their aesthetic versatility, combined with ease of shaping and durability, makes them ideal materials for creating stylish, lightweight, and impact resistant furniture pieces that stand out in both residential and commercial interiors.

Architectural Glazing

Polycarbonate and acrylic sheets are widely used in architectural glazing applications such as skylights, windows, canopies, and doors.

Particularly in UV-resistant grades, these materials provide durable, weather-resistant, and lightweight solutions for outdoor structures.

Their high impact resistance and excellent light transmittance make them ideal alternatives to traditional glass, offering enhanced safety and energy efficiency.

Automotive

Polycarbonate sheets are commonly used in the automotive industry for applications such as windshields, clear visors, and protective guards.

Their lightweight material and superior impact resistance make them an excellent alternative to standard glass in vehicles, enhancing safety without compromising visibility.

Acrylic vs Polycarbonate: Cost Analysis

When it comes to cost, acrylic is typically less expensive than polycarbonate, making it a cost-effective choice for various projects.

The higher cost of polycarbonate is often justified by its superior strength and impact resistance. For applications requiring UV protection, acrylic may be more economical, while polycarbonate is preferable when durability is essential.

Long-term maintenance costs can influence the overall cost-effectiveness of polycarbonate sheeting despite its initial higher price.

Acrylic sheeting is less expensive, but polycarbonate offers significantly higher impact resistance, making it suitable for applications where safety is a priority.

Both materials weigh less than half the weight of what traditional glass does, yet polycarbonate is recognized for its superior strength compared to acrylic.

The cost differences between acrylic and polycarbonate can influence decision-making for projects, especially when budget constraints are a concern.

How To Choose Between Polycarbonate Or Acrylic?

Choosing the right material between polycarbonate and acrylic depends on your specific project needs and priorities.

If you require a lightweight material with superior clarity, excellent scratch resistance, and inherent UV resistance, acrylic sheets are often the preferred choice, especially for applications like transparent shelves, diffusing panels, indoor print materials, and craft or DIY projects.

Acrylic’s ability to be polished to restore clarity and its exceptional light transmittance make it ideal for aesthetic-focused uses.

On the other hand, if your project demands high impact resistance, durability under extreme temperature changes, and enhanced protection—such as in bullet resistant windows, clear visors for vehicles, doors, windshields, or outdoor signage—polycarbonate sheets offer the stronger, more resilient material solution.

Polycarbonate’s flexibility allows it to be shaped without heating, making it perfect for complex designs and heavy-duty use in industrial settings and vehicles.

Additionally, consider fabrication methods and long-term performance: acrylic requires heating to form but offers better polishability and maintains clarity without yellowing.

Polycarbonate, although more expensive, provides superior impact resistance and can be produced with present UV grades to protect against excessive UV rays.

Evaluating these key differences—including cost, scratch resistance, impact resistance, UV stability, and manufacturing processes—will help you select the right material that balances performance, durability, cost, and aesthetics for your specific project.

Frequently Asked Questions

What Are The Main Differences Between Polycarbonate And Acrylic?

The main differences between polycarbonate and acrylic are that polycarbonate offers superior impact and heat resistance, making it ideal for applications such as vehicles, clear visors, and outdoor signage. Acrylic, on the other hand, excels in optical clarity and ease of shaping, making it perfect for diffusing panels, transparent shelves, craft, and DIY projects.

Which Material Is More Cost Effective, Acrylic Or Polycarbonate?

Acrylic is usually more cost-effective than polycarbonate; however, polycarbonate’s greater strength and durability may justify its higher price for demanding uses like skylights, vehicles, and protective guards.

Can Polycarbonate And Acrylic Be Used Interchangeably?

Polycarbonate and acrylic cannot be used interchangeably due to their differing properties. Polycarbonate is preferred for high-impact, heavy-duty applications such as bullet resistant windows, clear visors, and outdoor signage, while acrylic is favored for its superior clarity and polished finish in applications like diffusing panels, transparent shelves, and craft or DIY projects.

What Are The Common Applications Of Polycarbonate?

Polycarbonate is widely used in safety equipment, automotive components including vehicles and clear visors, medical devices, aerospace, electronics, and outdoor signage. Its impact resistance and durability make it suitable for skylights and other demanding environments.

How Are Acrylic Sheets Manufactured?

Acrylic sheets are manufactured through bulk polymerization, where a mixture of methyl methacrylate and a catalyst is heated within a mold. This process ensures the sheets possess the desired clarity and strength, making them ideal for applications such as diffusing panels, transparent shelves, and various craft and DIY projects.